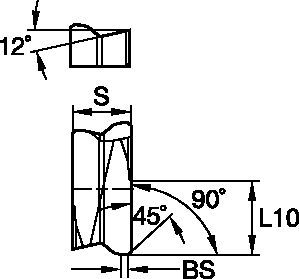

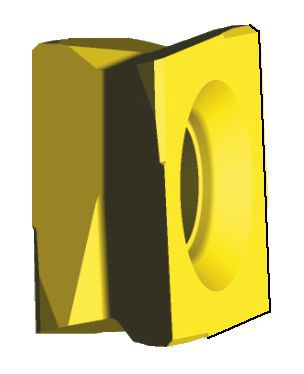

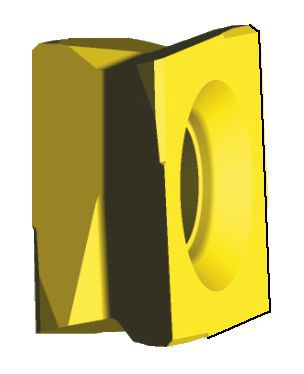

Fix-Perfect™ 90°刀片 • SPHX1205-GPB • 粗加工

可转位刀片 • SPHX1205...• 粗加工

物料号1712714

公制样本编号SPHX1205PCERGPB英制样本编号SPHX1205PCERGPB

- K 铸铁

Sending to {{cadTool}} in progress...

Downloaded file will be available after import in the {{cadTool}} tool library.

| 物料号 | 1712714 |

| 公制样本编号 | SPHX1205PCERGPB |

| 英制样本编号 | SPHX1205PCERGPB |

| 材质 | KC520M |

| [L10] 刀片切削刃长度 | 6.57 mm |

| [L10] 刀片切削刃长度 | 0.2587 in |

| [S] 刀片厚度 | 5.5 mm |

| [S] 刀片厚度 | 0.2165 in |

| [BS] 刀尖刃口长度 | 0.7 mm |

| [BS] 刀尖刃口长度 | 0.0276 in |

| 平均切屑厚度 [HM] | 0.02 mm |

| 平均切屑厚度 [HM] | 0.0008 in |

| 每个刀片的切削刃 | 8 |

工件材料

- 铸铁

Grades

KC520M

采用 TiAlN 涂层(PVD)的硬质合金材质。KC520M 是一种硬质合金材质,特别适合球墨铸铁材料的通用加工应用。这种材质在应用中可以使用冷却液,也可以不使用冷却液。

通过创建解决方案计算速度和进给

创建解决方案后,只需选择进给和速度图标,我们的系统将提供建议。您可以通过添加您的机床和参数来定制信息,或者使用滑块进行调整。

Feeds

推荐初始进给率 [mm]

| 轻切削 | 中等切削 | 重切削 |

| 刀片槽型 | 不同切宽(ae)百分比情况下,所建议的每齿进给量设定值(fz) | 刀片槽型 | ||||||||||||||

| 5% | 10% | 20% | 30% | 40–100% | ||||||||||||

| .E..GPB | 0,12 | 0,46 | 0,82 | 0,08 | 0,33 | 0,59 | 0,06 | 0,25 | 0,44 | 0,06 | 0,22 | 0,38 | 0,05 | 0,20 | 0,35 | .E..GPB |

| .T..GPB | 0,23 | 0,59 | 0,95 | 0,17 | 0,43 | 0,68 | 0,13 | 0,32 | 0,51 | 0,11 | 0,28 | 0,44 | 0,10 | 0,25 | 0,41 | .T..GPB |

| .S..GPB | 0,23 | 0,59 | 0,95 | 0,17 | 0,43 | 0,68 | 0,13 | 0,32 | 0,51 | 0,11 | 0,28 | 0,44 | 0,10 | 0,25 | 0,41 | .S..GPB |

