Product Similar To :

KCRA - RN • Face Mills • Inch

Face Mills

Material Number5704051

ISO Catalog IDKCRA300RN4311S100L200ANSI Catalog IDKCRA300RN4311S100L200

- P Steel

- S High-Temp Alloys

- .caption

Milling - Pressurized Air Coolant

Face Milling

Side Milling/Shoulder Milling: Ball Nose

Milling - Side and Face

Sending to {{cadTool}} in progress...

Downloaded file will be available after import in the {{cadTool}} tool library.

- Overview

- Application Data

- Downloads

- Compatible Parts Machine Side

- Compatible Parts Workpiece Side

- Spare Parts

- Reviews

- Q&A

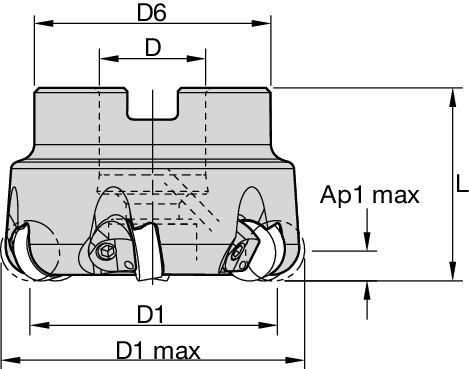

| Material Number | 5704051 |

| ISO Catalog ID | KCRA300RN4311S100L200 |

| ANSI Catalog ID | KCRA300RN4311S100L200 |

| [D1MAX] Maximum Cutting Diameter | 76.2 mm |

| [D1MAX] Maximum Cutting Diameter | 3 in |

| [D1] Effective Cutting Diameter | 63.5 mm |

| [D1] Effective Cutting Diameter | 2.5 in |

| [D] Adapter / Shank / Bore Diameter | 25.4 mm |

| [D] Adapter / Shank / Bore Diameter | 1 in |

| [D6] Hub Diameter | 69.85 mm |

| [D6] Hub Diameter | 2.75 in |

| [L] Overall Length | 50.8 mm |

| [L] Overall Length | 2 in |

| [AP1MAX] 1st Maximum Cutting Depth | 6.35 mm |

| [AP1MAX] 1st Maximum Cutting Depth | 0.25 in |

| Number of Inserts | 11 |

| Max RPM | 18100 |

| Weight Pounds | 2.82 |

| Gage Insert | RNGN120400 |

Workpiece Materials

- Steel

- High-Temp Alloys

- .caption

Uses and application

Milling - Pressurized Air Coolant

Face Milling

Side Milling/Shoulder Milling: Ball Nose

Milling - Side and Face

Features and benefits

- First choice for face and shoulder milling high-temperature alloys.

- Higher material removal rate due to fine pitch cutters.

- Secure clamping system, improving process stability and reliability.

- Effective air coolant feature. Better chip flow and increased insert tool life.

Create Solution to calculate Feeds and Speeds

After creating a solution just choose the Feeds & Speeds icon and our system will provide recommendations. You can customize the information by adding your machine and specifications or make adjustments using the sliders.

Feeds

| Insert Geometry | Recommended Starting Feed per Tooth (Fz) in Relation to % of Radial Engagement (ae) | Insert Geometry | ||||||||||||||

| 10% | 20% | 30% | 40% | 50–100% | ||||||||||||

| .EGN | .003 | .004 | .005 | .003 | .003 | .003 | .002 | .002 | .003 | .002 | .002 | .003 | .002 | .002 | .003 | .EGN |

| .TGN | .005 | .007 | .008 | .004 | .005 | .006 | .003 | .004 | .005 | .003 | .004 | .005 | .003 | .004 | .005 | .TGN |

| Light | General | Heavy |

| Insert Geometry | Recommended Starting Feed per Tooth (Fz) in Relation to % of Radial Engagement (ae) | Insert Geometry | ||||||||||||||

| 10% | 20% | 30% | 40% | 50–100% | ||||||||||||

| .EGN | .004 | .004 | .005 | .003 | .003 | .004 | .003 | .003 | .003 | .002 | .003 | .003 | .002 | .003 | .003 | .EGN |

| .TGN | .006 | .008 | .009 | .004 | .006 | .007 | .004 | .005 | .006 | .004 | .005 | .005 | .003 | .005 | .005 | .TGN |

| Insert Geometry | Recommended Starting Feed per Tooth (Fz) in Relation to % of Radial Engagement (ae) | Insert Geometry | ||||||||||||||

| 10% | 20% | 30% | 40% | 50–100% | ||||||||||||

| .EGN | .007 | .008 | .009 | .005 | .006 | .007 | .005 | .005 | .006 | .004 | .005 | .006 | .004 | .005 | .006 | .EGN |

| .TGN | .010 | .014 | .016 | .008 | .010 | .012 | .007 | .009 | .010 | .006 | .008 | .010 | .006 | .008 | .010 | .TGN |

| Insert Geometry | Recommended Starting Feed per Tooth (Fz) in Relation to % of Radial Engagement (ae) | Insert Geometry | ||||||||||||||

