KNS® • Shell Mount • Inch

Slot milling cutter for multiple materials.

物料号5614914

公制样本编号KNSU050R07X51S125英制样本编号KNSU050R07X51S125

- P 钢

- M 不锈钢

- K 铸铁

- N 非铁材质

- S 高温合金

- .caption

100055043

槽铣: 侧铣

侧铣/方肩铣削: 底孔方肩铣削

Sending to {{cadTool}} in progress...

Downloaded file will be available after import in the {{cadTool}} tool library.

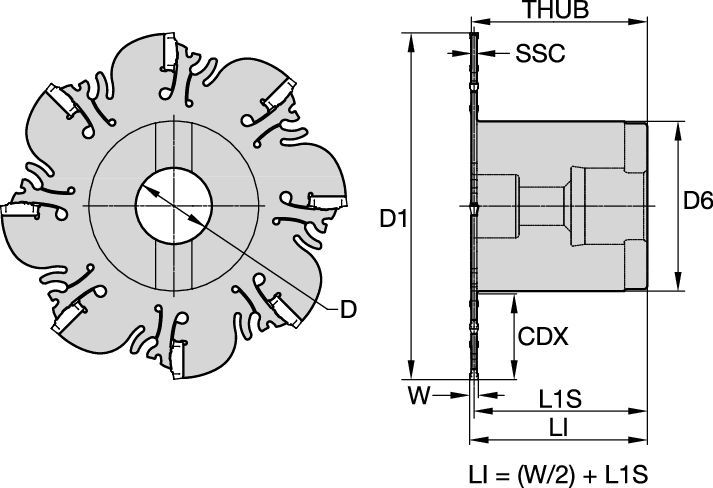

| 物料号 | 5614914 |

| 公制样本编号 | KNSU050R07X51S125 |

| 英制样本编号 | KNSU050R07X51S125 |

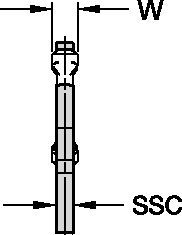

| 刀片尺寸 [SSC] | 51 |

| [BM] 最小切削宽度 | 6 mm |

| [BM] 最小切削宽度 | 0.236 in |

| [BMAX] 最大切削宽度 | 7 mm |

| [BMAX] 最大切削宽度 | 0.276 in |

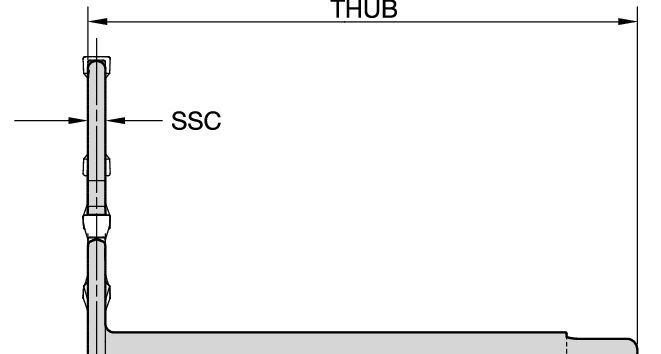

| [D1] 有效的切削直径 | 127 mm |

| [D1] 有效的切削直径 | 5 in |

| [D]适配接头/刀柄/镗孔直径 | 31.8 mm |

| [D]适配接头/刀柄/镗孔直径 | 1.25 in |

| [D6] 保护区孔直径 | 69.85 mm |

| [D6] 保护区孔直径 | 2.75 in |

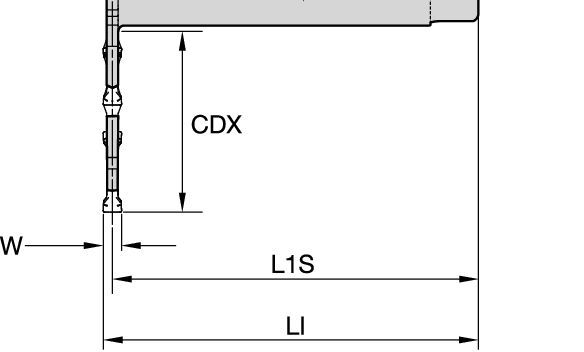

| [CDX] 径向最大切深 | 27.77 mm |

| [CDX] 径向最大切深 | 1.094 in |

| [L1] 量规长度 | 53.35 mm |

| [L1] 量规长度 | 2.1181 in |

| [L1S] 二级量规长度 | 50.8 mm |

| [L1S] 二级量规长度 | 2 in |

| [W1] 刀片宽度 | 5.1 mm |

| [W1] 刀片宽度 | 0.201 in |

| [THUB] 保护区孔厚度 | 53.35 mm |

| [THUB] 保护区孔厚度 | 2.1 in |

| 刀片数量 | 7 |

| Gage 刀片 | XCP51_____ |

| 重量(磅) | 3.66 |

| 最大 RPM | 640 |

工件材料

- 钢

- 不锈钢

- 铸铁

- 非铁材质

- 高温合金

- .caption

Uses and application

100055043

槽铣: 侧铣

侧铣/方肩铣削: 底孔方肩铣削

Features and benefits

- The Double-V Design of the insert and the insert pocket securely holds the insert in place, minimises radial runout, providing high slot width accuracy and high repeatability.

