Witamy

Potwierdź swoje preferencje

Aktualizuj preferencje

Sugestie dotyczące produktów

Product Family suggestions

Witaj, User Name

Wybrane konto:

Wystąpił problem z Twoim kontem. Skontaktuj się z działem obsługi klienta.

Konto kupującego

Zmień konto

Konto odbiorcy

Zmień konto

- Panel przyborów

- Zarządzaj zamówieniami

- Zarządzaj kanałami

- Książka adresowa

-

Powiadomienia

Oznacz wszystkie jako przeczytane - Zmień hasło

- Mój profil

- Wyloguj się

Pozycje

pomyślnie dodano do koszyka

Wyświetl koszyk

Wyświetl koszyk

Rozpocznij rok 2024 z fenomenalnymi oszczędnościami w narzędziach do wykonywania otworów.

Kup teraz.

Pozycje

pomyślnie dodano do koszyka

Wyświetl koszyk

Wyświetl koszyk

Edytuj

Dodaj

Nazwa : {{SolutionName}}- Produkty

- /

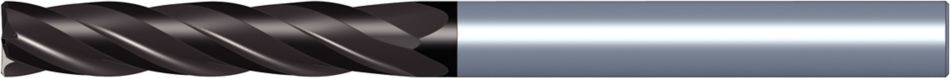

- GOmill GP • 4BN..MR-ML • 4 ostrza • Ostrze kuliste • Metryczne

Sending to SolidCAM in progress...

Downloaded file will be available after import in the SolidCAM tool library.

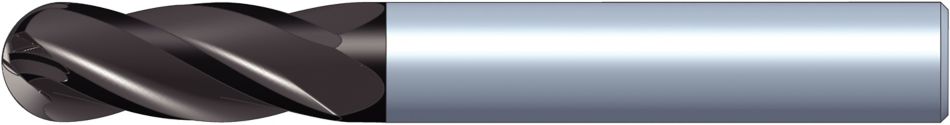

GOmill GP • 4BN..MR-ML • 4 ostrza • Ostrze kuliste • Metryczne

GOmill GP • 4BN..MR-ML • Standardowe • Długie

Właściwości i zalety

- Ostrze centralne.

