TMS • 螺纹铣削系统 • 螺纹铣刀 • 普通型

可转位螺纹铣刀

物料号1280481

公制样本编号K045TM1RW050STN11N英制样本编号K045TM1RW050STN11N

- P 钢

- M 不锈钢

- K 铸铁

- H 淬火材料

Sending to {{cadTool}} in progress...

Downloaded file will be available after import in the {{cadTool}} tool library.

| 物料号 | 1280481 |

| 公制样本编号 | K045TM1RW050STN11N |

| 英制样本编号 | K045TM1RW050STN11N |

| [D1] 有效的切削直径 | 11.43 mm |

| [D1] 有效的切削直径 | 0.45 in |

| [D]适配接头/刀柄/镗孔直径 | 12.7 mm |

| [D]适配接头/刀柄/镗孔直径 | 0.5 in |

| [D2] 钻体最大直径 | 8.89 mm |

| [D2] 钻体最大直径 | 0.35 in |

| [L] 总长 | 69.85 mm |

| [L] 总长 | 2.75 in |

| [L3] 可用长度 | 11.94 mm |

| [L3] 可用长度 | 0.47 in |

| 刀片数量 | 1 |

| 最大 RPM | 36825 |

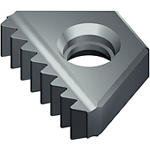

| Gage 刀片 | STN11 |

工件材料

- 钢

- 不锈钢

- 铸铁

- 淬火材料

Features and benefits

- 用于多种材料工件的内螺纹和外螺纹加工。

