Witamy

Potwierdź swoje preferencje

Aktualizuj preferencje

Sugestie dotyczące produktów

Product Family suggestions

Witaj, User Name

Wybrane konto:

Wystąpił problem z Twoim kontem. Skontaktuj się z działem obsługi klienta.

Konto kupującego

Zmień konto

Konto odbiorcy

Zmień konto

- Panel przyborów

- Zarządzaj zamówieniami

- Zarządzaj kanałami

- Książka adresowa

-

Powiadomienia

Oznacz wszystkie jako przeczytane - Zmień hasło

- Mój profil

- Wyloguj się

Pozycje

pomyślnie dodano do koszyka

Wyświetl koszyk

Wyświetl koszyk

Rozpocznij rok 2024 z fenomenalnymi oszczędnościami w narzędziach do wykonywania otworów.

Kup teraz.

Pozycje

pomyślnie dodano do koszyka

Wyświetl koszyk

Wyświetl koszyk

Edytuj

Dodaj

Nazwa : {{SolutionName}}- Produkty

- /

- Narzędzia do obróbki skrawaniem

- /

- Frezowanie

- /

- Frezy składane

- /

- Frezy czołowe

- /

- Dodeka Series

- /

- Dodeka™

- /

- Dodeka™ Inserts

- /

- Dodeka™ • Płytka z węglika spiekanego • HNGJ-GD • Obróbka średniodokładna

Sending to SolidCAM in progress...

Downloaded file will be available after import in the SolidCAM tool library.