Zastosowania

Slotting: Ball Nose

Side Milling/Shoulder Milling: Ball Nose

3D Profiling

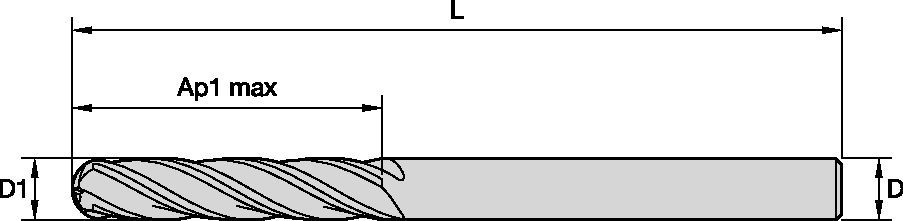

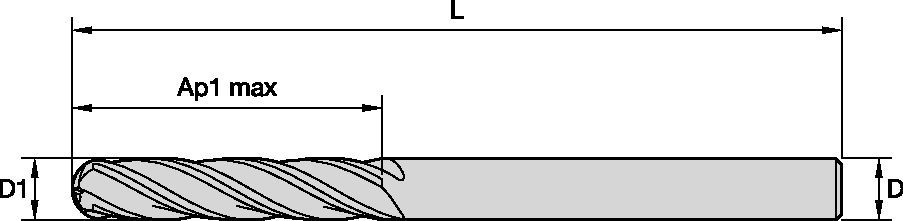

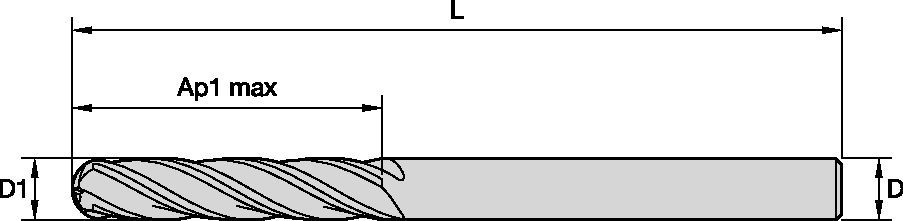

Tool Dimensions: Flute Configuration: 4

Helix Angle: 30°

Corner Style: Ball Nose

| End Mill Tolerances | |||

| D1 | tolerance e8 | D | tolerance h6 + / - |

| ≤ 3 | -0,014 / -0,028 | ≤ 3 | +0 / -0,006 |

|

|

-0,020 / -0,038 |

|

+0 / -0,008 |

|

|

-0,025 / -0,047 |

|

+0 / -0,009 |

|

|

-0,032 / -0,059 |

|

+0 / -0,011 |

|

|

-0,040 / -0,073 |

|

+0 / -0,013 |

<="" td=""> <="" td=""> |  <="" td=""> <="" td=""> |  <="" td="" /> <="" td="" /> |

||||||||||||||||||

| Side Milling (A) and Slotting (B) | KC633M | Recommended feed per tooth (fz = mm/th) for side milling (A). For slotting (B), reduce fz by 20%. | ||||||||||||||||||

| A | B | Cutting Speed

|

D1

|

|||||||||||||||||

| Material

|

ap | ae | ap | Min | Max | mm | 2,0 | 3,0 | 4,0 | 5,0 | 6,0 | 8,0 | 10,0 | 12,0 | 14,0 | 16,0 | 18,0 | 20,0 | ||

| P | 0 | Ap1 max | 0,1 x D | 0,5 x D | 150 | – | 200 | fz | 0,014 | 0,021 | 0,028 | 0,036 | 0,044 | 0,060 | 0,072 | 0,083 | 0,092 | 0,101 | 0,108 | 0,114 |

| 1 | Ap1 max | 0,1 x D | 0,5 x D | 150 | – | 200 | fz | 0,014 | 0,021 | 0,028 | 0,036 | 0,044 | 0,060 | 0,072 | 0,083 | 0,092 | 0,101 | 0,108 | 0,114 | |

| 2 | Ap1 max | 0,1 x D | 0,5 x D | 140 | – | 190 | fz | 0,014 | 0,021 | 0,028 | 0,036 | 0,044 | 0,060 | 0,072 | 0,083 | 0,092 | 0,101 | 0,108 | 0,114 | |

| 3 | Ap1 max | 0,1 x D | 0,5 x D | 120 | – | 160 | fz | 0,011 | 0,017 | 0,023 | 0,030 | 0,036 | 0,050 | 0,061 | 0,070 | 0,079 | 0,087 | 0,095 | 0,101 | |

| 4 | Ap1 max | 0,1 x D | 0,5 x D | 90 | – | 150 | fz | 0,010 | 0,016 | 0,021 | 0,027 | 0,033 | 0,045 | 0,054 | 0,062 | 0,070 | 0,077 | 0,083 | 0,088 | |

| M | 1 | Ap1 max | 0,1 x D | 0,5 x D | 90 | – | 115 | fz | 0,011 | 0,017 | 0,023 | 0,030 | 0,036 | 0,050 | 0,061 | 0,070 | 0,079 | 0,087 | 0,095 | 0,101 |

| 2 | Ap1 max | 0,1 x D | 0,5 x D | 60 | – | 80 | fz | 0,009 | 0,014 | 0,019 | 0,024 | 0,029 | 0,040 | 0,048 | 0,056 | 0,063 | 0,070 | 0,076 | 0,081 | |

| K | 1 | Ap1 max | 0,1 x D | 0,5 x D | 120 | – | 150 | fz | 0,014 | 0,021 | 0,028 | 0,036 | 0,044 | 0,060 | 0,072 | 0,083 | 0,092 | 0,101 | 0,108 | 0,114 |

| 2 | Ap1 max | 0,1 x D | 0,5 x D | 110 | – | 140 | fz | 0,011 | 0,017 | 0,023 | 0,030 | 0,036 | 0,050 | 0,061 | 0,070 | 0,079 | 0,087 | 0,095 | 0,101 | |

