DUO-LOCK • RSM II™ • Radiused • Multi-Flute • Inch

RSM II • FSDE • High-Performance Finishing

物料号6127237

公制样本编号FSDE1000Y19CQC英制样本编号FSDE1000Y19CQC

- P 钢

- M 不锈钢

- S 高温合金

- H 淬火材料

Helix Angle: 36°

侧铣/方肩铣削: 方头立铣

刀具尺寸: 排屑槽数: X (变量)

刀尖类型: 刀尖半径

侧铣/方肩铣削: 完工精加工

Sending to {{cadTool}} in progress...

Downloaded file will be available after import in the {{cadTool}} tool library.

| 物料号 | 6127237 |

| 公制样本编号 | FSDE1000Y19CQC |

| 英制样本编号 | FSDE1000Y19CQC |

| 材质 | KC643M |

| 机床侧适配接头样式 | DUO-LOCK |

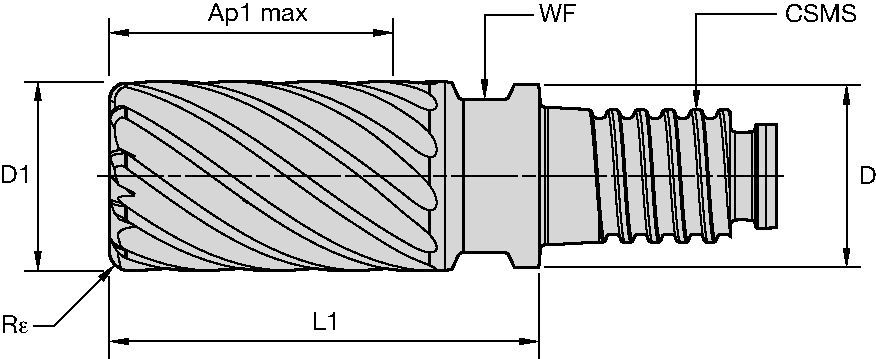

| [D]适配接头/刀柄/镗孔直径 | 24.4 mm |

| [D]适配接头/刀柄/镗孔直径 | 0.9606 in |

| [L1] 量规长度 | 57.2 mm |

| [L1] 量规长度 | 2.252 in |

| [CSMS] 机床侧系统规格 | DL25 |

| [WF] 平面宽度 | 21 mm |

| [WF] 平面宽度 | 0.8268 in |

| [Re] 刀尖半径 | 1.525 mm |

| [Re] 刀尖半径 | 0.06 in |

| [Z] 排屑槽数量 | 19 |

| [D1] 有效的切削直径 | 25.4 mm |

| [D1] 有效的切削直径 | 1 in |

| [AP1MAX] 第一个最大切深 | 38.1 mm |

| [AP1MAX] 第一个最大切深 | 1.5 in |

工件材料

- 钢

- 不锈钢

- 高温合金

- 淬火材料

Uses and application

Helix Angle: 36°

侧铣/方肩铣削: 方头立铣

刀具尺寸: 排屑槽数: X (变量)

刀尖类型: 刀尖半径

侧铣/方肩铣削: 完工精加工

Grades

KC643M

采用 PVD (AlTiN) 复合涂层的细晶粒材质。KC643M™是一种薄层硬质的 PVD 复合涂层材质,特别适合钢、铸铁、不锈钢(湿式),以及钛材料(湿式)的加工应用。这种材质可用于硬度高达 52 HRC 材料的加工。

Features and benefits

- Non-center cutting.

- Optimized geometry for titanium machining.

- Unequal flute spacing minimizes chatter for smoother machining.

- Standard items listed. Additional styles and coatings made-to-order.

通过创建解决方案计算速度和进给

创建解决方案后,只需选择进给和速度图标,我们的系统将提供建议。您可以通过添加您的机床和参数来定制信息,或者使用滑块进行调整。

应用数据

FSDE • Inch

| 材料 分组 |  | 短 | 中等 | 长 | Recommended feed per tooth (IPT = inch/th) for side milling (A). | |||||||||||||

| A | 接杆长度类型 | D1 | ||||||||||||||||

| KC643M | KC643M | KC643M | ||||||||||||||||

| 切削速度 | 切削速度 | 切削速度 | frac. | 3/8 | 1/2 | 5/8 | 3/4 | 1 | ||||||||||

| ap | ae | 最小值 | 最大值 | 最小值 | 最大值 | 最小值 | 最大值 | dec. | .375 | .500 | .625 | .750 | 1.000 | |||||

| P | 4 | Ap max | 0.008 | 445 | – | 1628 | 401 | – | 1465 | 401 | – | 1465 | IPT | .0045 | .0053 | .0058 | .0061 | .0066 |

| 5 | Ap max | 0.008 | 295 | – | 1078 | 251 | – | 916 | 236 | – | 862 | IPT | .0040 | .0048 | .0052 | .0056 | .0061 | |

| M | 1 | Ap max | 0.008 | 445 | – | 1243 | 356 | – | 994 | 312 | – | 870 | IPT | .0050 | .0060 | .0066 | .0070 | .0077 |

| 2 | Ap max | 0.008 | 295 | – | 869 | 236 | – | 695 | 207 | – | 608 | IPT | .0040 | .0048 | .0052 | .0056 | .0061 | |

| 3 | Ap max | 0.008 | 295 | – | 759 | 236 | – | 607 | 207 | – | 531 | IPT | .0033 | .0040 | .0043 | .0045 | .0048 | |

| S | 1 | Ap max | 0.008 | 245 | – | 979 | 196 | – | 783 | 147 | – | 587 | IPT | .0050 | .0060 | .0066 | .0070 | .0077 |

| 2 | Ap max | 0.008 | 125 | – | 429 | 100 | – | 343 | 75 | – | 257 | IPT | .0026 | .0032 | .0035 | .0037 | .0041 | |

| 3 | Ap max | 0.008 | 125 | – | 429 | 100 | – | 343 | 75 | – | 257 | IPT | .0026 | .0032 | .0035 | .0037 | .0041 | |

| 4 | Ap max | 0.008 | 245 | – | 649 | 196 | – | 519 | 147 | – | 389 | IPT | .0037 | .0044 | .0048 | .0051 | .0056 | |

| H | 1 | Ap max | 0.008 | 395 | – | 1518 | 316 | – | 1214 | 237 | – | 911 | IPT | .0045 | .0053 | .0058 | .0061 | .0066 |

| 2 | Ap max | 0.008 | 345 | – | 1298 | 276 | – | 1038 | 207 | – | 779 | IPT | .0033 | .0040 | .0043 | .0045 | .0048 | |

公差

| 立铣刀公差 | |

| D1 | 公差等级 e8 |

| 13/32 | -0,00126"/-0,00232" |

| 23/32 | -0,00157"/-0,00287" |

| -0,00197''/-0,00350'' | |

I have read and accepted the Terms & Conditions of use