- 一款刀具产品即可用于右旋和左旋螺纹的加工。

- 所有刀具具备内冷性能。

- 使用多种牙型和牙距的刀片。

通过创建解决方案计算速度和进给

创建解决方案后,只需选择进给和速度图标,我们的系统将提供建议。您可以通过添加您的机床和参数来定制信息,或者使用滑块进行调整。

应用数据

|  |

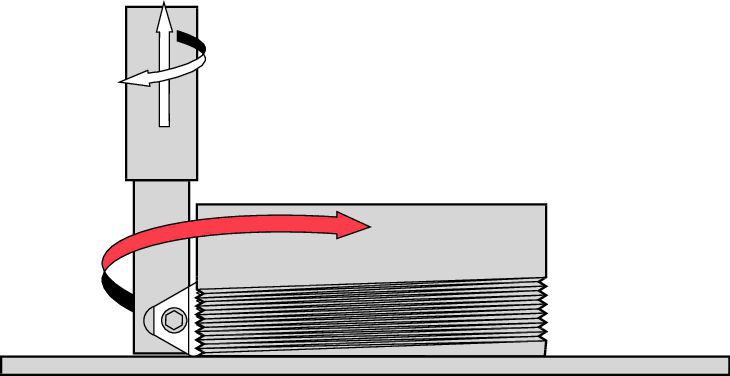

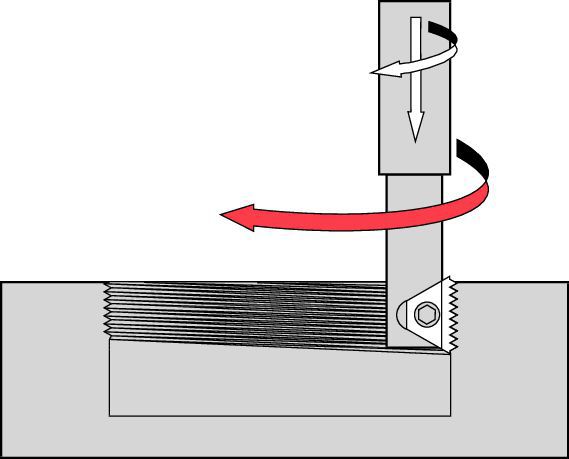

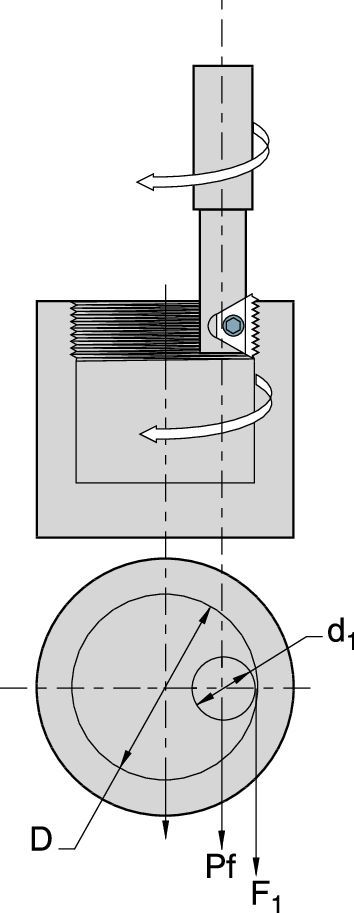

| 右旋螺纹……逆铣 | 左旋螺纹……逆铣 |

|  |

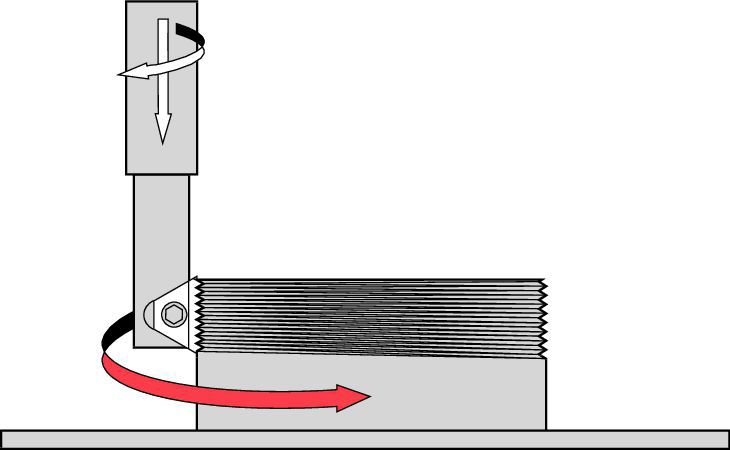

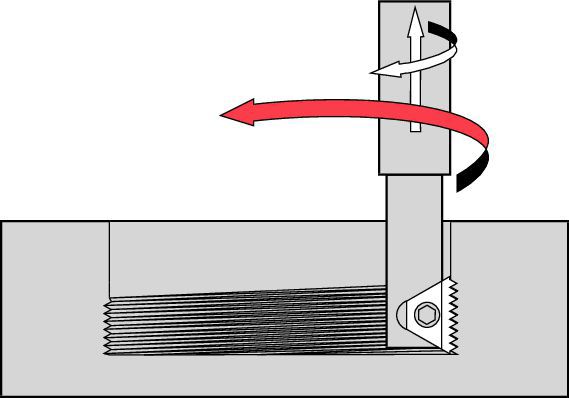

| 右旋螺纹……顺铣 | 左旋螺纹……顺铣 |

|  |

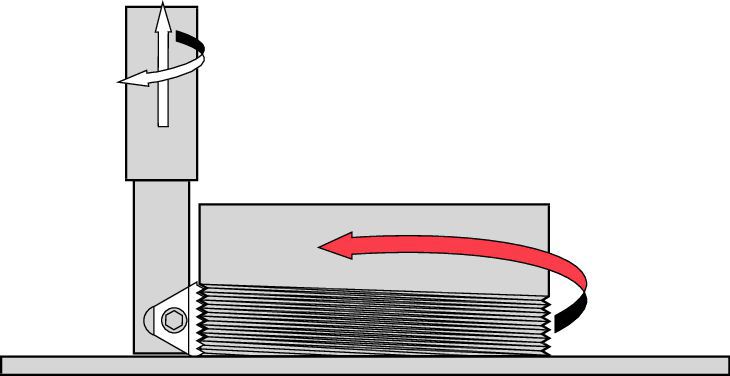

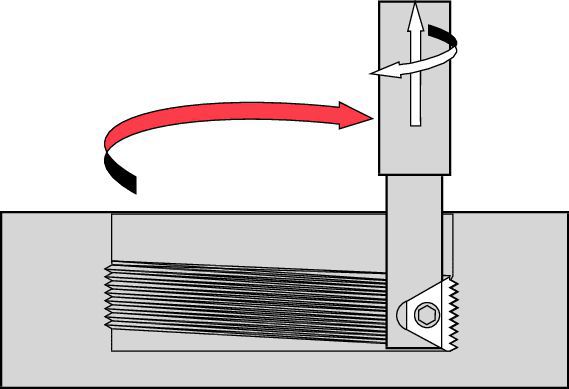

| 右旋螺纹……逆铣 | 左旋螺纹……逆铣 |

|  |

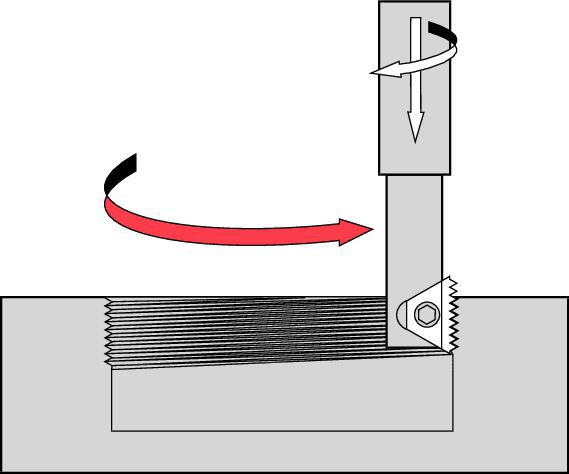

| 右旋螺纹……顺铣 | 左旋螺纹……顺铣 |

| 刀具 | TPI | 48 | 32 | 24 | 20 | 16 | 12 | 10 | 8 | 7 | 6 | 5.5 | 5 | 4.5 | 4.5 | 4 | 4 |

| 螺距(毫米) | 0,5 | 0,75 | 1,0 | 1,25 | 1,5 | 2,0 | 2,5 | 3,0 | 3,5 | 4,0 | 4,5 | 5,0 | 5,5 | – | 6,0 | – | |

