Produit similaire à:

RPPT12-SGD-X4, X5, X8 • Pressée Frittée de précision • 4, 5 ou 8 index • Pour l'inox et les alliages réfractaires en conditions difficiles.

Plaquettes indexables

Numéro de matériel5883444

Ref. ISO CatalogueRPPT1204M0SGDX8Ref. ANSI CatalogueRPPT1204M0SGDX8

- P Acier

- M Acier inoxydable

- S Alliages hautes températures

Sending to {{cadTool}} in progress...

Downloaded file will be available after import in the {{cadTool}} tool library.

| Numéro de matériel | 5883444 |

| Ref. ISO Catalogue | RPPT1204M0SGDX8 |

| Ref. ANSI Catalogue | RPPT1204M0SGDX8 |

| Nuance | KCM40 |

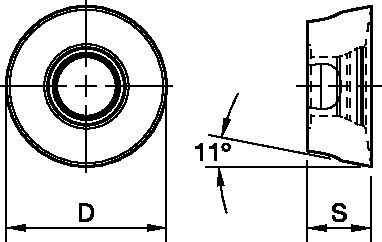

| [D] Taille de plaquette CI | 12 mm |

| [D] Taille de plaquette CI | 0.472 in |

| [S] Épaisseur de la plaquette | 4.76 mm |

| [S] Épaisseur de la plaquette | 0.188 in |

| Épaisseur moyenne du copeau [HM] | 0.04 mm |

| Épaisseur moyenne du copeau [HM] | 0.0016 in |

| Insérer le nombre d’index | 8 |

Matériaux de pièce à usiner

- Acier

- Acier inoxydable

- Alliages hautes températures

Grades

KCM40

Coated carbide grade with PVD AlTiN/AlTiSiN coating. Tough substrate with high-speed capability. KCM40 is first choice for milling stainless steel. Good thermal shock resistance makes this grade ideal for both wet and dry machining. Primarily for use in general and heavy machining.

Features and benefits

- Pour l'ébauche dans l'inox et les alliages réfractaires en conditions difficiles.

- Plaquette pressée.

- Cinq positions d'indexage : — Ap maxi : 4mm [.157″] — Ap recommandée : ≤2,5mm [.098″]

Créez une Solution pour calculer les avances et vitesses

Après avoir créé une Solution, choisissez simplement l'icône "Avances et Vitesses" et notre système vous fournira ses recommandations. Vous pouvez les personnaliser en ajoutant votre machine et vos spécifications techniques, ou en ajustant votre demande à l'aide des curseurs.

Feeds

A une profondeur de coupe axiale (ap) de 6,00

| Géométrie de plaquette | Avance par dent de départ recommandée (Fz) en relation avec le % de l'Engagement Radial (ae) | Géométrie de plaquette | ||||||||||||||

| 5% | 10% | 20% | 30% | 40–100% | ||||||||||||

| 701–X4 | 0,12 | 0,16 | 0,22 | 0,08 | 0,12 | 0,16 | 0,06 | 0,09 | 0,12 | 0,05 | 0,08 | 0,10 | 0,05 | 0,07 | 0,10 | 701–X4 |

| 432–X5 | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | 432–X5 |

| 432–X8 | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | 432–X8 |

| 442–X5 | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | 442–X5 |

| 442–X8 | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | 442–X8 |

| 442–X4 | 0,23 | 0,41 | 0,66 | 0,17 | 0,30 | 0,47 | 0,13 | 0,22 | 0,35 | 0,11 | 0,19 | 0,31 | 0,10 | 0,18 | 0,28 | 442–X4 |

| GD–X5 | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | GD–X5 |

| GD–X8 | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | GD–X8 |

| T–X4 | 0,23 | 0,41 | 0,66 | 0,17 | 0,30 | 0,47 | 0,13 | 0,22 | 0,35 | 0,11 | 0,19 | 0,31 | 0,10 | 0,18 | 0,28 | T–X4 |

A une profondeur de coupe axiale (ap) de 3,00

| Travaux légers | Applications générales | Travaux lourds |

A une profondeur de coupe axiale (ap) de 2,50

| Géométrie de plaquette | Avance par dent de départ recommandée (Fz) en relation avec le % de l'Engagement Radial (ae) | Géométrie de plaquette | ||||||||||||||

