Product Similar To :

KenFeed™ 2X • Shell Mill • Metric

Copy milling cutter for multiple materials.

Material Number4114000

ISO Catalog IDKF2X80Z07WO09ANSI Catalog IDKF2X80Z07WO09

- P Steel

- M Stainless Steel

- K Cast Iron

- S High-Temp Alloys

- H Hardened Materials

- .caption

Face Milling

Helical Milling

Plunge Milling

Ramping: Blank

Slotting: Ball Nose

Side Milling/Shoulder Milling: Ball Nose

3D Profiling

Milling - Through Coolant

Milling - Side and Face

Pocketing

Sending to {{cadTool}} in progress...

Downloaded file will be available after import in the {{cadTool}} tool library.

- Overview

- Application Data

- Downloads

- Compatible Parts Machine Side

- Compatible Parts Workpiece Side

- Spare Parts

- Reviews

- Q&A

| Material Number | 4114000 |

| ISO Catalog ID | KF2X80Z07WO09 |

| ANSI Catalog ID | KF2X80Z07WO09 |

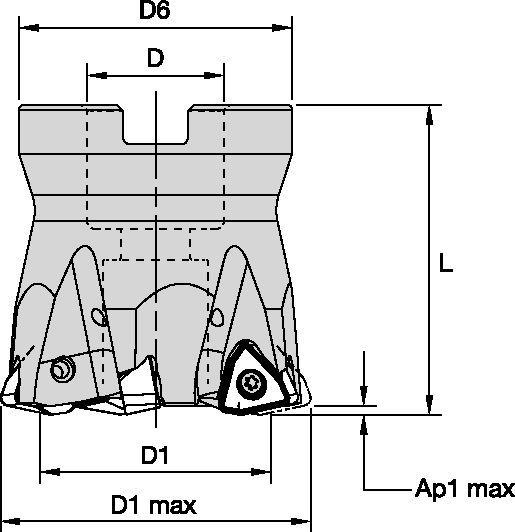

| [D1MAX] Maximum Cutting Diameter | 80 mm |

| [D1MAX] Maximum Cutting Diameter | 3.1492 in |

| [D1] Effective Cutting Diameter | 63.83 mm |

| [D1] Effective Cutting Diameter | 2.513 in |

| [D] Adapter / Shank / Bore Diameter | 27 mm |

| [D] Adapter / Shank / Bore Diameter | 1.064 in |

| [D6] Hub Diameter | 60.4 mm |

| [D6] Hub Diameter | 2.378 in |

| [L] Overall Length | 50.01 mm |

| [L] Overall Length | 1.969 in |

| [AP1MAX] 1st Maximum Cutting Depth | 1.5 mm |

| [AP1MAX] 1st Maximum Cutting Depth | 0.059 in |

| Number of Inserts | 7 |

| Weight Kilograms | 1.07 |

| Max RPM | 17500 |

| Gage Insert | WOEJ090512__ |

Workpiece Materials

- Steel

- Stainless Steel

- Cast Iron

- High-Temp Alloys

- Hardened Materials

- .caption

Uses and application

Face Milling

Helical Milling

Plunge Milling

Ramping: Blank

Slotting: Ball Nose

Side Milling/Shoulder Milling: Ball Nose

3D Profiling

Milling - Through Coolant

Milling - Side and Face

Pocketing

Features and benefits

- Internal coolant supply.

- For pocketing, ramping, helical interpolation, and z-plunging.

Create Solution to calculate Feeds and Speeds

After creating a solution just choose the Feeds & Speeds icon and our system will provide recommendations. You can customize the information by adding your machine and specifications or make adjustments using the sliders.

Feeds

Recommended Starting Feeds [mm]

| Insert Geometry | Recommended Starting Feed per Tooth (Fz) in Relation to % of Radial Engagement (ae) | Insert Geometry | ||||||||||||||

| 5% | 10% | 20% | 30% | 40–100% | ||||||||||||

| .S..GD | 1,15 | 2,42 | 3,84 | 0,82 | 1,71 | 2,67 | 0,61 | 1,26 | 1,96 | 0,53 | 1,10 | 1,70 | 0,49 | 1,01 | 1,55 | .S..GD |

| .S..HD | 1,15 | 2,78 | 4,27 | 0,82 | 1,96 | 2,94 | 0,61 | 1,44 | 2,16 | 0,53 | 1,26 | 1,87 | 0,49 | 1,15 | 1,71 | .S..HD |

