Welcome

Please confirm your preferences

Update Preferences

Product Suggestions

Product Family suggestions

Hi, User Name

Your Selected Account:

There is an issue with your account. Please contact customer support.

Sold To Account Change Account

Ship To Account Change Account

- Dashboard

- Manage Orders

- Manage Channels

- Address Book

Notifications

Mark all as read- Change Password

- My Profile

- Sign Out

Item(s) successfully added to cart

View Cart

View Cart

Turn up your volume for less with our limited-time offers! Shop Now

Item(s) successfully added to cart

View Cart

View Cart

Editing Solution

Adding Solution

Solution Name:{{SolutionName}}- Products

- /

- Metalworking Tools

- /

- Milling

- /

- Indexable Milling

- /

- Copy Mills

- /

- 7713VR Copy Mill Series • Stellram

- /

- 7713VR12 • IC12 • Stellram

- /

- RPMW12-T-X4 • 4 Indexes • General purpose for roughing

Product Similar To: [Product Name]

Sending to {{cadTool}} in progress...

Downloaded file will be available after import in the {{cadTool}} tool library.

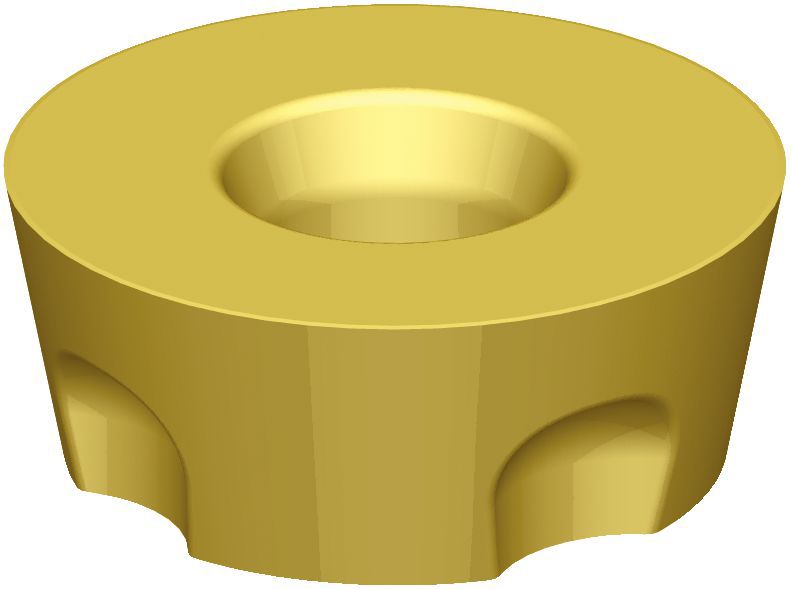

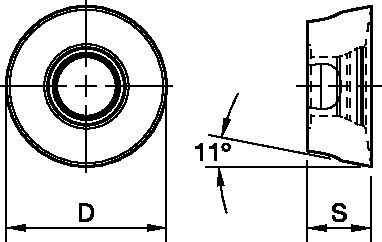

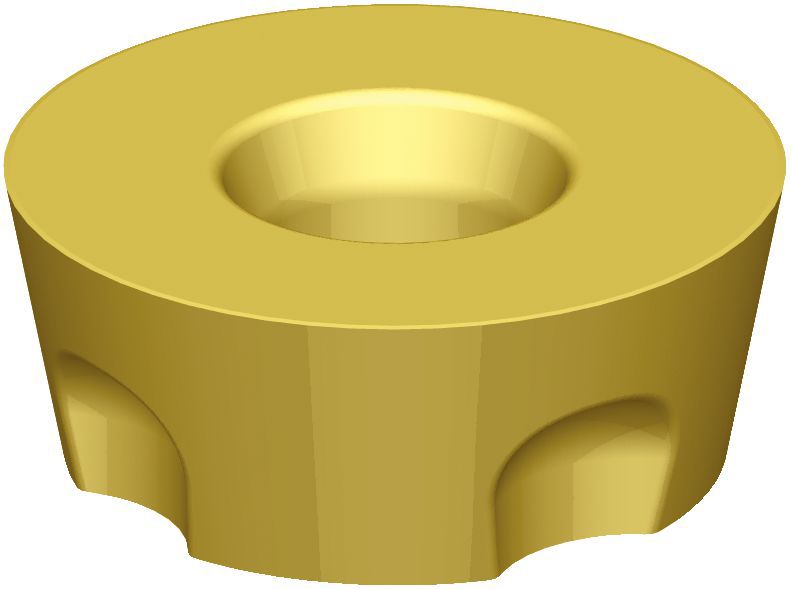

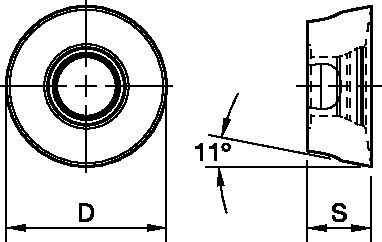

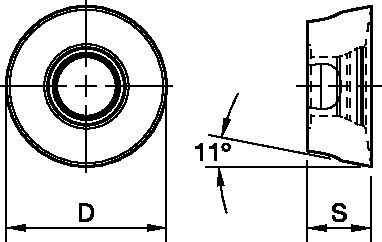

RPMW12-T-X4 • 4 Indexes • General purpose for roughing

Indexable Inserts

Features and benefits

- General purpose for roughing alloy steel, stainless steel, and heat-resistant alloys with heavy scale.

- Four indexation positions:

— Ap max: 6mm [.236″]

— Ap recommended: ≤3,5mm [.137″]

| Malzeme grubu | Hafif işleme | Genel amaçlı kullanım | Ağır işleme | |||