| 5% | 10% | 20% | 30% | 40–100% | ||||||||||||

| 701–X4 | 0,13 | 0,19 | 0,25 | 0,10 | 0,14 | 0,18 | 0,07 | 0,10 | 0,14 | 0,06 | 0,09 | 0,12 | 0,06 | 0,08 | 0,11 | 701–X4 |

| 432–X5 | 0,16 | 0,49 | 0,93 | 0,12 | 0,35 | 0,66 | 0,09 | 0,26 | 0,49 | 0,08 | 0,23 | 0,43 | 0,07 | 0,21 | 0,39 | 432–X5 |

| 432–X8 | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | 432–X8 |

| 442–X5 | 0,16 | 0,49 | 0,93 | 0,12 | 0,35 | 0,66 | 0,09 | 0,26 | 0,49 | 0,08 | 0,23 | 0,43 | 0,07 | 0,21 | 0,39 | 442–X5 |

| 442–X8 | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | 442–X8 |

| 442–X4 | 0,16 | 0,49 | 0,93 | 0,12 | 0,35 | 0,66 | 0,09 | 0,26 | 0,49 | 0,08 | 0,23 | 0,43 | 0,07 | 0,21 | 0,39 | 442–X4 |

| GD–X5 | 0,16 | 0,54 | 0,99 | 0,12 | 0,39 | 0,70 | 0,09 | 0,29 | 0,52 | 0,08 | 0,25 | 0,45 | 0,07 | 0,23 | 0,42 | GD–X5 |

| GD–X8 | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | GD–X8 |

| T–X4 | 0,27 | 0,68 | 1,10 | 0,19 | 0,49 | 0,78 | 0,14 | 0,36 | 0,58 | 0,13 | 0,32 | 0,50 | 0,12 | 0,29 | 0,46 | T–X4 |

A une profondeur de coupe axiale (ap) de 1,50

| Géométrie de plaquette | Avance par dent de départ recommandée (Fz) en relation avec le % de l'Engagement Radial (ae) | Géométrie de plaquette | ||||||||||||||

| 5% | 10% | 20% | 30% | 40–100% | ||||||||||||

| 701–X4 | 0,17 | 0,24 | 0,33 | 0,13 | 0,18 | 0,24 | 0,09 | 0,13 | 0,18 | 0,08 | 0,12 | 0,16 | 0,08 | 0,11 | 0,14 | 701–X4 |

| 432–X5 | 0,21 | 0,64 | 1,23 | 0,15 | 0,46 | 0,87 | 0,11 | 0,34 | 0,65 | 0,10 | 0,30 | 0,56 | 0,09 | 0,27 | 0,51 | 432–X5 |

| 432–X8 | 0,21 | 0,64 | 1,23 | 0,15 | 0,46 | 0,87 | 0,11 | 0,34 | 0,65 | 0,10 | 0,30 | 0,56 | 0,09 | 0,27 | 0,51 | 432–X8 |

| 442–X5 | 0,21 | 0,64 | 1,23 | 0,15 | 0,46 | 0,87 | 0,11 | 0,34 | 0,65 | 0,10 | 0,30 | 0,56 | 0,09 | 0,27 | 0,51 | 442–X5 |

| 442–X8 | 0,21 | 0,64 | 1,23 | 0,15 | 0,46 | 0,87 | 0,11 | 0,34 | 0,65 | 0,10 | 0,30 | 0,56 | 0,09 | 0,27 | 0,51 | 442–X8 |

| 442–X4 | 0,21 | 0,64 | 1,23 | 0,15 | 0,46 | 0,87 | 0,11 | 0,34 | 0,65 | 0,10 | 0,30 | 0,56 | 0,09 | 0,27 | 0,51 | 442–X4 |

| GD–X5 | 0,21 | 0,71 | 1,31 | 0,15 | 0,51 | 0,93 | 0,11 | 0,38 | 0,68 | 0,10 | 0,33 | 0,60 | 0,09 | 0,30 | 0,54 | GD–X5 |

| GD–X8 | 0,21 | 0,71 | 1,31 | 0,15 | 0,51 | 0,93 | 0,11 | 0,38 | 0,68 | 0,10 | 0,33 | 0,60 | 0,09 | 0,30 | 0,54 | GD–X8 |

