Welcome

Please confirm your preferences

Update Preferences

Product Suggestions

Product Family suggestions

Contact a Kennametal Expert

Customer Support

Find customer support centers around the globe.

Hi, User Name

Your Selected Account:

There is an issue with your account. Please contact customer support.

Sold To Account

Change Account

Ship To Account

Change Account

- Dashboard

- Manage Orders

- Manage Channels

- Address Book

-

Notifications

Mark all as read - Change Password

- My Profile

- Logout

Item(s)

successfully added to cart

View Cart

View Cart

Contact a Kennametal Expert

Customer Support

Find customer support centers around the globe.

Item(s)

successfully added to cart

View Cart

View Cart

Editing Solution

Adding Solution

Solution Name: {{SolutionName}}- Products

- /

- Metalworking Tools

- /

- Milling

- /

- Solid Carbide End Milling

- /

- High-Performance Solid Carbide End Mills

- /

- KOR6™ DT • High-Performance Solid Carbide End Mills

- /

- KOR6™ DT • Radiused • 6 Flutes • 5 x D • Plain Shank • Metric

Product Similar To: [Product Name]

Sending to SolidCAM in progress...

Downloaded file will be available after import in the SolidCAM tool library.

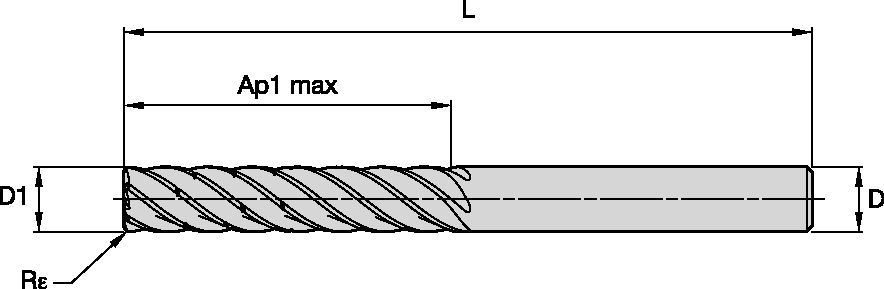

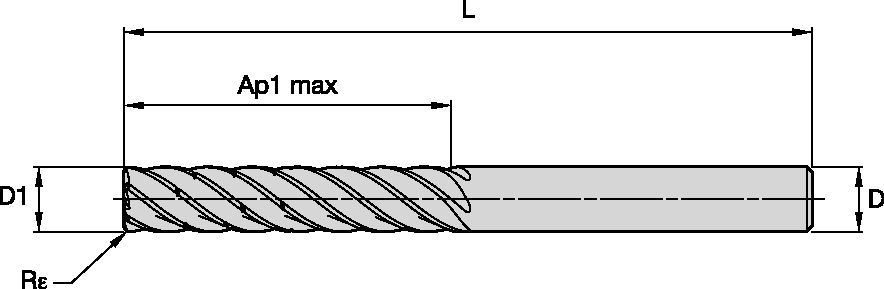

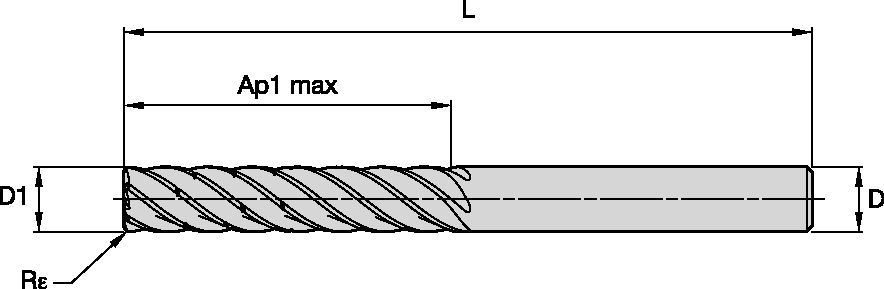

KOR6™ DT • Radiused • 6 Flutes • 5 x D • Plain Shank • Metric

KOR6™ DT Solid Carbide End Mill for Dynamic Milling of Titanium

Features and benefits

- Designed for trochoidal milling with low radial engagement and full length of cut.

- With chip splitters for ideal chip evacuation.

- Proprietary flute form reduces vibrations and improves tool life.

- Helix angle tailored to minimize vibration and optimize tool life.

- Front end geometry designed for maximum tool life in helical and ramping operations.

- Centre cutting for plunging and ramping operations.

