Witamy

Potwierdź swoje preferencje

Aktualizuj preferencje

Sugestie dotyczące produktów

Product Family suggestions

Witaj, User Name

Wybrane konto:

Wystąpił problem z Twoim kontem. Skontaktuj się z działem obsługi klienta.

Konto kupującego

Zmień konto

Konto odbiorcy

Zmień konto

- Panel przyborów

- Zarządzaj zamówieniami

- Zarządzaj kanałami

- Książka adresowa

-

Powiadomienia

Oznacz wszystkie jako przeczytane - Zmień hasło

- Mój profil

- Wyloguj się

Pozycje

pomyślnie dodano do koszyka

Wyświetl koszyk

Wyświetl koszyk

Rozpocznij rok 2024 z fenomenalnymi oszczędnościami w narzędziach do wykonywania otworów.

Kup teraz.

Pozycje

pomyślnie dodano do koszyka

Wyświetl koszyk

Wyświetl koszyk

Edytuj

Dodaj

Nazwa : {{SolutionName}}- Produkty

- /

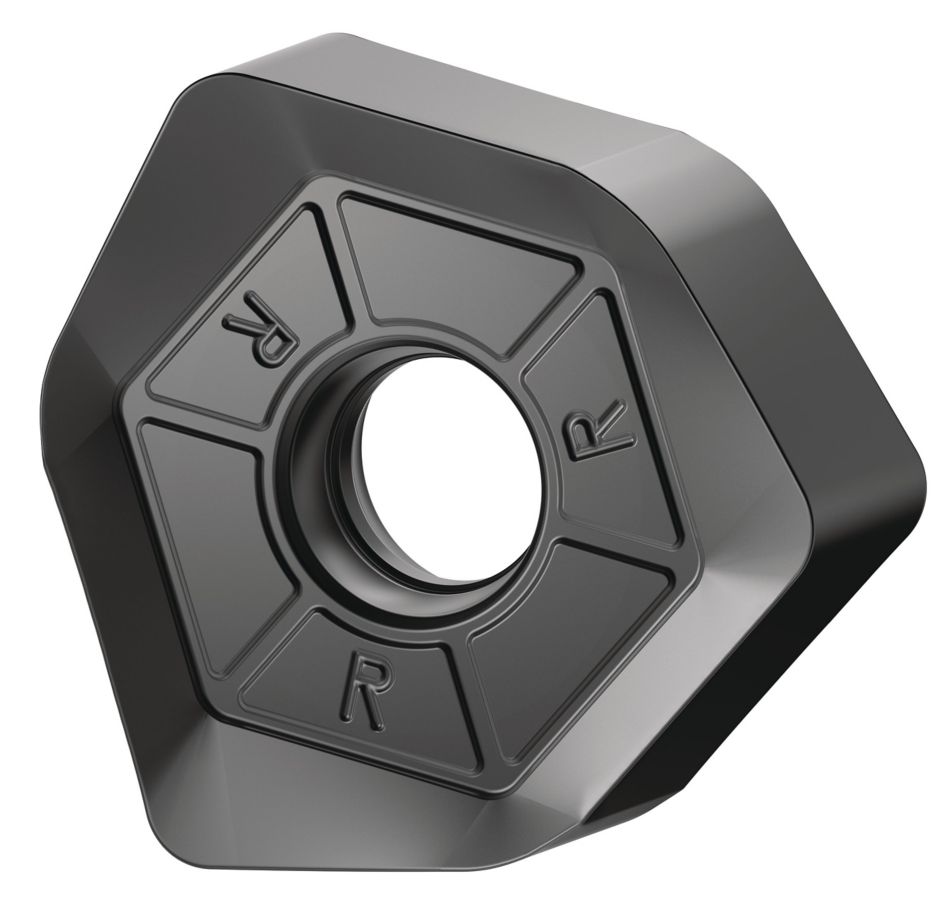

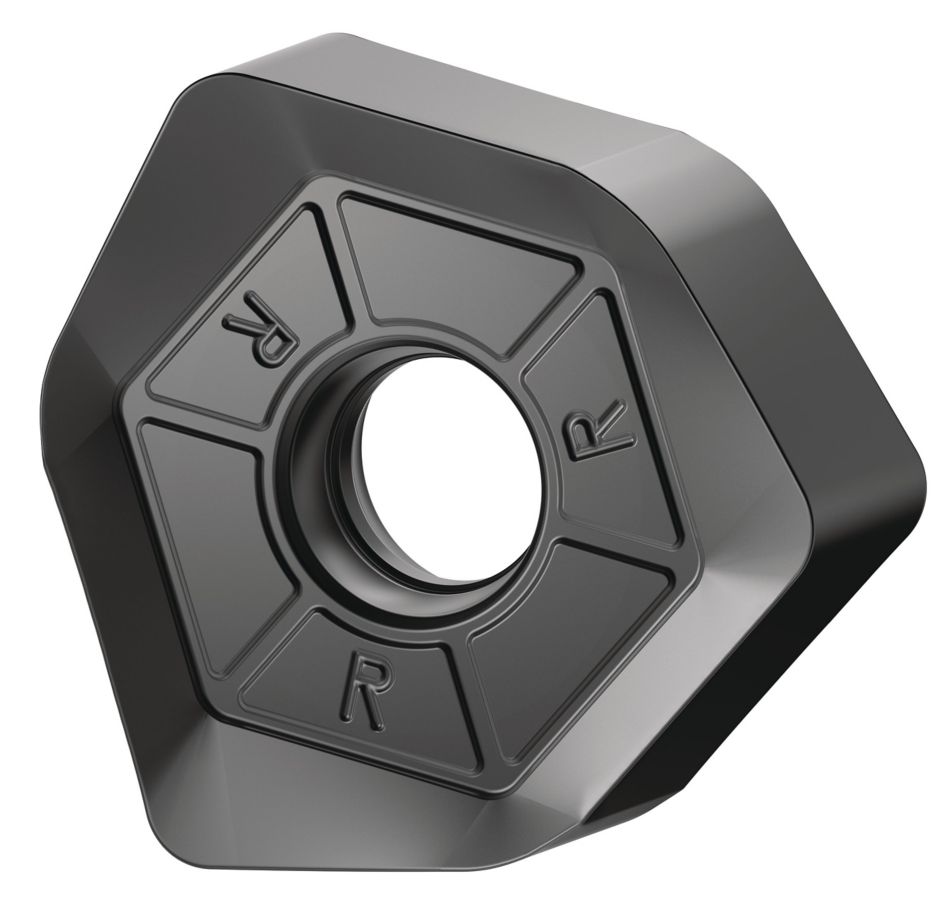

- Płytki do frezów Dodeka™ • • XNGJ-LDJ3W i -GD3W

Sending to SolidCAM in progress...

Downloaded file will be available after import in the SolidCAM tool library.

Płytki do frezów Dodeka™ • • XNGJ-LDJ3W i -GD3W

Płytki wymienne • Dodeka • XNGU • Obróbka wykańczająca

Właściwości i zalety

- Płytka typu Wiper zapewnia doskonałe wykończenie powierzchni dna.

Poradnik doboru płytek

| Werkstoffgruppe | Leichte Bearbeitung | Allgemeine Anwendung | Schruppbearbeitung | |||