| T–X4 | 0,35 | 0,90 | 1,47 | 0,25 | 0,64 | 1,03 | 0,19 | 0,47 | 0,76 | 0,17 | 0,41 | 0,66 | 0,15 | 0,38 | 0,60 | T–X4 |

| Géométrie de plaquette | Avance par dent de départ recommandée (Fz) en relation avec le % de l'Engagement Radial (ae) | Géométrie de plaquette | ||||||||||||||

| 5% | 10% | 20% | 30% | 40–100% | ||||||||||||

| 701–X4 | 0,14 | 0,20 | 0,27 | 0,10 | 0,14 | 0,20 | 0,08 | 0,11 | 0,15 | 0,07 | 0,09 | 0,13 | 0,06 | 0,09 | 0,12 | 701–X4 |

| 432–X5 | 0,17 | 0,52 | 1,00 | 0,12 | 0,37 | 0,71 | 0,09 | 0,28 | 0,53 | 0,08 | 0,24 | 0,46 | 0,07 | 0,22 | 0,42 | 432–X5 |

| 432–X8 | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | 432–X8 |

| 442–X5 | 0,17 | 0,52 | 1,00 | 0,12 | 0,37 | 0,71 | 0,09 | 0,28 | 0,53 | 0,08 | 0,24 | 0,46 | 0,07 | 0,22 | 0,42 | 442–X5 |

| 442–X8 | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | 442–X8 |

| 442–X4 | 0,17 | 0,52 | 1,00 | 0,12 | 0,37 | 0,71 | 0,09 | 0,28 | 0,53 | 0,08 | 0,24 | 0,46 | 0,07 | 0,22 | 0,42 | 442–X4 |

| GD–X5 | 0,17 | 0,58 | 1,06 | 0,12 | 0,41 | 0,75 | 0,09 | 0,31 | 0,56 | 0,08 | 0,27 | 0,48 | 0,07 | 0,25 | 0,44 | GD–X5 |

| GD–X8 | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | GD–X8 |

| T–X4 | 0,29 | 0,73 | 1,18 | 0,21 | 0,52 | 0,84 | 0,15 | 0,39 | 0,62 | 0,13 | 0,34 | 0,54 | 0,12 | 0,31 | 0,49 | T–X4 |

At .236 Axial Depth of Cut (ap)

| Travaux légers | Applications générales | Travaux lourds |

At .118 Axial Depth of Cut (ap)

| Géométrie de plaquette | Avance par dent (fz) programmée en % de la profondeur de coupe radiale (ae) | Géométrie de plaquette | ||||||||||||||

| 5% | 10% | 20% | 30% | 40–100% | ||||||||||||

| 701–X4 | .005 | .008 | .011 | .003 | .006 | .008 | .002 | .004 | .006 | .002 | .004 | .005 | .002 | .004 | .005 | 701–X4 |

| 432–X5 | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | 432–X5 |

| 432–X8 | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | 432–X8 |

| 442–X5 | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | 442–X5 |

| 442–X8 | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | 442–X8 |

| 442–X4 | .007 | .021 | .037 | .005 | .015 | .027 | .004 | .011 | .020 | .003 | .010 | .017 | .003 | .009 | .016 | 442–X4 |

| GD–X5 | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | GD–X5 |

| GD–X8 | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | GD–X8 |

| T–X4 | .009 | .023 | .037 | .007 | .017 | .027 | .005 | .012 | .020 | .004 | .011 | .017 | .004 | .010 | .016 | T–X4 |

At .098 Axial Depth of Cut (ap)

| Géométrie de plaquette | Avance par dent (fz) programmée en % de la profondeur de coupe radiale (ae) | Géométrie de plaquette | ||||||||||||||

| 5% | 10% | 20% | 30% | 40–100% | ||||||||||||

| 701–X4 | .005 | .009 | .013 | .004 | .007 | .009 | .003 | .005 | .007 | .002 | .004 | .006 | .002 | .004 | .005 | 701–X4 |

| 432–X5 | .006 | .019 | .037 | .005 | .014 | .027 | .003 | .010 | .020 | .003 | .009 | .017 | .003 | .008 | .016 | 432–X5 |

| 432–X8 | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | 432–X8 |

| 442–X5 | .006 | .019 | .037 | .005 | .014 | .027 | .003 | .010 | .020 | .003 | .009 | .017 | .003 | .008 | .016 | 442–X5 |

| 442–X8 | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | 442–X8 |

| 442–X4 | .008 | .024 | .043 | .006 | .017 | .031 | .004 | .013 | .023 | .004 | .011 | .020 | .003 | .010 | .018 | 442–X4 |

