Welcome

Please confirm your preferences

Update Preferences

Product Suggestions

Product Family suggestions

Contact a Kennametal Expert

Customer Support

Find customer support centers around the globe.

Hi, User Name

Your Selected Account:

There is an issue with your account. Please contact customer support.

Sold To Account

Change Account

Ship To Account

Change Account

- Dashboard

- Manage Orders

- Manage Channels

- Address Book

-

Notifications

Mark all as read - Change Password

- My Profile

- Logout

Item(s)

successfully added to cart

View Cart

View Cart

Spring into action with the latest deals on your favorite tools.

Shop Now!

Contact a Kennametal Expert

Customer Support

Find customer support centers around the globe.

Item(s)

successfully added to cart

View Cart

View Cart

Editing Solution

Adding Solution

Solution Name: {{SolutionName}}- Products

- /

- ADCT-LD/LDJ

Product Similar To: [Product Name]

Sending to SolidCAM in progress...

Downloaded file will be available after import in the SolidCAM tool library.

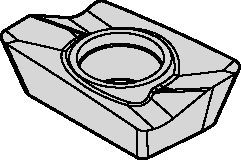

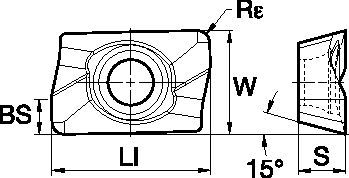

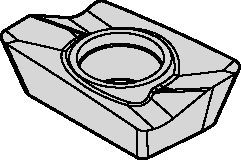

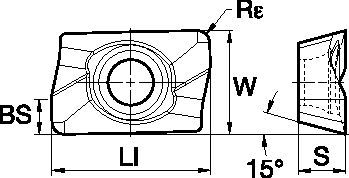

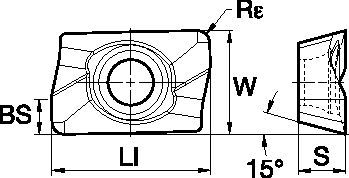

ADCT-LD/LDJ

Indexable Inserts

| Werkstoffgruppe | Leichte Bearbeitung | Allgemeine Anwendung | Schruppbearbeitung | |||

| – | (Leicht schneidende Geometrie) | – | (Stabile Geometrie) | |||

| – | Verschleiß- festigkeit |  <="" td=""> <="" td=""> | Zähigkeit | |||

| – | Geometrie | Sorte | Geometrie | Sorte | Geometrie | Sorte |

| P1–P2 | – | – | – | – | – | – |

| P3–P4 | – | – | – | – | – | – |

| P5–P6 | ADCT…E..LD | KCPM20 | ADCT…E..LD | KCPM20 | ADCT…E..LD | KCPK30 |

| M1–M2 | ADCT…E..LD | KC725M | ADCT…E..LD | KC725M | ADCT…E..LD | KC725M |

| M3 | ADCT…E..LD | KCPK30 | ADCT…E..LD | KCPK30 | ADCT…E..LD | KCPK30 |

| K1–K2 | – | – | – | – | – | – |

| K3 | – | – | – | – | – | – |

| N1–N2 | – | – | – | – | – | – |

| N3 | – | – | – | – | – | – |

| S1–S2 | ADCT…E..LD | KC725M | ADCT…E..LD | KC725M | ADCT…E..LD | KC725M |

| S3 | ADCT…E..LD | KC725M | ADCT…E..LD | KC725M | ADCT…E..LD | KC725M |

| S4 | ADCT…E..LD | KC725M | ADCT…E..LD | KC725M | ADCT…E..LD | KC725M |

| H1 | – | – | – | – | – | – |

Recommended Starting Feeds [mm]

| Schneidkörper- Geometrie | Empfohlener Start-Vorschub pro Zahn (fz) im Verhältnis zur radialen Schnitttiefe (ae) in % | Schneidkörper- Geometrie | ||||||||

| 10% | 20

|

|

||||||||

| ADCT…E..LD | 0,10 | 0,20 | 0,36 | 0,05 | 0,13 | 0,23 | 0,05 | 0,13 | 0,20 | ADCT…E..LD |

| Leichte Bearbeitung | Allgemeine Anwendung | Schruppbearbeitung |

Recommended Starting Feeds [IPT]

| Leichte Bearbeitung | Allgemeine Anwendung | Schruppbearbeitung |

| Schneidkörper- Geometrie | Empfohlener Start-Vorschub pro Zahn (fz) im Verhältnis zur radialen Schnitttiefe (ae) in % | Schneidkörper- Geometrie | ||||||||

| 10% | 20

|

|

||||||||

| ADCT…E..LD | .004 | .008 | .014 | .002 | .005 | .009 | .002 | .005 | .008 | ADCT…E..LD |

Recommended Starting Feeds [IPT]

| Schneidkörper- Geometrie | Empfohlener Start-Vorschub pro Zahn (fz) im Verhältnis zur radialen Schnitttiefe (ae) in % | Schneidkörper- Geometrie | ||

| 50

|

||||

| Alle Wendeschneidplatten | .004 | .010 | .016 | Alle Wendeschneidplatten |

| Leichte Bearbeitung | Allgemeine Anwendung | Schruppbearbeitung |

Recommended Starting Speeds [m/min]