推荐初始进给率 [mm]

| 刀片槽型 | 不同切宽(ae)百分比情况下,所建议的每齿进给量设定值(fz) | 刀片槽型 | ||||||||||||||

| 5% | 10% | 20% | 30% | 40–100% | ||||||||||||

| .E..GP | 0,12 | 0,46 | 0,82 | 0,08 | 0,33 | 0,59 | 0,06 | 0,25 | 0,44 | 0,06 | 0,22 | 0,38 | 0,05 | 0,20 | 0,35 | .E..GP |

| .S..GP | 0,23 | 0,59 | 0,95 | 0,17 | 0,43 | 0,68 | 0,13 | 0,32 | 0,51 | 0,11 | 0,28 | 0,44 | 0,10 | 0,25 | 0,41 | .S..GP |

| 轻切削 | 中等切削 | 重切削 |

Speeds

推荐初始速度 [m/min]

| 材料 分组 | KB1340 | KC520M | KCK15 | KTPK20 | KCPK30 | KY3500 | |||||||||||||

| P | 1 | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – |

| 2 | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | |

| 3 | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | |

| 4 | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | |

| 5 | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | |

| 6 | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | |

| M | 1 | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – |

| 2 | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | |

| 3 | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | |

| K | 1 | 1370 | 915 | 490 | 270 | 245 | 215 | 420 | 385 | 340 | 230 | 195 | 160 | 295 | 265 | 240 | 805 | 730 | 650 |

| 2 | – | – | – | 210 | 190 | 175 | 335 | 295 | 275 | 185 | 150 | 130 | 235 | 210 | 190 | 635 | 570 | 530 | |

| 3 | – | – | – | 175 | 160 | 145 | 280 | 250 | 230 | 150 | 130 | 105 | 195 | 175 | 160 | 535 | 475 | 435 | |

| N | 1–2 | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – |

| 3 | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | |

| S | 1 | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – |

| 2 | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | |

| 3 | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | |

| 4 | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | |

| H | 1 | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – |

推荐初始速度 [m/min]

| 材料 分组 | KB1340 | KC520M | KCK15 | KCPK30 | KY3500 | |||||||||||

| P | 1 | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – |

| 2 | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | |

| 3 | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | |

| 4 | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | |

| 5 | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | |

| 6 | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | |

| M | 1 | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – |

| 2 | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | |

| 3 | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | |

| K | 1 | 1370 | 915 | 490 | 270 | 245 | 215 | 420 | 385 | 340 | 295 | 265 | 240 | 805 | 730 | 650 |

| 2 | – | – | – | 210 | 190 | 175 | 335 | 295 | 275 | 235 | 210 | 190 | 635 | 570 | 530 | |

| 3 | – | – | – | 175 | 160 | 145 | 280 | 250 | 230 | 195 | 175 | 160 | 535 | 475 | 435 | |

