Welcome

Please confirm your preferences

Update Preferences

Product Suggestions

Product Family suggestions

Contact a Kennametal Expert

Customer Support

Find customer support centers around the globe.

Hi, User Name

Your Selected Account:

There is an issue with your account. Please contact customer support.

Sold To Account

Change Account

Ship To Account

Change Account

- Dashboard

- Manage Orders

- Manage Channels

- Address Book

-

Notifications

Mark all as read - Change Password

- My Profile

- Logout

Item(s)

successfully added to cart

View Cart

View Cart

Spring into action with the latest deals on your favorite tools.

Shop Now!

Contact a Kennametal Expert

Customer Support

Find customer support centers around the globe.

Item(s)

successfully added to cart

View Cart

View Cart

Editing Solution

Adding Solution

Solution Name: {{SolutionName}}- Products

- /

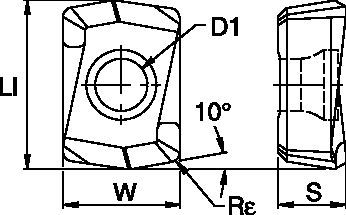

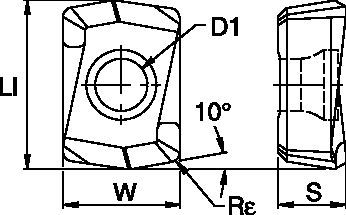

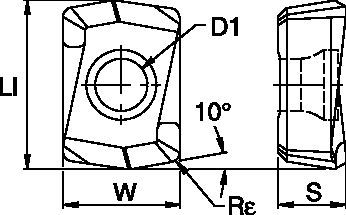

- Drill Fix side inserts • DFR-LD Geometry

Product Similar To: [Product Name]

Sending to SolidCAM in progress...

Downloaded file will be available after import in the SolidCAM tool library.

Drill Fix side inserts • DFR-LD Geometry

Drill Fix™ DFR Inserts • Application Data

Features and benefits

- Rectangular shaped Drill Fix™ DFR cutting inserts offer the highest feed rates for smaller sized KSEM PLUS™ systems on A1 heads. 2 indexable cutting edges.

- KC7225™ offers the highest level of process safety for non-ferrous materials, super alloys, and titanium. It features a TiAlN-PVD-coated fine-grain carbide.

- 2 indexable cutting edges.

Warnings • Drill Fix DFR

| WARNING During through-hole operations, a slug or disc is produced as the tool breaks through the workpiece. When the drill is stationary and the workpiece is rotating, this slug may be hurled from the chuck by centrifugal force. Provide adequate shielding to protect bystanders. |

Dimensions • DFR Whistle Notch (WD) Shank

| D | LS |

| 20 | 45 |

| 25 | 45 |

| 32 | 58 |

Dimensions • DFR Weldon Shank • DIN 1835-1 Form B

| D | LS |

| 20 | 50 |

Dimensions • DFR Flanged Shank

| D | LS |

| 20 | 50 |

| Material

|

Condition | Pocket Seat | Geometry | Grade | Cutting Speed

|

|||||

| Range

|

Recommended Feed Rate (fz) by Diameter | |||||||||

| Min | Starting Value | Max | Tool Diameter (in) | DFR04 .813"-1.00" | ||||||

| N | 1 | S | O | ST | KD1425 | 1300 | 2362 | 2760 | ipr | .002–.003 |

| I | ST | KD1425 | 1300 | 2362 | 2760 | ipr | .002–.003 | |||

| 2 | S | O | ST | KD1425 | 1209 | 2197 | 2567 | ipr | .005–.007 | |

| I | ST | KD1425 | 1209 | 2197 | 2567 | ipr | .005–.007 | |||

| 3 | S | O | ST | KD1425 | 1118 | 2032 | 2374 | ipr | .005–.007 | |

| I | ST | KD1425 | 1118 | 2032 | 2374 | ipr | .005–.007 | |||

| 4 | S | O | ST | KD1425 | 1560 | 2362 | 2760 | ipr | .005–.007 | |

| I | ST | KD1425 | 1560 | 2362 | 2760 | ipr | .005–.007 | |||

| Cutting Speed

|

||||||||||

| Range

|

Recommended Feed Rate (fz) by Diameter | |||||||||

| Material

|

Condition | Pocket Seat | Geometry | Grade | Min | Starting Value | Max | Tool Diameter (in) | DFR04 .813"-1.00" | |