- A unique self-clamping mechanism ensures easy insert exchange.

通过创建解决方案计算速度和进给

创建解决方案后,只需选择进给和速度图标,我们的系统将提供建议。您可以通过添加您的机床和参数来定制信息,或者使用滑块进行调整。

Feeds

推荐初始进给率 [毫米]

| KNS® Slotting Cutter • Recommended Starting Feeds [mm/th] | ||||||||||||

| 刀片槽型 | 不同切宽(ae)百分比情况下,所建议的每齿进给量设定值(fz) | |||||||||||

| 5% | 10% | 20% | 30–100% | |||||||||

| L | M | H | L | M | H | L | M | H | L | M | H | |

| .S..GP | 0,13 | 0,28 | 0,35 | 0,09 | 0,20 | 0,32 | 0,07 | 0,15 | 0,32 | 0,06 | 0,12 | 0,30 |

| L = Light Machining; M = Medium Machining; H = Heavy Machining NOTE: Use "Light Machining" values as starting feed rate. | ||||||||||||

| KNS® Slotting Cutter • Recommended Starting Feeds [IPT] | ||||||||||||

| 刀片槽型 | 不同切宽(ae)百分比情况下,所建议的每齿进给量设定值(fz) | |||||||||||

| 5% | 10% | 20% | 30–100% | |||||||||

| L | M | H | L | M | H | L | M | H | L | M | H | |

| .S..GP | 0.005 | 0.011 | 0.027 | 0.004 | 0.008 | 0.020 | 0.003 | 0.006 | 0.015 | 0.002 | 0.005 | 0.012 |

| L = Light Machining; M = Medium Machining; H = Heavy Machining NOTE: Use "Light Machining" values as starting feed rate. | ||||||||||||

Speeds

推荐初始切削速度[米/分钟]

| KNS® Slotting Cutter • Recommended Starting Speed [m/min] | ||||||||||

| 刀片材质 | KCU25 | KCPK30 | KMF | |||||||

| 切削厚度 hex mm | 最小值 | 最大值 | 最小值 | 最大值 | 最小值 | 最大值 | ||||

| 材料 分组 | 最大值 | 初始值 | 最小值 | 最大值 | 初始值 | 最小值 | 最大值 | 初始值 | 最小值 | |

| P | 1 | 260 | 230 | 215 | 455 | 395 | 370 | 295 | 260 | 245 |

| 2 | 220 | 190 | 160 | 280 | 255 | 230 | 250 | 215 | 180 | |

| 3 | 200 | 170 | 140 | 255 | 230 | 205 | 230 | 195 | 160 | |

| 4 | 180 | 150 | 120 | 225 | 185 | 160 | 205 | 170 | 135 | |

| 5 | 150 | 135 | 120 | 190 | 170 | 150 | 170 | 155 | 135 | |

| 6 | 130 | 100 | 80 | 160 | 135 | 110 | 150 | 115 | 90 | |

| M | 1 | 210 | 170 | 135 | 205 | 185 | 155 | 195 | 170 | 155 |

| 2 | 170 | 150 | 110 | 185 | 160 | 140 | 175 | 150 | 125 | |

| 3 | 130 | 120 | 85 | 145 | 130 | 115 | 130 | 115 | 90 | |

| K | 1 | 270 | 220 | 170 | 295 | 265 | 240 | – | – | – |

| 2 | 230 | 190 | 160 | 235 | 210 | 190 | – | – | – | |

| 3 | 210 | 160 | 140 | 195 | 175 | 160 | – | – | – | |

| N | 1 | – | – | – | – | – | – | – | – | – |

| 2 | – | – | – | – | – | – | – | – | – | |

| 3 | – | – | – | – | – | – | – | – | – | |

| S | 1 | 30 | 25 | 20 | – | – | – | 40 | 35 | 30 |

| 2 | 30 | 25 | 20 | – | – | – | 40 | 35 | 30 | |

| 3 | 40 | 30 | 20 | – | – | – | 50 | 40 | 30 | |

| 4 | 55 | 40 | 25 | 50 | 45 | 35 | 55 | 50 | 35 | |

| H | 1 | – | – | – | – | – | – | – | – | – |

| Recommended Starting Speed are pointing to 90° Shoulder Milling . Starting Speed for Face and Copy Milling can be Increased by 20 %. As the average chip thickness increases, speed should be decreased. Material groups P, M, K and H show recommended starting speeds for dry machining. For wet machining, reduce speed by 20%. Material groups N and S show recommended starting speeds for wet machining. Not recommended for dry machining. | ||||||||||