| 刀具直径 (D1 mm) | 最小孔径 (D) (mm) | ||||||||||||||||

| K035TM1RW050-STN10 | 8.89 | 9.50 | 10.01 | 10.69 | 11.40 | ||||||||||||

| K045TM1RW050-STN11N | 11.43 | 11.99 | 12.50 | 13.21 | 13.89 | 14.50 | |||||||||||

| K049TM1RW037LT11S | 12.45 | 13.00 | 13.49 | 14.20 | 14.91 | 15.49 | |||||||||||

| K061TM1RW062-STN16T | 15.49 | 16.00 | 16.51 | 16.94 | 17.91 | 18.49 | 19.51 | ||||||||||

| K067TM2RW075-STN11D | 17.02 | 17.60 | 18.21 | 19.00 | 19.61 | 19.99 | 21.01 | ||||||||||

| K075TM1RW075-STN16T | 19.05 | 19.71 | 20.40 | 21.01 | 21.59 | 22.00 | 23.01 | ||||||||||

| K079TM1RW075-STN16N | 20.07 | 20.70 | 21.41 | 22.00 | 22.61 | 23.01 | 24.00 | ||||||||||

| K087TM1RW100-STN16L | 22.10 | 22.68 | 23.39 | 24.00 | 24.61 | 24.99 | 26.01 | ||||||||||

| K102TM2RW100-STN16D | 25.91 | 26.70 | 27.41 | 27.99 | 28.70 | 29.31 | 30.30 | ||||||||||

| K118TM1RW100-STN27N | 29.97 | 30.71 | 31.39 | 32.00 | 32.79 | 33.50 | 34.59 | 36.60 | 38.99 | 42.01 | 45.01 | 48.01 | |||||

| K146TM1RW125-STN27N | 37.08 | 38.00 | 38.61 | 39.50 | 40.41 | 41.00 | 42.01 | 43.99 | 46.48 | 49.00 | 51.99 | 55.50 | |||||

| K165TM2RW125-STN27D | 41.91 | 43.21 | 43.79 | 45.01 | 46.00 | 46.51 | 47.40 | 49.00 | 51.99 | 54.51 | 57.61 | 60.99 | |||||

| – | 1.38 (UN) | – | – | – | – | – | – | – | – | – | 50.01 | – | 46.81 | – | 44.60 | – | 56.59 |

| – | 1.38 (ISO) | – | – | – | – | – | – | – | – | – | 50.01 | 53.39 | 42.49 | 50.01 | – | 57.51 | – |

| – | 1.38 (BSW) | – | – | – | – | – | – | – | – | – | 49.81 | – | 46.51 | – | 47.40 | – | – |

| 刀具 | TPI | 48 | 32 | 24 | 20 | 16 | 12 | 10 | 8 | 7 | 6 | 5.5 | 5 | 4.5 | 4.5 | 4 | 4 |

| 螺距(mm) | 0,5 | 0,75 | 1,0 | 1,25 | 1,5 | 2,0 | 2,5 | 3,0 | 3,5 | 4,0 | 4,5 | 5,0 | 5,5 | – | 6,0 | – | |

| 刀具直径 (D1 mm) | 最小孔径 (D) (mm) | ||||||||||||||||

| K035TM1RW050-STN10 | 8,89 | 9,50 | 10,01 | 10,69 | 11,40 | ||||||||||||

| K045TM1RW050-STN11N | 11,43 | 11,99 | 12,50 | 13,21 | 13,89 | 14,50 | |||||||||||

| K049TM1RW037LT11S | 12,45 | 13,00 | 13,49 | 14,20 | 14,91 | 15,49 | |||||||||||

| K061TM1RW062-STN16T | 15,49 | 16,00 | 16,51 | 16,94 | 17,91 | 18,49 | 19,51 | ||||||||||

| K067TM2RW075-STN11D | 17,02 | 17,60 | 18,21 | 19,00 | 19,61 | 19,99 | 21,01 | ||||||||||

| K075TM1RW075-STN16T | 19,05 | 19,71 | 20,40 | 21,01 | 21,59 | 22,00 | 23,01 | ||||||||||

| K079TM1RW075-STN16N | 20,07 | 20,70 | 21,41 | 22,00 | 22,61 | 23,01 | 24,00 | ||||||||||

| K087TM1RW100-STN16L | 22,10 | 22,68 | 23,39 | 24,00 | 24,61 | 24,99 | 26,01 | ||||||||||

| K102TM2RW100-STN16D | 25,91 | 26,70 | 27,41 | 27,99 | 28,70 | 29,31 | 30,30 | ||||||||||

| K118TM1RW100-STN27N | 29,97 | 30,71 | 31,39 | 32,00 | 32,79 | 33,50 | 34,59 | 36,60 | 38,99 | 42,01 | 45,01 | 48,01 | |||||

| K146TM1RW125-STN27N | 37,08 | 38,00 | 38,61 | 39,50 | 40,41 | 41,00 | 42,01 | 43,99 | 46,48 | 49,00 | 51,99 | 55,50 | |||||

| K165TM2RW125-STN27D | 41,91 | 43,21 | 43,79 | 45,01 | 46,00 | 46,51 | 47,40 | 49,00 | 51,99 | 54,51 | 57,61 | 60,99 | |||||