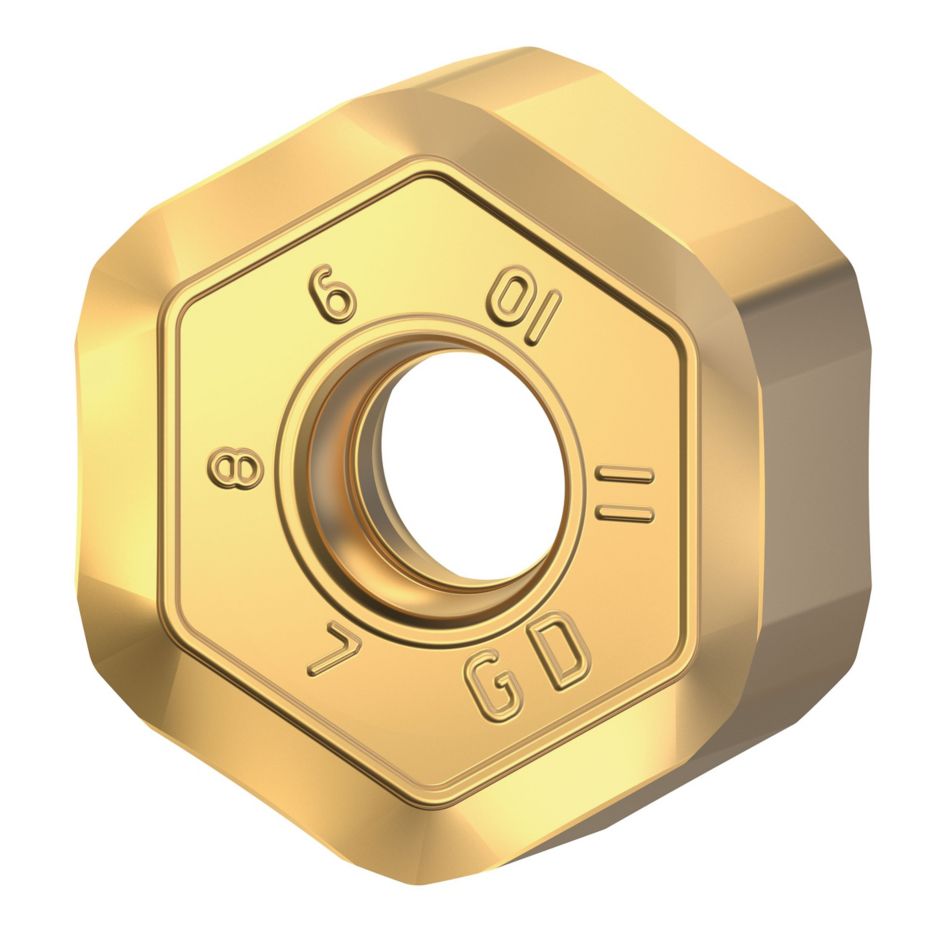

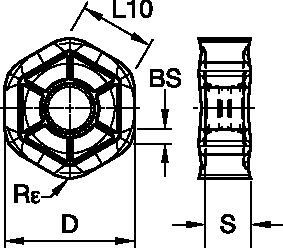

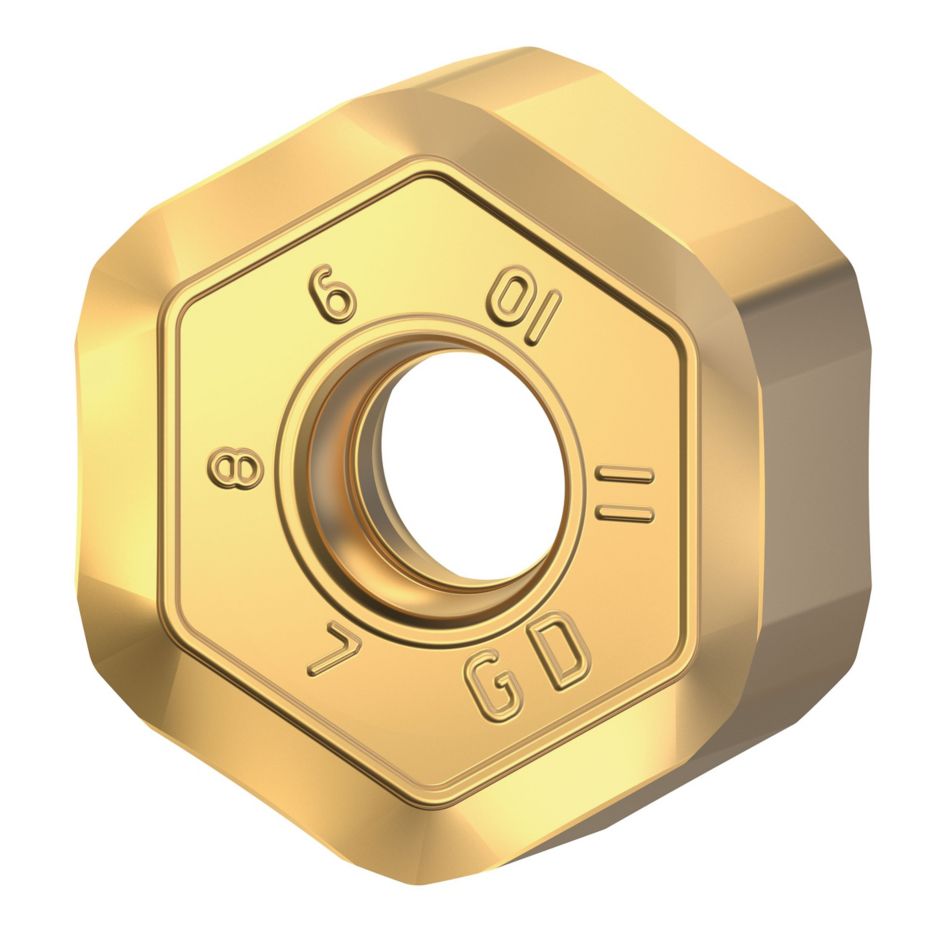

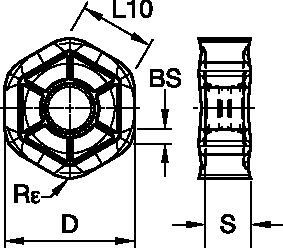

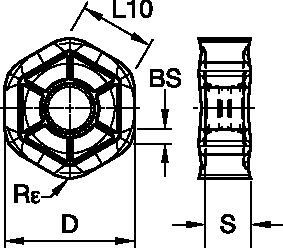

Dodeka™ • Płytka z węglika spiekanego • HNGJ-GD • Obróbka średniodokładna

Płytka do frezowania płaszczyzn z dwunastoma krawędziami skrawającymi, precyzyjnie szlifowana

Właściwości i zalety

- Płytka do frezów Dodeka 15/45 (metryczne).

