Product Similar To :

KenFeed™ KSWM • End Mill • Cylindrical Shank • Inch

Copy milling cutter for multiple materials.

Material Number2509391

ISO Catalog IDKF150WP0603C125L400ANSI Catalog IDKF150WP0603C125L400

- P Steel

- M Stainless Steel

- K Cast Iron

- S High-Temp Alloys

- H Hardened Materials

- .caption

Sending to {{cadTool}} in progress...

Downloaded file will be available after import in the {{cadTool}} tool library.

- Overview

- Application Data

- Downloads

- Compatible Parts Machine Side

- Compatible Parts Workpiece Side

- Spare Parts

- Reviews

- Q&A

| Material Number | 2509391 |

| ISO Catalog ID | KF150WP0603C125L400 |

| ANSI Catalog ID | KF150WP0603C125L400 |

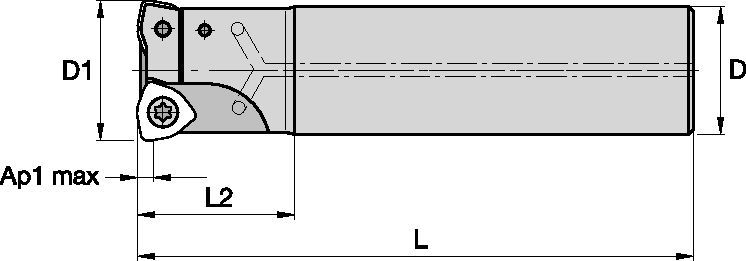

| [D1] Effective Cutting Diameter | 38.1 mm |

| [D1] Effective Cutting Diameter | 1.5 in |

| [D] Adapter / Shank / Bore Diameter | 31.75 mm |

| [D] Adapter / Shank / Bore Diameter | 1.25 in |

| [L] Overall Length | 177.8 mm |

| [L] Overall Length | 7 in |

| [L2] Head Length | 101.6 mm |

| [L2] Head Length | 4 in |

| [AP1MAX] 1st Maximum Cutting Depth | 1.5 mm |

| [AP1MAX] 1st Maximum Cutting Depth | 0.06 in |

| Number of Inserts | 3 |

| Maximum Ramping Angle | 5 |

| Gage Insert | WP..06X4. |

| Weight Pounds | 1.25 |

Workpiece Materials

- Steel

- Stainless Steel

- Cast Iron

- High-Temp Alloys

- Hardened Materials

- .caption

Features and benefits

- Suitable for a wide range of applications, including helical interpolation, ramping, slotting, face milling, and contour milling for roughing applications.

- Enables higher productivity.

- Single-sided solution. Ideal for long overhang applications.

- Feed rates up to .118 IPT for high metal removal rates, depending on workpiece material.

- Three cutting edges per insert.

Create Solution to calculate Feeds and Speeds

After creating a solution just choose the Feeds & Speeds icon and our system will provide recommendations. You can customize the information by adding your machine and specifications or make adjustments using the sliders.

Feeds

| Insert Geometry | Recommended Starting Feed per Tooth (Fz) in Relation to % of Radial Engagement (ae) | Insert Geometry | ||||||||||||||

| 10% | 20% | 30% | 40% | 50–100% | ||||||||||||

| .E..GP | 0,34 | 1,23 | 2,49 | 0,26 | 0,91 | 1,83 | 0,22 | 0,79 | 1,59 | 0,21 | 0,74 | 1,48 | 0,21 | 0,73 | 1,45 | .E..GP |

| .S..HN | 0,34 | 1,23 | 2,49 | 0,26 | 0,91 | 1,83 | 0,22 | 0,79 | 1,59 | 0,21 | 0,74 | 1,48 | 0,21 | 0,73 | 1,45 | .S..HN |

| Light | General | Heavy |

| Insert | Recommended Starting Feed per Tooth (Fz) in Relation to % of Radial Engagement (ae) | Insert | ||||||||||||||

| Geometry | 10% | 20% | 30% | 40% | 50–100% | Geometry | ||||||||||

| .E..GP | 0,39 | 1,25 | 2,03 | 0,29 | 0,93 | 1,5 | 0,26 | 0,81 | 1,3 | 0,24 | 0,76 | 1,21 | 0,23 | 0,74 | 1,19 | .E..GP |

| .S..HN | 0,39 | 1,25 | 2,03 | 0,29 | 0,93 | 1,5 | 0,26 | 0,81 | 1,3 | 0,24 | 0,76 | 1,21 | 0,23 | 0,74 | 1,19 | .S..HN |

| Insert | Recommended Starting Feed per Tooth (Fz) in Relation to % of Radial Engagement (ae) | Insert | ||||||||||||||

| Geometry | 10% | 20% | 30% | 40% | 50–100% | Geometry | ||||||||||

| .E..GP | 0,55 | 1,96 | 4,02 | 0,41 | 1,45 | 2,92 | 0,36 | 1,26 | 2,53 | 0,33 | 1,18 | 2,35 | 0,33 | 1,15 | 2,3 | .E..GP |

| .S..HN | 0,55 | 1,96 | 4,02 | 0,41 | 1,45 | 2,92 | 0,36 | 1,26 | 2,53 | 0,33 | 1,18 | 2,35 | 0,33 | 1,15 | 2,3 | .S..HN |

| Light | General | Heavy |

| Insert Geometry | Recommended Starting Feed per Tooth (Fz) in Relation to % of Radial Engagement (ae) | Insert Geometry | ||||||||||||||

| 10% | 20% | 30% | 40% | 50–100% | ||||||||||||

| .E..GP | .014 | .051 | .112 | .010 | .037 | .075 | .009 | .032 | .064 | .008 | .030 | .059 | .008 | .029 | .058 | .E..GP |