| – | 35,05 (UN) | – | – | – | – | – | – | – | – | – | 50,01 | – | 46,81 | – | 44,60 | – | 56,59 |

| – | 35,05 (ISO) | – | – | – | – | – | – | – | – | – | 50,01 | 53,39 | 42,49 | 50,01 | – | 57,51 | – |

| – | 35,05 (BSW) | – | – | – | – | – | – | – | – | – | 49,81 | – | 46,51 | – | 47,40 | – | – |

| 工件材料 | 切削速度 | 每转进给量 (mm) |

| KC635M | ||

| 碳钢 187 HB | 90–210 | 0,10–0,20 |

| 碳钢 187–220 HB | 90–150 | 0,10–0,15 |

| 合金钢 200–250 HB | 60–130 | 0,10–0,15 |

| 合金钢 250–325 HB | 50–90 | 0,10–0,15 |

| 不锈钢,奥氏体 210 HB | 90–140 | 0,10–0,15 |

| 不锈钢,马氏体 321 HB | 80–110 | 0,05–0,15 |

| 不锈钢,铁素体 245 HB | 110–170 | 0,05–0,10 |

| 铸铁 140 HB | 110–170 | 0,05–0,15 |

| 铸铁 220 | 70–130 | 0,05–0,10 |

| 钛合金 | 60–120 | 0,03–0,08 |

| 高温合金(镍基和铁基) | 20–45 | 0,03–0,05 |

| 高温合金(钴基) | 15–30 | 0,03–0,05 |

| 铸铁 | 80–110 | 0,05–0,15 |

| 可锻铸铁 | 80–120 | 0,03–0,08 |

| 工件材料 | 切削速度 | 每转进给量 (mm) |

| KC635M | ||

| 碳钢 187 HB | 90–210 | 0.10–0.20 |

| 碳钢 187–220 HB | 90–150 | 0.10–0.15 |

| 合金钢 200–250 HB | 60–130 | 0.10–0.15 |

| 合金钢 250–325 HB | 50–90 | 0.10–0.15 |

| 不锈钢,奥氏体 210 HB | 90–140 | 0.10–0.15 |

| 不锈钢,马氏体 321 HB | 80–110 | 0.05–0.15 |

| 不锈钢,铁素体 245 HB | 110–170 | 0.05–0.10 |

| 铸铁 140 HB | 110–170 | 0.05–0.15 |

| 铸铁 220 | 70–130 | 0.05–0.10 |

| 钛合金 | 60–120 | 0.03–0.08 |

| 高温合金(镍基和铁基) | 20–45 | 0.03–0.05 |

| 高温合金(钴基) | 15–30 | 0.03–0.05 |

| 铸铁 | 80–110 | 0.05–0.15 |

| 可锻铸铁 | 80–120 | 0.03–0.08 |

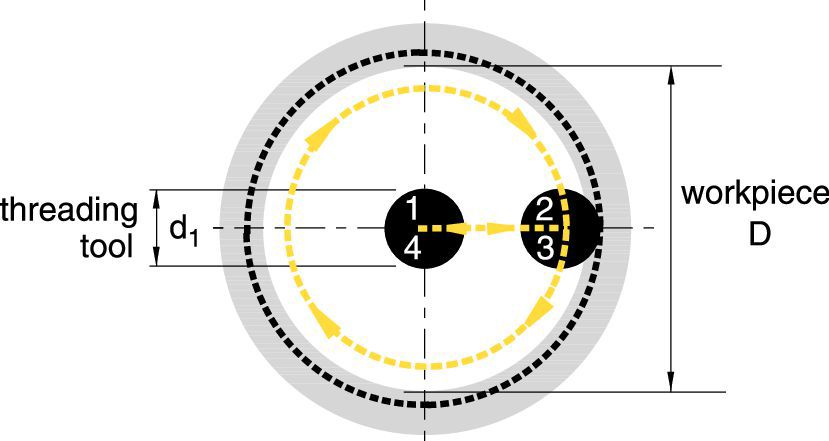

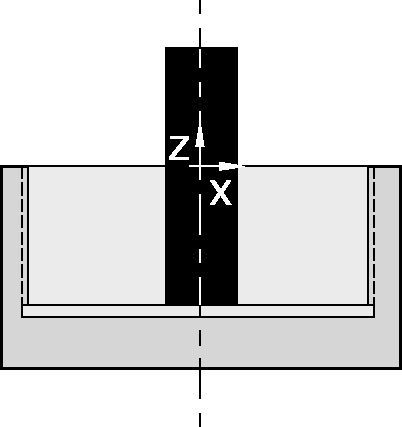

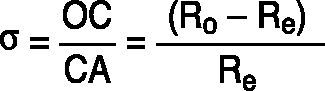

| 1–2: | 径向进刀 |

| 2–3: | 在一个完整轨迹内 (360°)以螺旋状运动 |

| 3–4: | 径向退刀 |

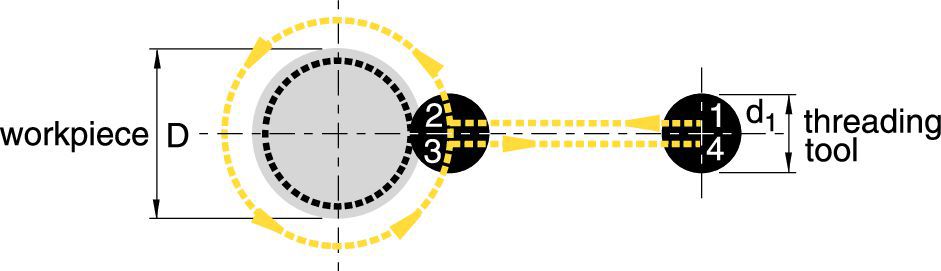

| P1 = F1 + | (F1 x d1) |  |  |

| D | 外螺纹 | 内螺纹 | |

