Witamy

Potwierdź swoje preferencje

Aktualizuj preferencje

Sugestie dotyczące produktów

Product Family suggestions

Witaj, User Name

Wybrane konto:

Wystąpił problem z Twoim kontem. Skontaktuj się z działem obsługi klienta.

Konto kupującego

Zmień konto

Konto odbiorcy

Zmień konto

- Panel przyborów

- Zarządzaj zamówieniami

- Zarządzaj kanałami

- Książka adresowa

-

Powiadomienia

Oznacz wszystkie jako przeczytane - Zmień hasło

- Mój profil

- Wyloguj się

Pozycje

pomyślnie dodano do koszyka

Wyświetl koszyk

Wyświetl koszyk

Rozpocznij rok 2024 z fenomenalnymi oszczędnościami w narzędziach do wykonywania otworów.

Kup teraz.

Pozycje

pomyślnie dodano do koszyka

Wyświetl koszyk

Wyświetl koszyk

Edytuj

Dodaj

Nazwa : {{SolutionName}}- Produkty

- /

- Narzędzia do obróbki skrawaniem

- /

- Toczenie gwintów

- /

- Gwintowniki HSS

- /

- Gwintowniki HP HSS-E-PM

- /

- T63_ HP Taps for Steel and Stainless Steel

- /

- T630 • DIN 371, 374 i 376 • Nakrój półwykańczający C • Metryczne • Do obróbki stali i stali nierdzewnej

Sending to SolidCAM in progress...

Downloaded file will be available after import in the SolidCAM tool library.

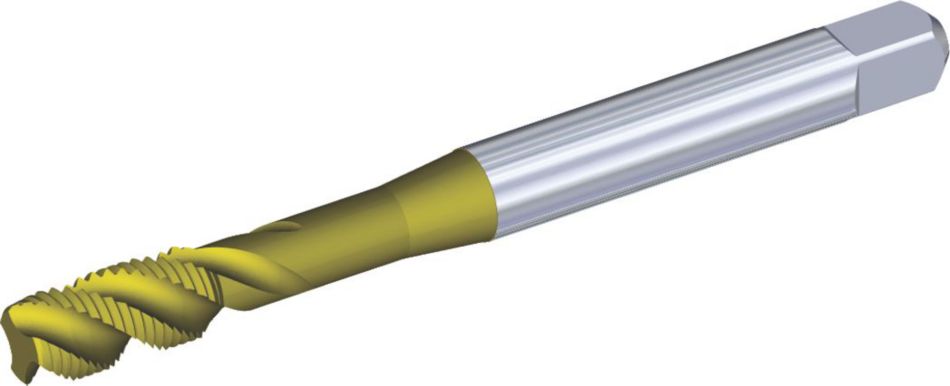

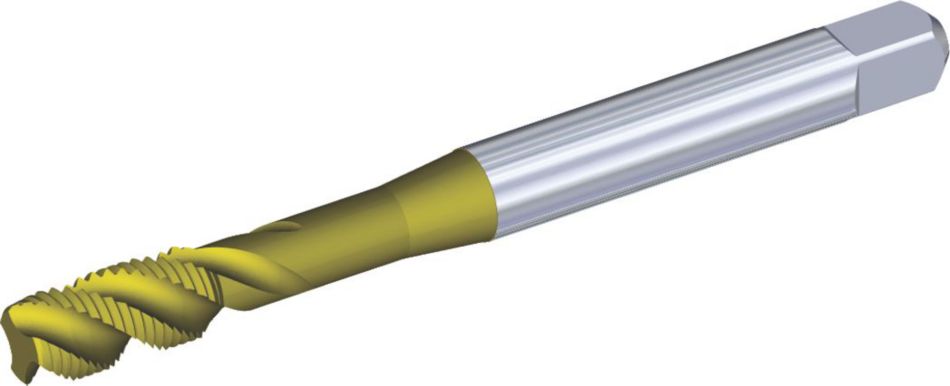

T630 • DIN 371, 374 i 376 • Nakrój półwykańczający C • Metryczne • Do obróbki stali i stali nierdzewnej

Gwintowniki Beyond™ HSS-E-PM z rowkiem wiórowym spiralnym • Otwory nieprzelotowe

Właściwości i zalety

- KM6515 TiN + CrC/C do obróbki stali nierdzewnej.

- KP6525 TiCN + TiN do obróbki stali.

Zastosowania

Threading: Blind Hole

Class of Fit: 6HX

DIN number 371

DIN number 374

DIN number 376

Chamfer Form C (2–3)

HSS-E-PM

Manufacturer’s Specs: M

Manufacturer’s Specs: MF

Flood Coolant: Tapping

Tapping Helix Angle: 45°