| (Leicht schneidende Geometrie) | (Stabile Geometrie) | |||||

| Verschleiß- festigkeit |  <="" td=""> <="" td=""> | Zähigkeit | ||||

| Geometrie | Sorte | Geometrie | Sorte | Geometrie | Sorte | |

| P1–P2 | .E..LD | KCPK30 | .S..GD | KCPM40 | .S..HD | KCPM40 |

| P3–P4 | .E..LD | KCPK30 | .S..GD | KCPK30 | .S..HD | KCPK30 |

| P5–P6 | .E..LD | KC725M | .S..GD | KC725M | .S..HD | KC725M |

| M1–M2 | .E..LD | KCSM40 | .S..GD | KCSM40 | .S..HD | KCSM40 |

| M3 | .E..LD | KCSM40 | .S..GD | KCSM40 | .S..HD | KCSM40 |

| K1–K2 | .E..LD | KCK15 | .S..GD | KCK15 | .S..HD | KC520M |

| K3 | .E..LD | KC520M | .S..GD | KC520M | .S..HD | KC520M |

| N1–N2 | .F..LDJ | KC410M | .F..LDJ | KC410M | .F..LDJ | KC410M |

| N3 | .F..LDJ | KC410M | .F..LDJ | KC410M | .F..LDJ | KC410M |

| S1–S2 | .E..LD | KC725M | .S..GD | KC725M | .S..HD | KC725M |

| S3 | .E..LD | KCSM40 | .S..GD | KCSM40 | .S..HD | KCSM40 |

| S4 | .E..LD | KCSM40 | .S..GD | KCSM40 | .S..HD | KCSM40 |

| H1 | – | – | – | – | – | – |

Insert Selection Guide

| Werkstoffgruppe | Leichte Bearbeitung | Allgemeine Anwendung | Schruppbearbeitung | |||

| – | (Leicht schneidende Geometrie) | (Stabile Geometrie) | ||||

| – | Verschleiß- festigkeit |  <="" td=""> <="" td=""> | Zähigkeit | |||

| – | Geometrie | Sorte | Geometrie | Sorte | Geometrie | Sorte |

| P1–P2 | .E..LD | KCPK30 | .S..GD | KCPM40 | .S..HD | KCPM40 |

| P3–P4 | .E..LD | KCPK30 | .S..GD | KCPK30 | .S..HD | KCPK30 |

| P5–P6 | .E..LD | KC725M | .S..GD | KC725M | .S..HD | KC725M |

| M1–M2 | .E..LD | KCSM40 | .S..GD | KCSM40 | .S..HD | KCSM40 |

| M3 | .E..LD | KCSM40 | .S..GD | KCSM40 | .S..HD | KCSM40 |

| K1–K2 | .E..LD | KCK15 | .S..GD | KCK15 | .S..HD | KC520M |

| K3 | .E..LD | KC520M | .S..GD | KC520M | .S..HD | KC520M |

| N1–N2 | .F..LDJ | KC410M | .F..LDJ | KC410M | .F..LDJ | KC410M |

| N3 | .F..LDJ | KC410M | .F..LDJ | KC410M | .F..LDJ | KC410M |

| S1–S2 | .E..LD | KC725M | .S..GD | KC725M | .S..HD | KC725M |

| S3 | .E..LD | KCSM40 | .S..GD | KCSM40 | .S..HD | KCSM40 |

| S4 | .E..LD | KCSM40 | .S..GD | KCSM40 | .S..HD | KCSM40 |

| H1 | – | – | – | – | – | – |

Zalecane wyjściowe wartości posuwu [mm]

| Schneidkörper- Geometrie | Empfohlener Start-Vorschub pro Zahn (fz) im Verhältnis zur radialen Schnitttiefe (ae) in % | Schneidkörper- Geometrie | ||||||||||||||

| 5% | 10% | 20% | 30% | 40–100% | ||||||||||||

| .F..LDJ | 0,17 | 0,46 | 0,79 | 0,12 | 0,33 | 0,57 | 0,09 | 0,25 | 0,43 | 0,08 | 0,22 | 0,37 | 0,07 | 0,20 | 0,34 | .F..LDJ |

| .E..LD | 0,23 | 0,66 | 0,99 | 0,17 | 0,47 | 0,71 | 0,13 | 0,35 | 0,53 | 0,11 | 0,31 | 0,46 | 0,10 | 0,28 | 0,42 | .E..LD |

| .S..GD | 0,33 | 0,72 | 1,15 | 0,24 | 0,52 | 0,82 | 0,18 | 0,39 | 0,61 | 0,16 | 0,34 | 0,54 | 0,14 | 0,31 | 0,49 | .S..GD |