| P1 = 编程进给率 (mm/min) D = 大径(外螺纹) D = 小径(内螺纹) d1 = 切削直径,刀片上 | 刀具 工件 | ||

| F1 = fz x Z x n | RPM = | 12 x SFM | |

| π x d 1 | |||

| character name="tab"/>F1 = 切削刃部位的刀具进给率(in/min) fz = 每齿英寸数(进给率) Z = 刀具内的有效刀片数 n = 转动速度 (主轴 RPM) | SFM = 切削速度,每分钟表面英尺数 d1 = 刀具直径,刀片上 π = 3.1416 | ||

|  |

| 内螺纹 | 外螺纹 |

| pitch (TPI) | 24 | 20 | 16 | 12 |

| pitch mm | 1,0 | 1,25 | 1,5 | 2,0 |

| cutter dia. d1 | minimum bore diameter D | |||

| .67 | .748 | .772 | .787 | .827 |

| .75 | .827 | .850 | .866 | .906 |

| .79 | .866 | .890 | .906 | .945 |

| 刀片IC | a (mm) | 螺距(TPI) | 内螺纹 | b | 牙数 | 刀片材质 | 外螺纹 | b | 牙数 | 刀片材质 | 刀具类型 | ||

| 目录编号 | KC610M | KC620M | 目录编号 | KC610M | KC620M | ||||||||

| 32 | STN16 32UN-I | 14,99 | 19 | STN16 32UN-E | 14,99 | 19 | |||||||

| 28 | STN16 28UN-I | 14,48 | 16 | STN16 28UN-E | 14,48 | 16 | |||||||

| 27 | STN16 27UN-I | 14,22 | 15 | STN16 27UN-E | 14,22 | 15 | |||||||

| 24 | STN16 24UN-I | 13,97 | 14 | STN16 24UN-E | 14,73 | 14 | |||||||

| 9,53 | 16 | 20 | STN16 20UN-I | 13,97 | 11 | STN16 20UN-E | 13,97 | 11 | STN16 | ||||

| 18 | STN16 18UN-I | 14,22 | 10 | STN16 18UN-E | 14,22 | 10 | |||||||

| 16 | STN16 16UN-I | 14,22 | 9 | STN16 16UN-E | 14,22 | 9 | |||||||

| 14 | STN16 14UN-I | 14,48 | 8 | STN16 14UN-E | 14,48 | 8 | |||||||

| 13 | STN16 13UN-I | 13,72 | 7 | STN16 13UN-E | 13,72 | 7 | |||||||

| 12 | STN16 12UN-I | 14,73 | 7 | STN16 12UN-E | 14,73 | 7 | |||||||

| 螺距(TPI) | 24 | 20 | 16 | 12 |

| 螺距(mm) | 1,0 | 1,25 | 1,5 | 2,0 |

| 刀具直径 d1 | 最小孔径 D | |||

| 17,02 | 19,00 | 19,61 | 19,99 | 21,01 |

| 19,05 | 21,01 | 21,59 | 22,00 | 23,01 |

| 20,07 | 22,00 | 22,61 | 23,01 | 24,00 |

| 刀片IC | a inch (mm) | pitch (TPI) | 内螺纹 | b | 牙数 | 刀片材质 | external thread | b | 牙数 | 刀片材质 | 刀具类型 | ||