| KNS® Slotting Cutter • Recommended Starting Speed [SFM] | ||||||||||

| 刀片材质 | KCPK30 | KCPK30 | KMF | |||||||

| Chip Thickness hex Inch | 最小值 | 最大值 | 最小值 | 最大值 | 最小值 | 最大值 | ||||

| 材料 分组 | 最大值 | 初始值 | 最小值 | 最大值 | 初始值 | 最小值 | 最大值 | 初始值 | 最小值 | |

| P | 1 | 855 | 755 | 705 | 1495 | 1295 | 1215 | 970 | 855 | 805 |

| 2 | 720 | 625 | 525 | 920 | 835 | 755 | 820 | 705 | 590 | |

| 3 | 655 | 560 | 460 | 835 | 755 | 675 | 755 | 640 | 525 | |

| 4 | 590 | 490 | 395 | 740 | 605 | 525 | 675 | 560 | 445 | |

| 5 | 490 | 445 | 395 | 625 | 560 | 490 | 560 | 510 | 445 | |

| 6 | 425 | 330 | 260 | 525 | 445 | 360 | 490 | 375 | 295 | |

| M | 1 | 690 | 560 | 445 | 675 | 605 | 510 | 640 | 560 | 510 |

| 2 | 560 | 490 | 360 | 605 | 525 | 460 | 575 | 490 | 410 | |

| 3 | 425 | 395 | 280 | 475 | 425 | 375 | 425 | 375 | 295 | |

| K | 1 | 885 | 720 | 560 | 970 | 870 | 785 | – | – | – |

| 2 | 755 | 625 | 525 | 770 | 690 | 625 | – | – | – | |

| 3 | 690 | 525 | 460 | 640 | 575 | 525 | – | – | – | |

| N | 1 | – | – | – | – | – | – | – | – | – |

| 2 | – | – | – | – | – | – | – | – | – | |

| 3 | – | – | – | – | – | – | – | – | – | |

| S | 1 | 100 | 80 | 65 | – | – | – | 130 | 115 | 100 |

| 2 | 100 | 80 | 65 | – | – | – | 130 | 115 | 100 | |

| 3 | 130 | 100 | 65 | – | – | – | 165 | 130 | 100 | |

| 4 | 180 | 130 | 80 | 165 | 150 | 115 | 180 | 165 | 115 | |

| H | 1 | – | – | – | – | – | – | – | – | – |

| Recommended Starting Speed are pointing to 90° Shoulder Milling . Starting Speed for Face and Copy Milling can be Increased by 20 %. As the average chip thickness increases, speed should be decreased. Material groups P, M, K and H show recommended starting speeds for dry machining. For wet machining, reduce speed by 20%. Material groups N and S show recommended starting speeds for wet machining. Not recommended for dry machining. | ||||||||||

High Performance Combination Tools

刀片选择指南

| KNS® Slotting Cutter • Insert Selection Guide | ||||||

| 材料 分组 | 轻切削 | 中等切削 | 重切削 | |||

| – | (锋利的槽型) | (强壮的槽型) | ||||

| – | 耐磨性 |  | 韧性 | |||

| – | 槽型 | 材质 | 槽型 | 材质 | 槽型 | 材质 |

| P1-P2 | .S..GP | KCU25 | .S..GP | KCU25 | .S..GP | KCPM40 |

| P3-P4 | .S..GP | KCU25 | .S..GP | KCU25 | .S..GP | KCPM40 |

| P5-P6 | .S..GP | KCU25 | .S..GP | KCU25 | .S..GP | KCPM40 |

| M1-M2 | .S..GP | KCU25 | .S..GP | KCPM40 | .S..GP | KCPM40 |

| M3 | .S..GP | KCU25 | .S..GP | KCPM40 | .S..GP | KCPM40 |

| K1-K2 | .S..GP | KCU25 | .S..GP | KCPK30 | .S..GP | KCPK30 |

| K3 | .S..GP | KCU25 | .S..GP | KCPK30 | .S..GP | KCPK30 |

| N1-N2 | – | – | .S..GP | KCU25 | – | – |

| N3 | – | – | .S..GP | KCU25 | – | – |

| S1-S2 | .S..GP | KCU25 | .S..GP | KCU25 | .S..GP | KCU25 |

| S3 | .S..GP | KCU25 | .S..GP | KCU25 | .S..GP | KCU25 |

| S4 | .S..GP | KCU25 | .S..GP | KCU25 | .S..GP | KCU25 |

| H1 | – | – | – | – | – | – |

I have read and accepted the Terms & Conditions of use