| GD–X5 | .006 | .022 | .040 | .005 | .016 | .028 | .003 | .012 | .021 | .003 | .010 | .018 | .003 | .009 | .017 | GD–X5 |

| GD–X8 | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | GD–X8 |

| T–X4 | .011 | .027 | .043 | .008 | .019 | .031 | .006 | .014 | .023 | .005 | .012 | .020 | .005 | .011 | .018 | T–X4 |

At .059 Axial Depth of Cut (ap)

| Géométrie de plaquette | Avance par dent (fz) programmée en % de la profondeur de coupe radiale (ae) | Géométrie de plaquette | ||||||||||||||

| – | 5% | 10% | 20% | 30% | 40–100% | |||||||||||

| 701–X4 | .007 | .012 | .017 | .005 | .009 | .012 | .004 | .007 | .009 | .003 | .006 | .008 | .003 | .005 | .007 | 701–X4 |

| 432–X5 | .008 | .026 | .049 | .006 | .018 | .035 | .005 | .014 | .026 | .004 | .012 | .022 | .004 | .011 | .021 | 432–X5 |

| 432–X8 | .008 | .026 | .049 | .006 | .018 | .035 | .005 | .014 | .026 | .004 | .012 | .022 | .004 | .011 | .021 | 432–X8 |

| 442–X5 | .008 | .026 | .049 | .006 | .018 | .035 | .005 | .014 | .026 | .004 | .012 | .022 | .004 | .011 | .021 | 442–X5 |

| 442–X8 | .008 | .026 | .049 | .006 | .018 | .035 | .005 | .014 | .026 | .004 | .012 | .022 | .004 | .011 | .021 | 442–X8 |

| 442–X4 | .011 | .032 | .058 | .008 | .023 | .041 | .006 | .017 | .030 | .005 | .015 | .026 | .005 | .014 | .024 | 442–X4 |

| GD–X5 | .008 | .028 | .053 | .006 | .020 | .037 | .005 | .015 | .027 | .004 | .013 | .024 | .004 | .012 | .022 | GD–X5 |

| GD–X8 | .008 | .028 | .053 | .006 | .020 | .037 | .005 | .015 | .027 | .004 | .013 | .024 | .004 | .012 | .022 | GD–X8 |

| T–X4 | .014 | .035 | .058 | .010 | .025 | .041 | .007 | .019 | .030 | .006 | .016 | .026 | .006 | .015 | .024 | T–X4 |

| Géométrie de plaquette | Avance par dent (fz) programmée en % de la profondeur de coupe radiale (ae) | Géométrie de plaquette | ||||||||||||||

| 5% | 10% | 20% | 30% | 40–100% | ||||||||||||

| 701–X4 | .006 | .010 | .014 | .004 | .007 | .010 | .003 | .005 | .007 | .003 | .005 | .006 | .002 | .004 | .006 | 701–X4 |

| 432–X5 | .007 | .021 | .040 | .005 | .015 | .028 | .004 | .011 | .021 | .003 | .010 | .018 | .003 | .009 | .017 | 432–X5 |

| 432–X8 | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | 432–X8 |

| 442–X5 | .007 | .021 | .040 | .005 | .015 | .028 | .004 | .011 | .021 | .003 | .010 | .018 | .003 | .009 | .017 | 442–X5 |

| 442–X8 | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | 442–X8 |

| 442–X4 | .009 | .026 | .046 | .006 | .019 | .033 | .005 | .014 | .024 | .004 | .012 | .021 | .004 | .011 | .019 | 442–X4 |

| GD–X5 | .007 | .023 | .042 | .005 | .017 | .030 | .004 | .012 | .022 | .003 | .011 | .019 | .003 | .010 | .018 | GD–X5 |

| GD–X8 | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | GD–X8 |

| T–X4 | .011 | .029 | .046 | .008 | .020 | .033 | .006 | .015 | .024 | .005 | .013 | .021 | .005 | .012 | .019 | T–X4 |

Speeds

Vitesses de départ recommandées [m/mn]

| Groupe Matières | GH1 | X700 | KCM40 | SP6519 | X500 | MP91M | SC6525 | |||||||||||||||