| 10% | 20% | 30% | 40% | 50–100% | ||||||||||||

| .EGN | .005 | .006 | .007 | .004 | .004 | .005 | .003 | .004 | .004 | .003 | .003 | .004 | .003 | .003 | .004 | .EGN |

| .TGN | .008 | .010 | .012 | .006 | .008 | .009 | .005 | .007 | .008 | .005 | .006 | .007 | .005 | .006 | .007 | .TGN |

Speeds

Recommended Starting Speeds [SFM]

| Material Group | KYS30 | KYSP30 | |||||

| P | 1 | – | – | – | – | – | – |

| 2 | – | – | – | – | – | – | |

| 3 | – | – | – | – | – | – | |

| 4 | – | – | – | – | – | – | |

| 5 | – | – | – | – | – | – | |

| 6 | – | – | – | – | – | – | |

| M | 1 | – | – | – | – | – | – |

| 2 | – | – | – | – | – | – | |

| 3 | – | – | – | – | – | – | |

| K | 1 | – | – | – | – | – | – |

| 2 | – | – | – | – | – | – | |

| 3 | – | – | – | – | – | – | |

| N | 1 | – | – | – | – | – | – |

| 2 | – | – | – | – | – | – | |

| S | 1 | 2640 | 2160 | 1680 | 2640 | 2160 | 1680 |

| 2 | 2640 | 2160 | 1680 | 2640 | 2160 | 1680 | |

| 3 | 3840 | 3120 | 2400 | 3840 | 3120 | 2400 | |

| 4 | – | – | – | – | – | – | |

| H | 1 | – | – | – | – | – | – |

| 2 | – | – | – | – | – | – | |

| 3 | – | – | – | – | – | – | |

Insert Selection

| Material Group | Light | General | Heavy | |||

| – | (Light geometry) | – | (Strong geometry) | |||

| – | wear |  | toughness | |||

| – | Geometry | Grade | Geometry | Grade | Geometry | Grade |

| P1–P2 | – | – | – | – | – | – |

| P3–P4 | – | – | – | – | – | – |

| P5–P6 | – | – | – | – | – | – |

| M1–M2 | – | – | – | – | – | – |

| M3 | – | – | – | – | – | – |

| K1–K2 | – | – | – | – | – | – |

| K3 | – | – | – | – | – | – |

| N1–N2 | – | – | – | – | – | – |

| N3 | – | – | – | – | – | – |

| S1–S2 | .EGN | KYS30 | .EGN | KYS30 | .TGN | KYS30 |

| S3 | .EGN | KYSP30 | .EGN | KYSP30 | .TGN | KYSP30 |

| S4 | – | – | – | – | – | – |

| H1 | – | – | – | – | – | – |

TechnicalInfo

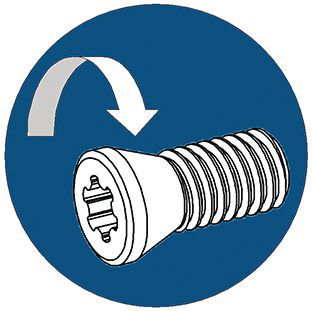

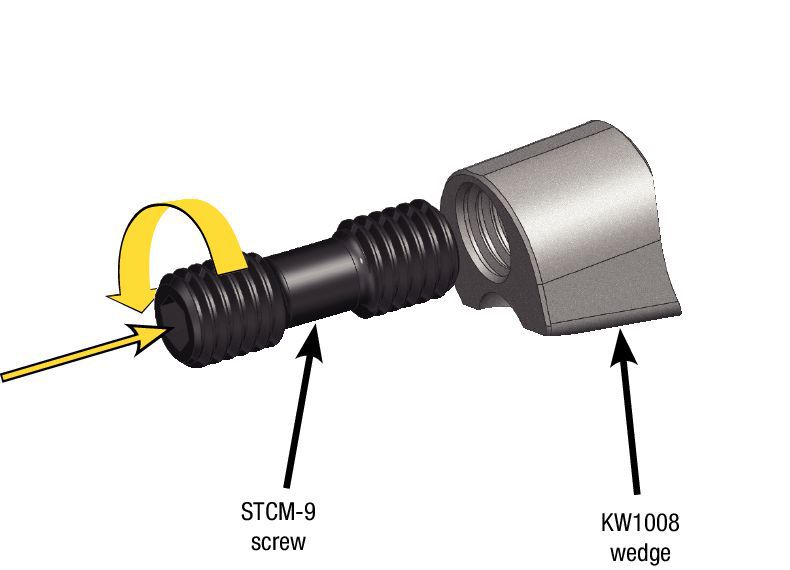

Insert Assembly Guide

| Safety Notes | |||||

|  |  |  |  |  |

| Read all instructions carefully | Wear eye protection | Inspect and tighten fasteners regularly | Warning: Cutting hazard | Warning: Hot surfaces | Do not exceed maximum RPM |

| Assembly Instructions | |

| Assemble STCM-25 screw to KW1008 wedge, 1 to 1 1/2 turns. | Wedge/screw assembly. |

|  |

| Install wedge/screw assembly into cutter body, but maintain assembly gap for installing insert. | Slide insert, RNGN12... into pocket and torque wedge/insert assembly to 3,5 Nm (31 in/lbs). Repeat for each pocket. |

|  |

I have read and accepted the Terms & Conditions of use