Dodeka™ Mini • 硬质合金刀片 • HNGJ-LD • 轻型切削

端面铣刀片,有十二个切削刃,精磨

物料号4119190

公制样本编号HNGJ0604ANENLD英制样本编号HNGJ43ANENLD

- P 钢

- M 不锈钢

- K 铸铁

- S 高温合金

Sending to {{cadTool}} in progress...

Downloaded file will be available after import in the {{cadTool}} tool library.

| 物料号 | 4119190 |

| 公制样本编号 | HNGJ0604ANENLD |

| 英制样本编号 | HNGJ43ANENLD |

| 材质 | KCPK30 |

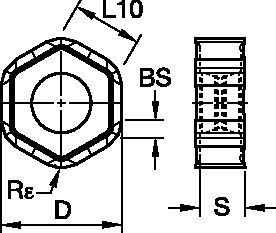

| [SSC] 刀片 IC 尺寸 | 12 mm |

| [SSC] 刀片 IC 尺寸 | 0.472 in |

| [BS] 刀尖刃口长度 | 1.515 mm |

| [BS] 刀尖刃口长度 | 0.0596 in |

| [L10] 刀片切削刃长度 | 6.928 mm |

| [L10] 刀片切削刃长度 | 0.2728 in |

| [Rε] 刀尖半径 | 1 mm |

| [Rε] 刀尖半径 | 0.039 in |

| [S] 刀片厚度 | 4.479 mm |

| [S] 刀片厚度 | 0.1763 in |

| 平均切屑厚度 [HM] | 0.04 mm |

| 平均切屑厚度 [HM] | 0.0016 in |

| 每个刀片的切削刃 | 12 |

工件材料

- 钢

- 不锈钢

- 铸铁

- 高温合金

Grades

KCPK30

CVD 复合涂层 (TiN/TiCN/Al2O3) 硬质合金材质以及先进的 Beyond™ 涂层后处理工艺。基体材料有极好的韧性。KCPK30 材质应用广泛,可用于钢和铸铁材料的一般铣削和粗铣加工。在干式加工中具有最佳的性能,但同时也可用于湿式加工。

Features and benefits

- Insert for Dodeka Mini 15/45/60 cutters (metric)

- Insert for Dodeka Mini 75/45/30 cutters (inch)