| – | (Hafif geometri) | – | (Sert geometri) | |||

| – | Aşınma direnci |  | Tokluk | |||

| – | Geometri | Kalite | Geometri | Kalite | Geometri | Kalite |

| P1–P2 | 442-X8 | SC6525 | 432-X5 | SC6525 | GD-X5 | KCM40 |

| P3–P4 | 432-X8 | SP6519 | 432-X5 | SP6519 | GD-X5 | KCM40 |

| P5–P6 | 432-X8 | SP6519 | T-X4 | SP6519 | T-X4 | X500 |

| M1–M2 | 442-X8 | SC6525 | 432-X5 | SC6525 | GD-X5 | KCM40 |

| M3 | 432-X8 | SP6519 | GD-X5 | KCM40 | 442-X4 | X500 |

| K1–K2 | T-X4 | MP91M | T-X4 | MP91M | T-X4 | MP91M |

| K3 | T-X4 | MP91M | T-X4 | MP91M | T-X4 | MP91M |

| N1–N2 | 701-X4 | GH1 | 701-X4 | GH1 | 701-X4 | GH1 |

| N3 | 701-X4 | GH1 | 701-X4 | GH1 | 701-X4 | GH1 |

| S1–S2 | 442-X5 | SP6519 | GD-X5 | KCM40 | 442-X4 | X500 |

| S3 | 442-X5 | SP6519 | GD-X5 | KCM40 | 442-X4 | X500 |

| S4 | 442-X5 | SP6519 | 442-X5 | X500 | 442-X4 | X500 |

| H1 | – | – | T-X4 | MP91M | – | – |

At 6,00 Axial Depth of Cut (ap)

| Kesici uç geometrisi | Frezenin iş parçasına radyal giriş temasında (ae), diş başına başlangıç ilerleme (Fz) % oranı. | Kesici uç geometrisi | ||||||||||||||

| 5% | 10% | 20% | 30% | 40–100% | ||||||||||||

| 701–X4 | 0,12 | 0,16 | 0,22 | 0,08 | 0,12 | 0,16 | 0,06 | 0,09 | 0,12 | 0,05 | 0,08 | 0,10 | 0,05 | 0,07 | 0,10 | 701–X4 |

| 432–X5 | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | 432–X5 |

| 432–X8 | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | 432–X8 |

| 442–X5 | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | 442–X5 |

| 442–X8 | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | 442–X8 |

| 442–X4 | 0,23 | 0,41 | 0,66 | 0,17 | 0,30 | 0,47 | 0,13 | 0,22 | 0,35 | 0,11 | 0,19 | 0,31 | 0,10 | 0,18 | 0,28 | 442–X4 |

