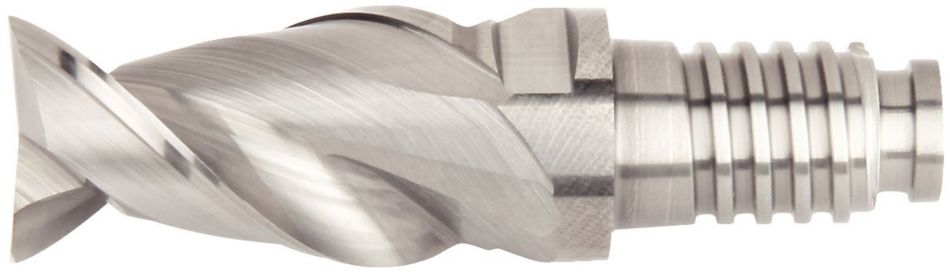

DUO-LOCK™ • MaxiMet™ • Square End • 2 Flutes • Inch

MaxiMet • ABDF • Wiper Facet

物料号6151114

公制样本编号ABDF0625Y2CU英制样本编号ABDF0625Y2CU

- N 非铁材质

插铣

坡铣: 毛坯

槽铣: 方头立铣

侧铣/方肩铣削: 方头立铣

刀具尺寸: 排屑槽数: 2

螺旋角: 45°

刀尖类型: 方头立铣

Sending to {{cadTool}} in progress...

Downloaded file will be available after import in the {{cadTool}} tool library.

| 物料号 | 6151114 |

| 公制样本编号 | ABDF0625Y2CU |

| 英制样本编号 | ABDF0625Y2CU |

| 材质 | K600 |

| 机床侧适配接头样式 | DUO-LOCK |

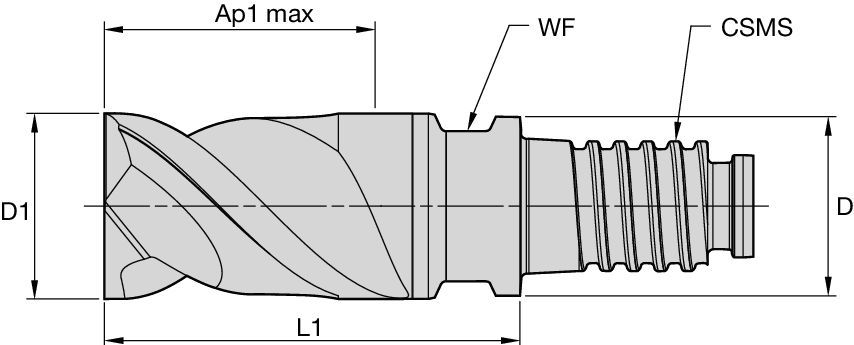

| [D]适配接头/刀柄/镗孔直径 | 15.375 mm |

| [D]适配接头/刀柄/镗孔直径 | 0.6053 in |

| [AP1MAX] 第一个最大切深 | 23.813 mm |

| [AP1MAX] 第一个最大切深 | 0.9375 in |

| [L1] 量规长度 | 35.7 mm |

| [L1] 量规长度 | 1.4055 in |

| [CSMS] 机床侧系统规格 | DL16 |

| [WF] 平面宽度 | 13 mm |

| [WF] 平面宽度 | 0.5118 in |

| [Z] 排屑槽数量 | 2 |

| [D1] 有效的切削直径 | 15.875 mm |

| [D1] 有效的切削直径 | 0.625 in |

工件材料

- 非铁材质

Uses and application

插铣

坡铣: 毛坯

槽铣: 方头立铣

侧铣/方肩铣削: 方头立铣

刀具尺寸: 排屑槽数: 2

螺旋角: 45°

刀尖类型: 方头立铣

Grades

K600

采用高品质,微晶材料制成的硬质合金材质产品,可用于各种类型材料的切削加工。极高的韧性确保磨损率在可控状态。微晶材料结构确保切削刃的锋利。

Features and benefits

- Center cutting.

- Optimized for thin-wall applications.

- Wiper facet, special end gash, and flute geometry enable improved surface finishes.

- Standard items listed. Additional styles and coatings made-to-order.