| .S..HN | .014 | .051 | .112 | .010 | .037 | .075 | .009 | .032 | .064 | .008 | .030 | .059 | .008 | .029 | .058 | .S..HN |

| Insert Geometry | Recommended Starting Feed per Tooth (Fz) in Relation to % of Radial Engagement (ae) | Insert Geometry | ||||||||||||||

| 10% | 20% | 30% | 40% | 50–100% | ||||||||||||

| .E..GP | .022 | .085 | .220 | .016 | .059 | .124 | .014 | .051 | .103 | .013 | .047 | .094 | .013 | .046 | .092 | .E..GP |

| .S..HN | .022 | .085 | .220 | .016 | .059 | .124 | .014 | .051 | .103 | .013 | .047 | .094 | .013 | .046 | .092 | .S..HN |

| Insert Geometry | Recommended Starting Feed per Tooth (Fz) in Relation to % of Radial Engagement (ae) | Insert Geometry | ||||||||||||||

| 10% | 20% | 30% | 40% | 50–100% | ||||||||||||

| .E..GP | .016 | .052 | .087 | .012 | .037 | .060 | .010 | .032 | .052 | .010 | .030 | .048 | .009 | .029 | .047 | .E..GP |

| .S..HN | .016 | .052 | .087 | .012 | .037 | .060 | .010 | .032 | .052 | .010 | .030 | .048 | .009 | .029 | .047 | .S..HN |

Speeds

Recommended Starting Speeds [m/min]

| Material Group | KC522M | KC525M | |||||

| P | 1 | 395 | 345 | 325 | 260 | 240 | 215 |

| 2 | 330 | 290 | 240 | 215 | 190 | 180 | |

| 3 | 305 | 255 | 215 | 190 | 180 | 170 | |

| 4 | 270 | 225 | 180 | 170 | 160 | 145 | |

| 5 | 225 | 200 | 180 | 180 | 170 | 160 | |

| 6 | 200 | 150 | 120 | 160 | 145 | 130 | |

| M | 1 | 245 | 215 | 200 | 180 | 170 | 160 |

| 2 | 225 | 190 | 160 | 160 | 145 | 130 | |

| 3 | 170 | 145 | 115 | 110 | 95 | 85 | |

| K | 1 | 275 | 250 | 220 | – | – | – |

| 2 | 215 | 195 | 180 | – | – | – | |

| 3 | 180 | 160 | 145 | – | – | – | |

| N | 1–2 | – | – | – | – | – | – |

| 3 | – | – | – | – | – | – | |

| S | 1 | 50 | 45 | 35 | 75 | 65 | 60 |

| 2 | 50 | 45 | 35 | 75 | 65 | 60 | |

| 3 | 60 | 50 | 35 | 60 | 55 | 50 | |

| 4 | 85 | 60 | 45 | 75 | 60 | 50 | |

| H | 1 | 145 | 110 | 85 | – | – | – |

Recommended Starting Speeds [SFM]

| Material Group | KC522M | KC525M | |||||

| P | 1 | 1300 | 1130 | 1060 | 860 | 790 | 710 |

| 2 | 1080 | 950 | 790 | 710 | 620 | 590 | |

| 3 | 1000 | 840 | 700 | 620 | 590 | 550 | |

| 4 | 890 | 730 | 590 | 550 | 520 | 470 | |

| 5 | 730 | 660 | 590 | 590 | 550 | 520 | |

| 6 | 650 | 490 | 400 | 520 | 470 | 430 | |

| M | 1 | 800 | 710 | 650 | 590 | 550 | 520 |

| 2 | 730 | 620 | 520 | 520 | 470 | 430 | |

| 3 | 550 | 480 | 370 | 360 | 310 | 280 | |

| K | 1 | – | – | – | – | – | – |

| 2 | – | – | – | – | – | – | |

| 3 | – | – | – | – | – | – | |

| N | 1–2 | – | – | – | – | – | – |

| 3 | – | – | – | – | – | – | |

| S | 1 | 160 | 140 | 110 | 240 | 220 | 190 |

| 2 | 160 | 140 | 110 | 240 | 220 | 190 | |

| 3 | 200 | 160 | 110 | 190 | 180 | 160 | |

| 4 | 280 | 200 | 140 | 240 | 190 | 160 | |

| H | 1 | 470 | 360 | 280 | – | – | – |

Insert Selection

Insert Selection Guide

| Material Group | Light | General | Heavy | |||

| (Light geometry) | (Strong geometry) | |||||

| wear |  | toughness | ||||

| Geometry | Grade | Geometry | Grade | Geometry | Grade | |

| P1–P2 | .E..GP | KC522M | .E..GP | KC522M | .S..HN | KC522M |

| P3–P4 | .E..GP | KC522M | .S..HN | KC522M | .S..HN | KC525M |

| P5–P6 | .E..GP | KC522M | .S..HN | KC522M | .S..HN | KC525M |

| M1–M2 | .E..GP | KC522M | .E..GP | KC525M | .S..HN | KC525M |

| M3 | .E..GP | KC522M | .E..GP | KC525M | .S..HN | KC525M |

| K1–K2 | – | – | – | – | – | – |

| K3 | – | – | – | – | – | – |

| N1–N2 | – | – | – | – | – | – |

| N3 | – | – | – | – | – | – |

| S1–S2 | .E..GP | KC522M | .E..GP | KC525M | – | – |

| S3 | .E..GP | KC522M | .E..GP | KC525M | – | – |

| S4 | .E..GP | KC522M | .E..GP | KC525M | – | – |

| H1 | – | – | .S..HN | KC522M | – | – |

I have read and accepted the Terms & Conditions of use