Product Similar To:

K255_YPC (~5 x D) • KCK10 • A-Shank • YPC Beyond Drills

YPC Beyond™ Drills • Iron Materials • Through Coolant

Material Number4052307

ISO Catalog IDK255A04219YPCANSI Catalog IDK255A04219YPC

- K Cast Iron

Drilling

Drilling: Inclined Exit

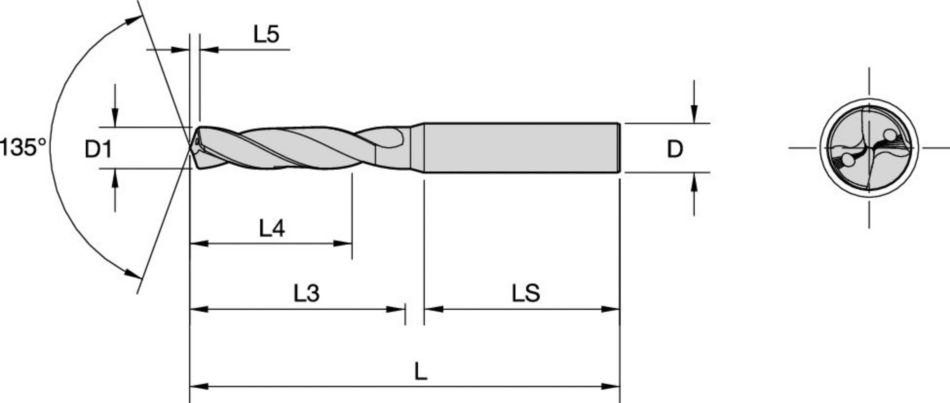

Tool Dimensions: 2flute/3margin/coolant

Drilling - Through Coolant

Through Coolant: MQL (Minimum Quantity Lubricant): Drilling

Corner Style: Corner Chamfer

Shank - Cylindrical Plain ≤h6

Helix Angle: 30°

Drilling: Cross-Hole Drilling

Sending to {{cadTool}} in progress...

Downloaded file will be available after import in the {{cadTool}} tool library.

| Material Number | 4052307 |

| ISO Catalog ID | K255A04219YPC |

| ANSI Catalog ID | K255A04219YPC |

| Grade | KCK10 |

| [D1] Drill Diameter M | 10.716 mm |

| [D1] Drill Diameter M | 0.4219 in |

| [L] Overall Length | 111 mm |

| [L] Overall Length | 4.3701 in |

| [L3] Flute Length | 66 mm |

| [L3] Flute Length | 2.5984 in |

| [L4] Maximum Drilling Depth | 53.1 mm |

| [L4] Maximum Drilling Depth | 2.0906 in |

| [L5] Drill Point Length | 2.748 mm |

| [L5] Drill Point Length | 0.1082 in |

| [LS] Shank Length | 42.499 mm |

| [LS] Shank Length | 1.6732 in |

| [D] Adapter / Shank / Bore Diameter | 11.113 mm |

| [D] Adapter / Shank / Bore Diameter | 0.4375 in |

Workpiece Materials

- Cast Iron

Uses and application

Drilling

Drilling: Inclined Exit

Tool Dimensions: 2flute/3margin/coolant

Drilling - Through Coolant

Through Coolant: MQL (Minimum Quantity Lubricant): Drilling

Corner Style: Corner Chamfer

Shank - Cylindrical Plain ≤h6

Helix Angle: 30°

Drilling: Cross-Hole Drilling

Grades

KCK10

Composition: Multilayered PVD AlCrN-based coated fine-grain carbide with superior surface finish.

Application: First choice for cast iron. Due to the uniquely developed coating combined with the state-of-the-art surface condition, this grade offers extraordinary wear resistance in abrasive materials at elevated cutting conditions.

Features and benefits

- YPC Beyond drills with through coolant for iron materials.

- Material-specific SC drill specifically engineered to deliver best-in-class hole quality and longest tool life in cast iron, ductile iron, CGI, and ADI.

- Y-TECH™ technology with uneven flute-to-flute angle creates unbalanced forces by design avoid chipping on margin lands.

- Three-margin lands reduce pendulum motion by directing forces towards third margin for superior hole accuracy (cylindricity, constant diameter, hole straightness).

- Corner chamfer avoids breakout when drilling through holes in gray iron.

- KCK10™ Beyond grade contains multiple layers of PVD coating offering outstanding wear resistance for the drilling of cast irons.

Create Solution to calculate Feeds and Speeds

After creating a solution just choose the Feeds & Speeds icon and our system will provide recommendations. You can customize the information by adding your machine and specifications or make adjustments using the sliders.

Application Data

YPC Drills • B/K25_YPC • Grade KCK10™ • Through Coolant • Drill Diameters 3–20mm • Metric

Tolerance

| Tolerance • Metric | ||

| nominal size range | D1 tolerance m7 | D tolerance h6 |

| 0,004/0,016 | 0,000/-0,008 | |

| 0,006/0,021 | 0,000/-0,009 | |

| 0,007/0,025 | 0,000/-0,011 | |

| 0,008/0,029 | 0,000/-0,013 | |

| Tolerance • Inch | ||

| nominal size range | D1 tolerance m7 | D tolerance h6 |

| .0002/.0006 | .0000/-.0003 | |

| .0002/.0008 | .0000/-.0004 | |

| .0003/.0010 | .0000/-.0004 | |

| .0003/.0011 | .0000/-.0005 | |

Dimension

Dimensions for Kennametal Solid Carbide Drills (K* Series)

Dimensions for Kennametal Solid Carbide Drills (B* Series)

I have read and accepted the Terms & Conditions of use