| N | 1 | S | O | ST | KD1425 | 1300 | 2362 | 2760 | ipr | .002–.003 |

| 1 | S | I | ST | KD1425 | 1300 | 2362 | 2760 | ipr | .002–.003 | |

| 2 | S | O | ST | KD1425 | 1209 | 2197 | 2567 | ipr | .005–.007 | |

| 2 | S | I | ST | KD1425 | 1209 | 2197 | 2567 | ipr | .005–.007 | |

| 3 | S | O | ST | KD1425 | 1118 | 2032 | 2374 | ipr | .005–.007 | |

| 3 | S | I | ST | KD1425 | 1118 | 2032 | 2374 | ipr | .005–.007 | |

| 4 | S | O | ST | KD1425 | 1560 | 2362 | 2760 | ipr | .005–.007 | |

| 4 | S | I | ST | KD1425 | 1560 | 2362 | 2760 | ipr | .005–.007 | |

| Metric | ||||||||||||

| Material

|

Condition | Pocket Seat | Geometry | Grade | Cutting Speed

|

Recommended Feed Rate (fz) by Diameter | ||||||

| Range

|

||||||||||||

| Min | Starting Value | Max | Ø | DFR02... 12,50–16,00mm | DFR03... 16,50–20,00mm | DFR04... 20,50–24,00mm | ||||||

| P | 1 | S | O | MD | KCU25 | 310 | 325 | 360 | mm/r | 0,09–0,15 | 0,11–0,18 | 0,15–0,25 |

| I | MD | KC7140 | ||||||||||

| U | O | MD | KCU40 | 200 | 215 | 230 | mm/r | 0,09–0,15 | 0,11–0,18 | 0,15–0,25 | ||

| I | MD | KC7140 | ||||||||||

| I | O | MD | KC7140 | 130 | 135 | 150 | mm/r | 0,09–0,15 | 0,11–0,18 | 0,15–0,25 | ||

| I | MD | KC7140 | ||||||||||

| 2 | S | O | GD | KCPK10 | 310 | 325 | 360 | mm/r | 0,09–0,15 | 0,11–0,18 | 0,15–0,25 | |

| I | LD | KC7140 | ||||||||||

| U | O | GD | KCU40 | 200 | 215 | 230 | mm/r | 0,09–0,15 | 0,11–0,18 | 0,15–0,25 | ||

| I | LD | KC7140 | ||||||||||

| I | O | MD | KC7140 | 130 | 135 | 150 | mm/r | 0,09–0,15 | 0,11–0,18 | 0,15–0,25 | ||

| I | LD | KC7140 | ||||||||||

| 3 | S | O | GD | KCPK10 | 260 | 285 | 320 | mm/r | 0,09–0,15 | 0,11–0,18 | 0,15–0,25 | |

| I | LD | KC7140 | ||||||||||

| U | O | GD | KCU40 | 180 | 195 | 220 | mm/r | 0,09–0,15 | 0,11–0,18 | 0,15–0,25 | ||

| I | LD | KC7140 | ||||||||||

| I | O | GD | KC7140 | 110 | 120 | 140 | mm/r | 0,09–0,15 | 0,11–0,18 | 0,15–0,25 | ||

| I | LD | KC7140 | ||||||||||

| 4 | S | O | GD | KCU25 | 220 | 250 | 300 | mm/r | 0,09–0,15 | 0,11–0,18 | 0,15–0,25 | |

| I | LD | KC7140 | ||||||||||

| U | O | GD | KCU40 | 150 | 180 | 220 | mm/r | 0,09–0,15 | 0,11–0,18 | 0,15–0,25 | ||

| I | LD | KC7140 | ||||||||||

| I | O | GD | KC7140 | 90 | 110 | 140 | mm/r | 0,09–0,15 | 0,11–0,18 | 0,15–0,25 | ||

