- P 钢

- .caption

槽铣: 侧铣

槽铣: AE/AP尺寸侧铣

槽铣: T形

刀柄— 圆柱 Weldon

槽铣: AP尺寸T形

Sending to {{cadTool}} in progress...

Downloaded file will be available after import in the {{cadTool}} tool library.

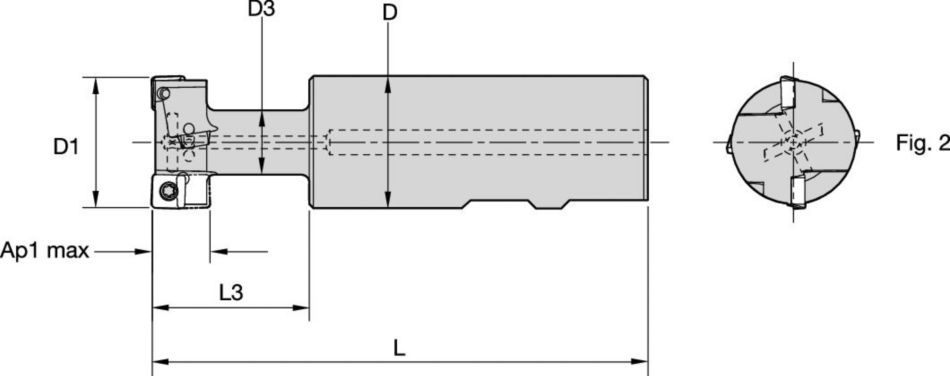

| 物料号 | 3577135 |

| 公制样本编号 | KTMS40S32SD12H |

| 英制样本编号 | KTMS40S32SD12H |

| [D1] 有效的切削直径 | 40 mm |

| [D1] 有效的切削直径 | 1.5748 in |

| [D]适配接头/刀柄/镗孔直径 | 32 mm |

| [D]适配接头/刀柄/镗孔直径 | 1.2598 in |

| [D3] 颈部直径 | 20.5 mm |

| [D3] 颈部直径 | 0.8071 in |

| [L] 总长 | 130 mm |

| [L] 总长 | 5.1181 in |

| [L3] 可用长度 | 50 mm |

| [L3] 可用长度 | 1.9685 in |

| [AP1MAX] 第一个最大切深 | 18 mm |

| [AP1MAX] 第一个最大切深 | 0.7087 in |

| 刀片数量 | 4 |

| [Z] 排屑槽数量 | 2 |

| Gage 刀片 | SDMT120408EGG |

| 重量(千克) | 0.66 |

工件材料

- 钢

- .caption

Uses and application

槽铣: 侧铣

槽铣: AE/AP尺寸侧铣

槽铣: T形

刀柄— 圆柱 Weldon

槽铣: AP尺寸T形

Features and benefits

- 准备带槽工件。

- 倒圆切削刃。

- 进给率在 0,10mm–0,15mm 范围;过低进给率会诱发刀振。

- 使用压缩空气吹出切屑。

- 总是使用新切削刃开始切削过程。

通过创建解决方案计算速度和进给

创建解决方案后,只需选择进给和速度图标,我们的系统将提供建议。您可以通过添加您的机床和参数来定制信息,或者使用滑块进行调整。

Feeds

推荐初始进给率 [mm]

| 刀片槽型 | 不同切宽(ae)百分比情况下,所建议的每齿进给量设定值(fz) | 刀片槽型 | ||||||||||||||

| 5% | 10% | 20% | 30% | 40–100% | ||||||||||||

| .06..EGG | 0,20 | 0,46 | 0,70 | 0,14 | 0,33 | 0,50 | 0,11 | 0,25 | 0,38 | 0,09 | 0,22 | 0,33 | 0,08 | 0,20 | 0,30 | .06..EGG |

| .08..EGG | 0,20 | 0,53 | 0,82 | 0,14 | 0,38 | 0,59 | 0,11 | 0,29 | 0,44 | 0,09 | 0,25 | 0,39 | 0,08 | 0,23 | 0,35 | .08..EGG |