| 目录编号 | KC610M | KC620M | 目录编号 | KC610M | KC620M | ||||||||

| 32 | STN16 32UN-I | .59 | 19 | STN16 32UN-E | .59 | 19 | |||||||

| 28 | STN16 28UN-I | .57 | 16 | STN16 28UN-E | .57 | 16 | |||||||

| 27 | STN16 27UN-I | .56 | 15 | STN16 27UN-E | .56 | 15 | |||||||

| 24 | STN16 24UN-I | .55 | 14 | STN16 24UN-E | .58 | 14 | |||||||

| 3/8 | .63 (16) | 20 | STN16 20UN-I | .55 | 11 | STN16 20UN-E | .55 | 11 | STN16 | ||||

| 18 | STN16 18UN-I | .56 | 10 | STN16 18UN-E | .56 | 10 | |||||||

| 16 | STN16 16UN-I | .56 | 9 | STN16 16UN-E | .56 | 9 | |||||||

| 14 | STN16 14UN-I | .57 | 8 | STN16 14UN-E | .57 | 8 | |||||||

| 13 | STN16 13UN-I | .54 | 7 | STN16 13UN-E | .54 | 7 | |||||||

| 12 | STN16 12UN-I | .58 | 7 | STN16 12UN-E | .58 | 7 | |||||||

| Calculate the feed rates: | |||||

| First, find the RPM. | |||||

| RPM = | 12 x SFM | = | 12 x 500 | = | 2418 RPM |

| π x d1 | 3.14 x .79 | ||||

| Next, calculate the feed rate at the insert cutting edge (F1): | |||||

| (using the chosen feed per tooth of .004.) | |||||

| F1 = | IPT x nt x RPM | = | .004 X 1 X 2418 | = | 9.67 in/min |

| Finally, calculate the feed rate at the cutter centerline (F2): | |||||

| F2 = | F1 x (D - d1) | = | 9.67 x (1.182 - .79) | = | 3.207 in/min |

| D | 1.182 | ||||

| Select the thread milling method. | |||||

| Climb milling (preferred) see page . | |||||

| Calculate the radius of the tangential arc Re: | |||||

| Re = | (Ri - CL)2 + R02 | = | (.591 - .02)2 + .6252 | ||

| 2Ro | 2 x .625 | ||||

| Re = | .573333 in. | ||||

| Calculate the angle (β): | |||||

| β = | 90° + arc sin | Ro - Re | |||

| Re | |||||

| β = | 90° + arc sin | .625 - .573333 | |||

| .57333 | |||||

| β = | 90° + 5.17° | = | 95.17° | = | 95° 10' |

| Calculate the movement along the Z-axis during the entry approach from point “A” to point “B” (Zα). | |||||

| Zα= P (英寸) x | α° | = | .0625 | = | .0156 in, because α = 90° |

| 360° | 4 | ||||

| Calculate the “X” and “Y” values at the start of the entry approach. | |||||

| X = 0Y = -Ri + CL = -.591 + .02 = - .571 in. | |||||

| Define Z-axis location at the start of the entry approach. (NOTE: L = length of thread) | |||||