| .S..HD | 0,33 | 0,84 | 1,35 | 0,24 | 0,60 | 0,97 | 0,18 | 0,45 | 0,72 | 0,16 | 0,39 | 0,63 | 0,14 | 0,36 | 0,57 | .S..HD |

| Leichte Bearbeitung | Allgemeine Anwendung | Schruppbearbeitung |

Recommended Starting Feeds [IPT]

| Schneidkörper- Geometrie | Empfohlener Start-Vorschub pro Zahn (fz) im Verhältnis zur radialen Schnitttiefe (ae) in % | Schneidkörper- Geometrie | ||||||||||||||

| 5% | 10% | 20% | 30% | 40–100% | ||||||||||||

| .F..LDJ | .007 | .018 | .032 | .005 | .013 | .023 | .004 | .010 | .017 | .003 | .009 | .015 | .003 | .008 | .014 | .F..LDJ |

| .E..LD | .009 | .026 | .040 | .007 | .019 | .029 | .005 | .014 | .021 | .004 | .012 | .019 | .004 | .011 | .017 | .E..LD |

| .S..GD | .013 | .028 | .045 | .009 | .020 | .032 | .007 | .015 | .024 | .006 | .013 | .021 | .006 | .012 | .019 | .S..GD |

| .S..HD | .013 | .033 | .053 | .009 | .024 | .038 | .007 | .018 | .028 | .006 | .015 | .025 | .006 | .014 | .023 | .S..HD |

| Leichte Bearbeitung | Allgemeine Anwendung | Schruppbearbeitung |

Zalecane wyjściowe wartości prędkości skrawania [m/min]

| Werkstoffgruppe | KC410M | KC520M | KC522M | KC725M | KCK15 | KCPM20 | KCPK30 | KCSM30 | KCSM40 | KCPM40 | KY3500 | |||||||||||||||||||||||

| P | 1 | – | – | – | – | – | – | 395 | 340 | 325 | 310 | 275 | 260 | 545 | 475 | 445 | 660 | 580 | 540 | 545 | 475 | 445 | 445 | 385 | 360 | – | – | – | 355 | 310 | 295 | – | – | – |

| 2 | – | – | – | – | – | – | 330 | 290 | 240 | 265 | 230 | 190 | 335 | 305 | 275 | 410 | 370 | 330 | 335 | 305 | 275 | 365 | 325 | 265 | – | – | – | 300 | 260 | 215 | – | – | – | |

| 3 | – | – | – | – | – | – | 305 | 260 | 210 | 240 | 205 | 170 | 305 | 275 | 245 | 370 | 330 | 305 | 305 | 275 | 245 | 340 | 290 | 235 | – | – | – | 275 | 235 | 190 | – | – | – | |

| 4 | – | – | – | – | – | – | 270 | 220 | 180 | 215 | 180 | 145 | 230 | 210 | 190 | 275 | 260 | 230 | 230 | 210 | 190 | 300 | 245 | 200 | – | – | – | 245 | 205 | 160 | – | – | – | |

| 5 | – | – | – | – | – | – | 220 | 205 | 180 | 180 | 160 | 145 | 310 | 275 | 250 | 330 | 300 | 275 | 310 | 275 | 250 | 245 | 230 | 200 | 165 | 120 | 85 | 205 | 185 | 160 | – | – | – | |

| 6 | – | – | – | – | – | – | 200 | 150 | 120 | 155 | 120 | 95 | 190 | 160 | 0 | 230 | 205 | 175 | 190 | 160 | – | 220 | 170 | 130 | 140 | 100 | 60 | 180 | 140 | 110 | – | – | – | |

| M | 1 | – | – | – | – | – | – | 245 | 215 | 200 | 205 | 180 | 160 | 245 | 220 | 185 | 270 | 240 | 210 | 245 | 220 | 185 | 270 | 240 | 220 | 315 | 225 | 140 | 235 | 205 | 185 | – | – | – |

| 2 | – | – | – | – | – | – | 220 | 190 | 155 | 185 | 155 | 130 | 220 | 190 | 170 | 245 | 210 | 190 | 220 | 190 | 170 | 245 | 215 | 175 | 280 | 205 | 130 | 210 | 180 | 150 | – | – | – | |