- Płytka do frezów Dodeka 75/45 (metryczne).

| Material

|

Light

|

Medium

|

Heavy

|

High Speed

|

||||||||

| P1–P2 | .E..LD | KC522M | .E..LP | KC522M | .E..GP | KC522M | .S..GD | KC522M | .S..HD | KC725M |

|

|

| P3–P4 | .E..LD | KCPK30 | .E..LP | KCPM40 | .E..GP | KCPM40 | .S..GD | KCPK30 | .S..HD | KCPK30 |

|

|

| P5–P6 | .E..LD | KC725M | .E..LP | KCPM40 | .E..GP | KCPM40 | .S..GD | KCPM40 | .S..HD | KCPM40 |

|

|

| M1–M2 | .E..LD | KC522M | .E..LM | KC522M | .E..GM | KCSM40 | .S..GD | KCSM40 | .S..HD | KCSM40 |

|

|

| M3 | .E..LD | KCSM40 | .E..LM | KCSM40 | .E..GM | KCSM40 | .S..GD | KCSM40 | .S..HD | KCPM40 |

|

|

| K1–K2 | .E..LD | KCK20B | .E..LP | KCK20B | .E..LP | KCK20B | .S..GD | KCK15 | .S..HD | KCK15 | .ANSN | KY3500 |

| K3 | .E..LD | KCK20B | .E..LP | KCKP30 | .E..LP | KCPK30 | .S..GD | KCK20B | .S..HD | KCPK30 |

|

|

| N1–N2 | .F..LDJ | KC410M | .F..LDJ | KC410M | .F..LDJ | KC410M | .F..LDJ | KC410M | .F..LDJ | KC410M |

|

|

| N3 | .F..LDJ | KC410M | .F..LDJ | KC410M | .F..LDJ | KC410M | .F..LDJ | KC410M | .F..LDJ | KC410M |

|

|

| S1–S2 | .E..LD | KC725M | .E..LM | KCSM40 | .E..GM | KCSM40 | .S..GD | KC725M | .S..HD | KC725M |

|

|

| S3 | .E..LD | KCSM40 | .E..LM | KCSM40 | .E..GM | KCSM40 | .S..GD | KCSM40 | .S..HD | KCSM40 |

|

|

| S4 | .E..LD | KCSM40 | .E..LM | KCSM40 | .E..GM | KCSM40 | .S..GD | KCSM40 | .S..HD | KCSM40 |

|

|

| H1 |

|

|

|

|

.E..GP | KC522M |

|

|

|

|

|

|

| Material

|

Light

|

Medium

|

Heavy

|

|||

| P1–P2 | .E..LD | KC522M | .S..GD | KC522M | .S..HD | KC725M |

| P3–P4 | .E..LD | KCPK30 | .S..GD | KCPK30 | .S..HD | KCPK30 |

| P5–P6 | .E..LD | KC725M | .S..GD | KCPM40 | .S..HD | KCPM40 |

| M1–M2 | .E..LD | KC522M | .S..GD | KCSM40 | .S..HD | KCSM40 |

| M3 | .E..LD | KCSM40 | .S..GD | KCSM40 | .S..HD | KCPM40 |

| K1–K2 | .E..LD | KCK20B | .S..GD | KCK15 | .S..HD | KCK15 |

| K3 | .E..LD | KCK20B | .S..GD | KCK20B | .S..HD | KCPK30 |

| N1–N2 | .F..LDJ | KC410M | .F..LDJ | KC410M | .F..LDJ | KC410M |

| N3 | .F..LDJ | KC410M | .F..LDJ | KC410M | .F..LDJ | KC410M |

| S1–S2 | .E..LD | KC725M | .S..GD | KC725M | .S..HD | KC725M |

| S3 | .E..LD | KCSM40 | .S..GD | KCSM40 | .S..HD | KCSM40 |

| S4 | .E..LD | KCSM40 | .S..GD | KCSM40 | .S..HD | KCSM40 |