Product Similar To:

LNUX-RRH

Wisselplaten

Material Number5586626

ISO Catalog IDLNUX301940RRHANSI Catalog IDLNUX301940RRH

- P Steel

- K Cast Iron

Sending to {{cadTool}} in progress...

Downloaded file will be available after import in the {{cadTool}} tool library.

| Material Number | 5586626 |

| ISO Catalog ID | LNUX301940RRH |

| ANSI Catalog ID | LNUX301940RRH |

| Grade | KCP10B |

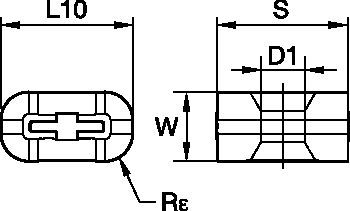

| [W] Insert Width | 12 mm |

| [W] Insert Width | 0.4724 in |

| [L10] Insert Cutting Edge Length | 30 mm |

| [L10] Insert Cutting Edge Length | 1.1811 in |

| [S] Insert Thickness | 19.05 mm |

| [S] Insert Thickness | 0.75 in |

| [Rε] Corner Radius | 4 mm |

| [Rε] Corner Radius | 0.157 in |

| [D1] Insert Hole Size | 6.35 mm |

| [D1] Insert Hole Size | 0.25 in |

Workpiece Materials

- Steel

- Cast Iron

Grades

KCP10B

Composition: A specially engineered cobalt-enriched carbide grade with thick MTCVD-TiCN-Al2O3-TiOCN coating for maximum wear resistance.

Application: An excellent finishing to medium machining grade for a variety of workpiece materials, including most steels, ferritic, martensitic, and PH stainless steels, and cast irons. The cobalt-enriched substrate offers a balanced combination of deformation resistance and edge toughness, while the thick coating layers offer outstanding abrasion resistance and crater wear resistance for high-speed machining. Smooth coating provides resistance to edge build-up and microchipping and produces excellent surface finishes.

Features and benefits

Kennametal houdt een compleet programma standaard wisselplaten voor treinwielen en assen bewerking in voorraad. Wisselplaten zijn in verschillende types, afmetingen en hardmetaalsoorten leverbaar.- Treinwielen uitdraaien — geperste spaanbreker wisselplaten als ronde, vierkante, achtkantige en herslijpbare wisselplaten.

- Assen draaien — Driekant en diamant vorm wisselplaten met spaanbrekers.

- Treinwielen draaien — rechthoekige en vierkante uitvoeringen, met of zonder geperste spaanbrekers.

- Treinwielen draaien — ronde knoppen met centrumgat voor borging.

Create Solution to calculate Feeds and Speeds

After creating a solution just choose the Feeds & Speeds icon and our system will provide recommendations. You can customize the information by adding your machine and specifications or make adjustments using the sliders.

I have read and accepted the Terms & Conditions of use