| Werkstoffgruppe | KC522M | KC725M | KCPK30 | KCSM30 | |||||||||

| P | 1 | – | – | – | – | – | – | – | – | – | – | – | – |

| 2 | – | – | – | – | – | – | – | – | – | – | – | – | |

| 3 | – | – | – | – | – | – | – | – | – | – | – | – | |

| 4 | – | – | – | – | – | – | – | – | – | – | – | – | |

| 5 | 10 | 250 | 230 | 150 | 135 | 120 | 260 | 230 | 210 | – | – | – | |

| 6 | 190 | 170 | 145 | 90 | 80 | – | 160 | 135 | – | – | – | – | |

| M | 1 | 225 | 200 | 175 | 170 | 150 | 135 | 205 | 185 | 155 | – | – | – |

| 2 | 205 | 175 | 160 | 155 | 140 | 130 | 185 | 160 | 140 | – | – | – | |

| 3 | 160 | 145 | 125 | 115 | 105 | – | 145 | 130 | 115 | – | – | – | |

| K | 1 | – | – | – | – | – | – | – | – | – | – | – | – |

| 2 | – | – | – | – | – | – | – | – | – | – | – | – | |

| 3 | – | – | – | – | – | – | – | – | – | – | – | – | |

| N | 1–2 | – | – | – | – | – | – | – | – | – | – | – | – |

| 3 | – | – | – | – | – | – | – | – | – | – | – | – | |

| S | 1 | – | – | – | 35 | 30 | 25 | – | – | – | – | – | – |

| 2 | – | – | – | 30 | 30 | 25 | – | – | – | – | – | – | |

| 3 | – | – | – | 40 | 35 | 25 | – | – | – | – | – | – | |

| 4 | – | – | – | 50 | 45 | 30 | – | – | – | – | – | – | |

| H | 1 | – | – | – | – | – | – | – | – | – | – | – | – |

Recommended Starting Speeds [SFM]

| Werkstoffgruppe | KCPM20 | KC725M | KCPK30 | KCSM30 | |||||||||

| P | 1 | – | – | – | – | – | – | – | – | – | – | – | – |

| 2 | – | – | – | – | – | – | – | – | – | – | – | – | |

| 3 | – | – | – | – | – | – | – | – | – | – | – | – | |

| 4 | – | – | – | – | – | – | – | – | – | – | – | – | |

| 5 | 30 | 820 | 750 | 490 | 440 | 400 | 850 | 760 | 690 | – | – | – | |

| 6 | 630 | 550 | 475 | 300 | 260 | – | 520 | 450 | – | – | – | – | |

| M | 1 | 730 | 655 | 570 | 560 | 490 | 450 | 680 | 600 | 515 | – | – | – |

| 2 | 670 | 580 | 520 | 510 | 460 | 420 | 610 | 530 | 460 | – | – | – | |

| 3 | 530 | 475 | 410 | 380 | 340 | – | 475 | 430 | 380 | – | – | – | |

| K | 1 | – | – | – | – | – | – | – | – | – | – | – | – |

| 2 | – | – | – | – | – | – | – | – | – | – | – | – | |

| 3 | – | – | – | – | – | – | – | – | – | – | – | – | |

| N | 1–2 | – | – | – | – | – | – | – | – | – | – | – | – |

| 3 | – | – | – | – | – | – | – | – | – | – | – | – | |

| S | 1 | – | – | – | 120 | 100 | 80 | – | – | – | – | – | – |

| 2 | – | – | – | 100 | 100 | 80 | – | – | – | – | – | – | |

| 3 | – | – | – | 130 | 120 | 80 | – | – | – | – | – | – | |

| 4 | – | – | – | 170 | 150 | 100 | – | – | – | – | – | – | |

| H | 1 | – | – | – | – | – | – | – | – | – | – | – | – |

Recommended Starting Speeds [SFM]

| Werkstoffgruppe | KC522M | KC725M | KCPK30 | KCSM30 | |||||||||

| P | 1 | – | – | – | – | – | – | – | – | – | – | – | – |

| 2 | – | – | – | – | – | – | – | – | – | – | – | – | |

| 3 | – | – | – | – | – | – | – | – | – | – | – | – | |

| 4 | – | – | – | – | – | – | – | – | – | – | – | – | |

| 5 | – | – | – | – | – | – | – | – | – | – | – | – | |

| 6 | 650 | 490 | 400 | 520 | 400 | 310 | – | – | – | – | – | – | |

| M | 1 | 800 | 710 | 650 | 670 | 590 | 540 | – | – | – | – | – | – |

| 2 | 730 | 620 | 520 | 610 | 520 | 430 | – | – | – | – | – | – | |

| 3 | 550 | 480 | 370 | 460 | 400 | 310 | – | – | – | – | – | – | |

| K | 1 | – | – | – | – | – | – | – | – | – | – | – | – |

| 2 | – | – | – | – | – | – | – | – | – | – | – | – | |

| 3 | – | – | – | – | – | – | – | – | – | – | – | – | |

| N | 1–2 | – | – | – | – | – | – | – | – | – | – | – | – |

| 3 | – | – | – | – | – | – | – | – | – | – | – | – | |

| S | 1 | 160 | 140 | 110 | 120 | 100 | – | – | – | – | – | – | – |

| 2 | 160 | 140 | 110 | 100 | 100 | – | – | – | – | – | – | – | |

| 3 | 200 | 160 | 110 | 130 | 130 | – | – | – | – | – | – | – | |

| 4 | 280 | 200 | 140 | 170 | 150 | – | – | – | – | – | – | – | |

| H | 1 | – | – | – | – | – | – | – | – | – | – | – | – |