通过创建解决方案计算速度和进给

创建解决方案后,只需选择进给和速度图标,我们的系统将提供建议。您可以通过添加您的机床和参数来定制信息,或者使用滑块进行调整。

High Performance Combination Tools

| 材料 分组 | 轻切削 | 中等加工 | 重切削 | |||||||

| P1–P2 | .E..LD | KC522M | .E..LP | KC522M | .E..GP | KC522M | .S..GD | KC522M | .S..HD | KC725M |

| P3–P4 | .E..LD | KCPM40 | .E..LP | KCPM40 | .E..GP | KCPM40 | .S..GD | KCPK30 | .S..HD | KCPK30 |

| P5–P6 | .E..LD | KCPM40 | .E..LP | KCPM40 | .E..GP | KCPM40 | .S..GD | KCPM40 | .S..HD | KCPM40 |

| M1–M2 | .E..LD | KC522M | .E..LM | KC522M | .E..GM | KCSM40 | .S..GD | KCSM40 | .S..HD | KCSM40 |

| M3 | .E..LD | KCSM40 | .E..LM | KCSM40 | .E..GM | KCSM40 | .S..GD | KCSM40 | .S..HD | KCPM40 |

| K1–K2 | .E..LD | KCK20B | .E..LP | KCK20B | .E..LP | KCK20B | .S..GD | KCK15 | .S..HD | KCK15 |

| K3 | .E..LD | KCKP10 | .E..LP | KCPK30 | .E..LP | KCPK30 | .S..GD | KCK20B | .S..HD | KCPK30 |

| N1–N2 | .F..LDJ | KC410M | .F..LDJ | KC410M | .F..LDJ | KC410M | .F..LDJ | KC410M | .E..LD | KCKP10 |

| N3 | .F..LDJ | KC410M | .F..LDJ | KC410M | .F..LDJ | KC410M | .F..LDJ | KC410M | .E..LD | KCKP10 |

| S1–S2 | .E..LD | KC725M | .E..LM | KCSM40 | .E..GM | KCSM40 | .S..GD | KC725M | .S..HD | KC725M |

| S3 | .E..LD | KCSM40 | .E..LM | KCSM40 | .E..GM | KCSM40 | .S..GD | KCSM40 | .S..HD | KCSM40 |

| S4 | .E..LD | KCSM40 | .E..LM | KCSM40 | .E..GM | KCSM40 | .S..GD | KCSM40 | .S..HD | KCSM40 |

| H1 | .E..LD | KCKP10 | – | – | .E..GP | KC522M | – | – | – | – |

| 材料 分组 | 轻切削 | 中等加工 | 重切削 | |||

| P1–P2 | .E..LD | KC522M | .S..GD | KC522M | .S..HD | KC725M |

| P3–P4 | .E..LD | KCPM40 | .S..GD | KCPK30 | .S..HD | KCPK30 |

| P5–P6 | .E..LD | KCPM40 | .S..GD | KCPM40 | .S..HD | KCPM40 |

| M1–M2 | .E..LD | KC522M | .S..GD | KCSM40 | .S..HD | KCSM40 |

| M3 | .E..LD | KCSM40 | .S..GD | KCSM40 | .S..HD | KCPM40 |

| K1–K2 | .E..LD | KCK20B | .S..GD | KCK15 | .S..HD | KCK15 |

| K3 | .E..LD | KCKP10 | .S..GD | KCK20B | .S..HD | KCPK30 |

| N1–N2 | .F..LDJ | KC410M | .F..LDJ | KC410M | .E..LD | KCKP10 |

| N3 | .F..LDJ | KC410M | .F..LDJ | KC410M | .E..LD | KCKP10 |

| S1–S2 | .E..LD | KC725M | .S..GD | KC725M | .S..HD | KC725M |

| S3 | .E..LD | KCSM40 | .S..GD | KCSM40 | .S..HD | KCSM40 |

| S4 | .E..LD | KCSM40 | .S..GD | KCSM40 | .S..HD | KCSM40 |

| H1 | .E..LD | KCKP10 | – | – | – | – |

| 材料 分组 | 轻切削 | 中等加工 | 重切削 | |||

| P1–P2 | .E..LD | KC522M | .S..GD | KC522M | .S..HD | KC725M |

| P3–P4 | .E..LD | KCPM40 | .S..GD | KCPK30 | .S..HD | KCPK30 |

| P5–P6 | .E..LD | KCPM40 | .S..GD | KCPM40 | .S..HD | KCPM40 |

| M1–M2 | .E..LD | KC522M | .S..GD | KCSM40 | .S..HD | KCSM40 |

| M3 | .E..LD | KCSM40 | .S..GD | KCSM40 | .S..HD | KCPM40 |

| K1–K2 | .E..LD | KCK20B | .S..GD | KCK15 | .S..HD | KCK15 |

| K3 | .E..LD | KCKP10 | .S..GD | KCK20B | .S..HD | KCPK30 |

| N1–N2 | .F..LDJ | KC410M | .F..LDJ | KC410M | .E..LD | KCKP10 |

| N3 | .F..LDJ | KC410M | .F..LDJ | KC410M | .E..LD | KCKP10 |

| S1–S2 | .E..LD | KC725M | .S..GD | KC725M | .S..HD | KC725M |

| S3 | .E..LD | KCSM40 | .S..GD | KCSM40 | .S..HD | KCSM40 |

| S4 | .E..LD | KCSM40 | .S..GD | KCSM40 | .S..HD | KCSM40 |

| H1 | .E..LD | KCKP10 | – | – | – | – |

I have read and accepted the Terms & Conditions of use