Inserts for Fix-Perfect™ • Aluminium • BGHX15L5... • -GG • Roughing

Indexable Inserts for Fix-Perfect • BGHX15L5...

物料号1794653

公制样本编号BGHX15L5PCTRGG英制样本编号BGHX15L5PCTRGG

- K 铸铁

- N 非铁材质

Sending to {{cadTool}} in progress...

Downloaded file will be available after import in the {{cadTool}} tool library.

| 物料号 | 1794653 |

| 公制样本编号 | BGHX15L5PCTRGG |

| 英制样本编号 | BGHX15L5PCTRGG |

| 材质 | K110M |

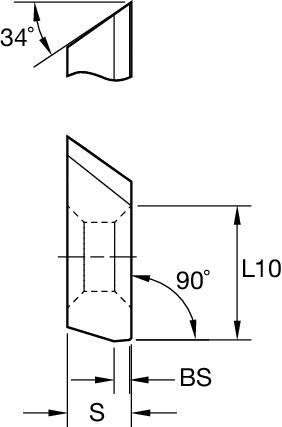

| [L10] 刀片切削刃长度 | 10.5 mm |

| [L10] 刀片切削刃长度 | 0.4134 in |

| [S] 刀片厚度 | 5 mm |

| [S] 刀片厚度 | 0.1969 in |

| [BS] 刀尖刃口长度 | 1.217 mm |

| [BS] 刀尖刃口长度 | 0.0479 in |

| 平均切屑厚度 [HM] | 0.02 mm |

| 平均切屑厚度 [HM] | 0.0008 in |

| 每个刀片的切削刃 | 2 |

工件材料

- 铸铁

- 非铁材质

Grades

K110M

K110M 是一种非涂层硬质合金材质,用于非铁金属材料的通用加工。适合轻型加工和一般加工类型。K110M 材质在应用中可以使用冷却液,也可以不使用冷却液。

Features and benefits

- Roughing Fix-Perfect inserts for aluminum and non-ferrous materials.

- 0.374″ (9,5mm) max depth of cut.

- Two cutting edges.

通过创建解决方案计算速度和进给

创建解决方案后,只需选择进给和速度图标,我们的系统将提供建议。您可以通过添加您的机床和参数来定制信息,或者使用滑块进行调整。

Feeds

Recommended Starting Feeds [IPT]

| 刀片槽型 | 不同切宽(ae)百分比情况下,所建议的每齿进给量设定值(fz) | 刀片槽型 | ||||||||||||||

| 5% | 10% | 20% | 30% | 40 | ||||||||||||

| BGHX… | .005 | .014 | .023 | .003 | .010 | .017 | .003 | .008 | .013 | .002 | .007 | .011 | .002 | .006 | .010 | BGHX… |

| 轻切削 | 中等切削 | 重切削 |

Speeds

Recommended Starting Speeds [SFM]

| 材料 分组 | K110M | KC510M | KD1410 | KD1415 | |||||||||

| P | 1 | – | – | – | – | – | – | – | – | – | – | – | – |

| 2 | – | – | – | – | – | – | – | – | – | – | – | – | |

| 3 | – | – | – | – | – | – | – | – | – | – | – | – | |

| 4 | – | – | – | – | – | – | – | – | – | – | – | – | |

| 5 | – | – | – | – | – | – | – | – | – | – | – | – | |

| 6 | – | – | – | – | – | – | – | – | – | – | – | – | |

| M | 1 | – | – | – | – | – | – | – | – | – | – | – | – |

| 2 | – | – | – | – | – | – | – | – | – | – | – | – | |

| 3 | – | – | – | – | – | – | – | – | – | – | – | – | |

| K | 1 | – | – | – | – | – | – | – | – | – | – | – | – |

| 2 | – | – | – | – | – | – | – | – | – | – | – | – | |

| 3 | – | – | – | – | – | – | – | – | – | – | – | – | |

| N | 1–2 | 1650 | 1550 | 1475 | 2100 | 1870 | 1720 | 13150 | 11500 | 9800 | 13150 | 11500 | 9800 |

| 3 | 1350 | 1200 | 1050 | 1900 | 1750 | 1600 | 5250 | 4900 | 4600 | 5250 | 4900 | 4600 | |

| S | 1 | – | – | – | – | – | – | – | – | – | – | – | – |

| 2 | – | – | – | – | – | – | – | – | – | – | – | – | |

| 3 | – | – | – | – | – | – | – | – | – | – | – | – | |

| 4 | – | – | – | – | – | – | – | – | – | – | – | – | |

| H | 1 | – | – | – | – | – | – | – | – | – | – | – | – |

High Performance Combination Tools

| 材料 分组 | 轻切削 | 中等切削 | 重切削 | |||

| – | (锋利的槽型) | (强壮的槽型) | ||||

| – | 耐磨性 |  | 韧性 | |||

| – | 槽型 | 材质 | 槽型 | 材质 | 槽型 | 材质 |

| P1–P2 | – | – | – | – | – | – |

| P3–P4 | – | – | – | – | – | – |

| P5–P6 | – | – | – | – | – | – |

| M1–M2 | – | – | – | – | – | – |

| M3 | – | – | – | – | – | – |

| K1–K2 | – | – | – | – | – | – |

| K3 | – | – | – | – | – | – |

| N1–N2 | BGHX… | K110M | BGHX… | KC510M | BGHX… | KD1415 |

| N3 | BGHX… | K110M | BGHX… | KD1410 | BGHX… | KD1410 |

| S1–S2 | – | – | – | – | – | – |

| S3 | – | – | – | – | – | – |

| S4 | – | – | – | – | – | – |

| H1 | – | – | – | – | – | – |

I have read and accepted the Terms & Conditions of use