| N | 1–2 | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – |

| 3 | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | |

| S | 1 | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – |

| 2 | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | |

| 3 | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | |

| 4 | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | |

| H | 1 | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – |

应用数据

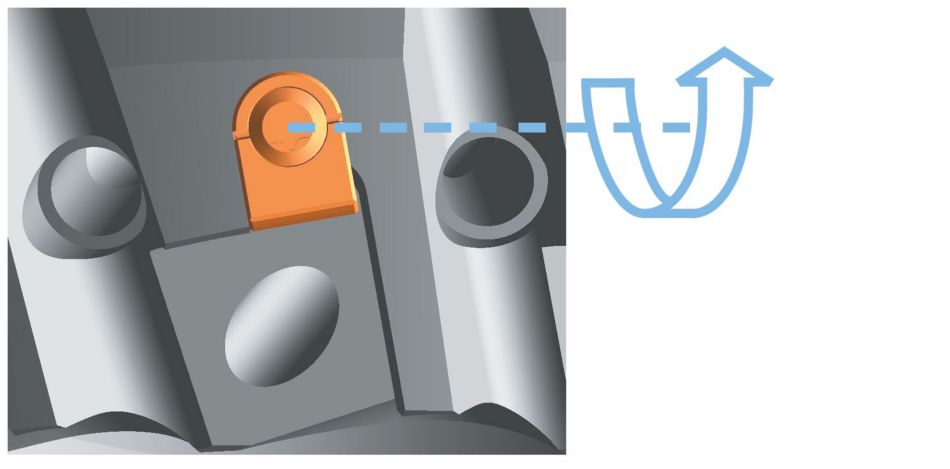

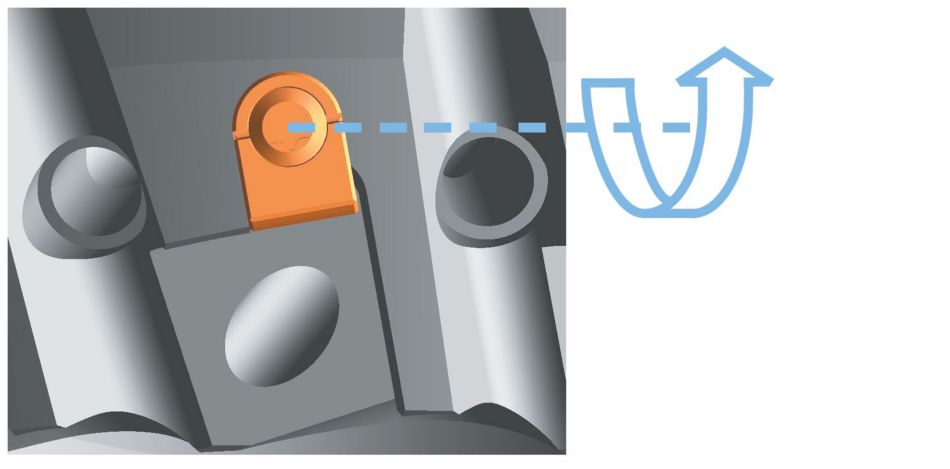

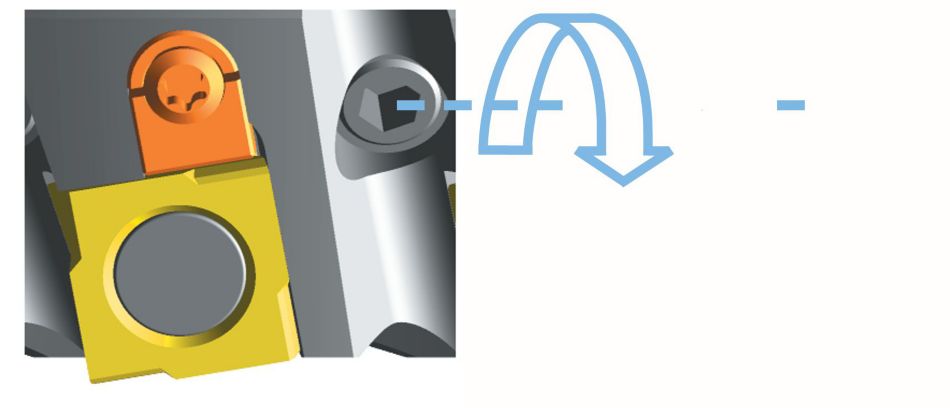

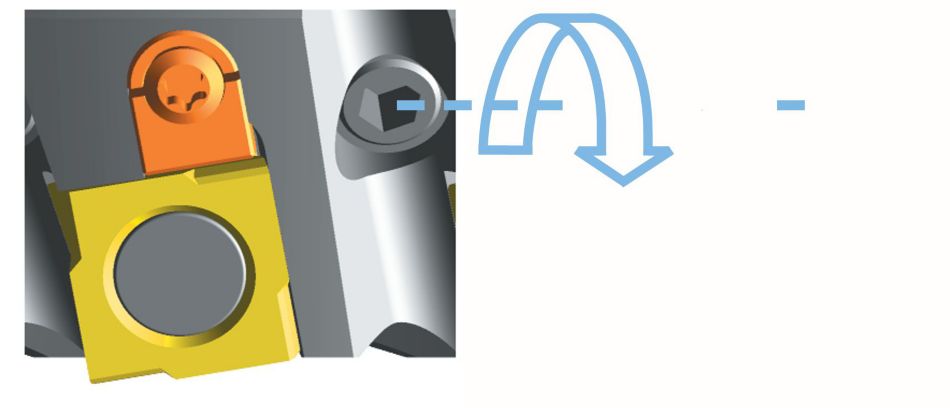

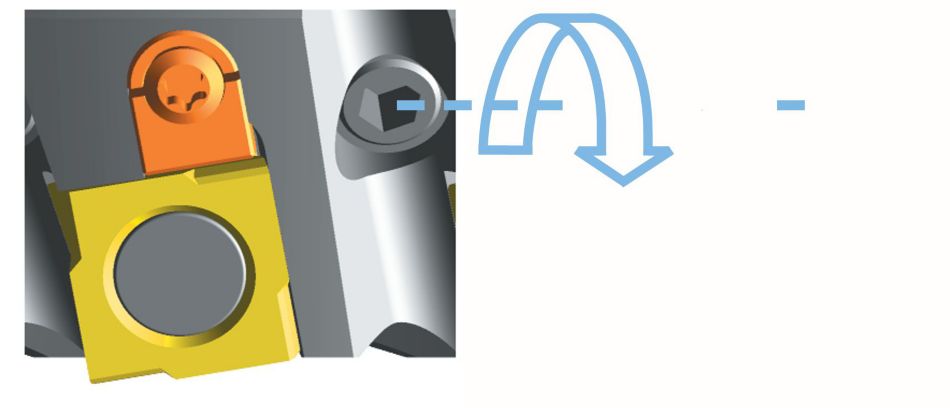

Fix-Perfect™ 铸铁铣刀的刀片装配

| roughing | procedures | roughing/finishing | |||

|  |  |  | ||

| insert seat | insert seat | ||||

| 标准精度 | adjustable | 标准精度 | adjustable | ||

| ― |  | 1 | Reset adjusting element T x T9 | ― |  |

|  | 2 | insert roughing insert tighten SW 3 MAn = 5 Nm |  | ― |

| ― |  | 3 | tighten adjusting element gently | ― | ― |

| 4 | insert finishing insert and pre-tighten SW 3 M VG = 1 Nm | ― |  | ||

| 5 | the finishing insert is positioned 0,04mm in front of the highest roughing insert | ― | 0,04mm (.0016in.) | ||

| 6 | tighten the finishing insert MAn = 5 Nm | ― |  | ||

High Performance Combination Tools

