BB KSSM 45°使用刀片 • SECX-EN GN

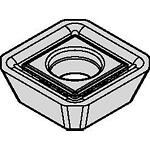

可转位刀片

物料号4140628

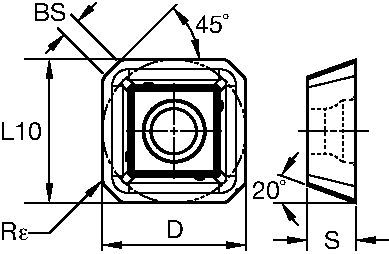

公制样本编号SECX1404AEENGN英制样本编号SECX443AEEN7GN

- P 钢

- M 不锈钢

- S 高温合金

Sending to {{cadTool}} in progress...

Downloaded file will be available after import in the {{cadTool}} tool library.

| 物料号 | 4140628 |

| 公制样本编号 | SECX1404AEENGN |

| 英制样本编号 | SECX443AEEN7GN |

| 材质 | KC725M |

| [SSC] 刀片 IC 尺寸 | 14 mm |

| [SSC] 刀片 IC 尺寸 | 0.551 in |

| [BS] 刀尖刃口长度 | 1.85 mm |

| [BS] 刀尖刃口长度 | 0.073 in |

| [L10] 刀片切削刃长度 | 14 mm |

| [L10] 刀片切削刃长度 | 0.5512 in |

| [Rε] 刀尖半径 | 1 mm |

| [Rε] 刀尖半径 | 0.039 in |

| [S] 刀片厚度 | 4.763 mm |

| [S] 刀片厚度 | 0.1875 in |

| 平均切屑厚度 [HM] | 0.064 mm |

| 平均切屑厚度 [HM] | 0.0025 in |

| 每个刀片的切削刃 | 4 |

工件材料

- 钢

- 不锈钢

- 高温合金

Grades

KC725M

一种高性能 TiAlN-PVD 涂层硬质合金材质,用于铣削钢、不锈钢和球墨铸铁。材质的基体具有良好的抗高温冲击性能,是干/湿加工的理想之选。KC725M 主要用于一般加工和重型负载加工

Features and benefits

- -GD2 槽型具有更低的切削力。

- -GN 槽型是粗加工应用的首选刀具。

通过创建解决方案计算速度和进给

创建解决方案后,只需选择进给和速度图标,我们的系统将提供建议。您可以通过添加您的机床和参数来定制信息,或者使用滑块进行调整。

Feeds

推荐初始进给量[毫米]

| 刀片槽型 | 不同切宽(ae)百分比情况下,所建议的每齿进给量设定值(fz) | 刀片槽型 | ||||||||||||||

| 10% | 20% | 30% | 40% | 50–100% | ||||||||||||

| .E..NGD2 | 0,88 | 1,70 | 2,85 | 0,65 | 1,26 | 2,09 | 0,57 | 1,10 | 1,82 | 0,53 | 1,02 | 1,69 | 0,52 | 1,00 | 1,66 | .E..NGD2 |

| .E..NGN | 0,88 | 1,70 | 2,85 | 0,65 | 1,26 | 2,09 | 0,57 | 1,10 | 1,82 | 0,53 | 1,02 | 1,69 | 0,52 | 1,00 | 1,66 | .E..NGN |

| .S..NGN | 1,04 | 2,03 | 3,41 | 0,78 | 1,50 | 2,49 | 0,68 | 1,30 | 2,16 | 0,63 | 1,22 | 2,01 | 0,62 | 1,19 | 1,97 | .S..NGN |

| 轻切削 | 中等切削 | 重切削 |

Recommended Starting Feeds [IPT]

| 轻切削 | 中等切削 | 重切削 |

| 刀片槽型 | 不同切宽(ae)百分比情况下,所建议的每齿进给量设定值(fz) | 刀片槽型 | ||||||||||||||

| 10% | 20% | 30% | 40% | 50–100% | ||||||||||||

| .E..NGD2 | .035 | .071 | .129 | .026 | .050 | .085 | .022 | .043 | .072 | .021 | .040 | .066 | .020 | .039 | .065 | .E..NGD2 |

| .E..NGN | .035 | .071 | .129 | .026 | .050 | .085 | .022 | .043 | .072 | .021 | .040 | .066 | .020 | .039 | .065 | .E..NGN |

| .S..NGN | .043 | .087 | .165 | .031 | .061 | .103 | .027 | .052 | .086 | .025 | .048 | .080 | .024 | .047 | .078 | .S..NGN |