| Z = - (L + Zα) = - (.50 + .0156) = - .5156 in. | |||||

| Define the starting point. | |||||

| Xa = 0 | |||||

| Ya = 0 | |||||

| 计算进给率: | |||||

| 首先,确定 RPM 值。 | |||||

| RPM = | 1000 x Vc | = | 1000 x 150 | = | 2387 RPM |

| π x d1 | π x 20 | ||||

| 接下来,计算切削刃部位的进给率 (F1): | |||||

| (使用选定的 0,1mm 每齿进给量参数) | |||||

| F1 = | Fz x Z x N | = | 0,1 X 1 X 2387 | = | 238,7 mm/min |

| 最后,计算刀具中心线部位的进给率 (F2): | |||||

| F2 = | F1 x (D - d1) | = | 238,7 x (30 | = | 79,57 mm/min |

| D | 30 | ||||

| 选择螺纹铣削法。 | |||||

| 顺铣(推荐)参看页面W48。 | |||||

| 计算切向圆弧半径 Re: | |||||

| Re = | (Ri - CL)2 + RO2 | = | (15 | ||

| 2 x RO | 2 x 15,875 | ||||

| Re = | 14,55mm | ||||

| 计算角度 (β): | |||||

| β = | 90° + arc sin | Ro - Re | |||

| Re | |||||

| β = | 90° + arc sin | 15,875 - 14,55 | |||

| 14,55 | |||||

| β = | 90° + 5.17° | = | 95,2° | = | 95° 12' |

| 计算从“A”点开始进刀至 “B”点(Za)期间,在 Z 轴方向的移动量。 | |||||

| Zα= P (mm) x | α° | = | 1,578 | = | 0,394mm 因为 α = 90° |

| 360° | 4 | ||||

| 计算在进刀初始时的 “X”和 “Y”值。 | |||||

| X = 0Y = Ri + CL = 15 + 0,5 = 15,5mm | |||||

| 确定在进刀初始时在 Z 轴上的位置。(注:L = 螺纹长度) | |||||

| Z = (L + Zα) = 12,7 + 0,3945 = 13,0945mm | |||||

| 确定起点。 | |||||

| Xa = 0 | |||||

| Ya = 0 | |||||

| 数控编程 (Fanuc 11M) | |||

| % | |||

| N10G90G00G57X0.000Y0.000 | |||

| N20G43H10Z0.M3S2417 | |||

| N30G91G00X0.Y0.Z–0.5156 | |||

| N40G41D60X0.000Y–0.5710Z0. | |||

| N50G03X0.6250Y0.5710Z0.0156R0.5733F3.206 | |||

| N60G03X0.Y0.Z0.0625I–0.625J0. | |||

| N70G03X–0.625Y0.5710Z0.0156R0.5733 | |||

| N80G00G40X0.Y–0.5710Z0. | |||

| N90G49G57G00Z8.0M5 | |||

| N100M30 | |||

| % | |||

| Ri = | D | RO = | DO |

| 2 | 2 | ||

| D = 小径 | DO = 公称直径 | ||

| α 90° | |||

| |||

| |||

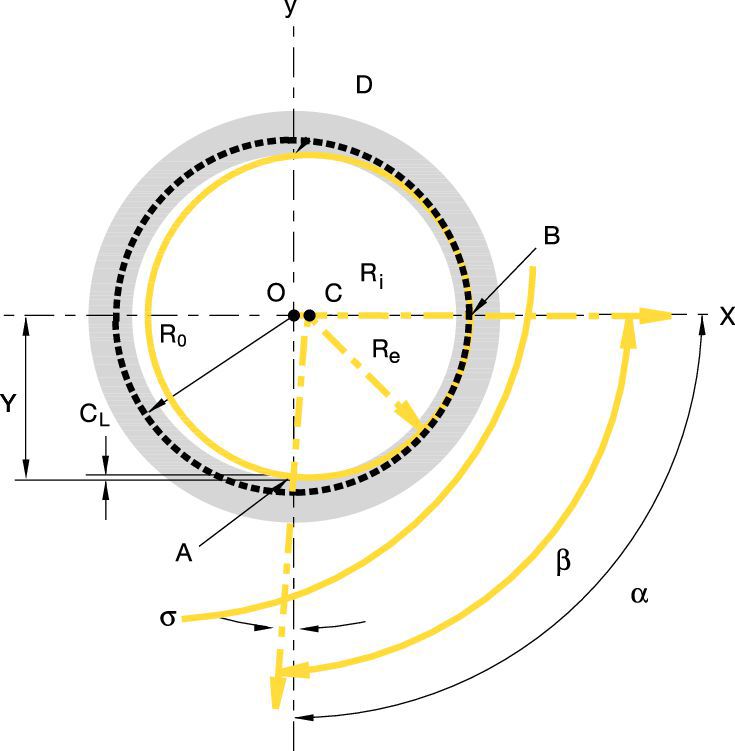

| 附录 A | |

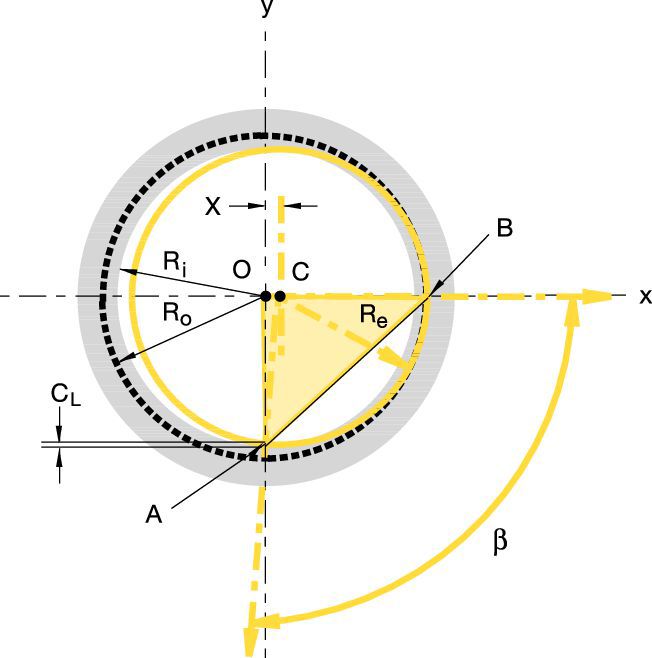

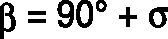

| 内螺纹铣削公式的推导公式 | |

| Re, β, 和 X 可以根据进刀路径的几何分析得出结果。 | |

| 这个进刀路径是由刀具以 C 点为圆心,以 Re 为半径作的圆周运动路径 确定的。 | |

| R e = | (R i - C L) 2 + R o2 |