刀片选择指南

| 材料 分组 | 轻切削 | 中等切削 | 重切削 | |||

| (锋利的槽型) | – | (强壮的槽型) | ||||

| 耐磨性 |  | 韧性 | ||||

| 槽型 | 材质 | 槽型 | 材质 | 槽型 | 材质 | |

| P1–P2 | – | – | – | – | – | – |

| P3–P4 | – | – | – | – | – | – |

| P5–P6 | – | – | – | – | – | – |

| M1–M2 | – | – | – | – | – | – |

| M3 | – | – | – | – | – | – |

| K1–K2 | .E..GPB | KC520M | .E..GPB | KCK15 | .S..GPB | KCK15 |

| K3 | .E..GPB | KC520M | .E..GPB | KCK15 | .S..GPB | KCK15 |

| N1–N2 | – | – | – | – | – | – |

| N3 | – | – | – | – | – | – |

| S1–S2 | – | – | – | – | – | – |

| S3 | – | – | – | – | – | – |

| S4 | – | – | – | – | – | – |

| H1 | – | – | – | – | – | – |

刀片选择指南

| 材料 分组 | 轻切削 | 中等切削 | 重切削 | |||

| (锋利的槽型) | – | (强壮的槽型) | ||||

| 耐磨性 |  | 韧性 | ||||

| 槽型 | 材质 | 槽型 | 材质 | 槽型 | 材质 | |

| P1–P2 | – | – | – | – | – | – |

| P3–P4 | – | – | – | – | – | – |

| P5–P6 | – | – | – | – | – | – |

| M1–M2 | – | – | – | – | – | – |

| M3 | – | – | – | – | – | – |

| K1–K2 | .E..GP | KC520M | .E..GP | KCK15 | .E..GP | KCK15 |

| K3 | .E..GP | KC520M | .E..GP | KCK15 | .S..GP | KCPK30 |

| N1–N2 | – | – | – | – | – | – |

| N3 | – | – | – | – | – | – |

| S1–S2 | – | – | – | – | – | – |

| S3 | – | – | – | – | – | – |

| S4 | – | – | – | – | – | – |

| H1 | – | – | – | – | – | – |

I have read and accepted the Terms & Conditions of use