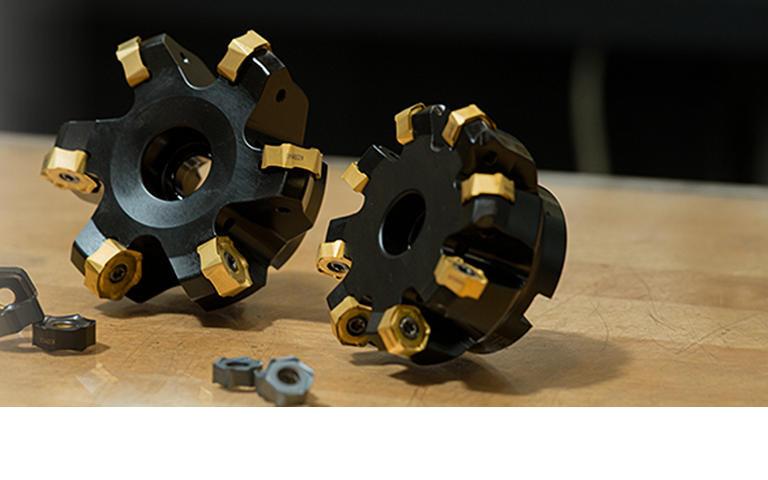

Frezowanie płaszczyzn z 12 rzeczywistymi krawędziami skrawającymi w każdej płytce

- Gatunki Dodeka, Dodeka Mini i Dodeka MAX™ to obecnie najbardziej wszechstronne platformy do frezowania płaszczyzn, wspomagające wydajność w tego typu operacjach.

- Dwanaście efektywnych krawędzi skrawających na każdej płytce oznacza niski koszt jednej krawędzi i wysoką produktywność.

- Dzięki znakomitym gatunkom Beyond™ można uzyskać do 30% większą wydajność obróbki (MRR), o 25% niższe siły skrawania dzięki lekkiej pracy narzędzia oraz do 35% większą trwałość narzędzia używanego zarówno do obróbki lekkiej, jak i ciężkiej.