Produkt podobny do:

KNS® • Carbide Insert • XCP-SGP • Single Ended

Slot milling insert for flat-bottom machining in multiple materials.

Nr materiału5624963

Nr katalogowy ISOXCP42S500F030SGPNr katalogowy ANSIXCP42S500F030SGP

- P Steel

- M Stainless Steel

- S High-Temp Alloys

Sending to {{cadTool}} in progress...

Downloaded file will be available after import in the {{cadTool}} tool library.

| Nr materiału | 5624963 |

| Nr katalogowy ISO | XCP42S500F030SGP |

| Nr katalogowy ANSI | XCP42S500F030SGP |

| Grade | KCPM40 |

| Insert Size | 42 |

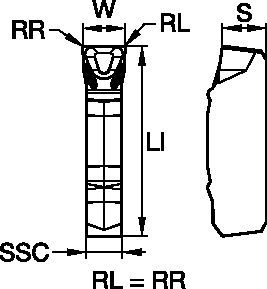

| [W] Cutting Width | 5.01 mm |

| [W] Cutting Width | .197 in |

| [LI] Insert Length | 18 mm |

| [LI] Insert Length | .709 in |

| [RR] Corner Radius | 0.3 mm |

| [RR] Corner Radius | .012 in |

| [RL] Corner Radius | 0.3 mm |

| [RL] Corner Radius | .012 in |

| [S] Insert Thickness | 4.65 mm |

| [S] Insert Thickness | .183 in |

| Average Chip Thickness [HM] | 0.04 mm |

| Average Chip Thickness [HM] | .0016 in |

| Cutting Edges per Insert | 1 |

Materiały przedmiotu obrabianego

- Steel

- Stainless Steel

- High-Temp Alloys

Właściwości i zalety

- From light to heavy machining, the positive SGP chipbreaker geometry ensures smooth cutting action, and efficient chip evacuation.

- The Double-V Design of the insert and the insert pocket securely holds the insert in place, minimises radial runout, providing high slot width accuracy and high repeatability.

Złóż nowe rozwiązanie aby obliczyc parametry posuwu i prędkości

Po złóżeniu rozwiązania wybierz ikonę "Posuwy i prędkości" a system pokaże rekomendowane wartości. Możesz doprecyzować wyniki dodając maszynę i jej specyfikacje lub zmień wartości początkowe Używając suwaki.

Dobór płytek

Poradnik doboru płytek

| KNS® Slotting Cutter • Insert Selection Guide | ||||||

| Material Group | Light | General | Heavy | |||

| – | (Light geometry) | (Strong geometry) | ||||

| – | wear |  | toughness | |||

| – | Geometry | Grade | Geometry | Grade | Geometry | Grade |

| P1-P2 | .S..GP | KCU25 | .S..GP | KCU25 | .S..GP | KCPM40 |

| P3-P4 | .S..GP | KCU25 | .S..GP | KCU25 | .S..GP | KCPM40 |

| P5-P6 | .S..GP | KCU25 | .S..GP | KCU25 | .S..GP | KCPM40 |

| M1-M2 | .S..GP | KCU25 | .S..GP | KCPM40 | .S..GP | KCPM40 |

| M3 | .S..GP | KCU25 | .S..GP | KCPM40 | .S..GP | KCPM40 |

| K1-K2 | .S..GP | KCU25 | .S..GP | KCPK30 | .S..GP | KCPK30 |

| K3 | .S..GP | KCU25 | .S..GP | KCPK30 | .S..GP | KCPK30 |

| N1-N2 | – | – | .S..GP | KCU25 | – | – |

| N3 | – | – | .S..GP | KCU25 | – | – |

| S1-S2 | .S..GP | KCU25 | .S..GP | KCU25 | .S..GP | KCU25 |

| S3 | .S..GP | KCU25 | .S..GP | KCU25 | .S..GP | KCU25 |

| S4 | .S..GP | KCU25 | .S..GP | KCU25 | .S..GP | KCU25 |

| H1 | – | – | – | – | – | – |