Welcome

Please confirm your preferences

Update Preferences

Product Suggestions

Product Family suggestions

Contact a Kennametal Expert

Customer Support

Find customer support centers around the globe.

Hi, User Name

Your Selected Account:

There is an issue with your account. Please contact customer support.

Sold To Account

Change Account

Ship To Account

Change Account

- Dashboard

- Manage Orders

- Manage Channels

- Address Book

-

Notifications

Mark all as read - Change Password

- My Profile

- Logout

Item(s)

successfully added to cart

View Cart

View Cart

Contact a Kennametal Expert

Customer Support

Find customer support centers around the globe.

Item(s)

successfully added to cart

View Cart

View Cart

Editing Solution

Adding Solution

Solution Name: {{SolutionName}}- Products

- /

- Metalworking Tools

- /

- Milling

- /

- Indexable Milling

- /

- Face Mills

- /

- Dodeka Series

- /

- Dodeka™

- /

- Dodeka™ Inserts

- /

- Dodeka™ • Carbide Insert • HNGJ-LD • Light Machining

Product Similar To: [Product Name]

Sending to SolidCAM in progress...

Downloaded file will be available after import in the SolidCAM tool library.

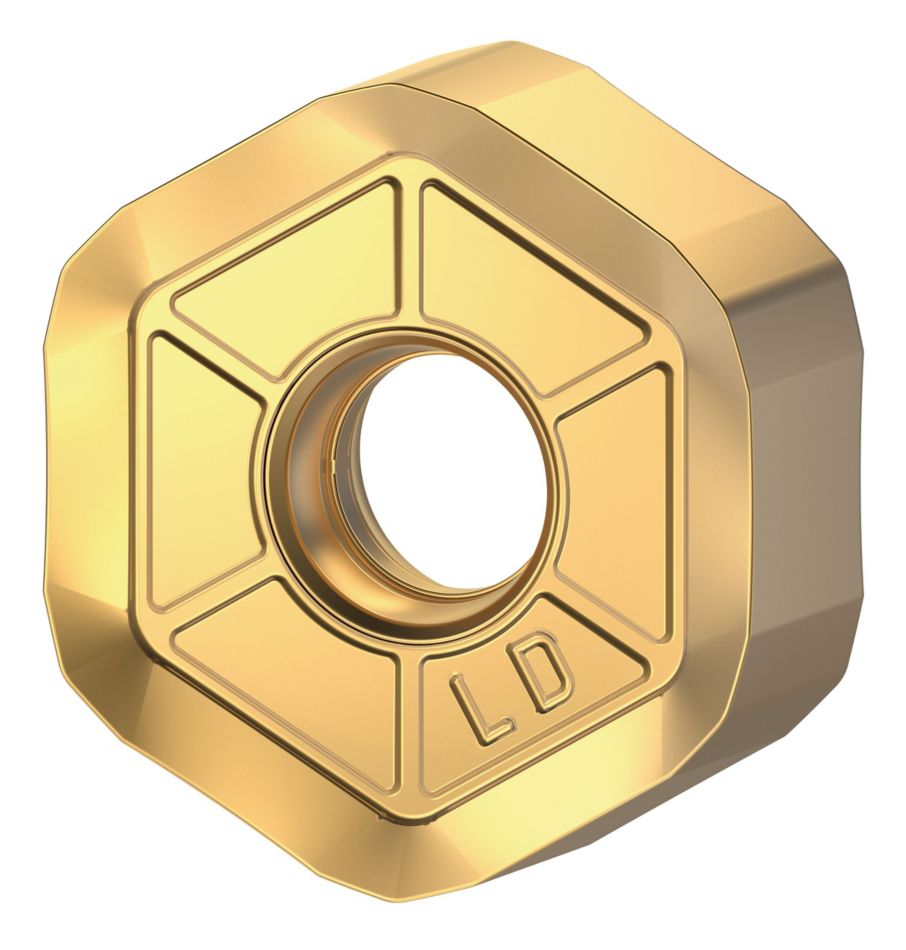

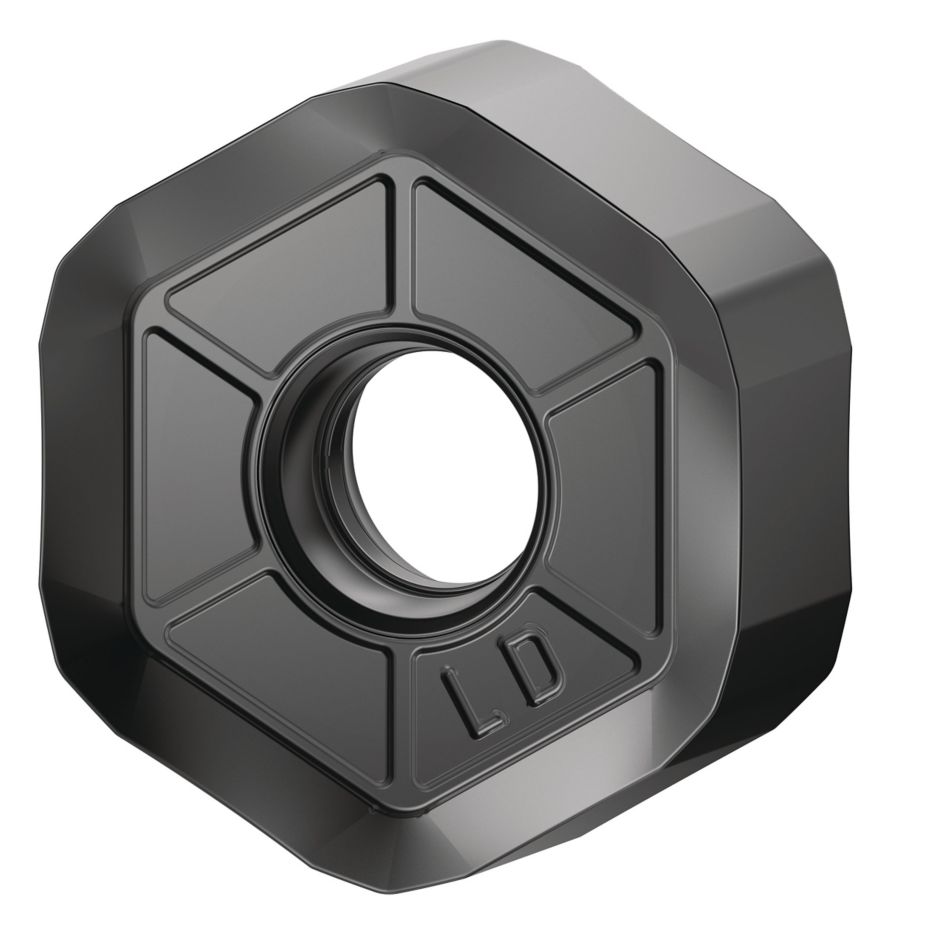

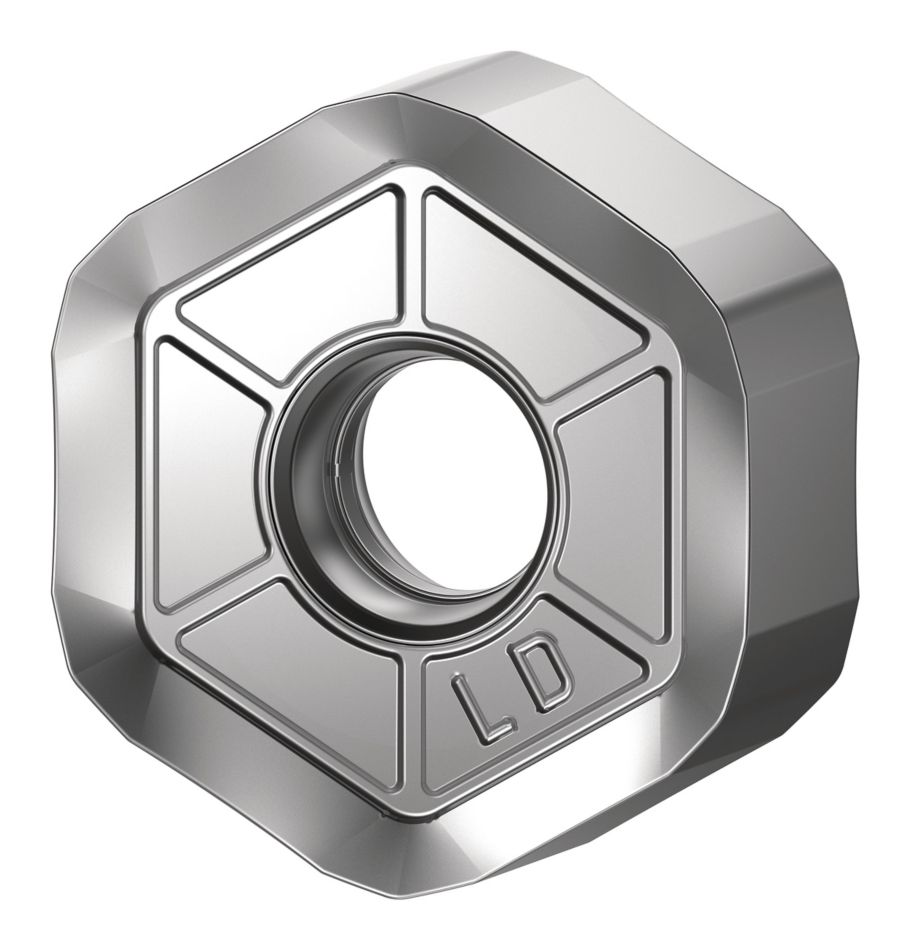

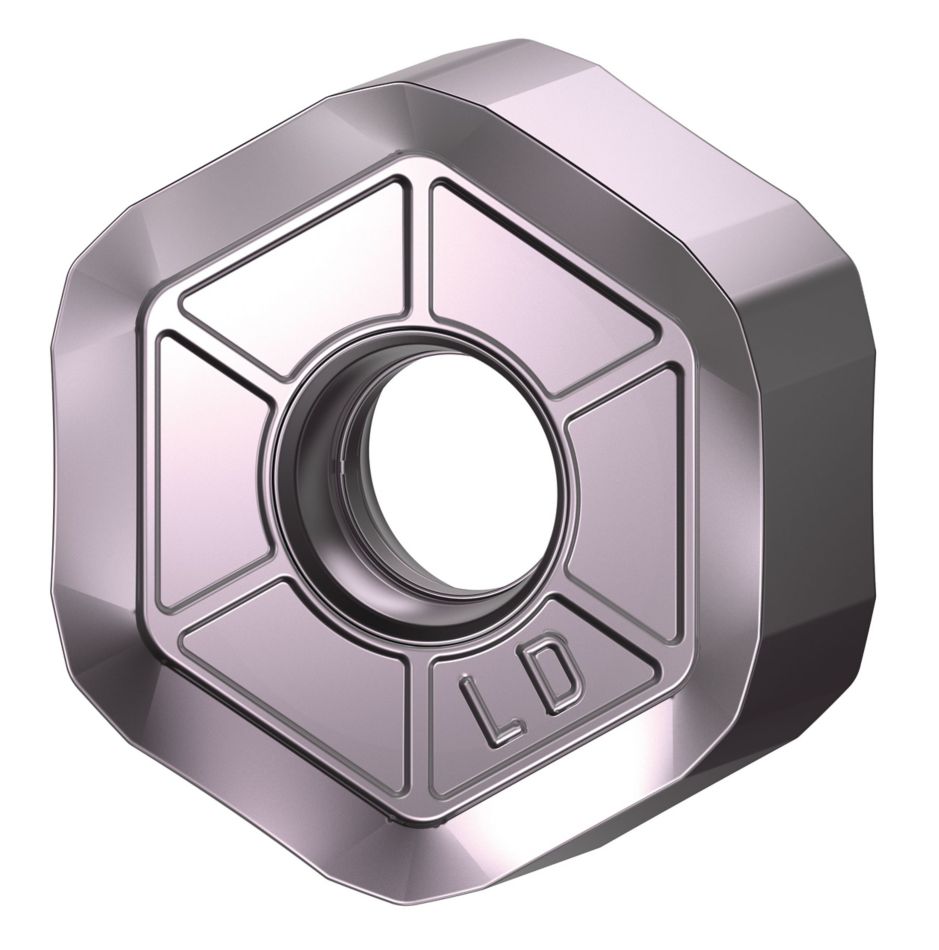

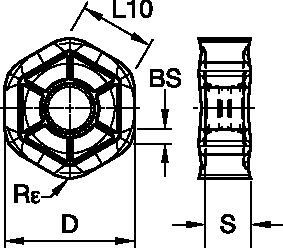

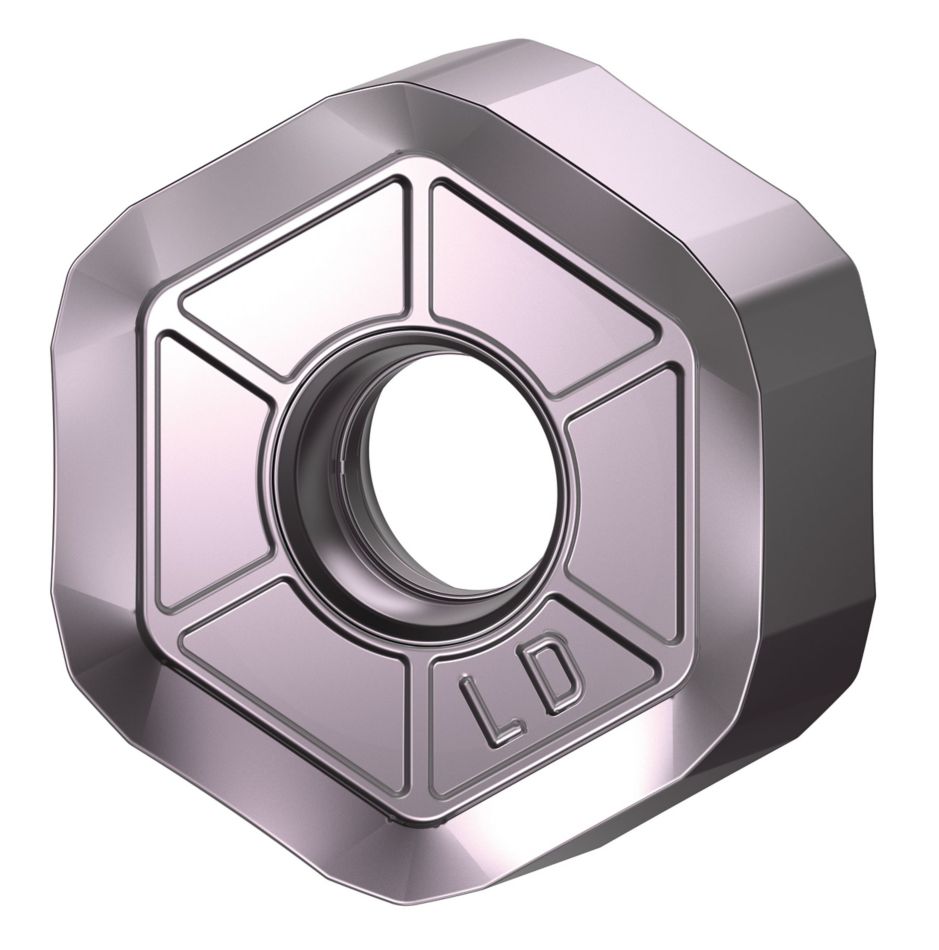

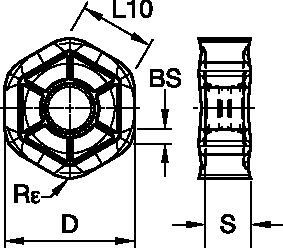

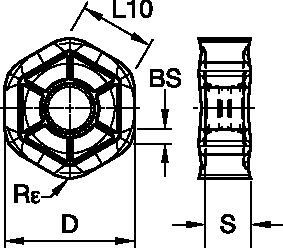

Dodeka™ • Carbide Insert • HNGJ-LD • Light Machining

Face Mills

