Product Similar To :

KDMT Flat Bottom and Back Draft Finishing End Mill • Necked End Mills • Cylindrical Shank • Carbide • Inch

Flat-Bottom and Back-Draft Finishing End Mills

Material Number2878452

ISO Catalog IDKDMT0500R472A050HNCANSI Catalog IDKDMT0500R472A050HNC

- P Steel

- M Stainless Steel

- K Cast Iron

- N Non-Ferrous

- S High-Temp Alloys

- H Hardened Materials

- .caption

Ramping: Blank

Slotting: Ball Nose

Side Milling/Shoulder Milling: Ball Nose

3D Profiling

Shank - Cylindrical Plain

Milling - Through Coolant

Pocketing

Sending to {{cadTool}} in progress...

Downloaded file will be available after import in the {{cadTool}} tool library.

- Overview

- Application Data

- Downloads

- Compatible Parts Machine Side

- Compatible Parts Workpiece Side

- Spare Parts

- Reviews

- Q&A

| Material Number | 2878452 |

| ISO Catalog ID | KDMT0500R472A050HNC |

| ANSI Catalog ID | KDMT0500R472A050HNC |

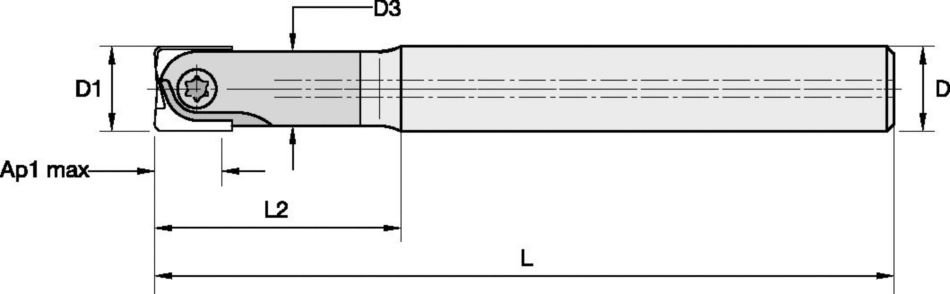

| [D1] Effective Cutting Diameter | 12.7 mm |

| [D1] Effective Cutting Diameter | 0.5 in |

| [D] Adapter / Shank / Bore Diameter | 12.7 mm |

| [D] Adapter / Shank / Bore Diameter | 0.5 in |

| [D3] Neck Diameter | 10.67 mm |

| [D3] Neck Diameter | 0.42 in |

| [L] Overall Length | 122 mm |

| [L] Overall Length | 4.8031 in |

| [L2] Head Length | 37 mm |

| [L2] Head Length | 1.4567 in |

| [AP1MAX] 1st Maximum Cutting Depth | 3 mm |

| [AP1MAX] 1st Maximum Cutting Depth | 0.118 in |

| Number of Inserts | 1 |

| [Z] Number of Flutes | 2 |

| Maximum Ramping Angle | 3 |

| Max RPM | 40000 |

| Gage Insert | KDMT0500. |

| Weight Pounds | 0.39 |

Workpiece Materials

- Steel

- Stainless Steel

- Cast Iron

- Non-Ferrous

- High-Temp Alloys

- Hardened Materials

- .caption

Uses and application

Ramping: Blank

Slotting: Ball Nose

Side Milling/Shoulder Milling: Ball Nose

3D Profiling

Shank - Cylindrical Plain

Milling - Through Coolant

Pocketing

Features and benefits

- Cutting diameter ranges from .500–1.000".

- High precision and runout accuracy.

- Can be used with the heat shrink technology, h6 shank tolerance.

- Suitable for roughing and finishing operations.

- Works with toroidal and high-feed inserts.

Create Solution to calculate Feeds and Speeds

After creating a solution just choose the Feeds & Speeds icon and our system will provide recommendations. You can customize the information by adding your machine and specifications or make adjustments using the sliders.

Feeds

Recommended Starting Feeds [IPT]

| Insert Geometry | Recommended Starting Feed per Tooth (Fz) in Relation to % of Radial Engagement (ae) | Insert Geometry | ||||||||||||||

| 10% | 20% | 30% | 40% | 50–100% | ||||||||||||

| .E..GC | .007 | .010 | .014 | .005 | .008 | .010 | .004 | .007 | .009 | .004 | .006 | .008 | .004 | .006 | .008 | .E..GC |

| .E..GN | .007 | .010 | .014 | .005 | .008 | .010 | .004 | .007 | .009 | .004 | .006 | .008 | .004 | .006 | .008 | .E..GN |

| Light | General | Heavy |

Recommended Starting Feeds [IPT]

| Insert Geometry | Recommended Starting Feed per Tooth (Fz) in Relation to % of Radial Engagement (ae) | Insert Geometry | ||||||||||||||

| 10% | 20% | 30% | 40% | 50–100% | ||||||||||||

| .S..HF | .059 | .092 | .131 | .042 | .064 | .086 | .036 | .054 | .073 | .034 | .050 | .067 | .033 | .049 | .066 | .S..HF |

| Light | General | Heavy |

Speeds

Recommended Starting Speeds [SFM]

| Material Group | KC515M | |||

| P | 1 | 1080 | 960 | 840 |

| 2 | 1020 | 900 | 780 | |

| 3 | 900 | 780 | 660 | |

| 4 | 780 | 660 | 540 | |

| 5 | 660 | 540 | 420 | |

| 6 | 540 | 420 | 360 | |

| M | 1 | 1080 | 900 | 780 |

| 2 | 900 | 720 | 540 | |

| 3 | 720 | 600 | 480 | |

| K | 1 | 1440 | 1080 | 720 |

| 2 | 1080 | 840 | 600 | |

| 3 | 480 | 360 | 240 | |

| N | 1–2 | – | – | – |

| 3 | – | – | – | |

| S | 1 | – | – | – |

| 2 | – | – | – | |

| 3 | – | – | – | |

| 4 | – | – | – | |

| H | 1 | 550 | 400 | 310 |

Insert Selection

| Material Group | Light | General | Heavy | |||

| – | (Light geometry) | – | (Strong geometry) | |||

| – | wear |  | toughness | |||

| – | Geometry | Grade | Geometry | Grade | Geometry | Grade |

| P1–P2 | .E..GC | KC515M | .E..GC | KC515M | .E..GN | KC515M |

| P3–P4 | .E..GN | KC515M | .E..GN | KC515M | .E..GN | KC515M |

| P5–P6 | .E..GN | KC515M | .E..GN | KC515M | .E..GN | KC515M |

| M1–M2 | – | – | .E..GN | KC515M | – | – |

| M3 | – | – | .E..GN | KC515M | – | – |

| K1–K2 | .E..GN | KC515M | .E..GN | KC515M | .E..GN | KC515M |

| K3 | .E..GN | KC515M | .E..GN | KC515M | .E..GN | KC515M |

| N1–N2 | – | – | – | – | – | – |

| N3 | – | – | – | – | – | – |

| S1–S2 | – | – | – | – | – | – |

| S3 | – | – | – | – | – | – |

| S4 | – | – | – | – | – | – |

| H1 | – | – | .E..GN | KC515M | – | – |

I have read and accepted the Terms & Conditions of use