KSSR 刀片• XNXF-ENW

可转位刀片 • KSSR • SNXF 1204...

物料号4061407

公制样本编号XNXF1204ZNENW英制样本编号XNXF43ZNENW

- K 铸铁

Sending to {{cadTool}} in progress...

Downloaded file will be available after import in the {{cadTool}} tool library.

| 物料号 | 4061407 |

| 公制样本编号 | XNXF1204ZNENW |

| 英制样本编号 | XNXF43ZNENW |

| 材质 | KY3500 |

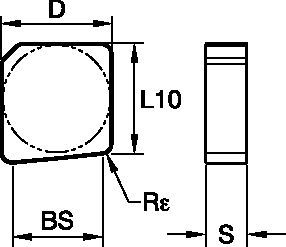

| [SSC] 刀片 IC 尺寸 | 12.7 mm |

| [SSC] 刀片 IC 尺寸 | 0.5 in |

| [S] 刀片厚度 | 4.76 mm |

| [S] 刀片厚度 | 0.1875 in |

| [L10] 刀片切削刃长度 | 12.7 mm |

| [L10] 刀片切削刃长度 | 0.5 in |

| [BS] 刀尖刃口长度 | 9.5 mm |

| [BS] 刀尖刃口长度 | 0.374 in |

| [Rε] 刀尖半径 | 1.2 mm |

| [Rε] 刀尖半径 | 0.047 in |

| 平均切屑厚度 [HM] | 0.203 mm |

| 平均切屑厚度 [HM] | 0.008 in |

| 每个刀片的切削刃 | 2 |

工件材料

- 铸铁

Grades

KY3500

材质结构:纯氮化硅材质

应用:最大限度地提高韧性。适用于在高进给率下对灰口铸铁进行粗加工,包括断续加工。

Features and benefits

- Milling insert for cast iron and compacted graphite iron (CGI) machining.

- Perfect solution for any production with transfer lines.

通过创建解决方案计算速度和进给

创建解决方案后,只需选择进给和速度图标,我们的系统将提供建议。您可以通过添加您的机床和参数来定制信息,或者使用滑块进行调整。

Feeds

推荐初始进给率 [mm]

| 刀片槽型 | 不同切宽(ae)百分比情况下,所建议的每齿进给量设定值(fz) | 刀片槽型 | ||||||||||||||

| 5% | 10% | 20% | 30% | 40–100% | ||||||||||||

| .E..LD | 0,18 | 0,46 | 0,82 | 0,13 | 0,33 | 0,59 | 0,10 | 0,25 | 0,44 | 0,09 | 0,22 | 0,39 | 0,08 | 0,20 | 0,35 | .E..LD |

| .S..GP | 0,20 | 0,50 | 0,90 | 0,14 | 0,36 | 0,65 | 0,11 | 0,27 | 0,48 | 0,09 | 0,24 | 0,42 | 0,09 | 0,22 | 0,39 | .S..GP |

| .S..HE | 0,18 | 0,51 | 0,95 | 0,13 | 0,37 | 0,69 | 0,10 | 0,28 | 0,51 | 0,09 | 0,24 | 0,45 | 0,08 | 0,22 | 0,41 | .S..HE |

| .A..SN | 0,24 | 0,59 | 0,95 | 0,17 | 0,43 | 0,69 | 0,13 | 0,32 | 0,51 | 0,11 | 0,28 | 0,45 | 0,10 | 0,26 | 0,41 | .A..SN |

| 轻切削 | 中等切削 | 重切削 |

Speeds

推荐初始速度 [m/min]

| 材料 分组 | KCK15 | KC514M | KC524M | KC907M | KC914M | KC917M | KY3500 | |||||||||||||||

| P | 1 | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – |

| 2 | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | |

| 3 | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | |

| 4 | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | |

| 5 | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | |

| 6 | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | |

| M | 1 | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – |

| 2 | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | |

| 3 | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | |

| K | 1 | 505 | 460 | 410 | 480 | 350 | 255 | 450 | 320 | 230 | 490 | 365 | 305 | 420 | 360 | 300 | 360 | 300 | 240 | 965 | 880 | 780 |

| 2 | 400 | 355 | 330 | 420 | 280 | 205 | 390 | 250 | 190 | 385 | 300 | 250 | 360 | 300 | 250 | 300 | 240 | 200 | 765 | 685 | 635 | |

| 3 | 335 | 300 | 275 | 335 | 260 | 200 | 300 | 225 | 160 | 300 | 250 | 200 | 300 | 250 | 200 | 240 | 200 | 160 | 645 | 570 | 525 | |

| N | 1–2 | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – |

| 3 | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | |

| S | 1 | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – |

| 2 | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | |

| 3 | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | |

| 4 | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | |

| H | 1 | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – |

High Performance Combination Tools

| 材料 分组 | 轻切削 | 中等切削 | 重切削 | |||

| (锋利的槽型) | – | (强壮的槽型) | ||||

| 耐磨性 |  | 韧性 | ||||

| 槽型 | 材质 | 槽型 | 材质 | 槽型 | 材质 | |

| P1 | – | – | – | – | – | – |

| P3 | – | – | – | – | – | – |

| P5 | – | – | – | – | – | – |

| M1 | – | – | – | – | – | – |

| M3 | – | – | – | – | – | – |

| K1 | .E..LD | KCK15 | .S..GP | KCK15 | .A..SN | KY3500 |

| K3 | .E..LD | KCK20 | .S..GP | KCK20 | .S..HE | KCK20 |

| N1 | – | – | – | – | – | – |

| N3 | – | – | – | – | – | – |

| S1 | – | – | – | – | – | – |

| S3 | – | – | – | – | – | – |

| S4 | – | – | – | – | – | – |

| H1 | – | – | – | – | – | – |

I have read and accepted the Terms & Conditions of use