| GD–X5 | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | GD–X5 |

| GD–X8 | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | GD–X8 |

| T–X4 | 0,23 | 0,41 | 0,66 | 0,17 | 0,30 | 0,47 | 0,13 | 0,22 | 0,35 | 0,11 | 0,19 | 0,31 | 0,10 | 0,18 | 0,28 | T–X4 |

At 3,00 Axial Depth of Cut (ap)

| Hafif işleme | Genel amaçlı kullanım | Ağır işleme |

At 2,50 Axial Depth of Cut (ap)

| Kesici uç geometrisi | Frezenin iş parçasına radyal giriş temasında (ae), diş başına başlangıç ilerleme (Fz) % oranı. | Kesici uç geometrisi | ||||||||||||||

| 5% | 10% | 20% | 30% | 40–100% | ||||||||||||

| 701–X4 | 0,13 | 0,19 | 0,25 | 0,10 | 0,14 | 0,18 | 0,07 | 0,10 | 0,14 | 0,06 | 0,09 | 0,12 | 0,06 | 0,08 | 0,11 | 701–X4 |

| 432–X5 | 0,16 | 0,49 | 0,93 | 0,12 | 0,35 | 0,66 | 0,09 | 0,26 | 0,49 | 0,08 | 0,23 | 0,43 | 0,07 | 0,21 | 0,39 | 432–X5 |

| 432–X8 | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | 432–X8 |

| 442–X5 | 0,16 | 0,49 | 0,93 | 0,12 | 0,35 | 0,66 | 0,09 | 0,26 | 0,49 | 0,08 | 0,23 | 0,43 | 0,07 | 0,21 | 0,39 | 442–X5 |

| 442–X8 | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | 442–X8 |

| 442–X4 | 0,16 | 0,49 | 0,93 | 0,12 | 0,35 | 0,66 | 0,09 | 0,26 | 0,49 | 0,08 | 0,23 | 0,43 | 0,07 | 0,21 | 0,39 | 442–X4 |

| GD–X5 | 0,16 | 0,54 | 0,99 | 0,12 | 0,39 | 0,70 | 0,09 | 0,29 | 0,52 | 0,08 | 0,25 | 0,45 | 0,07 | 0,23 | 0,42 | GD–X5 |

| GD–X8 | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | GD–X8 |

| T–X4 | 0,27 | 0,68 | 1,10 | 0,19 | 0,49 | 0,78 | 0,14 | 0,36 | 0,58 | 0,13 | 0,32 | 0,50 | 0,12 | 0,29 | 0,46 | T–X4 |

At 1,50 Axial Depth of Cut (ap)

| Kesici uç geometrisi | Frezenin iş parçasına radyal giriş temasında (ae), diş başına başlangıç ilerleme (Fz) % oranı. | Kesici uç geometrisi | ||||||||||||||

| 5% | 10% | 20% | 30% | 40–100% | ||||||||||||

| 701–X4 | 0,17 | 0,24 | 0,33 | 0,13 | 0,18 | 0,24 | 0,09 | 0,13 | 0,18 | 0,08 | 0,12 | 0,16 | 0,08 | 0,11 | 0,14 | 701–X4 |

| 432–X5 | 0,21 | 0,64 | 1,23 | 0,15 | 0,46 | 0,87 | 0,11 | 0,34 | 0,65 | 0,10 | 0,30 | 0,56 | 0,09 | 0,27 | 0,51 | 432–X5 |

| 432–X8 | 0,21 | 0,64 | 1,23 | 0,15 | 0,46 | 0,87 | 0,11 | 0,34 | 0,65 | 0,10 | 0,30 | 0,56 | 0,09 | 0,27 | 0,51 | 432–X8 |

| 442–X5 | 0,21 | 0,64 | 1,23 | 0,15 | 0,46 | 0,87 | 0,11 | 0,34 | 0,65 | 0,10 | 0,30 | 0,56 | 0,09 | 0,27 | 0,51 | 442–X5 |

| 442–X8 | 0,21 | 0,64 | 1,23 | 0,15 | 0,46 | 0,87 | 0,11 | 0,34 | 0,65 | 0,10 | 0,30 | 0,56 | 0,09 | 0,27 | 0,51 | 442–X8 |