Speeds

推荐初始速度 [米/分钟]

| 材料 分组 | KC725M | |||

| P | 1 | – | – | – |

| 2 | – | – | – | |

| 3 | – | – | – | |

| 4 | – | – | – | |

| 5 | – | – | – | |

| 6 | – | – | – | |

| M | 1 | – | – | – |

| 2 | – | – | – | |

| 3 | – | – | – | |

| K | 1 | – | – | – |

| 2 | – | – | – | |

| 3 | – | – | – | |

| N | 1 | – | – | – |

| 2 | – | – | – | |

| S | 1 | – | – | – |

| 2 | – | – | – | |

| 3 | – | – | – | |

| 4 | 75 | 55 | 35 | |

| H | 1 | – | – | – |

| 2 | – | – | – | |

| 3 | – | – | – | |

Recommended Starting Speeds [SFM]

| 材料 分组 | KC725M | |||

| P | 1 | – | – | – |

| 2 | – | – | – | |

| 3 | – | – | – | |

| 4 | – | – | – | |

| 5 | – | – | – | |

| 6 | – | – | – | |

| M | 1 | – | – | – |

| 2 | – | – | – | |

| 3 | – | – | – | |

| K | 1 | – | – | – |

| 2 | – | – | – | |

| 3 | – | – | – | |

| N | 1 | – | – | – |

| 2 | – | – | – | |

| S | 1 | – | – | – |

| 2 | – | – | – | |

| 3 | – | – | – | |

| 4 | 240 | 180 | 120 | |

| H | 1 | – | – | – |

| 2 | – | – | – | |

| 3 | – | – | – | |

应用数据

一般编程信息

| cutter diameter | 最大坡铣角度 | Ap1 最大值 | 最小孔直径(DH) | 最小平底孔直径(DH1) | 最大孔直径(无平底) |

| 50mm | 2.11° | 1,65 | 96,34 | 78,02 | 100 |

| 52mm | 1.97° | 1,65 | 100,34 | 82,02 | 104 |

| 63mm | 1.46° | 1,65 | 122,34 | 104,02 | 126 |

| 66mm | 1.37° | 1,65 | 128,34 | 110,02 | 132 |

| 80mm | 1.04° | 1,65 | 156,34 | 138,02 | 160 |

| 100mm | 0.78° | 1,65 | 196,34 | 178,02 | 200 |

| 125mm | 0.59° | 1,65 | 246,34 | 228,02 | 250 |

| Rt | Wt | t |

| 4,1 | 11,0 | 1,3 |

| cutter diameter | max ramping | Ap1 max | min hole diameter (DH) | min flat-bottom hole diameter (DH1) | max hole diameter no flat bottom |

| 2.0" | 2.05° | .065" | 3.856" | 3.134" | 4.0" |

| 2.5" | 1.45° | .065" | 4.856" | 4.134" | 5.0" |

| 3.0" | 1.11° | .065" | 5.856" | 5.134" | 6.0" |

| 4.0" | 0.76° | .065" | 7.856" | 7.134" | 8.0" |

| 5.0" | 0.58° | .065" | 9.856" | 9.134" | 10.0" |

| Rt | Wt | t |

| .161 | .433 | .051 |

High Performance Combination Tools

| 材料 分组 | 轻切削 | 中等切削 | 重切削 | |||

| – | (锋利的槽型) | – | (强壮的槽型) | |||

| – | 耐磨性 |  | 韧性 | |||

| – | 槽型 | 材质 | 槽型 | 材质 | 槽型 | 材质 |

| P1–P2 | – | – | – | – | – | – |

| P3–P4 | – | – | – | – | – | – |

| P5–P6 | – | – | – | – | – | – |

| M1–M2 | – | – | – | – | – | – |

| M3 | – | – | – | – | – | – |

| K1–K2 | – | – | – | – | – | – |

| K3 | – | – | – | – | – | – |

| N1–N2 | – | – | – | – | – | – |

| N3 | – | – | – | – | – | – |

| S1–S2 | – | – | – | – | – | – |

| S3 | – | – | – | – | – | – |

| S4 | .E..NGD2 | KC725M | .E..NGN | KC725M | .S..NGN | KC725M |

| H1 | – | – | – | – | – | – |

I have read and accepted the Terms & Conditions of use