| N | 1 | Ap1 max | 0,1 x D | 0,5 x D | 250 | 1000 | fz | 0,020 | 0,030 | 0,040 | 0,050 | 0,060 | 0,080 | 0,100 | 0,120 | 0,140 | 0,160 | 0,180 | 0,200 | |

| 2 | Ap1 max | 0,1 x D | 0,5 x D | 250 | – | 750 | fz | 0,016 | 0,024 | 0,032 | 0,040 | 0,048 | 0,064 | 0,080 | 0,096 | 0,112 | 0,128 | 0,144 | 0,160 | |

| 4 | Ap1 max | 0,1 x D | 0,5 x D | 250 | 750 | fz | 0,018 | 0,027 | 0,036 | 0,045 | 0,054 | 0,072 | 0,090 | 0,108 | 0,126 | 0,144 | 0,162 | 0,180 | ||

<="" td=""> <="" td=""> |  <="" td="" /> <="" td="" /> |

|||||||||||||||||

| Side Milling (A) | KC633M | Recommended feed per tooth (fz = mm/th) for side milling (A). | ||||||||||||||||

| A | Cutting Speed

|

D1

|

||||||||||||||||

| Material

|

ap | ae | Min | Max | mm | 3,0 | 4,0 | 5,0 | 6,0 | 8,0 | 10,0 | 12,0 | 14,0 | 16,0 | 18,0 | 20,0 | ||

| P | 0 | Ap1 max | 0,1 x D | 150 | – | 200 | fz | 0,021 | 0,028 | 0,036 | 0,044 | 0,060 | 0,072 | 0,083 | 0,092 | 0,101 | 0,108 | 0,114 |

| 1 | Ap1 max | 0,1 x D | 150 | – | 200 | fz | 0,021 | 0,028 | 0,036 | 0,044 | 0,060 | 0,072 | 0,083 | 0,092 | 0,101 | 0,108 | 0,114 | |

| 2 | Ap1 max | 0,1 x D | 140 | – | 190 | fz | 0,021 | 0,028 | 0,036 | 0,044 | 0,060 | 0,072 | 0,083 | 0,092 | 0,101 | 0,108 | 0,114 | |

| 3 | Ap1 max | 0,1 x D | 120 | – | 160 | fz | 0,017 | 0,023 | 0,030 | 0,036 | 0,050 | 0,061 | 0,070 | 0,079 | 0,087 | 0,095 | 0,101 | |

| 4 | Ap1 max | 0,1 x D | 90 | – | 150 | fz | 0,016 | 0,021 | 0,027 | 0,033 | 0,045 | 0,054 | 0,062 | 0,070 | 0,077 | 0,083 | 0,088 | |

| M | 1 | Ap1 max | 0,1 x D | 90 | – | 115 | fz | 0,017 | 0,023 | 0,030 | 0,036 | 0,050 | 0,061 | 0,070 | 0,079 | 0,087 | 0,095 | 0,101 |

| 2 | Ap1 max | 0,1 x D | 60 | – | 80 | fz | 0,014 | 0,019 | 0,024 | 0,029 | 0,040 | 0,048 | 0,056 | 0,063 | 0,070 | 0,076 | 0,081 | |

| K | 1 | Ap1 max | 0,1 x D | 120 | – | 150 | fz | 0,021 | 0,028 | 0,036 | 0,044 | 0,060 | 0,072 | 0,083 | 0,092 | 0,101 | 0,108 | 0,114 |

| 2 | Ap1 max | 0,1 x D | 110 | – | 140 | fz | 0,017 | 0,023 | 0,030 | 0,036 | 0,050 | 0,061 | 0,070 | 0,079 | 0,087 | 0,095 | 0,101 | |

| N | 1 | Ap1 max | 0,1 x D | 250 | – | 1000 | fz | 0,030 | 0,040 | 0,050 | 0,060 | 0,080 | 0,100 | 0,120 | 0,140 | 0,160 | 0,180 | 0,200 |

| 2 | Ap1 max | 0,1 x D | 250 | – | 750 | fz | 0,024 | 0,032 | 0,040 | 0,048 | 0,064 | 0,080 | 0,096 | 0,112 | 0,128 | 0,144 | 0,160 | |

| 4 | Ap1 max | 0,1 x D | 250 | – | 750 | fz | 0,027 | 0,036 | 0,045 | 0,054 | 0,072 | 0,090 | 0,108 | 0,126 | 0,144 | 0,162 | 0,180 | |

