Product Similar To :

KCRA - RN • Face Mills • Metric

Shell Mills

Material Number5704054

ISO Catalog IDKCRA50Z04S22RN12ANSI Catalog IDKCRA50Z04S22RN12

- P Steel

- S High-Temp Alloys

- .caption

Milling - Pressurized Air Coolant

Face Milling

Side Milling/Shoulder Milling: Ball Nose

Milling - Side and Face

Sending to {{cadTool}} in progress...

Downloaded file will be available after import in the {{cadTool}} tool library.

- Overview

- Application Data

- Downloads

- Compatible Parts Machine Side

- Compatible Parts Workpiece Side

- Spare Parts

- Reviews

- Q&A

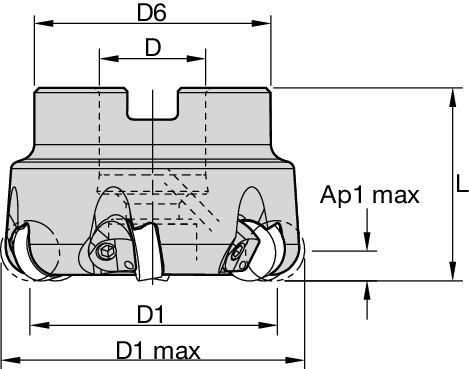

| Material Number | 5704054 |

| ISO Catalog ID | KCRA50Z04S22RN12 |

| ANSI Catalog ID | KCRA50Z04S22RN12 |

| [D1MAX] Maximum Cutting Diameter | 50 mm |

| [D1MAX] Maximum Cutting Diameter | 1.9685 in |

| [D1] Effective Cutting Diameter | 37.3 mm |

| [D1] Effective Cutting Diameter | 1.4685 in |

| [D] Adapter / Shank / Bore Diameter | 22 mm |

| [D] Adapter / Shank / Bore Diameter | 0.8666 in |

| [D6] Hub Diameter | 42 mm |

| [D6] Hub Diameter | 1.6535 in |

| [L] Overall Length | 45 mm |

| [L] Overall Length | 1.7717 in |

| [AP1MAX] 1st Maximum Cutting Depth | 6.35 mm |

| [AP1MAX] 1st Maximum Cutting Depth | 0.25 in |

| Number of Inserts | 4 |

| Weight Kilograms | 0.4 |

| Max RPM | 23700 |

| Gage Insert | RNGN120400 |

Workpiece Materials

- Steel

- High-Temp Alloys

- .caption

Uses and application

Milling - Pressurized Air Coolant

Face Milling

Side Milling/Shoulder Milling: Ball Nose

Milling - Side and Face

Features and benefits

- First choice for face and shoulder milling high-temperature alloys.

- Higher material removal rate due to fine pitch cutters.

- Secure clamping system, improving process stability and reliability.

- Effective air coolant feature. Better chip flow and increased insert tool life.

Create Solution to calculate Feeds and Speeds

After creating a solution just choose the Feeds & Speeds icon and our system will provide recommendations. You can customize the information by adding your machine and specifications or make adjustments using the sliders.

Feeds

At 6,35 Axial Depth of Cut (ap)

| Insert Geometry | Recommended Starting Feed per Tooth (Fz) in Relation to % of Radial Engagement (ae) | Insert Geometry | ||||||||||||||

| 10% | 20% | 30% | 40% | 50–100% | ||||||||||||

| .EGN | 0,08 | 0,09 | 0,11 | 0,06 | 0,07 | 0,09 | 0,06 | 0,06 | 0,07 | 0,05 | 0,06 | 0,07 | 0,05 | 0,06 | 0,07 | .EGN |

| .TGN | 0,13 | 0,17 | 0,19 | 0,09 | 0,13 | 0,14 | 0,08 | 0,11 | 0,13 | 0,08 | 0,10 | 0,12 | 0,08 | 0,10 | 0,12 | .TGN |

At 3,00 Axial Depth of Cut (ap)

| Light | General | Heavy |

At 1,50 Axial Depth of Cut (ap)

| Insert Geometry | Recommended Starting Feed per Tooth (Fz) in Relation to % of Radial Engagement (ae) | Insert Geometry | ||||||||||||||

| 10% | 20% | 30% | 40% | 50–100% | ||||||||||||

| .EGN | 0,18 | 0,20 | 0,24 | 0,13 | 0,15 | 0,18 | 0,12 | 0,13 | 0,16 | 0,11 | 0,12 | 0,15 | 0,11 | 0,12 | 0,14 | .EGN |

| .TGN | 0,27 | 0,36 | 0,41 | 0,20 | 0,27 | 0,31 | 0,17 | 0,23 | 0,27 | 0,16 | 0,22 | 0,25 | 0,16 | 0,21 | 0,24 | .TGN |

At 0,75 Axial Depth of Cut (ap)

| Insert Geometry | Recommended Starting Feed per Tooth (Fz) in Relation to % of Radial Engagement (ae) | Insert Geometry | ||||||||||||||

| 10% | 20% | 30% | 40% | 50–100% | ||||||||||||

| .EGN | 0,10 | 0,11 | 0,13 | 0,07 | 0,08 | 0,10 | 0,07 | 0,07 | 0,09 | 0,06 | 0,07 | 0,08 | 0,06 | 0,07 | 0,08 | .EGN |

| .TGN | 0,15 | 0,20 | 0,23 | 0,11 | 0,15 | 0,17 | 0,10 | 0,13 | 0,15 | 0,09 | 0,12 | 0,14 | 0,09 | 0,12 | 0,14 | .TGN |

| Insert Geometry | Recommended Starting Feed per Tooth (Fz) in Relation to % of Radial Engagement (ae) | Insert Geometry | ||||||||||||||

