Product Similar To:

Face Mills • BB KSRM • RCGX64... • Inch

Face Mills

Material Number5971591

ISO Catalog IDKSRM200C09RC20BBHPANSI Catalog IDKSRM200C09RC20BBHP

- P Steel

- M Stainless Steel

- S High-Temp Alloys

- .caption

Face Milling

Helical Milling

Ramping: Blank

Slotting: Ball Nose

Side Milling/Shoulder Milling: Ball Nose

3D Profiling

Milling - Through Coolant

Milling - Side and Face

Pocketing

Sending to {{cadTool}} in progress...

Downloaded file will be available after import in the {{cadTool}} tool library.

- Overview

- Application Data

- Downloads

- Compatible Parts Machine Side

- Compatible Parts Workpiece Side

- Spare Parts

- Reviews

- Q&A

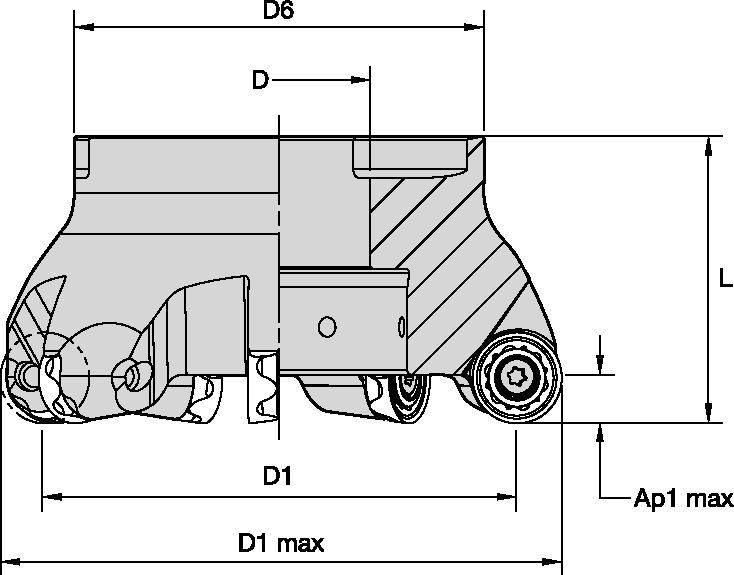

| Material Number | 5971591 |

| ISO Catalog ID | KSRM200C09RC20BBHP |

| ANSI Catalog ID | KSRM200C09RC20BBHP |

| [D1MAX] Maximum Cutting Diameter | 200 mm |

| [D1MAX] Maximum Cutting Diameter | 7.874 in |

| [D1] Effective Cutting Diameter | 180 mm |

| [D1] Effective Cutting Diameter | 7.09 in |

| [D] Adapter / Shank / Bore Diameter | 60 mm |

| [D] Adapter / Shank / Bore Diameter | 2.363 in |

| [D6] Hub Diameter | 150 mm |

| [D6] Hub Diameter | 5.906 in |

| [L] Overall Length | 63 mm |

| [L] Overall Length | 2.48 in |

| [AP1MAX] 1st Maximum Cutting Depth | 10 mm |

| [AP1MAX] 1st Maximum Cutting Depth | 0.394 in |

| Number of Inserts | 9 |

| Max RPM | 10700 |

| Gage Insert | RCGX2006M0__ |

| Weight Pounds | 15.69 |

Workpiece Materials

- Steel

- Stainless Steel

- High-Temp Alloys

- .caption

Uses and application

Face Milling

Helical Milling

Ramping: Blank

Slotting: Ball Nose

Side Milling/Shoulder Milling: Ball Nose

3D Profiling

Milling - Through Coolant

Milling - Side and Face

Pocketing

Features and benefits

- Use PCT technology, coolant through the insert.

- Engineered to provide the maximum performance in titanium machining.

- Anti-rotation feature enables up to six indexables rotations.

- Pocketing, ramping, plunging, and helical interpolations capabilities.

- High coolant pressure capabilities.

Create Solution to calculate Feeds and Speeds

After creating a solution just choose the Feeds & Speeds icon and our system will provide recommendations. You can customize the information by adding your machine and specifications or make adjustments using the sliders.

Feeds

| Insert Geometry | Recommended Starting Feed per Tooth (Fz) in Relation to % of Radial Engagement (ae) | Insert Geometry | ||||||||||||||

| 10% | 20% | 30% | 40% | 50–100% | ||||||||||||

| .E..LF | .007 | .014 | .020 | .005 | .010 | .015 | .004 | .009 | .013 | .004 | .008 | .012 | .004 | .008 | .012 | .E..LF |

| .S..GF | .007 | .017 | .028 | .005 | .013 | .020 | .004 | .011 | .018 | .004 | .010 | .016 | .004 | .010 | .016 | .S..GF |

| Light | General | Heavy |

| Insert Geometry | Recommended Starting Feed per Tooth (Fz) in Relation to % of Radial Engagement (ae) | Insert Geometry | ||||||||||||||

| 10% | 20% | 30% | 40% | 50–100% | ||||||||||||

| .E..LF | .008 | .016 | .024 | .006 | .012 | .017 | .005 | .010 | .015 | .005 | .010 | .014 | .005 | .009 | .014 | .E..LF |