| I | LD | KC7140 | ||||||||||

| 5 | S | O | GD | KCU25 | 180 | 200 | 220 | mm/r | 0,07–0,13 | 0,09–0,15 | 0,11–0,18 | |

| I | LD | KC7140 | ||||||||||

| U | O | GD | KCU40 | 120 | 135 | 150 | mm/r | 0,07–0,13 | 0,09–0,15 | 0,11–0,18 | ||

| I | LD | KC7140 | ||||||||||

| I | O | GD | KC7140 | 70 | 85 | 100 | mm/r | 0,07–0,13 | 0,09–0,15 | 0,11–0,18 | ||

| I | LD | KC7140 | ||||||||||

| 6 | S | O | GD | KCU25 | 180 | 200 | 220 | mm/r | 0,07–0,13 | 0,09–0,15 | 0,11–0,18 | |

| I | LD | KC7140 | ||||||||||

| U | O | GD | KCU40 | 120 | 135 | 150 | mm/r | 0,07–0,13 | 0,09–0,15 | 0,11–0,18 | ||

| I | LD | KC7140 | ||||||||||

| I | O | GD | KC7140 | 70 | 85 | 100 | mm/r | 0,07–0,13 | 0,09–0,15 | 0,11–0,18 | ||

| I | LD | KC7140 | ||||||||||

| M | 1 | S | O | MD | KC7140 | 150 | 190 | 230 | mm/r | 0,07–0,13 | 0,08–0,16 | 0,10–0,18 |

| I | MD | KC7140 | ||||||||||

| U | O | MD | KC7140 | 100 | 130 | 160 | mm/r | 0,07–0,13 | 0,08–0,16 | 0,10–0,18 | ||

| I | MD | KC7140 | ||||||||||

| I | O | MD | KC7140 | 60 | 80 | 100 | mm/r | 0,07–0,13 | 0,08–0,16 | 0,10–0,18 | ||

| I | MD | KC7140 | ||||||||||

| 2 | S | O | MD | KC7140 | 150 | 180 | 210 | mm/r | 0,07–0,13 | 0,08–0,16 | 0,10–0,18 | |

| I | MD | KC7140 | ||||||||||

| U | O | MD | KC7140 | 100 | 130 | 160 | mm/r | 0,07–0,13 | 0,08–0,16 | 0,10–0,18 | ||

| I | MD | KC7140 | ||||||||||

| I | O | MD | KC7140 | 60 | 80 | 100 | mm/r | 0,07–0,13 | 0,08–0,16 | 0,10–0,18 | ||

| I | MD | KC7140 | ||||||||||

| 3 | S | O | MD | KC7140 | 100 | 130 | 160 | mm/r | 0,07–0,13 | 0,08–0,16 | 0,10–0,18 | |

| I | MD | KC7140 | ||||||||||

| U | O | MD | KC7140 | 80 | 110 | 140 | mm/r | 0,07–0,13 | 0,08–0,16 | 0,10–0,18 | ||

| I | MD | KC7140 | ||||||||||

| I | O | MD | KC7140 | 50 | 70 | 90 | mm/r | 0,07–0,13 | 0,08–0,16 | 0,10–0,18 | ||

| I | MD | KC7140 | ||||||||||

| Metric | ||||||||||||

| Cutting Speed

|

||||||||||||

| Range

|

Recommended Feed Rate (fz) by Diameter | |||||||||||

| Material

|

Condition | Pocket Seat | Geometry | Grade | Min | Starting Value | Max | Ø | DFR02... 12,50–16,00mm | DFR03... 16,50–20,00mm | DFR04... 20,50–24,00mm | |

| P | 1 | S | O | MD | KCU25 | 310 | 325 | 360 | mm/r | 0,09–0,15 | 0,11–0,18 | 0,15–0,25 |

| 1 | S | I | MD | KC7140 | 310 | 325 | 360 | mm/r | 0,09–0,15 | 0,11–0,18 | 0,15–0,25 | |