Features and benefits

- Precision ground insert with polished rake face.

- Insert for Dodeka 15/45 cutters (metric).

- Insert for Dodeka 75/45 cutters (inch).

| Material

|

Light

|

Medium

|

Heavy

|

High Speed

|

||||||||

| P1–P2 | .E..LD | KC522M | .E..LP | KC522M | .E..GP | KC522M | .S..GD | KC522M | .S..HD | KC725M |

|

|

| P3–P4 | .E..LD | KCPK30 | .E..LP | KCPM40 | .E..GP | KCPM40 | .S..GD | KCPK30 | .S..HD | KCPK30 |

|

|

| P5–P6 | .E..LD | KC725M | .E..LP | KCPM40 | .E..GP | KCPM40 | .S..GD | KCPM40 | .S..HD | KCPM40 |

|

|

| M1–M2 | .E..LD | KC522M | .E..LM | KC522M | .E..GM | KCSM40 | .S..GD | KCSM40 | .S..HD | KCSM40 |

|

|

| M3 | .E..LD | KCSM40 | .E..LM | KCSM40 | .E..GM | KCSM40 | .S..GD | KCSM40 | .S..HD | KCPM40 |

|

|

| K1–K2 | .E..LD | KCK20B | .E..LP | KCK20B | .E..LP | KCK20B | .S..GD | KCK15 | .S..HD | KCK15 | .ANSN | KY3500 |

| K3 | .E..LD | KCK20B | .E..LP | KCKP30 | .E..LP | KCPK30 | .S..GD | KCK20B | .S..HD | KCPK30 |

|

|

| N1–N2 | .F..LDJ | KC410M | .F..LDJ | KC410M | .F..LDJ | KC410M | .F..LDJ | KC410M | .F..LDJ | KC410M |

|

|

| N3 | .F..LDJ | KC410M | .F..LDJ | KC410M | .F..LDJ | KC410M | .F..LDJ | KC410M | .F..LDJ | KC410M |

|

|

| S1–S2 | .E..LD | KC725M | .E..LM | KCSM40 | .E..GM | KCSM40 | .S..GD | KC725M | .S..HD | KC725M |

|

|

| S3 | .E..LD | KCSM40 | .E..LM | KCSM40 | .E..GM | KCSM40 | .S..GD | KCSM40 | .S..HD | KCSM40 |

|

|

| S4 | .E..LD | KCSM40 | .E..LM | KCSM40 | .E..GM | KCSM40 | .S..GD | KCSM40 | .S..HD | KCSM40 |

|

|

| H1 |

|

|

|

|

.E..GP | KC522M |

|

|

|

|

|

|