Product Similar To :

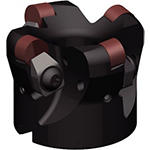

KSSR - RN • Shell Mills • Inch

Shell Mills

Material Number1244356

ISO Catalog ID4.00503R232ANSI Catalog ID4.00503R232

- K Cast Iron

- S High-Temp Alloys

- .caption

Face Milling

Slotting: Ball Nose

Side Milling/Shoulder Milling: Ball Nose

Milling - Side and Face

Sending to {{cadTool}} in progress...

Downloaded file will be available after import in the {{cadTool}} tool library.

- Overview

- Application Data

- Downloads

- Compatible Parts Machine Side

- Compatible Parts Workpiece Side

- Spare Parts

- Reviews

- Q&A

| Material Number | 1244356 |

| ISO Catalog ID | 4.00503R232 |

| ANSI Catalog ID | 4.00503R232 |

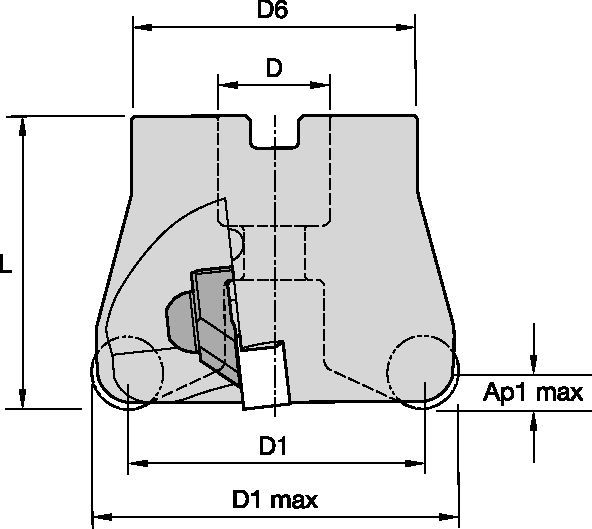

| [D1MAX] Maximum Cutting Diameter | 50 mm |

| [D1MAX] Maximum Cutting Diameter | 1.9685 in |

| [D1] Effective Cutting Diameter | 37.3 mm |

| [D1] Effective Cutting Diameter | 1.4685 in |

| [D] Adapter / Shank / Bore Diameter | 16 mm |

| [D] Adapter / Shank / Bore Diameter | 0.6299 in |

| [D6] Hub Diameter | 33 mm |

| [D6] Hub Diameter | 1.2992 in |

| [L] Overall Length | 50 mm |

| [L] Overall Length | 1.9685 in |

| [AP1MAX] 1st Maximum Cutting Depth | 3 mm |

| [AP1MAX] 1st Maximum Cutting Depth | 0.1181 in |

| Number of Inserts | 3 |

| Gage Insert | RN__1207 |

| Weight Pounds | 1.1 |

Workpiece Materials

- Cast Iron

- High-Temp Alloys

- .caption

Uses and application

Face Milling

Slotting: Ball Nose

Side Milling/Shoulder Milling: Ball Nose

Milling - Side and Face

Features and benefits

- First choice for face milling high-temp alloys and hard or hardened materials up to 60 HRC.

- Excellent productivity through massive reduction of machining time.

Create Solution to calculate Feeds and Speeds

After creating a solution just choose the Feeds & Speeds icon and our system will provide recommendations. You can customize the information by adding your machine and specifications or make adjustments using the sliders.

Feeds

| Insert Geometry | Recommended Starting Feed per Tooth (Fz) in Relation to % of Radial Engagement (ae) | Insert Geometry | ||||||||||||||

| 10% | 20% | 30% | 40% | 50–100% | ||||||||||||

| ..E | .004 | .004 | .005 | .003 | .003 | .003 | .002 | .003 | .003 | .002 | .003 | .003 | .002 | .002 | .003 | ..E |

| ..T.. | .007 | .010 | .011 | .005 | .008 | .009 | .004 | .007 | .007 | .004 | .006 | .007 | .004 | .006 | .007 | ..T.. |

| Light | General | Heavy |

| Insert Geometry | Recommended Starting Feed per Tooth (Fz) in Relation to % of Radial Engagement (ae) | Insert Geometry | ||||||||||||||