| 3 | – | – | – | – | – | – | 170 | 145 | 115 | 140 | 120 | 95 | 175 | 155 | 140 | 190 | 175 | 150 | 175 | 155 | 140 | 185 | 160 | 125 | 230 | 165 | 105 | 155 | 140 | 110 | – | – | – | |

| K | 1 | – | – | – | 325 | 295 | 260 | 275 | 245 | 220 | – | – | – | 355 | 320 | 290 | 430 | 390 | 355 | 355 | 320 | 290 | – | – | – | – | – | – | – | – | – | 965 | 875 | 780 |

| 2 | – | – | – | 250 | 230 | 210 | 215 | 190 | 180 | – | – | – | 280 | 250 | 230 | 340 | 305 | 280 | 280 | 250 | 230 | – | – | – | – | – | – | – | – | – | 760 | 685 | 635 | |

| 3 | – | – | – | 210 | 190 | 175 | 180 | 160 | 145 | – | – | – | 235 | 210 | 190 | 290 | 260 | 240 | 235 | 210 | 190 | – | – | – | – | – | – | – | – | – | 640 | 570 | 520 | |

| N | 1 | 1460 | 1295 | 1195 | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – |

| 2 | 1295 | 1195 | 1100 | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | |

| 3 | 1295 | 1195 | 1100 | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | |

| S | 1 | – | – | – | – | – | – | 50 | 40 | 30 | 40 | 35 | 30 | – | – | – | – | – | – | – | – | – | 55 | 50 | 35 | 75 | 55 | 35 | 50 | 40 | 35 | – | – | – |

| 2 | – | – | – | – | – | – | 50 | 40 | 30 | 40 | 35 | 30 | – | – | – | – | – | – | – | – | – | 55 | 50 | 35 | 70 | 50 | 35 | 50 | 40 | 35 | – | – | – | |

| 3 | – | – | – | – | – | – | 60 | 50 | 30 | 55 | 40 | 30 | – | – | – | – | – | – | – | – | – | 65 | 55 | 35 | 80 | 55 | 35 | 60 | 50 | 35 | – | – | – | |

| 4 | – | – | – | – | – | – | 85 | 60 | 40 | 70 | 55 | 35 | 80 | 60 | 40 | – | – | – | 80 | 60 | 40 | 100 | 70 | 50 | 110 | 80 | 50 | 80 | 60 | 40 | – | – | – | |

| H | 1 | – | – | – | – | – | – | 145 | 110 | 85 | – | – | – | – | – | – | 170 | 140 | 115 | – | – | – | 160 | 120 | 90 | – | – | – | – | – | – | – | – | – |

| 2 | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | |

| 3 | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | |

Recommended Starting Speeds [SFM]

| Werkstoffgruppe | KC410M | KC520M | KC522M | KC725M | KCK15 | KCPK30 | KCPM20 | KCPM40 | KCSM30 | KCSM40 | KY3500 | |||||||||||||||||||||||

| P | 1 | – | – | – | – | – | – | 1295 | 1120 | 1060 | 1025 | 905 | 845 | – | – | – | 1790 | 1555 | 1460 | 2165 | 1910 | 1770 | 1165 | 1025 | 965 | 1460 | 1260 | 1180 | – | – | – | – | – | – |

| 2 | – | – | – | – | – | – | 1080 | 940 | 785 | 865 | 750 | 630 | – | – | – | 1105 | 1000 | 905 | 1340 | 1220 | 1080 | 985 | 845 | 710 | 1200 | 1060 | 865 | – | – | – | – | – | – | |

| 3 | – | – | – | – | – | – | 1000 | 845 | 690 | 785 | 670 | 550 | – | – | – | 1000 | 905 | 805 | 1220 | 1080 | 1000 | 905 | 770 | 630 | 1120 | 940 | 770 | – | – | – | – | – | – | |

