Bem-vindo!

Confirme suas preferências

Atualizar preferências

Sugestões de produtos

Product Family suggestions

Kennametal ao seu serviço

Olá., User Name

Sua conta selecionada:

Existe um problema com a sua conta. Entre em contato com o suporte ao cliente.

Conta do vendedor

Alterar conta

Conta de entrega

Alterar conta

- Painel de controle

- Gerenciar pedidos

- Gerenciar canais

- Catálogo de endereços

-

Notificações

Marcar todas como lidas - Alterar senha

- Meu perfil

- Desconectar

Itens

adicionado com sucesso ao carrinho

Ver o carrinho

Ver o carrinho

- Recursos

- /

- Calculadoras de engenharia

- /

- Fresamento de Topo

- /

- Torque e potência da fresa de topo sólida da KM

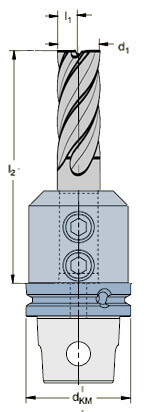

Torque e potência da fresa de topo sólida da KM

Para ângulo de posição sólido de 0° - Fresas de topo helicoidais de ângulo de saída positivo com a ferramenta de troca rápida da KM

Estes cálculos são baseados em valores teóricos e destinam-se apenas a propósitos de planejamento. Os resultados reais vão variar. A Kennametal não assume qualquer responsabilidade.