| P | 1 | – | – | – | – | – | – | – | – | – | 130 | 213 | 295 | 130 | 200 | 270 | 140 | 243 | 345 | 140 | 255 | 370 |

| 2 | – | – | – | – | – | – | – | – | – | 115 | 188 | 260 | 115 | 178 | 240 | 120 | 213 | 305 | 120 | 223 | 325 | |

| 3 | – | – | – | – | – | – | 100 | 170 | 240 | 100 | 165 | 230 | 100 | 155 | 210 | 105 | 188 | 270 | 105 | 198 | 290 | |

| 4 | – | – | – | – | – | – | 75 | 128 | 180 | 75 | 125 | 175 | 75 | 118 | 160 | 80 | 143 | 205 | 80 | 145 | 210 | |

| 5 | – | – | – | 70 | 103 | 135 | – | – | – | 70 | 105 | 140 | 70 | 100 | 130 | – | – | – | 80 | 120 | 160 | |

| 6 | – | – | – | 50 | 83 | 115 | – | – | – | 50 | 85 | 120 | 50 | 80 | 110 | – | – | – | 60 | 100 | 140 | |

| M | 1 | – | – | – | 115 | 188 | 260 | 115 | 188 | 260 | 115 | 193 | 270 | 115 | 183 | 250 | – | – | – | 120 | 205 | 290 |

| 2 | – | – | – | 105 | 168 | 230 | 100 | 165 | 230 | 105 | 170 | 235 | 100 | 160 | 220 | – | – | – | 110 | 185 | 260 | |

| 3 | – | – | – | 85 | 138 | 190 | 50 | 83 | 115 | 85 | 140 | 195 | 80 | 130 | 180 | – | – | – | 90 | 150 | 210 | |

| K | 1 | 135 | 213 | 290 | – | – | – | – | – | – | 140 | 218 | 295 | 120 | 200 | 280 | 145 | 255 | 365 | 145 | 268 | 390 |

| 2 | 120 | 183 | 245 | – | – | – | – | – | – | 110 | 175 | 240 | 105 | 155 | 205 | 115 | 200 | 285 | 115 | 210 | 305 | |

| 3 | 115 | 158 | 200 | – | – | – | – | – | – | 100 | 160 | 220 | 95 | 133 | 170 | 105 | 183 | 260 | – | – | – | |

| N | 1–2 | 400 | 1725 | 3050 | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – |

| 3 | 295 | 1368 | 2440 | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | |

| S | 1 | – | – | – | 23 | 38 | 52 | 23 | 38 | 52 | 23 | 39 | 55 | 23 | 36 | 48 | – | – | – | – | – | – |

| 2 | – | – | – | 22 | 34 | 46 | 22 | 34 | 46 | 22 | 35 | 48 | 21 | 33 | 44 | – | – | – | – | – | – | |

| 3 | – | – | – | 25 | 39 | 53 | 25 | 39 | 53 | 25 | 40 | 55 | 24 | 38 | 51 | – | – | – | – | – | – | |

| 4 | – | – | – | 36 | 56 | 75 | 36 | 56 | 75 | 36 | 58 | 79 | 35 | 54 | 73 | – | – | – | – | – | – | |

| H | 1 | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | 50 | 78 | 105 | 50 | 80 | 110 |

Recommended Starting Speeds [SFM]

| Groupe Matières | GH1 | X700 | KCM40 | SP6519 | X500 | MP91M | SC6525 | |||||||||||||||

| P | 1 | – | – | – | – | – | – | – | – | – | 426 | 697 | 459 | 426 | 656 | 886 | 459 | 795 | 1132 | 459 | 836 | 1214 |

| 2 | – | – | – | – | – | – | – | – | – | 377 | 615 | 394 | 377 | 582 | 787 | 394 | 697 | 1000 | 394 | 730 | 1066 | |

| 3 | – | – | – | – | – | – | 328 | 558 | 787 | 328 | 541 | 344 | 328 | 508 | 689 | 344 | 615 | 886 | 344 | 648 | 951 | |

| 4 | – | – | – | – | – | – | 246 | 418 | 590 | 246 | 410 | 262 | 246 | 385 | 525 | 262 | 467 | 672 | 262 | 476 | 689 | |

| 5 | – | – | – | 230 | 338 | 443 | – | – | – | 246 | 410 | 230 | 230 | 328 | 426 | – | – | – | 262 | 394 | 525 | |