| 442–X4 | 0,21 | 0,64 | 1,23 | 0,15 | 0,46 | 0,87 | 0,11 | 0,34 | 0,65 | 0,10 | 0,30 | 0,56 | 0,09 | 0,27 | 0,51 | 442–X4 |

| GD–X5 | 0,21 | 0,71 | 1,31 | 0,15 | 0,51 | 0,93 | 0,11 | 0,38 | 0,68 | 0,10 | 0,33 | 0,60 | 0,09 | 0,30 | 0,54 | GD–X5 |

| GD–X8 | 0,21 | 0,71 | 1,31 | 0,15 | 0,51 | 0,93 | 0,11 | 0,38 | 0,68 | 0,10 | 0,33 | 0,60 | 0,09 | 0,30 | 0,54 | GD–X8 |

| T–X4 | 0,35 | 0,90 | 1,47 | 0,25 | 0,64 | 1,03 | 0,19 | 0,47 | 0,76 | 0,17 | 0,41 | 0,66 | 0,15 | 0,38 | 0,60 | T–X4 |

| Kesici uç geometrisi | Frezenin iş parçasına radyal giriş temasında (ae), diş başına başlangıç ilerleme (Fz) % oranı. | Kesici uç geometrisi | ||||||||||||||

| 5% | 10% | 20% | 30% | 40–100% | ||||||||||||

| 701–X4 | 0,14 | 0,20 | 0,27 | 0,10 | 0,14 | 0,20 | 0,08 | 0,11 | 0,15 | 0,07 | 0,09 | 0,13 | 0,06 | 0,09 | 0,12 | 701–X4 |

| 432–X5 | 0,17 | 0,52 | 1,00 | 0,12 | 0,37 | 0,71 | 0,09 | 0,28 | 0,53 | 0,08 | 0,24 | 0,46 | 0,07 | 0,22 | 0,42 | 432–X5 |

| 432–X8 | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | 432–X8 |

| 442–X5 | 0,17 | 0,52 | 1,00 | 0,12 | 0,37 | 0,71 | 0,09 | 0,28 | 0,53 | 0,08 | 0,24 | 0,46 | 0,07 | 0,22 | 0,42 | 442–X5 |

| 442–X8 | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | 442–X8 |

| 442–X4 | 0,17 | 0,52 | 1,00 | 0,12 | 0,37 | 0,71 | 0,09 | 0,28 | 0,53 | 0,08 | 0,24 | 0,46 | 0,07 | 0,22 | 0,42 | 442–X4 |

| GD–X5 | 0,17 | 0,58 | 1,06 | 0,12 | 0,41 | 0,75 | 0,09 | 0,31 | 0,56 | 0,08 | 0,27 | 0,48 | 0,07 | 0,25 | 0,44 | GD–X5 |

| GD–X8 | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | GD–X8 |

| T–X4 | 0,29 | 0,73 | 1,18 | 0,21 | 0,52 | 0,84 | 0,15 | 0,39 | 0,62 | 0,13 | 0,34 | 0,54 | 0,12 | 0,31 | 0,49 | T–X4 |

At .236 Axial Depth of Cut (ap)

| Hafif işleme | Genel amaçlı kullanım | Ağır işleme |

At .118 Axial Depth of Cut (ap)

| Kesici uç geometrisi | Diş başına programlanan ilerleme (fz) İşleme çapının (dw) yüzde olarak radyal kesme derinliği (ae) | Kesici uç geometrisi | ||||||||||||||

| 5% | 10% | 20% | 30% | 40–100% | ||||||||||||

| 701–X4 | .005 | .008 | .011 | .003 | .006 | .008 | .002 | .004 | .006 | .002 | .004 | .005 | .002 | .004 | .005 | 701–X4 |

| 432–X5 | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | 432–X5 |

| 432–X8 | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | 432–X8 |

| 442–X5 | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | 442–X5 |

| 442–X8 | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | 442–X8 |

| 442–X4 | .007 | .021 | .037 | .005 | .015 | .027 | .004 | .011 | .020 | .003 | .010 | .017 | .003 | .009 | .016 | 442–X4 |

