Welcome

Please confirm your preferences

Update Preferences

Product Suggestions

Product Family suggestions

Contact a Kennametal Expert

Customer Support

Find customer support centers around the globe.

Hi, User Name

Your Selected Account:

There is an issue with your account. Please contact customer support.

Sold To Account

Change Account

Ship To Account

Change Account

- Dashboard

- Manage Orders

- Manage Channels

- Address Book

-

Notifications

Mark all as read - Change Password

- My Profile

- Logout

Item(s)

successfully added to cart

View Cart

View Cart

Contact a Kennametal Expert

Customer Support

Find customer support centers around the globe.

Item(s)

successfully added to cart

View Cart

View Cart

Editing Solution

Adding Solution

Solution Name: {{SolutionName}}- Products

- /

- KSSM™ Slotting Cutters • 1/2" IC Inserts • KSSS™ Shell Mount • .709–.813" Adjustment Range • Inch

Product Similar To: [Product Name]

Sending to SolidCAM in progress...

Downloaded file will be available after import in the SolidCAM tool library.

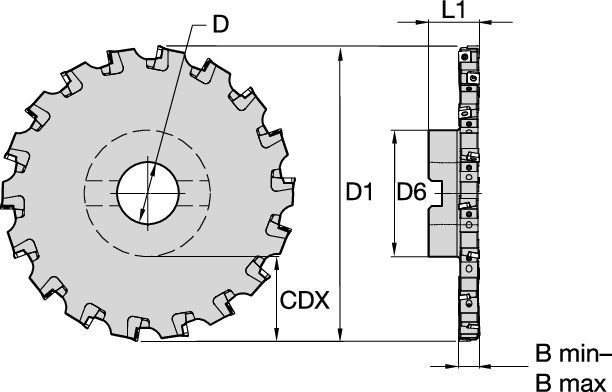

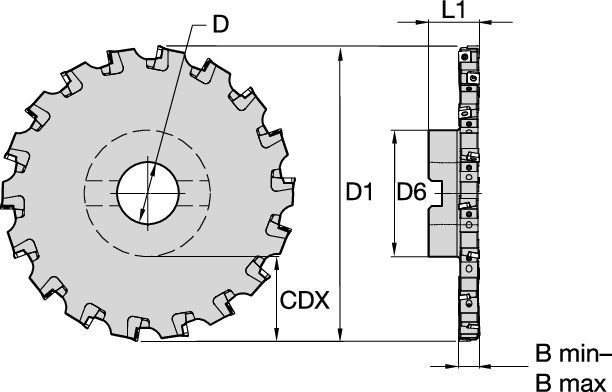

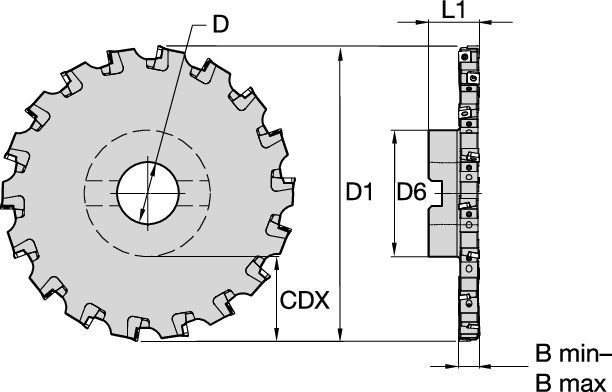

KSSM™ Slotting Cutters • 1/2" IC Inserts • KSSS™ Shell Mount • .709–.813" Adjustment Range • Inch

KSSS™ • Shell Mount

Features and benefits

- Rapid adjustment and setting via unique cam adjustment mechanism.

- Large selection of insert geometries and grades to cut most workpiece materials.

- Four insert cutting edges.

- Large selection of insert radii.

- Wiper insert facets for superior surface finishes.

Uses and application

Slotting: Side

| KSSM™ 12 Slotting • Recommended Starting Feeds [IPT] | |||||||||||||||

| Insert Geometry | Recommended Starting Feed per Tooth (Fz) in Relation to % of Radial Engagement (ae) | ||||||||||||||

| 5% | 10% | 20% | 30% | 40–100% | |||||||||||

| L | M | H | L | M | H | L | M | H | L | M | H | L | M | H | |

| .F..LE | 0.005 | 0.017 | 0.030 | 0.003 | 0.012 | 0.021 | 0.003 | 0.009 | 0.016 | 0.002 | 0.008 | 0.014 | 0.002 | 0.007 | 0.013 |

| .E..LD2 | 0.005 | 0.018 | 0.032 | 0.004 | 0.013 | 0.023 | 0.003 | 0.010 | 0.017 | 0.002 | 0.009 | 0.015 | 0.002 | 0.008 | 0.014 |

| .E..GB2 | 0.009 | 0.021 | 0.035 | 0.007 | 0.015 | 0.025 | 0.005 | 0.011 | 0.019 | 0.004 | 0.010 | 0.016 | 0.004 | 0.009 | 0.015 |

| .S..GB2 | 0.009 | 0.023 | 0.037 | 0.007 | 0.017 | 0.027 | 0.005 | 0.013 | 0.020 | 0.004 | 0.011 | 0.017 | 0.004 | 0.010 | 0.016 |

| L = Light Machining; M = Medium Machining; H = Heavy Machining NOTE: Use "Light Machining" values as starting feed rate. | |||||||||||||||

| Light

|

General

|

Heavy

|

| KSSM™ 12 Slotting • Recommended Starting Speed [SFM] | |||||||||||||||||||||||||||||||

| Grade | KCPM20 | KC410M | KC522M | KC725M | KCK15 | KCPK30 | KCK20B | KCPM40 | KCSM40 | KTPK20 | |||||||||||||||||||||

| Chip Thickness hex mm | Min | Max | Min | Max | Min | Max | Min | Max | Min | Max | Min | Max | Min | Max | Min | Max | Min | Max | Min | Max | |||||||||||

| Material Group | Max | Start | Min | Max | Start | Min | Max | Start | Min | Max | Start | Min | Max | Start | Min | Max | Start | Min | Max | Start | Min | Max | Start | Min | Max | Start | Min | Max | Start | Min | |

| P | 1 | 550 | 485 | 450 | – | – | – | 1085 | 935 | 885 | 855 | 755 | 705 | – | – | – | 1495 | 1295 | 1215 | – | – | – | 970 | 855 | 805 | 1150 | 1050 | 985 | 1200 | 985 | 835 |

| 2 | 340 | 310 | 275 | – | – | – | 900 | 785 | 655 | 720 | 625 | 525 | – | – | – | 920 | 835 | 755 | – | – | – | 820 | 705 | 590 | 985 | 885 | 720 | 870 | 720 | 655 | |

| 3 | 310 | 275 | 255 | – | – | – | 835 | 705 | 575 | 655 | 560 | 460 | – | – | – | 835 | 755 | 675 | – | – | – | 755 | 640 | 525 | 920 | 785 | 640 | 805 | 655 | 590 | |

| 4 | 230 | 215 | 190 | – | – | – | 740 | 605 | 490 | 590 | 490 | 395 | – | – | – | 740 | 605 | 525 | – | – | – | 675 | 560 | 445 | 785 | 675 | 540 | 690 | 590 | 525 | |

| 5 | 275 | 250 | 230 | – | – | – | 605 | 560 | 490 | 490 | 445 | 395 | – | – | – | 625 | 560 | 490 | – | – | – | 560 | 510 | 445 | 655 | 590 | 525 | 605 | 560 | 490 | |

| 6 | 190 | 170 | 145 | – | – | – | 540 | 410 | 330 | 425 | 330 | 260 | – | – | – | 525 | 445 | 360 | – | – | – | 490 | 375 | 295 | 590 | 460 | 330 | 525 | 425 | 330 | |

| M | 1 | 225 | 200 | 175 | – | – | – | 675 | 590 | 540 | 560 | 490 | 445 | – | – | – | 675 | 605 | 510 | – | – | – | 640 | 560 | 510 | 855 | 690 | 605 | 785 | 640 | 540 |

| 2 | 205 | 175 | 160 | – | – | – | 605 | 525 | 425 | 510 | 425 | 360 | – | – | – | 605 | 525 | 460 | – | – | – | 575 | 490 | 410 | 770 | 590 | 475 | 705 | 605 | 490 | |

| 3 | 160 | 145 | 125 | – | – | – | 460 | 395 | 310 | 375 | 330 | 260 | – | – | – | 475 | 425 | 375 | – | – | – | 425 | 375 | 295 | 575 | 475 | 360 | 525 | 445 | 360 | |

| K | 1 | 360 | 325 | 295 | – | – | – | 755 | 675 | 605 | – | – | – | 1380 | 1265 | 1115 | 970 | 870 | 785 | 1180 | 950 | 805 | – | – | – | – | – | – | 755 | 640 | 525 |

| 2 | 285 | 255 | 235 | – | – | – | 590 | 525 | 490 | – | – | – | 1100 | 970 | 900 | 770 | 690 | 625 | 920 | 755 | 640 | – | – | – | – | – | – | 605 | 490 | 425 | |

| 3 | 240 | 215 | 200 | – | – | – | 490 | 445 | 395 | – | – | – | 920 | 820 | 755 | 640 | 575 | 525 | 690 | 575 | 460 | – | – | – | – | – | – | 490 | 425 | 345 | |

| N | 1 | – | – | – | 3985 | 3545 | 3265 | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – |

| 2 | – | – | – | 3545 | 3265 | 3000 | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | |

| 3 | – | – | – | 3545 | 3265 | 3000 | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | |

| S | 1 | – | – | – | – | – | – | 130 | 115 | 80 | 115 | 100 | 80 | – | – | – | – | – | – | – | – | – | 130 | 115 | 100 | 165 | 130 | 80 | – | – | – |

| 2 | – | – | – | – | – | – | 130 | 115 | 80 | 115 | 100 | 80 | – | – | – | – | – | – | – | – | – | 130 | 115 | 100 | 180 | 130 | 80 | – | – | – | |

| 3 | – | – | – | – | – | – | 165 | 130 | 80 | 150 | 115 | 80 | – | – | – | – | – | – | – | – | – | 165 | 130 | 100 | 215 | 150 | 100 | – | – | – | |

| 4 | – | – | – | – | – | – | 165 | 150 | 115 | 165 | 150 | 100 | – | – | – | 165 | 150 | 115 | – | – | – | 180 | 165 | 115 | 245 | 195 | 130 | – | – | – | |

| H | 1 | – | – | – | – | – | – | 395 | 295 | 230 | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – |

| Recommended Starting Speed are pointing to 90° Shoulder Milling . Starting Speed for Face and Copy Milling can be Increased by 20 %. As the average chip thickness increases, speed should be decreased. Material groups P, M, K and H show recommended starting speeds for dry machining. For wet machining, reduce speed by 20%. Material groups N and S show recommended starting speeds for wet machining. Not recommended for dry machining. | |||||||||||||||||||||||||||||||