| .12..EGG | 0,20 | 0,59 | 0,92 | 0,14 | 0,43 | 0,66 | 0,11 | 0,32 | 0,50 | 0,09 | 0,28 | 0,43 | 0,08 | 0,25 | 0,40 | .12..EGG |

| 轻切削 | 中等切削 | 重切削 |

Recommended Starting Feeds [IPT]

| 刀片槽型 | 不同切宽(ae)百分比情况下,所建议的每齿进给量设定值(fz) | 刀片槽型 | ||||||||||||||

| 5% | 10% | 20% | 30% | 40–100% | ||||||||||||

| .06..EGG | 0.20 | 0.46 | 0.70 | 0.14 | 0.33 | 0.50 | 0.11 | 0.25 | 0.38 | 0.09 | 0.22 | 0.33 | 0.08 | 0.20 | 0.30 | .06..EGG |

| .08..EGG | 0.20 | 0.53 | 0.82 | 0.14 | 0.38 | 0.59 | 0.11 | 0.29 | 0.44 | 0.09 | 0.25 | 0.39 | 0.08 | 0.23 | 0.35 | .08..EGG |

| .12..EGG | 0.20 | 0.59 | 0.92 | 0.14 | 0.43 | 0.66 | 0.11 | 0.32 | 0.50 | 0.09 | 0.28 | 0.43 | 0.08 | 0.25 | 0.40 | .12..EGG |

| 轻切削 | 中等切削 | 重切削 |

Speeds

推荐初始速度 [m/min]

| 材料 分组 | KC110M | KC505M | KC730M | KC735M | |||||||||

| P | 1 | – | – | – | – | – | – | 130 | 120 | 100 | 160 | 140 | 130 |

| 2 | – | – | – | – | – | – | 120 | 110 | 105 | 140 | 130 | 120 | |

| 3 | – | – | – | – | – | – | 110 | 100 | 90 | 130 | 120 | 110 | |

| 4 | – | – | – | – | – | – | 100 | 90 | 80 | 120 | 110 | 100 | |

| 5 | – | – | – | – | – | – | 90 | 80 | 75 | 110 | 90 | 80 | |

| 6 | – | – | – | – | – | – | 80 | 75 | 70 | 90 | 80 | 70 | |

| M | 1 | – | – | – | – | – | – | – | – | – | – | – | – |

| 2 | – | – | – | – | – | – | – | – | – | – | – | – | |

| 3 | – | – | – | – | – | – | – | – | – | – | – | – | |

| K | 1 | 130 | 120 | 115 | 150 | 140 | 120 | – | – | – | – | – | – |

| 2 | 115 | 105 | 100 | 140 | 120 | 105 | – | – | – | – | – | – | |

| 3 | 100 | 90 | 80 | 105 | 95 | 80 | – | – | – | – | – | – | |

| N | 1–2 | – | – | – | – | – | – | – | – | – | – | – | – |

| 3 | – | – | – | – | – | – | – | – | – | – | – | – | |

| S | 1 | – | – | – | – | – | – | – | – | – | – | – | – |

| 2 | – | – | – | – | – | – | – | – | – | – | – | – | |

| 3 | – | – | – | – | – | – | – | – | – | – | – | – | |

| 4 | – | – | – | – | – | – | – | – | – | – | – | – | |

| H | 1 | – | – | – | – | – | – | – | – | – | – | – | – |

Recommended Starting Speeds [SFM]