| GD–X5 | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | GD–X5 |

| GD–X8 | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | GD–X8 |

| T–X4 | .009 | .023 | .037 | .007 | .017 | .027 | .005 | .012 | .020 | .004 | .011 | .017 | .004 | .010 | .016 | T–X4 |

At .098 Axial Depth of Cut (ap)

| Kesici uç geometrisi | Diş başına programlanan ilerleme (fz) İşleme çapının (dw) yüzde olarak radyal kesme derinliği (ae) | Kesici uç geometrisi | ||||||||||||||

| 5% | 10% | 20% | 30% | 40–100% | ||||||||||||

| 701–X4 | .005 | .009 | .013 | .004 | .007 | .009 | .003 | .005 | .007 | .002 | .004 | .006 | .002 | .004 | .005 | 701–X4 |

| 432–X5 | .006 | .019 | .037 | .005 | .014 | .027 | .003 | .010 | .020 | .003 | .009 | .017 | .003 | .008 | .016 | 432–X5 |

| 432–X8 | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | 432–X8 |

| 442–X5 | .006 | .019 | .037 | .005 | .014 | .027 | .003 | .010 | .020 | .003 | .009 | .017 | .003 | .008 | .016 | 442–X5 |

| 442–X8 | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | 442–X8 |

| 442–X4 | .008 | .024 | .043 | .006 | .017 | .031 | .004 | .013 | .023 | .004 | .011 | .020 | .003 | .010 | .018 | 442–X4 |

| GD–X5 | .006 | .022 | .040 | .005 | .016 | .028 | .003 | .012 | .021 | .003 | .010 | .018 | .003 | .009 | .017 | GD–X5 |

| GD–X8 | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | GD–X8 |

| T–X4 | .011 | .027 | .043 | .008 | .019 | .031 | .006 | .014 | .023 | .005 | .012 | .020 | .005 | .011 | .018 | T–X4 |

At .059 Axial Depth of Cut (ap)

| Kesici uç geometrisi | Diş başına programlanan ilerleme (fz) İşleme çapının (dw) yüzde olarak radyal kesme derinliği (ae) | Kesici uç geometrisi | ||||||||||||||

| – | 5% | 10% | 20% | 30% | 40–100% | |||||||||||

| 701–X4 | .007 | .012 | .017 | .005 | .009 | .012 | .004 | .007 | .009 | .003 | .006 | .008 | .003 | .005 | .007 | 701–X4 |

| 432–X5 | .008 | .026 | .049 | .006 | .018 | .035 | .005 | .014 | .026 | .004 | .012 | .022 | .004 | .011 | .021 | 432–X5 |

| 432–X8 | .008 | .026 | .049 | .006 | .018 | .035 | .005 | .014 | .026 | .004 | .012 | .022 | .004 | .011 | .021 | 432–X8 |

| 442–X5 | .008 | .026 | .049 | .006 | .018 | .035 | .005 | .014 | .026 | .004 | .012 | .022 | .004 | .011 | .021 | 442–X5 |

| 442–X8 | .008 | .026 | .049 | .006 | .018 | .035 | .005 | .014 | .026 | .004 | .012 | .022 | .004 | .011 | .021 | 442–X8 |

| 442–X4 | .011 | .032 | .058 | .008 | .023 | .041 | .006 | .017 | .030 | .005 | .015 | .026 | .005 | .014 | .024 | 442–X4 |

| GD–X5 | .008 | .028 | .053 | .006 | .020 | .037 | .005 | .015 | .027 | .004 | .013 | .024 | .004 | .012 | .022 | GD–X5 |

| GD–X8 | .008 | .028 | .053 | .006 | .020 | .037 | .005 | .015 | .027 | .004 | .013 | .024 | .004 | .012 | .022 | GD–X8 |

| T–X4 | .014 | .035 | .058 | .010 | .025 | .041 | .007 | .019 | .030 | .006 | .016 | .026 | .006 | .015 | .024 | T–X4 |

| Kesici uç geometrisi | Diş başına programlanan ilerleme (fz) İşleme çapının (dw) yüzde olarak radyal kesme derinliği (ae) | Kesici uç geometrisi | ||||||||||||||