| 1 | U | O | MD | KCU40 | 200 | 215 | 230 | mm/r | 0,09–0,15 | 0,11–0,18 | 0,15–0,25 | |

| 1 | U | I | MD | KC7140 | 200 | 215 | 230 | mm/r | 0,09–0,15 | 0,11–0,18 | 0,15–0,25 | |

| 1 | I | O | MD | KC7140 | 130 | 135 | 150 | mm/r | 0,09–0,15 | 0,11–0,18 | 0,15–0,25 | |

| 1 | I | I | MD | KC7140 | 130 | 135 | 150 | mm/r | 0,09–0,15 | 0,11–0,18 | 0,15–0,25 | |

| 2 | S | O | GD | KCPK10 | 310 | 325 | 360 | mm/r | 0,09–0,15 | 0,11–0,18 | 0,15–0,25 | |

| 2 | S | I | LD | KC7140 | 310 | 325 | 360 | mm/r | 0,09–0,15 | 0,11–0,18 | 0,15–0,25 | |

| 2 | U | O | GD | KCU40 | 200 | 215 | 230 | mm/r | 0,09–0,15 | 0,11–0,18 | 0,15–0,25 | |

| 2 | U | I | LD | KC7140 | 200 | 215 | 230 | mm/r | 0,09–0,15 | 0,11–0,18 | 0,15–0,25 | |

| 2 | I | O | MD | KC7140 | 130 | 135 | 150 | mm/r | 0,09–0,15 | 0,11–0,18 | 0,15–0,25 | |

| 2 | I | I | LD | KC7140 | 130 | 135 | 150 | mm/r | 0,09–0,15 | 0,11–0,18 | 0,15–0,25 | |

| 3 | S | O | GD | KCPK10 | 260 | 285 | 320 | mm/r | 0,09–0,15 | 0,11–0,18 | 0,15–0,25 | |

| 3 | S | I | LD | KC7140 | 260 | 285 | 320 | mm/r | 0,09–0,15 | 0,11–0,18 | 0,15–0,25 | |

| 3 | U | O | GD | KCU40 | 180 | 195 | 220 | mm/r | 0,09–0,15 | 0,11–0,18 | 0,15–0,25 | |

| 3 | U | I | LD | KC7140 | 180 | 195 | 220 | mm/r | 0,09–0,15 | 0,11–0,18 | 0,15–0,25 | |

| 3 | I | O | GD | KC7140 | 110 | 120 | 140 | mm/r | 0,09–0,15 | 0,11–0,18 | 0,15–0,25 | |

| 3 | I | I | LD | KC7140 | 110 | 120 | 140 | mm/r | 0,09–0,15 | 0,11–0,18 | 0,15–0,25 | |

| 4 | S | O | GD | KCU25 | 220 | 250 | 300 | mm/r | 0,09–0,15 | 0,11–0,18 | 0,15–0,25 | |

| 4 | S | I | LD | KC7140 | 220 | 250 | 300 | mm/r | 0,09–0,15 | 0,11–0,18 | 0,15–0,25 | |

| 4 | U | O | GD | KCU40 | 150 | 180 | 220 | mm/r | 0,09–0,15 | 0,11–0,18 | 0,15–0,25 | |

| 4 | U | I | LD | KC7140 | 150 | 180 | 220 | mm/r | 0,09–0,15 | 0,11–0,18 | 0,15–0,25 | |

| 4 | I | O | GD | KC7140 | 90 | 110 | 140 | mm/r | 0,09–0,15 | 0,11–0,18 | 0,15–0,25 | |

| 4 | I | I | LD | KC7140 | 90 | 110 | 140 | mm/r | 0,09–0,15 | 0,11–0,18 | 0,15–0,25 | |

| 5 | S | O | GD | KCU25 | 180 | 200 | 220 | mm/r | 0,07–0,13 | 0,09–0,15 | 0,11–0,18 | |

| 5 | S | I | LD | KC7140 | 180 | 200 | 220 | mm/r | 0,07–0,13 | 0,09–0,15 | 0,11–0,18 | |

| 5 | U | O | GD | KCU40 | 120 | 135 | 150 | mm/r | 0,07–0,13 | 0,09–0,15 | 0,11–0,18 | |