| 材料 分组 | KC110M | KC505M | KC730M | KC735M | |||||||||

| P | 1 | – | – | – | – | – | – | 420 | 400 | 330 | 490 | 460 | 430 |

| 2 | – | – | – | – | – | – | 400 | 360 | 340 | 460 | 430 | 390 | |

| 3 | – | – | – | – | – | – | 360 | 330 | 300 | 430 | 390 | 360 | |

| 4 | – | – | – | – | – | – | 330 | 300 | 270 | 390 | 360 | 330 | |

| 5 | – | – | – | – | – | – | 300 | 270 | 250 | 360 | 290 | 260 | |

| 6 | – | – | – | – | – | – | 270 | 250 | 235 | 290 | 260 | 230 | |

| M | 1 | – | – | – | – | – | – | – | – | – | – | – | – |

| 2 | – | – | – | – | – | – | – | – | – | – | – | – | |

| 3 | – | – | – | – | – | – | – | – | – | – | – | – | |

| K | 1 | 425 | 400 | 375 | 490 | 460 | 390 | – | – | – | – | – | – |

| 2 | 375 | 350 | 325 | 460 | 390 | 340 | – | – | – | – | – | – | |

| 3 | 330 | 295 | 260 | 340 | 310 | 260 | – | – | – | – | – | – | |

| N | 1–2 | – | – | – | – | – | – | – | – | – | – | – | – |

| 3 | – | – | – | – | – | – | – | – | – | – | – | – | |

| S | 1 | – | – | – | – | – | – | – | – | – | – | – | – |

| 2 | – | – | – | – | – | – | – | – | – | – | – | – | |

| 3 | – | – | – | – | – | – | – | – | – | – | – | – | |

| 4 | – | – | – | – | – | – | – | – | – | – | – | – | |

| H | 1 | – | – | – | – | – | – | – | – | – | – | – | – |

High Performance Combination Tools

刀片选择指南

| 材料 分组 | 轻切削 | 中等切削 | 重切削 | |||

| – | (锋利的槽型) | – | (强壮的槽型) | |||

| – | 耐磨性 |  | 韧性 | |||

| – | 槽型 | 材质 | 槽型 | 材质 | 槽型 | 材质 |

| P1–P2 | ..EGG | KC735M | ..EGG | KC735M | ..EGG | KC735M |

| P3–P4 | ..EGG | KC735M | ..EGG | KC735M | ..EGG | KC735M |

| P5–P6 | ..EGG | KC735M | ..EGG | KC735M | ..EGG | KC735M |

| M1–M2 | – | – | – | – | – | – |

| M3 | – | – | – | – | – | – |

| K1–K2 | ..EGG | KC505M | ..EGG | KC505M | ..EGG | KC505M |

| K3 | ..EGG | KC505M | ..EGG | KC505M | ..EGG | KC505M |

| N1–N2 | – | – | – | – | – | – |

| N3 | – | – | – | – | – | – |

| S1–S2 | – | – | – | – | – | – |

| S3 | – | – | – | – | – | – |

| S4 | – | – | – | – | – | – |

| H1 | – | – | – | – | – | – |

TechnicalInfo

| 材质类型 | 目录编号 | 切削条件vc (米/分钟) | n (RPM) | 每齿进给量(毫米) | |

| P | KTMS21S25SD06H | 120 | 1820 | 0,10 | |

| KTMS25S25SD06H | 120 | 1530 | 0,10 | ||

| KTMS32S32SD08H | 120 | 1190 | 0,10 | ||

| KTMS40S32SD12H | 120 | 960 | 0,10 | ||

| KTMS50S32SD12H | 120 | 760 | 0,10 | ||

| K | KTMS21S25SD06H | 150 | 2270 | 0,12 | |

| KTMS25S25SD06H | 150 | 1910 | 0,12 | ||

| KTMS32S32SD08H | 150 | 1490 | 0,12 | ||

| KTMS40S32SD12H | 150 | 1190 | 0,15 | ||

| KTMS50S32SD12H | 150 | 960 | 0,15 |

| 材质类型 | 目录编号 | 切削条件vc (米/分钟) | 每齿进给量(毫米) | Vs* | |

| P | KTMS21S25SD06H | 120 | 0,10 | 图一 | |

| KTMS25S25SD06H | 120 | 0,10 | 图一 | ||

| KTMS32S32SD08H | 100 | 0,10 | 图一 | ||

| KTMS40S32SD12H | 80 | 0,15 | 图二 | ||

| KTMS50S32SD12H | 因经常发生振动,建议不采用 | ||||

| K | KTMS21S25SD06H | 120 | 0,12 | 图一、图二、图三 | |

| KTMS25S25SD06H | 120 | 0,12 | 图一、图二、图三 | ||

| KTMS32S32SD08H | 120 | 0,12 | 图一、图二、图三 | ||

| KTMS40S32SD12H | 120 | 0,15 | 图二、图三 | ||

| KTMS50S32SD12H | 120 | 0,15 | 图三 | ||

I have read and accepted the Terms & Conditions of use