| 2R o | |

| OAC 三角可以帮助简化 Re 值的计算过程。 | |

| OA = Ri – CL CA = Re OC = Ro – Re | |

| 毕达哥拉斯定律表明:OA2 + OC2 = AC2 | |

| 在替换实值后,我们得出结果: | |

| (R i - C L) 2 + (R o - R e) 2 = R e2 | |

| 简化计算过程,我们得出计算结果: | |

| R e = | (R i - C L) 2 + R o2 |

| 2R 0 | |

| |

| 求 β角 数值。 | |||

| 使用相同三角形可以轻易求得 β 值: | |||

| sin β = | AO | = | (Ro + CL) |

| AC | Re | ||

| β = arc sin | ( | Ro + CL | ) |

| Re | |||

| |||

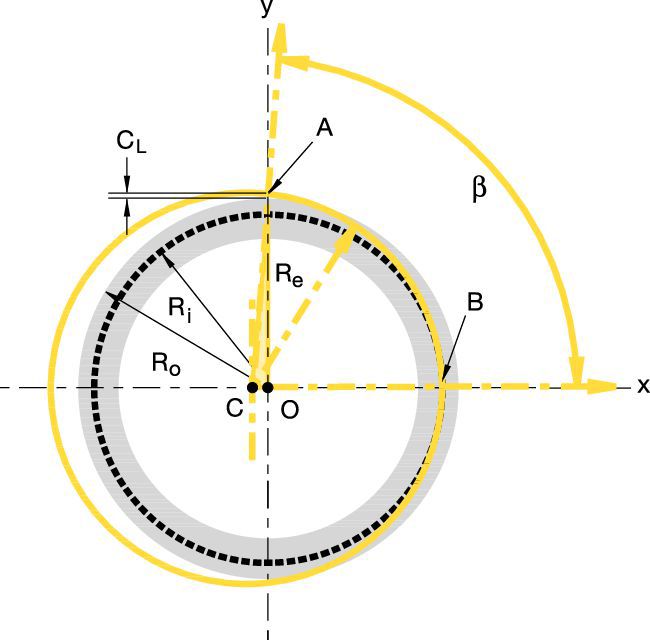

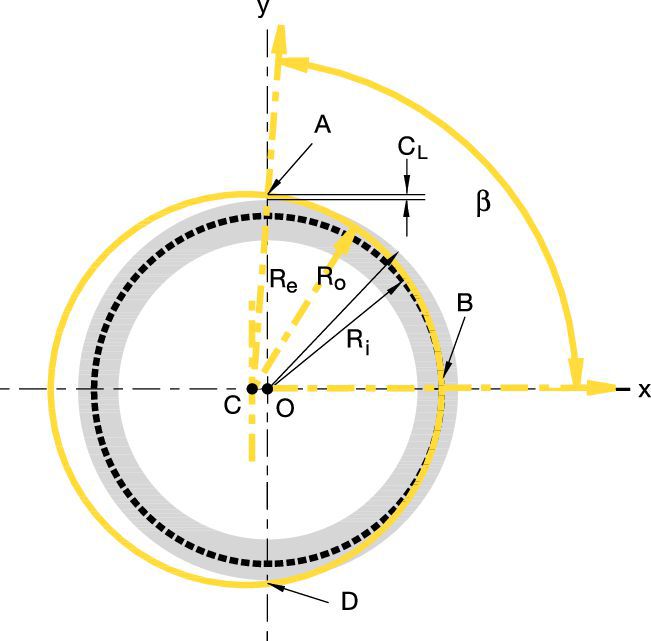

| 附录 B | |

| 外螺纹铣削公式的推导公式 | |

| Re, β, 和 X 值可以根据进刀路径的几何分析得出结果。 | |

| 这个进刀路径是由刀具以 C 点为圆心,以 Re 为半径作的圆周运动路径 确定的。 | |

| R e = | (R o - C L) 2 + R i2 |

| 2R i | |

| OAC 三角可以帮助简化 Re 值的计算过程。 | |

| OA = Ro – CL CA = Re OC = Re – Ri | |

| 毕达哥拉斯定律表明:OA2 + OC2 = AC2 | |

| 在替换实值后,我们得出结果: | |

| (R o - C L) 2 + (R e - R i) 2 = R e2 | |

| 简化计算过程,我们得出计算结果: | |

| R e = | (R o - C L) 2 + R i2 |

| 2R i | |

| |

| 求 β角 数值。 | ||||

| ||||

| sin |  | |||

| = arc sin | ( | Ro - Re | ) |

| Re | ||||

| 因此,β = 90° + arc sin | ( | Ro - Re | ) | |

| Re | ||||

| ||||

| 故障 | 形成原因 | 解决方案 | |

| 刀片侧面磨损过度 |  | • 切削速度过高。 | • 降低切削速度。 |

| • 切屑过薄。 | • 提高进给率。 | ||

| • 冷却液流量不够。 | • 增加冷却液流量/压力。 | ||

| 切削刃崩刃 |  | • 切屑过厚。 | • 降低进给率。 • 使用切向圆弧进刀法。 • 提高转速(RPM)。 |

| • 振动。 | • 检查刚性。 | ||

| 切屑刃部位出现积屑瘤 |  | • 切削速度过低。 | • 增加切削速度。 |

| • 切屑厚度过薄。 | • 提高进给率。 | ||

| 振刀/振动 | • 进给率过高。 | • 降低进给率。 | |

| • 牙型过深(粗齿螺纹)。 | • 两次走刀,每次增加切削深度。 • 两次走刀,每次仅完成一半螺纹深度 的加工。 | ||

| • 螺纹长度过长。 | • 两次走刀,每次仅完成一半螺纹深度 的加工。 | ||

| 螺纹精度低 | • 刀具变形。 | • 降低进给率。 • 进行一次零位切削。 | |

| 螺纹标记 | 标准名称 | 公差等级 |

| UN | ANSI B 1.174 | 2A/2B |

| UNJ | MIL-S-8879A | 3A/3B |

| ISO | R262 (DIN 13) | 6g/6H |

| NPT | USAS B2.1 :1968 | 标准 NPT |

| NPTF | ANSI B 1.20.3-1976 | 标准精度 |

| BSW | B.S.84 :1956, DIN 259, ISO 228/1 :1982 | 一般类别 A |

| BSPT | B.S.21 :1985 | 标准 BSPT |

| ACME | ANSI B1/5 :1988 | 3G |

| PG | DIN 40430 | 标准精度 |

| TR | DIN 103 | 7e/7H |

I have read and accepted the Terms & Conditions of use