<="" td=""> <="" td=""> |  <="" td=""> <="" td=""> |  <="" td="" /> <="" td="" /> |

|||||||||||||||||

| Side Milling (A) and Slotting (B) | KC633M | Recommended feed per tooth (fz = mm/th) for side milling (A). For slotting (B), reduce fz by 20%. | |||||||||||||||||

| A | B | Cutting Speed

|

D1

|

||||||||||||||||

| Material

|

ap | ae | ap | Min | Max | mm | 3,0 | 4,0 | 5,0 | 6,0 | 8,0 | 10,0 | 12,0 | 14,0 | 16,0 | 18,0 | 20,0 | ||

| P | 0 | Ap1 max | 0,1 x D | 0,5 x D | 150 | – | 200 | fz | 0,021 | 0,028 | 0,036 | 0,044 | 0,060 | 0,072 | 0,083 | 0,092 | 0,101 | 0,108 | 0,114 |

| 1 | Ap1 max | 0,1 x D | 0,5 x D | 150 | – | 200 | fz | 0,021 | 0,028 | 0,036 | 0,044 | 0,060 | 0,072 | 0,083 | 0,092 | 0,101 | 0,108 | 0,114 | |

| 2 | Ap1 max | 0,1 x D | 0,5 x D | 140 | – | 190 | fz | 0,021 | 0,028 | 0,036 | 0,044 | 0,060 | 0,072 | 0,083 | 0,092 | 0,101 | 0,108 | 0,114 | |

| 3 | Ap1 max | 0,1 x D | 0,5 x D | 120 | – | 160 | fz | 0,017 | 0,023 | 0,030 | 0,036 | 0,050 | 0,061 | 0,070 | 0,079 | 0,087 | 0,095 | 0,101 | |

| 4 | Ap1 max | 0,1 x D | 0,5 x D | 90 | – | 150 | fz | 0,016 | 0,021 | 0,027 | 0,033 | 0,045 | 0,054 | 0,062 | 0,070 | 0,077 | 0,083 | 0,088 | |

| M | 1 | Ap1 max | 0,1 x D | 0,5 x D | 90 | – | 115 | fz | 0,017 | 0,023 | 0,030 | 0,036 | 0,050 | 0,061 | 0,070 | 0,079 | 0,087 | 0,095 | 0,101 |

| 2 | Ap1 max | 0,1 x D | 0,5 x D | 60 | – | 80 | fz | 0,014 | 0,019 | 0,024 | 0,029 | 0,040 | 0,048 | 0,056 | 0,063 | 0,070 | 0,076 | 0,081 | |

| K | 1 | Ap1 max | 0,1 x D | 0,5 x D | 120 | – | 150 | fz | 0,021 | 0,028 | 0,036 | 0,044 | 0,060 | 0,072 | 0,083 | 0,092 | 0,101 | 0,108 | 0,114 |

| 2 | Ap1 max | 0,1 x D | 0,5 x D | 110 | – | 140 | fz | 0,017 | 0,023 | 0,030 | 0,036 | 0,050 | 0,061 | 0,070 | 0,079 | 0,087 | 0,095 | 0,101 | |

| N | 1 | Ap1 max | 0,1 x D | 0,5 x D | 250 | – | 1000 | fz | 0,030 | 0,040 | 0,050 | 0,060 | 0,080 | 0,100 | 0,120 | 0,140 | 0,160 | 0,180 | 0,200 |

| 2 | Ap1 max | 0,1 x D | 0,5 x D | 250 | – | 750 | fz | 0,024 | 0,032 | 0,040 | 0,048 | 0,064 | 0,080 | 0,096 | 0,112 | 0,128 | 0,144 | 0,160 | |

| 4 | Ap1 max | 0,1 x D | 0,5 x D | 250 | – | 750 | fz | 0,027 | 0,036 | 0,045 | 0,054 | 0,072 | 0,090 | 0,108 | 0,126 | 0,144 | 0,162 | 0,180 | |