| Light | General | Heavy |

Speeds

Recommended Starting Speeds [m/min]

| Material Group | KC522M | KC725M | KCK15 | KCPK30 | |||||||||

| P | 1 | 395 | 345 | 325 | 315 | 275 | 255 | – | – | – | 545 | 475 | 440 |

| 2 | 330 | 290 | 240 | 260 | 230 | 195 | – | – | – | 335 | 305 | 275 | |

| 3 | 305 | 255 | 215 | 240 | 205 | 170 | – | – | – | 305 | 275 | 250 | |

| 4 | 270 | 225 | 180 | 215 | 180 | 145 | – | – | – | 225 | 210 | 190 | |

| 5 | 225 | 200 | 180 | 180 | 160 | 145 | – | – | – | 310 | 275 | 255 | |

| 6 | 200 | 150 | 120 | 160 | 120 | 95 | – | – | – | 190 | 165 | – | |

| M | 1 | 245 | 215 | 200 | 205 | 180 | 165 | – | – | – | 250 | 220 | 190 |

| 2 | 225 | 190 | 160 | 185 | 160 | 130 | – | – | – | 225 | 195 | 170 | |

| 3 | 170 | 145 | 115 | 140 | 120 | 95 | – | – | – | 175 | 160 | 140 | |

| K | 1 | 275 | 250 | 220 | – | – | – | 505 | 460 | 410 | 355 | 320 | 285 |

| 2 | 215 | 195 | 180 | – | – | – | 400 | 355 | 330 | 280 | 255 | 230 | |

| 3 | 180 | 160 | 145 | – | – | – | 335 | 300 | 275 | 235 | 210 | 195 | |

| N | 1 | – | – | – | – | – | – | – | – | – | – | – | – |

| 2 | – | – | – | – | – | – | – | – | – | – | – | – | |

| S | 1 | 50 | 45 | 35 | 45 | 35 | 30 | – | – | – | – | – | – |

| 2 | 50 | 45 | 35 | 45 | 35 | 30 | – | – | – | – | – | – | |

| 3 | 60 | 50 | 35 | 55 | 45 | 30 | – | – | – | – | – | – | |

| 4 | 85 | 60 | 45 | 75 | 55 | 35 | – | – | – | – | – | – | |

| H | 1 | 145 | 110 | 85 | – | – | – | – | – | – | – | – | – |

| 2 | – | – | – | – | – | – | – | – | – | – | – | – | |

| 3 | – | – | – | – | – | – | – | – | – | – | – | – | |

Application Data

General Programming Information for Applying KenFeed 2X • IC09

| Rt | Wt | t |

| 2.70 | 8.15 | 1.15 |

Insert Selection

| Material Group | Light | General | Heavy | |||

| – | (Light geometry) | – | (Strong geometry) | |||

| – | wear |  | toughness | |||

| – | Geometry | Grade | Geometry | Grade | Geometry | Grade |

| P1–P2 | .S..GD | KCPK30 | .S..GD | KCPM40 | .S..HD | KCPM40 |

| P3–P4 | .S..GD | KCPK30 | .S..GD | KCPM40 | .S..HD | KCPM40 |

| P5–P6 | .S..GD | KCPK30 | .S..GD | KC725M | .S..HD | KC725M |

| M1–M2 | .S..GD | KC522M | .S..GD | KC725M | .S..HD | KC725M |

| M3 | .S..GD | KCPK30 | .S..GD | KCPM40 | .S..HD | KCPM40 |

| K1–K2 | .S..HD | KCK15 | .S..HD | KCK15 | .S..HD | KCK15 |

| K3 | .S..GD | KCPK30 | .S..HD | KCK15 | .S..HD | KCPK30 |

| N1–N2 | – | – | – | – | – | – |

| N3 | – | – | – | – | – | – |

| S1–S2 | .S..GD | KC522M | .S..GD | KC725M | .S..HD | KC725M |

| S3 | .S..GD | KC725M | .S..GD | KCPM40 | .S..HD | KCPM40 |

| S4 | .S..GD | KC522M | .S..HD | KC522M | .S..HD | KC725M |

| H1 | – | – | – | – | – | – |

I have read and accepted the Terms & Conditions of use