| 5% | 10% | 20% | 30% | 40–100% | ||||||||||||

| 701–X4 | .006 | .010 | .014 | .004 | .007 | .010 | .003 | .005 | .007 | .003 | .005 | .006 | .002 | .004 | .006 | 701–X4 |

| 432–X5 | .007 | .021 | .040 | .005 | .015 | .028 | .004 | .011 | .021 | .003 | .010 | .018 | .003 | .009 | .017 | 432–X5 |

| 432–X8 | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | 432–X8 |

| 442–X5 | .007 | .021 | .040 | .005 | .015 | .028 | .004 | .011 | .021 | .003 | .010 | .018 | .003 | .009 | .017 | 442–X5 |

| 442–X8 | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | 442–X8 |

| 442–X4 | .009 | .026 | .046 | .006 | .019 | .033 | .005 | .014 | .024 | .004 | .012 | .021 | .004 | .011 | .019 | 442–X4 |

| GD–X5 | .007 | .023 | .042 | .005 | .017 | .030 | .004 | .012 | .022 | .003 | .011 | .019 | .003 | .010 | .018 | GD–X5 |

| GD–X8 | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | GD–X8 |

| T–X4 | .011 | .029 | .046 | .008 | .020 | .033 | .006 | .015 | .024 | .005 | .013 | .021 | .005 | .012 | .019 | T–X4 |

Recommended Starting Speeds [m/min]

| Malzeme grubu | GH1 | X700 | KCM40 | SP6519 | X500 | MP91M | SC6525 | |||||||||||||||

| P | 1 | – | – | – | – | – | – | – | – | – | 130 | 213 | 295 | 130 | 200 | 270 | 140 | 243 | 345 | 140 | 255 | 370 |

| 2 | – | – | – | – | – | – | – | – | – | 115 | 188 | 260 | 115 | 178 | 240 | 120 | 213 | 305 | 120 | 223 | 325 | |

| 3 | – | – | – | – | – | – | 100 | 170 | 240 | 100 | 165 | 230 | 100 | 155 | 210 | 105 | 188 | 270 | 105 | 198 | 290 | |

| 4 | – | – | – | – | – | – | 75 | 128 | 180 | 75 | 125 | 175 | 75 | 118 | 160 | 80 | 143 | 205 | 80 | 145 | 210 | |

| 5 | – | – | – | 70 | 103 | 135 | – | – | – | 70 | 105 | 140 | 70 | 100 | 130 | – | – | – | 80 | 120 | 160 | |

| 6 | – | – | – | 50 | 83 | 115 | – | – | – | 50 | 85 | 120 | 50 | 80 | 110 | – | – | – | 60 | 100 | 140 | |

| M | 1 | – | – | – | 115 | 188 | 260 | 115 | 188 | 260 | 115 | 193 | 270 | 115 | 183 | 250 | – | – | – | 120 | 205 | 290 |

| 2 | – | – | – | 105 | 168 | 230 | 100 | 165 | 230 | 105 | 170 | 235 | 100 | 160 | 220 | – | – | – | 110 | 185 | 260 | |

| 3 | – | – | – | 85 | 138 | 190 | 50 | 83 | 115 | 85 | 140 | 195 | 80 | 130 | 180 | – | – | – | 90 | 150 | 210 | |

| K | 1 | 135 | 213 | 290 | – | – | – | – | – | – | 140 | 218 | 295 | 120 | 200 | 280 | 145 | 255 | 365 | 145 | 268 | 390 |

| 2 | 120 | 183 | 245 | – | – | – | – | – | – | 110 | 175 | 240 | 105 | 155 | 205 | 115 | 200 | 285 | 115 | 210 | 305 | |

| 3 | 115 | 158 | 200 | – | – | – | – | – | – | 100 | 160 | 220 | 95 | 133 | 170 | 105 | 183 | 260 | – | – | – | |

| N | 1–2 | 400 | 1725 | 3050 | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – |

| 3 | 295 | 1368 | 2440 | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | |

| S | 1 | – | – | – | 23 | 38 | 52 | 23 | 38 | 52 | 23 | 39 | 55 | 23 | 36 | 48 | – | – | – | – | – | – |

| 2 | – | – | – | 22 | 34 | 46 | 22 | 34 | 46 | 22 | 35 | 48 | 21 | 33 | 44 | – | – | – | – | – | – | |

| 3 | – | – | – | 25 | 39 | 53 | 25 | 39 | 53 | 25 | 40 | 55 | 24 | 38 | 51 | – | – | – | – | – | – | |

| 4 | – | – | – | 36 | 56 | 75 | 36 | 56 | 75 | 36 | 58 | 79 | 35 | 54 | 73 | – | – | – | – | – | – | |

| H | 1 | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | 50 | 78 | 105 | 50 | 80 | 110 |