| 4 | – | – | – | – | – | – | 890 | 725 | 590 | 710 | 590 | 475 | – | – | – | 750 | 690 | 630 | 905 | 845 | 750 | 805 | 670 | 535 | 985 | 805 | 650 | – | – | – | – | – | – | |

| 5 | – | – | – | – | – | – | 725 | 670 | 590 | 590 | 535 | 475 | – | – | – | 1025 | 905 | 830 | 1080 | 985 | 905 | 670 | 610 | 535 | 805 | 750 | 650 | 530 | 390 | 280 | – | – | – | |

| 6 | – | – | – | – | – | – | 650 | 490 | 395 | 510 | 395 | 310 | – | – | – | 630 | 535 | – | 750 | 670 | 570 | 590 | 450 | 355 | 725 | 550 | 430 | 450 | 730 | 200 | – | – | – | |

| M | 1 | – | – | – | – | – | – | 805 | 710 | 650 | 670 | 590 | 535 | – | – | – | 805 | 725 | 610 | 890 | 785 | 690 | 770 | 670 | 610 | 890 | 785 | 725 | 1020 | 730 | 450 | – | – | – |

| 2 | – | – | – | – | – | – | 725 | 630 | 510 | 610 | 510 | 430 | – | – | – | 725 | 630 | 550 | 805 | 690 | 630 | 690 | 590 | 490 | 805 | 710 | 570 | 910 | 675 | 415 | – | – | – | |

| 3 | – | – | – | – | – | – | 550 | 475 | 370 | 450 | 395 | 310 | – | – | – | 570 | 510 | 450 | 630 | 570 | 490 | 510 | 450 | 355 | 610 | 535 | 415 | 750 | 530 | 340 | – | – | – | |

| K | 1 | – | – | – | 1060 | 965 | 845 | 905 | 805 | 725 | – | – | – | 1655 | 1520 | 1340 | 1165 | 1045 | 940 | 1415 | 1280 | 1165 | – | – | – | – | – | – | – | – | – | 3170 | 2875 | 2555 |

| 2 | – | – | – | 830 | 750 | 690 | 710 | 630 | 590 | – | – | – | 1320 | 1165 | 1080 | 925 | 830 | 750 | 1120 | 1000 | 925 | – | – | – | – | – | – | – | – | – | 2500 | 2245 | 2090 | |

| 3 | – | – | – | 690 | 630 | 570 | 590 | 535 | 475 | – | – | – | 1105 | 985 | 905 | 770 | 690 | 630 | 940 | 845 | 785 | – | – | – | – | – | – | – | – | – | 2105 | 1870 | 1710 | |

| N | 1 | 4780 | 4250 | 3920 | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – |

| 2 | 4250 | 3920 | 3600 | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | |

| 3 | 4250 | 3920 | 3600 | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | |

| S | 1 | – | – | – | – | – | – | 155 | 140 | 95 | 140 | 120 | 95 | – | – | – | – | – | – | – | – | – | 155 | 140 | 120 | 180 | 155 | 120 | 240 | 175 | 110 | – | – | – |

| 2 | – | – | – | – | – | – | 155 | 140 | 95 | 140 | 120 | 95 | – | – | – | – | – | – | – | – | – | 155 | 140 | 120 | 180 | 155 | 120 | 220 | 160 | 100 | – | – | – | |

| 3 | – | – | – | – | – | – | 200 | 155 | 95 | 180 | 140 | 95 | – | – | – | – | – | – | – | – | – | 200 | 155 | 120 | 215 | 180 | 120 | 255 | 180 | 115 | – | – | – | |

| 4 | – | – | – | – | – | – | 275 | 200 | 140 | 235 | 180 | 120 | – | – | – | 260 | 200 | 130 | – | – | – | 260 | 200 | 140 | 335 | 235 | 155 | 355 | 260 | 165 | – | – | – | |

| H | 1 | – | – | – | – | – | – | 475 | 355 | 275 | – | – | – | – | – | – | – | – | – | 550 | 450 | 370 | – | – | – | 535 | 395 | 295 | – | – | – | – | – | – |

| 2 | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | |

| 3 | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | |