Product Similar To :

Fix-Perfect™ • Aluminum • Shell Mills • M Line • Inch

Shell Mills • M Line

Material Number2235058

ISO Catalog ID200C08RP90BG15CUMANSI Catalog ID200C08RP90BG15CUM

Face Milling

Side Milling/Shoulder Milling: Square End

Milling - Through Coolant

Milling - Side and Face

Sending to {{cadTool}} in progress...

Downloaded file will be available after import in the {{cadTool}} tool library.

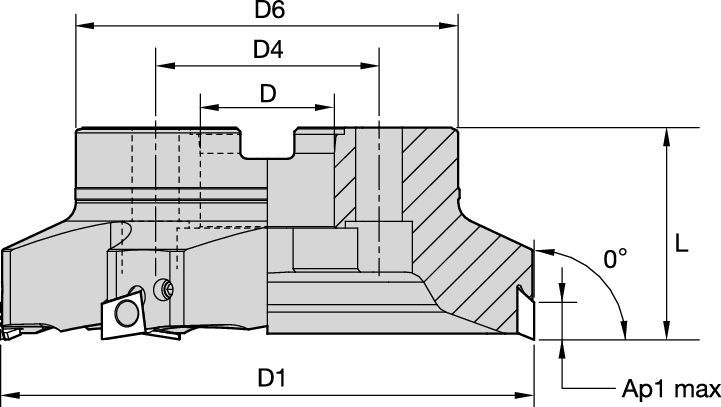

| Material Number | 2235058 |

| ISO Catalog ID | 200C08RP90BG15CUM |

| ANSI Catalog ID | 200C08RP90BG15CUM |

| [D1] Effective Cutting Diameter | 203.2 mm |

| [D1] Effective Cutting Diameter | 8 in |

| [D] Adapter / Shank / Bore Diameter | 63.5 mm |

| [D] Adapter / Shank / Bore Diameter | 2.5 in |

| [D4] Bolt Circle 4 | 101.6 mm |

| [D4] Bolt Circle 3 | 4 in |

| [D6] Hub Diameter | 130.05 mm |

| [D6] Hub Diameter | 5.12 in |

| [L] Overall Length | 60.452 mm |

| [L] Overall Length | 2.38 in |

| [AP1MAX] 1st Maximum Cutting Depth | 9.5 mm |

| [AP1MAX] 1st Maximum Cutting Depth | 0.374 in |

| Number of Inserts | 8 |

| Weight Pounds | 11.9 |

| Max RPM | 3130 |

Uses and application

Face Milling

Side Milling/Shoulder Milling: Square End

Milling - Through Coolant

Milling - Side and Face

Features and benefits

- Excellent for milling aluminum and non-ferrous materials.

- Good choice for thin-wall or poorly fixtured workpieces.

- 24° positive rake enables free cutting action.

- Produces excellent finish and flatness.

- Maximum speed is 6,500 SFM.

Create Solution to calculate Feeds and Speeds

After creating a solution just choose the Feeds & Speeds icon and our system will provide recommendations. You can customize the information by adding your machine and specifications or make adjustments using the sliders.

Feeds

Recommended Starting Feeds [IPT]

| Insert Geometry | Recommended Starting Feed per Tooth (Fz) in Relation to % of Radial Engagement (ae) | Insert Geometry | ||||||||||||||

| 5% | 10% | 20% | 30% | 40 | ||||||||||||

| BGHX… | .005 | .014 | .023 | .003 | .010 | .017 | .003 | .008 | .013 | .002 | .007 | .011 | .002 | .006 | .010 | BGHX… |

| Light | General | Heavy |

Speeds

Recommended Starting Speeds [SFM]

| Material Group | K110M | KC510M | KD1410 | KD1415 | |||||||||

| P | 1 | – | – | – | – | – | – | – | – | – | – | – | – |

| 2 | – | – | – | – | – | – | – | – | – | – | – | – | |

| 3 | – | – | – | – | – | – | – | – | – | – | – | – | |

| 4 | – | – | – | – | – | – | – | – | – | – | – | – | |

| 5 | – | – | – | – | – | – | – | – | – | – | – | – | |

| 6 | – | – | – | – | – | – | – | – | – | – | – | – | |

| M | 1 | – | – | – | – | – | – | – | – | – | – | – | – |

| 2 | – | – | – | – | – | – | – | – | – | – | – | – | |

| 3 | – | – | – | – | – | – | – | – | – | – | – | – | |

| K | 1 | – | – | – | – | – | – | – | – | – | – | – | – |

| 2 | – | – | – | – | – | – | – | – | – | – | – | – | |

| 3 | – | – | – | – | – | – | – | – | – | – | – | – | |

| N | 1–2 | 1650 | 1550 | 1475 | 2100 | 1870 | 1720 | 13150 | 11500 | 9800 | 13150 | 11500 | 9800 |

| 3 | 1350 | 1200 | 1050 | 1900 | 1750 | 1600 | 5250 | 4900 | 4600 | 5250 | 4900 | 4600 | |

| S | 1 | – | – | – | – | – | – | – | – | – | – | – | – |

| 2 | – | – | – | – | – | – | – | – | – | – | – | – | |

| 3 | – | – | – | – | – | – | – | – | – | – | – | – | |

| 4 | – | – | – | – | – | – | – | – | – | – | – | – | |

| H | 1 | – | – | – | – | – | – | – | – | – | – | – | – |

Insert Selection

| Material Group | Light | General | Heavy | |||

| – | (Light geometry) | (Strong geometry) | ||||

| – | wear |  | toughness | |||

| – | Geometry | Grade | Geometry | Grade | Geometry | Grade |

| P1–P2 | – | – | – | – | – | – |

| P3–P4 | – | – | – | – | – | – |

| P5–P6 | – | – | – | – | – | – |

| M1–M2 | – | – | – | – | – | – |

| M3 | – | – | – | – | – | – |

| K1–K2 | – | – | – | – | – | – |

| K3 | – | – | – | – | – | – |

| N1–N2 | BGHX… | K110M | BGHX… | KC510M | BGHX… | KD1415 |

| N3 | BGHX… | K110M | BGHX… | KD1410 | BGHX… | KD1410 |

| S1–S2 | – | – | – | – | – | – |

| S3 | – | – | – | – | – | – |

| S4 | – | – | – | – | – | – |

| H1 | – | – | – | – | – | – |

I have read and accepted the Terms & Conditions of use