| 5 | U | I | LD | KC7140 | 120 | 135 | 150 | mm/r | 0,07–0,13 | 0,09–0,15 | 0,11–0,18 | |

| 5 | I | O | GD | KC7140 | 70 | 85 | 100 | mm/r | 0,07–0,13 | 0,09–0,15 | 0,11–0,18 | |

| 5 | I | I | LD | KC7140 | 70 | 85 | 100 | mm/r | 0,07–0,13 | 0,09–0,15 | 0,11–0,18 | |

| 6 | S | O | GD | KCU25 | 180 | 200 | 220 | mm/r | 0,07–0,13 | 0,09–0,15 | 0,11–0,18 | |

| 6 | S | I | LD | KC7140 | 180 | 200 | 220 | mm/r | 0,07–0,13 | 0,09–0,15 | 0,11–0,18 | |

| 6 | U | O | GD | KCU40 | 120 | 135 | 150 | mm/r | 0,07–0,13 | 0,09–0,15 | 0,11–0,18 | |

| 6 | U | I | LD | KC7140 | 120 | 135 | 150 | mm/r | 0,07–0,13 | 0,09–0,15 | 0,11–0,18 | |

| 6 | I | O | GD | KC7140 | 70 | 85 | 100 | mm/r | 0,07–0,13 | 0,09–0,15 | 0,11–0,18 | |

| 6 | I | I | LD | KC7140 | 70 | 85 | 100 | mm/r | 0,07–0,13 | 0,09–0,15 | 0,11–0,18 | |

DFR™ • PCD • Metric

| Metric | ||||||||||

| Material

|

Condition | Pocket Seat | Geometry | Grade | Cutting Speed

|

Recommended Feed Rate (fz) by Diameter | ||||

| Range

|

||||||||||

| Min | Starting Value | Max | Ø | DFR04 20,50–24,00mm | ||||||

| N | 1 | S | O | ST | KD1425 | 396 | 720 | 841 | mm/r | 0,06–0,08 |

| I | ST | KD1425 | ||||||||

| 2 | S | O | ST | KD1425 | 369 | 670 | 782 | mm/r | 0,12–0,18 | |

| I | ST | KD1425 | ||||||||

| 3 | S | O | ST | KD1425 | 341 | 619 | 723 | mm/r | 0,12–0,18 | |

| I | ST | KD1425 | ||||||||

| 4 | S | O | ST | KD1425 | 475 | 720 | 841 | mm/r | 0,12–0,18 | |

| I | ST | KD1425 | ||||||||

| 5 | S | O | ST | KD1425 | 480 | 720 | 864 | mm/r | 0,06–0,08 | |

| I | ST | KD1425 | ||||||||

| Inch | ||||||||||

| Material

|

Condition | Pocket Seat | Geometry | Grade | Cutting Speed

|

Recommended Feed Rate (fz) by Diameter | ||||

| Range

|

||||||||||

| Min | Starting Value | Max | Ø | DFR04 .813–1.00" | ||||||

| N | 1 | S | O | ST | KD1425 | 1300 | 2362 | 2760 | IPR | .002–.003 |

| I | ST | KD1425 | ||||||||

| 2 | S | O | ST | KD1425 | 1209 | 2197 | 2567 | IPR | .005–.007 | |

| I | ST | KD1425 | ||||||||

| 3 | S | O | ST | KD1425 | 1118 | 2032 | 2374 | IPR | .005–.007 | |

| I | ST | KD1425 | ||||||||

| 4 | S | O | ST | KD1425 | 1560 | 2362 | 2760 | IPR | .005–.007 | |

| I | ST | KD1425 | ||||||||

| 5 | S | O | ST | KD1425 | 1575 | 2362 | 2834 | IPR | .002–.003 | |

| I | ST | KD1425 | ||||||||

| Metric | ||||||||||

| Cutting Speed

|

||||||||||

| Range

|

Recommended Feed Rate (fz) by Diameter | |||||||||

| Material

|

Condition | Pocket Seat | Geometry | Grade | Min | Starting Value | Max | Ø | DFR04 20,50–24,00 mm | |