| 6 | – | – | – | 164 | 272 | 377 | – | – | – | 230 | 344 | 164 | 164 | 262 | 361 | – | – | – | 197 | 328 | 459 | |

| M | 1 | – | – | – | 377 | 615 | 853 | 377 | 615 | 853 | 377 | 631 | 394 | 377 | 599 | 820 | – | – | – | 394 | 672 | 951 |

| 2 | – | – | – | 344 | 549 | 754 | 328 | 541 | 754 | 344 | 558 | 361 | 328 | 525 | 722 | – | – | – | 361 | 607 | 853 | |

| 3 | – | – | – | 279 | 451 | 623 | 164 | 271 | 377 | 279 | 459 | 295 | 262 | 426 | 590 | – | – | – | 295 | 492 | 689 | |

| K | 1 | 443 | 697 | 951 | – | – | – | – | – | – | 459 | 713 | 476 | 394 | 656 | 918 | 476 | 836 | 1197 | 476 | 877 | 1279 |

| 2 | 394 | 599 | 804 | – | – | – | – | – | – | 361 | 574 | 377 | 344 | 508 | 672 | 377 | 656 | 935 | 377 | 689 | 1000 | |

| 3 | 377 | 517 | 656 | – | – | – | – | – | – | 328 | 525 | 344 | 312 | 435 | 558 | 344 | 599 | 853 | – | – | – | |

| N | 1–2 | 1312 | 5658 | 10004 | – | – | – | – | – | – | – | – | 1312 | – | – | – | – | – | – | – | – | – |

| 3 | 968 | 4485 | 8003 | – | – | – | – | – | – | – | – | 968 | – | – | – | – | – | – | – | – | – | |

| S | 1 | – | – | – | 75 | 123 | 171 | 75 | 123 | 171 | 75 | 128 | 79 | 75 | 116 | 157 | – | – | – | – | – | – |

| 2 | – | – | – | 72 | 112 | 151 | 72 | 112 | 151 | 72 | 115 | 75 | 69 | 107 | 144 | – | – | – | – | – | – | |

| 3 | – | – | – | 82 | 128 | 174 | 82 | 128 | 174 | 82 | 131 | 85 | 79 | 123 | 167 | – | – | – | – | – | – | |

| 4 | – | – | – | 118 | 182 | 246 | 118 | 182 | 246 | 118 | 189 | 121 | 115 | 177 | 239 | – | – | – | – | – | – | |

| H | 1 | – | – | – | – | – | – | – | – | – | – | – | 164 | – | – | – | 164 | 254 | 344 | 164 | 262 | 361 |

| Groupe Matières | Travaux légers | Applications générales | Travaux lourds | |||

| – | (géomètrie légère) | – | (géomètrie solide) | |||

| – | résistance à l’usure |  | ténacité | |||

| – | Géométrie | Nuance | Géométrie | Nuance | Géométrie | Nuance |

| P1–P2 | 442-X8 | SC6525 | 432-X5 | SC6525 | GD-X5 | KCM40 |

| P3–P4 | 432-X8 | SP6519 | 432-X5 | SP6519 | GD-X5 | KCM40 |

| P5–P6 | 432-X8 | SP6519 | T-X4 | SP6519 | T-X4 | X500 |

| M1–M2 | 442-X8 | SC6525 | 432-X5 | SC6525 | GD-X5 | KCM40 |

| M3 | 432-X8 | SP6519 | GD-X5 | KCM40 | 442-X4 | X500 |

| K1–K2 | T-X4 | MP91M | T-X4 | MP91M | T-X4 | MP91M |

| K3 | T-X4 | MP91M | T-X4 | MP91M | T-X4 | MP91M |

| N1–N2 | 701-X4 | GH1 | 701-X4 | GH1 | 701-X4 | GH1 |

| N3 | 701-X4 | GH1 | 701-X4 | GH1 | 701-X4 | GH1 |

| S1–S2 | 442-X5 | SP6519 | GD-X5 | KCM40 | 442-X4 | X500 |

| S3 | 442-X5 | SP6519 | GD-X5 | KCM40 | 442-X4 | X500 |

| S4 | 442-X5 | SP6519 | 442-X5 | X500 | 442-X4 | X500 |

| H1 | – | – | T-X4 | MP91M | – | – |

I have read and accepted the Terms & Conditions of use

CAD Drawings Models

Can’t find the file type you’re looking for?

Product data