| .S..GF | .008 | .020 | .032 | .006 | .015 | .023 | .005 | .013 | .020 | .005 | .012 | .019 | .005 | .012 | .018 | .S..GF |

| Insert Geometry | Recommended Starting Feed per Tooth (Fz) in Relation to % of Radial Engagement (ae) | Insert Geometry | ||||||||||||||

| 10% | 20% | 30% | 40% | 50–100% | ||||||||||||

| .E..LF | .014 | .029 | .043 | .010 | .021 | .031 | .009 | .018 | .027 | .008 | .017 | .025 | .008 | .017 | .025 | .E..LF |

| .S..GF | .014 | .036 | .059 | .010 | .026 | .042 | .009 | .023 | .036 | .008 | .021 | .034 | .008 | .021 | .033 | .S..GF |

| Insert Geometry | Recommended Starting Feed per Tooth (Fz) in Relation to % of Radial Engagement (ae) | Insert Geometry | ||||||||||||||

| 10% | 20% | 30% | 40% | 50–100% | ||||||||||||

| .E..LF | .010 | .021 | .031 | .008 | .015 | .023 | .007 | .013 | .020 | .006 | .013 | .019 | .006 | .012 | .018 | .E..LF |

| .S..GF | .010 | .026 | .042 | .008 | .019 | .031 | .007 | .017 | .027 | .006 | .015 | .025 | .006 | .015 | .024 | .S..GF |

Speeds

Recommended Starting Speeds [SFM]

| Material Group | KC725M | |||

| P | 1 | – | – | – |

| 2 | – | – | – | |

| 3 | – | – | – | |

| 4 | – | – | – | |

| 5 | – | – | – | |

| 6 | – | – | – | |

| M | 1 | – | – | – |

| 2 | – | – | – | |

| 3 | – | – | – | |

| K | 1 | – | – | – |

| 2 | – | – | – | |

| 3 | – | – | – | |

| N | 1 | – | – | – |

| 2 | – | – | – | |

| S | 1 | – | – | – |

| 2 | – | – | – | |

| 3 | – | – | – | |

| 4 | 240 | 180 | 120 | |

| H | 1 | – | – | – |

| 2 | – | – | – | |

| 3 | – | – | – | |

Application Data

Ramping and Helical Interpolation Values from Solid

| insert IC | catalog number | max ramp angle | max ramp depth | max plunging depth | min hole diameter (DH min) | max flat-bottom hole diameter (DH1 max) | max diameter (no flat bottom) |

| RCGX64 | KSRM200R64BB03W150L200 | 1.27° | 0.025 | 0.045 | 2.989 | 3.253 | 4.000 |

| RCGX64 | KSRM250R64BB04S075L200 | 1.27° | 0.035 | 0.058 | 3.939 | 4.253 | 5.000 |

| RCGX64 | KSRM300R64BB05S100L200 | 1.22° | 0.044 | 0.068 | 4.904 | 5.253 | 6.000 |

| RCGX64 | KSRM400R64BB05S125L200 | 1.12° | 0.060 | 0.084 | 6.850 | 7.253 | 8.000 |

| RCGX64 | KSRM400R64BB06S125L200 | 0.73° | 0.039 | 0.083 | 6.921 | 7.253 | 8.000 |

| RCGX64 | KSRM500R64BB06S150L250 | 1.00° | 0.071 | 0.094 | 8.818 | 9.253 | 10.000 |

| RCGX64 | KSRM500R64BB08S150L250 | 0.98° | 0.069 | 0.092 | 8.823 | 9.253 | 10.000 |

| RCGX64 | KSRM600R64BB07S150L250 | 0.90° | 0.079 | 0.101 | 10.795 | 11.253 | 12.000 |

| RCGX64 | KSRM600R64BB08S150L250 | 0.90° | 0.079 | 0.100 | 10.796 | 11.253 | 12.000 |

| RCGX64 | KSRM800R64BB09S250L250 | 0.74° | 0.091 | 0.111 | 14.766 | 15.253 | 16.000 |

Insert Selection

| Material Group | Light | General | Heavy | |||

| – | (Light geometry) | – | (Strong geometry) | |||

| – | wear |  | toughness | |||

| – | Geometry | Grade | Geometry | Grade | Geometry | Grade |

| P1–P2 | – | – | – | – | – | – |

| P3–P4 | – | – | – | – | – | – |

| P5–P6 | – | – | – | – | – | – |

| M1–M2 | – | – | – | – | – | – |

| M3 | – | – | – | – | – | – |

| K1–K2 | – | – | – | – | – | – |

| K3 | – | – | – | – | – | – |

| N1–N2 | – | – | – | – | – | – |

| N3 | – | – | – | – | – | – |

| S1–S2 | – | – | – | – | – | – |

| S3 | – | – | – | – | – | – |

| S4 | .E..LF | KC725M | .S..GF | KC725M | .S..GF | KC725M |

| H1 | – | – | – | – | – | – |

I have read and accepted the Terms & Conditions of use