| 10% | 20% | 30% | 40% | 50–100% | ||||||||||||

| ..E | .004 | .005 | .005 | .003 | .004 | .004 | .003 | .003 | .003 | .003 | .003 | .003 | .003 | .003 | .003 | ..E |

| ..T.. | .008 | .012 | .013 | .006 | .009 | .010 | .005 | .008 | .009 | .005 | .007 | .008 | .005 | .007 | .008 | ..T.. |

| Insert Geometry | Recommended Starting Feed per Tooth (Fz) in Relation to % of Radial Engagement (ae) | Insert Geometry | ||||||||||||||

| 10% | 20% | 30% | 40% | 50–100% | ||||||||||||

| ..E | .008 | .009 | .009 | .006 | .006 | .007 | .005 | .006 | .006 | .005 | .005 | .006 | .005 | .005 | .006 | ..E |

| ..T.. | .014 | .022 | .024 | .010 | .016 | .018 | .009 | .014 | .015 | .008 | .013 | .014 | .008 | .013 | .014 | ..T.. |

| Insert Geometry | Recommended Starting Feed per Tooth (Fz) in Relation to % of Radial Engagement (ae) | Insert Geometry | ||||||||||||||

| 10% | 20% | 30% | 40% | 50–100% | ||||||||||||

| ..E | .006 | .006 | .007 | .004 | .005 | .005 | .004 | .004 | .004 | .003 | .004 | .004 | .003 | .004 | .004 | ..E |

| ..T.. | .010 | .016 | .017 | .008 | .012 | .013 | .007 | .010 | .011 | .006 | .010 | .010 | .006 | .009 | .010 | ..T.. |

Speeds

Recommended Starting Speeds [SFM]

| Material Group | KYS30 | KY2100 | KY4300 | |||||||

| P | 1 | – | – | – | – | – | – | – | – | – |

| 2 | – | – | – | – | – | – | – | – | – | |

| 3 | – | – | – | – | – | – | – | – | – | |

| 4 | – | – | – | – | – | – | – | – | – | |

| 5 | 3000 | 2400 | 1800 | 3960 | 3200 | 2380 | – | – | – | |

| 6 | 3000 | 2400 | 1800 | 3960 | 3200 | 2380 | – | – | – | |

| M | 1 | – | – | – | 3960 | 3200 | 2380 | – | – | – |

| 2 | – | – | – | 3740 | 3000 | – | – | – | – | |

| 3 | – | – | – | 2760 | 2400 | – | – | – | – | |

| K | 1 | – | – | – | – | – | – | – | – | – |

| 2 | – | – | – | – | – | – | – | – | – | |

| 3 | – | – | – | – | – | – | – | – | – | |

| N | 1–2 | – | – | – | – | – | – | – | – | – |

| 3 | – | – | – | – | – | – | – | – | – | |

| S | 1 | 2640 | 2160 | 1680 | 3490 | 2860 | 2220 | 1680 | 1320 | 960 |

| 2 | 2640 | 2160 | 1680 | 3490 | 2860 | 2220 | 1680 | 1320 | 960 | |

| 3 | 3840 | 3120 | 2400 | 5080 | 4130 | 3180 | 2400 | 2040 | 1680 | |

| 4 | – | – | – | – | – | – | – | – | – | |

| H | 1 | – | – | – | – | – | – | 1200 | 1020 | 780 |

Insert Selection

| Material Group | Light | General | Heavy | |||

| – | (Light geometry) | – | (Strong geometry) | |||

| – | wear |  | toughness | |||

| – | Geometry | Grade | Geometry | Grade | Geometry | Grade |

| P1–P2 | – | – | – | – | – | – |

| P3–P4 | – | – | – | – | – | – |

| P5–P6 | – | – | ..T.. | KY2100 / KYSM10 | – | – |

| M1–M2 | – | – | – | – | – | – |

| M3 | ..T.. | KY2100 / KYSM10 | ..T.. | KY2100 / KYSM10 | ..T.. | KY2100 / KYSM10 |

| K1–K2 | – | – | – | – | – | – |

| K3 | – | – | – | – | – | – |

| N1–N2 | – | – | – | – | – | – |

| N3 | – | – | – | – | – | – |

| S1–S2 | ..E | KY4300 / KYHS10 | ..T.. | KYS30 | ..T.. | KY2100 / KYSM10 |

| S3 | ..T.. | KYS30 | ..T.. | KYS30 | ..T.. | KY4300 / KYHS10 |

| S4 | – | – | – | – | – | – |

| H1 | ..E | KY4300 / KYHS10 | ..T.. | KY4300 / KYHS10 | – | – |

I have read and accepted the Terms & Conditions of use