Recommended Starting Speeds [SFM]

| Malzeme grubu | GH1 | X700 | KCM40 | SP6519 | X500 | MP91M | SC6525 | |||||||||||||||

| P | 1 | – | – | – | – | – | – | – | – | – | 426 | 697 | 459 | 426 | 656 | 886 | 459 | 795 | 1132 | 459 | 836 | 1214 |

| 2 | – | – | – | – | – | – | – | – | – | 377 | 615 | 394 | 377 | 582 | 787 | 394 | 697 | 1000 | 394 | 730 | 1066 | |

| 3 | – | – | – | – | – | – | 328 | 558 | 787 | 328 | 541 | 344 | 328 | 508 | 689 | 344 | 615 | 886 | 344 | 648 | 951 | |

| 4 | – | – | – | – | – | – | 246 | 418 | 590 | 246 | 410 | 262 | 246 | 385 | 525 | 262 | 467 | 672 | 262 | 476 | 689 | |

| 5 | – | – | – | 230 | 338 | 443 | – | – | – | 246 | 410 | 230 | 230 | 328 | 426 | – | – | – | 262 | 394 | 525 | |

| 6 | – | – | – | 164 | 272 | 377 | – | – | – | 230 | 344 | 164 | 164 | 262 | 361 | – | – | – | 197 | 328 | 459 | |

| M | 1 | – | – | – | 377 | 615 | 853 | 377 | 615 | 853 | 377 | 631 | 394 | 377 | 599 | 820 | – | – | – | 394 | 672 | 951 |

| 2 | – | – | – | 344 | 549 | 754 | 328 | 541 | 754 | 344 | 558 | 361 | 328 | 525 | 722 | – | – | – | 361 | 607 | 853 | |

| 3 | – | – | – | 279 | 451 | 623 | 164 | 271 | 377 | 279 | 459 | 295 | 262 | 426 | 590 | – | – | – | 295 | 492 | 689 | |

| K | 1 | 443 | 697 | 951 | – | – | – | – | – | – | 459 | 713 | 476 | 394 | 656 | 918 | 476 | 836 | 1197 | 476 | 877 | 1279 |

| 2 | 394 | 599 | 804 | – | – | – | – | – | – | 361 | 574 | 377 | 344 | 508 | 672 | 377 | 656 | 935 | 377 | 689 | 1000 | |

| 3 | 377 | 517 | 656 | – | – | – | – | – | – | 328 | 525 | 344 | 312 | 435 | 558 | 344 | 599 | 853 | – | – | – | |

| N | 1–2 | 1312 | 5658 | 10004 | – | – | – | – | – | – | – | – | 1312 | – | – | – | – | – | – | – | – | – |

| 3 | 968 | 4485 | 8003 | – | – | – | – | – | – | – | – | 968 | – | – | – | – | – | – | – | – | – | |

| S | 1 | – | – | – | 75 | 123 | 171 | 75 | 123 | 171 | 75 | 128 | 79 | 75 | 116 | 157 | – | – | – | – | – | – |

| 2 | – | – | – | 72 | 112 | 151 | 72 | 112 | 151 | 72 | 115 | 75 | 69 | 107 | 144 | – | – | – | – | – | – | |

| 3 | – | – | – | 82 | 128 | 174 | 82 | 128 | 174 | 82 | 131 | 85 | 79 | 123 | 167 | – | – | – | – | – | – | |

| 4 | – | – | – | 118 | 182 | 246 | 118 | 182 | 246 | 118 | 189 | 121 | 115 | 177 | 239 | – | – | – | – | – | – | |

| H | 1 | – | – | – | – | – | – | – | – | – | – | – | 164 | – | – | – | 164 | 254 | 344 | 164 | 262 | 361 |