| N | 1 | S | O | ST | KD1425 | 396 | 720 | 841 | mm/r | 0,06–0,08 |

| 1 | S | I | ST | KD1425 | 396 | 720 | 841 | mm/r | 0,06–0,08 | |

| 2 | S | O | ST | KD1425 | 369 | 670 | 782 | mm/r | 0,12–0,18 | |

| 2 | S | I | ST | KD1425 | 369 | 670 | 782 | mm/r | 0,12–0,18 | |

| 3 | S | O | ST | KD1425 | 341 | 619 | 723 | mm/r | 0,12–0,18 | |

| 3 | S | I | ST | KD1425 | 341 | 619 | 723 | mm/r | 0,12–0,18 | |

| 4 | S | O | ST | KD1425 | 475 | 720 | 841 | mm/r | 0,12–0,18 | |

| 4 | S | I | ST | KD1425 | 475 | 720 | 841 | mm/r | 0,12–0,18 | |

| 5 | S | O | ST | KD1425 | 480 | 720 | 864 | mm/r | 0,06–0,08 | |

| 5 | S | I | ST | KD1425 | 480 | 720 | 864 | mm/r | 0,06–0,08 | |

| Metric | ||||||||||

| Material

|

Condition | Pocket Seat | Geometry | Grade | Cutting Speed

|

Recommended Feed Rate (fz) by Diameter | ||||

| Range

|

||||||||||

| min | Starting Value | max | Ø | DFR04 20,50–24,00 | ||||||

| N | 1 | S | O | ST | KD1425 | 396 | 720 | 841 | mm/r | 0,06–0,08 |

| I | ST | KD1425 | 396 | 720 | 841 | mm/r | 0,06–0,08 | |||

| 2 | S | O | ST | KD1425 | 369 | 670 | 782 | mm/r | 0,12–0,18 | |

| I | ST | KD1425 | 369 | 670 | 782 | mm/r | 0,12–0,18 | |||

| 3 | S | O | ST | KD1425 | 341 | 619 | 723 | mm/r | 0,12–0,18 | |

| I | ST | KD1425 | 341 | 619 | 723 | mm/r | 0,12–0,18 | |||

| 4 | S | O | ST | KD1425 | 475 | 720 | 841 | mm/r | 0,12–0,18 | |

| I | ST | KD1425 | 475 | 720 | 841 | mm/r | 0,12–0,18 | |||

| 5 | S | O | ST | KD1425 | 480 | 720 | 864 | mm/r | 0,06–0,08 | |

| I | ST | KD1425 | 480 | 720 | 864 | mm/r | 0,06–0,08 | |||

| Inch | ||||||||||

| Material

|

Condition | Pocket Seat | Geometry | Grade | Cutting Speed

|

Recommended Feed Rate (fz) by Diameter | ||||

| Range

|

||||||||||

| min | Starting Value | max | Ø | DFR04 .813"–1.00" | ||||||

| N | 1 | S | O | ST | KD1425 | 1300 | 2362 | 2760 | IPR | .002–.003 |

| I | ST | KD1425 | 1300 | 2362 | 2760 | IPR | .002–.003 | |||

| 2 | S | O | ST | KD1425 | 1209 | 2197 | 2567 | IPR | .005–.007 | |

| I | ST | KD1425 | 1209 | 2197 | 2567 | IPR | .005–.007 | |||

| 3 | S | O | ST | KD1425 | 1118 | 2032 | 2374 | IPR | .005–.007 | |

| I | ST | KD1425 | 1118 | 2032 | 2374 | IPR | .005–.007 | |||

| 4 | S | O | ST | KD1425 | 1560 | 2362 | 2760 | IPR | .005–.007 | |

| I | ST | KD1425 | 1560 | 2362 | 2760 | IPR | .005–.007 | |||

| 5 | S | O | ST | KD1425 | 1575 | 2362 | 2834 | IPR | .002–.003 | |

| I | ST | KD1425 | 1575 | 2362 | 2834 | IPR | .002–.003 | |||