Uses and application

Trochoidal Milling

Ramping: Blank

Side Milling/Shoulder Milling: Square End

Tool Dimensions: Flute Configuration: 6

Shank - Cylindrical Plain

Helix Angle: 38°

Corner Style: Corner Radius

KOR6™ DT • 6 Flutes • 5 x D • Adjustment factor table for feed calculation • Metric

| Ae/D1 | 0,50% | 1,00% | 1,50% | 2,00% | 4,00% | 5,00% | |

| Speed factor | Kv | 2,00 | 1,97 | 1,93 | 1,38 | 1,03 | 1,00 |

| Feed factor | KFz | 1,27 | 1,18 | 1,14 | 1,09 | 1,05 | 1,00 |

KOR6™ DT • 6 Flutes • 5 x D • Application Data • Metric

<="" td=""> <="" td=""> |  <="" td="" /> <="" td="" /> |

||||||||||||

| Side Milling (A) | KCSM15 | Recommended feed per tooth (fz = mm/th) for side milling (A). | |||||||||||

| A | Cutting Speed

|

D1

|

|||||||||||

| Material

|

ap | ae | min | max | mm | 8,0 | 10,0 | 12,0 | 16,0 | 20,0 | 25,0 | ||

| P | 0 | 5 x D | 0.05 x D | 150 | – | 540 | fz | 0,097 | 0,117 | 0,134 | 0,163 | 0,185 | 0,200 |

| 1 | 5 x D | 0.05 x D | 150 | – | 540 | fz | 0,097 | 0,117 | 0,134 | 0,163 | 0,185 | 0,200 | |

| 2 | 5 x D | 0.05 x D | 140 | – | 513 | fz | 0,097 | 0,117 | 0,134 | 0,163 | 0,185 | 0,200 | |

| 3 | 5 x D | 0.05 x D | 120 | – | 432 | fz | 0,081 | 0,098 | 0,114 | 0,141 | 0,164 | 0,184 | |

| 4 | 5 x D | 0.05 x D | 90 | – | 405 | fz | 0,073 | 0,087 | 0,101 | 0,124 | 0,143 | 0,158 | |

| 5 | 5 x D | 0.05 x D | 60 | – | 270 | fz | 0,065 | 0,078 | 0,091 | 0,113 | 0,131 | 0,147 | |

| 6 | 5 x D | 0.05 x D | 50 | – | 202.5 | fz | 0,054 | 0,065 | 0,075 | 0,092 | 0,105 | 0,115 | |

| M | 1 | 5 x D | 0.05 x D | 90 | – | 310.5 | fz | 0,081 | 0,098 | 0,114 | 0,141 | 0,164 | 0,184 |

| 2 | 5 x D | 0.05 x D | 60 | – | 216 | fz | 0,065 | 0,078 | 0,091 | 0,113 | 0,131 | 0,147 | |

| 3 | 5 x D | 0.05 x D | 60 | – | 189 | fz | 0,054 | 0,065 | 0,075 | 0,092 | 0,105 | 0,115 | |

| K | 1 | 5 x D | 0.05 x D | 120 | – | 405 | fz | 0,097 | 0,117 | 0,134 | 0,163 | 0,185 | 0,200 |

| 2 | 5 x D | 0.05 x D | 110 | – | 378 | fz | 0,081 | 0,098 | 0,114 | 0,141 | 0,164 | 0,184 | |

| 3 | 5 x D | 0.05 x D | 110 | – | 351 | fz | 0,065 | 0,078 | 0,091 | 0,113 | 0,131 | 0,147 | |

| S | 1 | 5 x D | 0.05 x D | 50 | – | 243 | fz | 0,081 | 0,098 | 0,114 | 0,141 | 0,164 | 0,184 |

| 2 | 5 x D | 0.05 x D | 25 | – | 108 | fz | 0,043 | 0,052 | 0,060 | 0,075 | 0,087 | 0,099 | |

| 3 | 5 x D | 0.05 x D | 25 | – | 108 | fz | 0,043 | 0,052 | 0,060 | 0,075 | 0,087 | 0,099 | |

| 4 | 5 x D | 0.05 x D | 50 | – | 162 | fz | 0,060 | 0,072 | 0,084 | 0,104 | 0,120 | 0,135 | |

| H | 1 | 5 x D | 0.05 x D | 80 | – | 378 | fz | 0,073 | 0,087 | 0,101 | 0,124 | 0,143 | 0,158 |

| 2 | 5 x D | 0.05 x D | 70 | – | 324 | fz | 0,054 | 0,065 | 0,075 | 0,092 | 0,105 | 0,115 | |

-

KOR™6DT

-

KOR™ Series End Mills: Solid End Mills for Dynamic Milling