<="" td=""> <="" td=""> |  <="" td="" /> <="" td="" /> |

|||||||||||||||||

| Side Milling (A) | KC633M | Recommended feed per tooth (fz = mm/th) for side milling (A). | ||||||||||||||||

| A | Cutting Speed

|

D1

|

||||||||||||||||

| Material

|

ap | ae | Min | Max | mm | 3,0 | 4,0 | 5,0 | 6,0 | 8,0 | 10,0 | 12,0 | 14,0 | 16,0 | 18,0 | 20,0 | ||

| P | 0 | Ap1 max | 0,1 x D | 150 | – | 200 | fz | 0,021 | 0,028 | 0,036 | 0,044 | 0,060 | 0,072 | 0,083 | 0,092 | 0,101 | 0,108 | 0,114 |

| 1 | Ap1 max | 0,1 x D | 150 | – | 200 | fz | 0,021 | 0,028 | 0,036 | 0,044 | 0,060 | 0,072 | 0,083 | 0,092 | 0,101 | 0,108 | 0,114 | |

| 2 | Ap1 max | 0,1 x D | 140 | – | 190 | fz | 0,021 | 0,028 | 0,036 | 0,044 | 0,060 | 0,072 | 0,083 | 0,092 | 0,101 | 0,108 | 0,114 | |

| 3 | Ap1 max | 0,1 x D | 120 | – | 160 | fz | 0,017 | 0,023 | 0,030 | 0,036 | 0,050 | 0,061 | 0,070 | 0,079 | 0,087 | 0,095 | 0,101 | |

| 4 | Ap1 max | 0,1 x D | 90 | – | 150 | fz | 0,016 | 0,021 | 0,027 | 0,033 | 0,045 | 0,054 | 0,062 | 0,070 | 0,077 | 0,083 | 0,088 | |

| M | 1 | Ap1 max | 0,1 x D | 90 | – | 115 | fz | 0,017 | 0,023 | 0,030 | 0,036 | 0,050 | 0,061 | 0,070 | 0,079 | 0,087 | 0,095 | 0,101 |

| 2 | Ap1 max | 0,1 x D | 60 | – | 80 | fz | 0,014 | 0,019 | 0,024 | 0,029 | 0,040 | 0,048 | 0,056 | 0,063 | 0,070 | 0,076 | 0,081 | |

| K | 1 | Ap1 max | 0,1 x D | 120 | – | 150 | fz | 0,021 | 0,028 | 0,036 | 0,044 | 0,060 | 0,072 | 0,083 | 0,092 | 0,101 | 0,108 | 0,114 |

| 2 | Ap1 max | 0,1 x D | 110 | – | 140 | fz | 0,017 | 0,023 | 0,030 | 0,036 | 0,050 | 0,061 | 0,070 | 0,079 | 0,087 | 0,095 | 0,101 | |

| N | 1 | Ap1 max | 0,1 x D | 250 | – | 1000 | fz | 0,030 | 0,040 | 0,050 | 0,060 | 0,080 | 0,100 | 0,120 | 0,140 | 0,160 | 0,180 | 0,200 |

| 2 | Ap1 max | 0,1 x D | 250 | – | 750 | fz | 0,024 | 0,032 | 0,040 | 0,048 | 0,064 | 0,080 | 0,096 | 0,112 | 0,128 | 0,144 | 0,160 | |

| 4 | Ap1 max | 0,1 x D | 250 | – | 750 | fz | 0,027 | 0,036 | 0,045 | 0,054 | 0,072 | 0,090 | 0,108 | 0,126 | 0,144 | 0,162 | 0,180 | |