| 10% | 20% | 30% | 40% | 50–100% | ||||||||||||

| .EGN | 0,13 | 0,14 | 0,18 | 0,10 | 0,11 | 0,13 | 0,09 | 0,09 | 0,12 | 0,08 | 0,09 | 0,11 | 0,08 | 0,09 | 0,11 | .EGN |

| .TGN | 0,19 | 0,26 | 0,30 | 0,15 | 0,19 | 0,22 | 0,13 | 0,17 | 0,19 | 0,12 | 0,16 | 0,18 | 0,12 | 0,15 | 0,18 | .TGN |

Speeds

Recommended Starting Speeds [m/min]

| Material Group | KYS30 | KYSP30 | |||||

| P | 1 | – | – | – | – | – | – |

| 2 | – | – | – | – | – | – | |

| 3 | – | – | – | – | – | – | |

| 4 | – | – | – | – | – | – | |

| 5 | – | – | – | – | – | – | |

| 6 | – | – | – | – | – | – | |

| M | 1 | – | – | – | – | – | – |

| 2 | – | – | – | – | – | – | |

| 3 | – | – | – | – | – | – | |

| K | 1 | – | – | – | – | – | – |

| 2 | – | – | – | – | – | – | |

| 3 | – | – | – | – | – | – | |

| N | 1 | – | – | – | – | – | – |

| 2 | – | – | – | – | – | – | |

| S | 1 | 805 | 660 | 510 | 805 | 660 | 510 |

| 2 | 805 | 660 | 510 | 805 | 660 | 510 | |

| 3 | 1170 | 950 | 730 | 1170 | 950 | 730 | |

| 4 | – | – | – | – | – | – | |

| H | 1 | – | – | – | – | – | – |

| 2 | – | – | – | – | – | – | |

| 3 | – | – | – | – | – | – | |

Insert Selection

| Material Group | Light | General | Heavy | |||

| – | (Light geometry) | – | (Strong geometry) | |||

| – | wear |  | toughness | |||

| – | Geometry | Grade | Geometry | Grade | Geometry | Grade |

| P1–P2 | – | – | – | – | – | – |

| P3–P4 | – | – | – | – | – | – |

| P5–P6 | – | – | – | – | – | – |

| M1–M2 | – | – | – | – | – | – |

| M3 | – | – | – | – | – | – |

| K1–K2 | – | – | – | – | – | – |

| K3 | – | – | – | – | – | – |

| N1–N2 | – | – | – | – | – | – |

| N3 | – | – | – | – | – | – |

| S1–S2 | .EGN | KYS30 | .EGN | KYS30 | .TGN | KYS30 |

| S3 | .EGN | KYSP30 | .EGN | KYSP30 | .TGN | KYSP30 |

| S4 | – | – | – | – | – | – |

| H1 | – | – | – | – | – | – |

TechnicalInfo

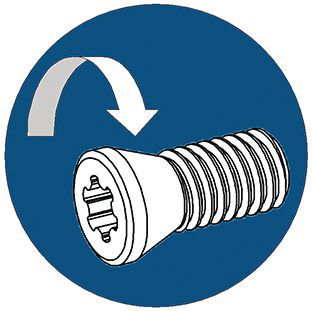

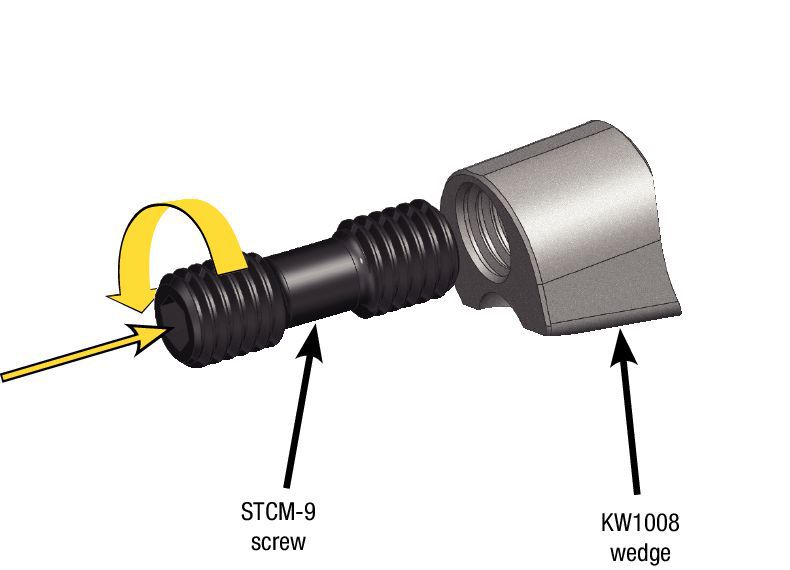

Insert Assembly Guide

| Safety Notes | |||||

|  |  |  |  |  |

| Read all instructions carefully | Wear eye protection | Inspect and tighten fasteners regularly | Warning: Cutting hazard | Warning: Hot surfaces | Do not exceed maximum RPM |

| Assembly Instructions | |

| Assemble STCM-25 screw to KW1008 wedge, 1 to 1 1/2 turns. | Wedge/screw assembly. |

|  |

| Install wedge/screw assembly into cutter body, but maintain assembly gap for installing insert. | Slide insert, RNGN12... into pocket and torque wedge/insert assembly to 3,5 Nm (31 in/lbs). Repeat for each pocket. |

|  |

I have read and accepted the Terms & Conditions of use