通过创建解决方案计算速度和进给

创建解决方案后,只需选择进给和速度图标,我们的系统将提供建议。您可以通过添加您的机床和参数来定制信息,或者使用滑块进行调整。

应用数据

MaxiMet • ABDF • Wiper Facet

| 材料 分组 |  |  |  | |||||||||||||||

| 侧铣加工(A)和槽铣加工(B) | 短 | 中等 | 长 | 侧铣加工(A)推荐每齿进给率(IPT=英寸/齿)。 槽铣加工(B),每齿进给率降低20%。 | ||||||||||||||

| A | B | 接杆长度类型 | D1 | |||||||||||||||

| K600 | K600 | K600 | ||||||||||||||||

| 切削速度 | 切削速度 | 切削速度 | frac. | 3/8 | 1/2 | 5/8 | 3/4 | |||||||||||

| ap | ae | ap | 最小值 | 最大值 | 最小值 | 最大值 | 最小值 | 最大值 | dec. | .3750 | .5000 | .6250 | .7500 | |||||

| N | 1 | 1.5 x D | 0.3 x D | 1.0 x D | 1640 | – | 6560 | 1312 | – | 3936 | 984 | – | 3936 | IPT | .0029 | .0038 | .0048 | .0057 |

| 2 | 1.5 x D | 0.3 x D | 1.0 x D | 1640 | – | 4920 | 1312 | – | 2952 | 984 | – | 2952 | IPT | .0023 | .0031 | .0038 | .0046 | |

| 3 | 1.5 x D | 0.3 x D | 1.0 x D | 1640 | – | 4920 | 1312 | – | 2952 | 984 | – | 2952 | IPT | .0020 | .0027 | .0033 | .0040 | |

| 4 | 1.5 x D | 0.3 x D | 1.0 x D | 1310 | – | 2460 | 1048 | – | 1476 | 786 | – | 1476 | IPT | .0020 | .0027 | .0033 | .0040 | |

| 5 | 1.5 x D | 0.3 x D | 1.0 x D | 820 | – | 3280 | 656 | – | 1968 | 492 | – | 1968 | IPT | .0026 | .0034 | .0043 | .0052 | |

MaxiMet • ABDE • Wiper Facet • Unequal Flute Spacing

| 材料 分组 |  |  |  | |||||||||||||||

| 侧铣加工(A)和槽铣加工(B) | 短 | 中等 | 长 | 侧铣加工(A)推荐每齿进给率(IPT=英寸/齿)。 槽铣加工(B),每齿进给率降低20%。 | ||||||||||||||

| A | B | 接杆长度类型 | D1 | |||||||||||||||

| K600 | K600 | K600 | ||||||||||||||||

| 切削速度 | 切削速度 | 切削速度 | frac. | 3/8 | 1/2 | 5/8 | 3/4 | |||||||||||

| ap | ae | ap | 最小值 | 最大值 | 最小值 | 最大值 | 最小值 | 最大值 | dec. | .375 | .500 | .6250 | .7500 | |||||

| N | 1 | 1.5 x D | 0.3 x D | 1.0 x D | 1640 | – | 6560 | 1312 | – | 3936 | 984 | – | 3936 | IPT | .0029 | .0038 | .0048 | .0057 |

| 2 | 1.5 x D | 0.3 x D | 1.0 x D | 1640 | – | 4920 | 1312 | – | 2952 | 984 | – | 2952 | IPT | .0023 | .0031 | .0038 | .0046 | |

| 3 | 1.5 x D | 0.3 x D | 1.0 x D | 1640 | – | 4920 | 1312 | – | 2952 | 984 | – | 2952 | IPT | .0020 | .0027 | .0033 | .0040 | |

| 4 | 1.5 x D | 0.3 x D | 1.0 x D | 1310 | – | 2460 | 1048 | – | 1476 | 786 | – | 1476 | IPT | .0020 | .0027 | .0033 | .0040 | |

| 5 | 1.5 x D | 0.3 x D | 1.0 x D | 820 | – | 3280 | 656 | – | 1968 | 492 | – | 1968 | IPT | .0026 | .0034 | .0043 | .0052 | |

公差

| 立铣刀公差 | |

| D1 | 公差等级 e8 |

| 13/32 | -0,00126"/-0,00232" |

| 23/32 | -0,00157"/-0,00287" |

| -0,00197''/-0,00350'' | |

I have read and accepted the Terms & Conditions of use