Prodotto simile a :

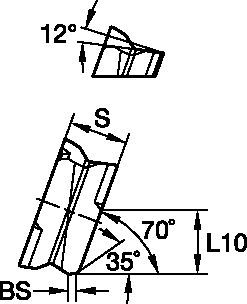

Inserts for Fix-Perfect™ 70° • SPHX1205-GP • Roughing

Indexable Inserts • SPHX1205... • Roughing

Material Number1322958

ISO Catalog IDSPHX1205ZCTRGPKANSI Catalog IDSPHX1205ZCTRGPK

- K Ghisa

Sending to {{cadTool}} in progress...

Downloaded file will be available after import in the {{cadTool}} tool library.

| Material Number | 1322958 |

| ISO Catalog ID | SPHX1205ZCTRGPK |

| ANSI Catalog ID | SPHX1205ZCTRGPK |

| Qualità | KY3500 |

| [L10] Lunghezza del tagliente dell’inserto | 5.41 mm |

| [L10] Lunghezza del tagliente dell’inserto | 0.213 in |

| [S] Spessore inserto | 5.5 mm |

| [S] Spessore inserto | 0.2165 in |

| [BS] Lunghezza sfaccettatura spigolo | 0.7 mm |

| [BS] Lunghezza sfaccettatura spigolo | 0.0276 in |

| Spessore medio del truciolo [HM] | 0.24 mm |

| Spessore medio del truciolo [HM] | 0.0094 in |

| Taglienti per inserto | 8 |

Materiale da lavorare

- Ghisa

Grades

KY3500

A ceramic cutting material based on micro-grain Si3N4 primarily for use in light to general machining of gray cast iron and ferritic ductile cast iron. Dry machining is recommended.

Crea una soluzione per calcolare avanzamenti e velocità

Dopo aver creato una soluzione, basta scegliere l'icona Avanzamento e Velocità e il nostro sistema fornirà dei suggerimenti. Puoi personalizzare le informazioni aggiungendo la tua macchina e le specifiche o apportare delle modifiche utilizzando i cursori.

Feeds

Recommended Starting Feeds [IPT]

| Geometria dell'inserto | Avanzamento per dente programmato (fz) in base alla % della profondità di taglio radiale (ae) | Geometria dell'inserto | ||||||||||||||

| 5% | 10% | 20% | 30% | 40–100% | ||||||||||||

| .E..GP | .006 | .020 | .038 | .004 | .014 | .027 | .003 | .011 | .020 | .003 | .009 | .018 | .002 | .009 | .016 | .E..GP |

| .T..GP | .010 | .025 | .040 | .007 | .018 | .029 | .005 | .013 | .021 | .005 | .012 | .019 | .004 | .011 | .017 | .T..GP |

| .S..GP | .010 | .025 | .040 | .007 | .018 | .029 | .005 | .013 | .021 | .005 | .012 | .019 | .004 | .011 | .017 | .S..GP |

| Lavorazione leggera | Uso generico | Lavorazione pesante |

Recommended Starting Feeds [IPT]

| Geometria dell'inserto | Avanzamento per dente programmato (fz) in base alla % della profondità di taglio radiale (ae) | Geometria dell'inserto | ||||||||||||||

| 5% | 10% | 20% | 30% | 40–100% | ||||||||||||

| .E..GP | .005 | .020 | .035 | .004 | .014 | .025 | .003 | .011 | .019 | .002 | .009 | .016 | .002 | .009 | .015 | .E..GP |

| .S..GP | .010 | .025 | .040 | .007 | .018 | .029 | .005 | .013 | .021 | .005 | .012 | .019 | .004 | .011 | .017 | .S..GP |

| Lavorazione leggera | Uso generico | Lavorazione pesante |

Speeds

Recommended Starting Speeds [SFM]

| Gruppo materiali | KB1340 | KC520M | KCK15 | KTPK20 | KCPK30 | KY3500 | |||||||||||||

| P | 1 | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – |

| 2 | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | |

| 3 | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | |

| 4 | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | |

| 5 | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | |

| 6 | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | |

| M | 1 | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – |

| 2 | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | |

| 3 | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | |

| K | 1 | 5400 | 3600 | 1920 | 1060 | 960 | 850 | 1660 | 1510 | 1340 | 910 | 770 | 640 | 1160 | 1050 | 940 | 3170 | 2880 | 2560 |

| 2 | – | – | – | 830 | 740 | 700 | 1310 | 1170 | 1090 | 720 | 590 | 520 | 920 | 830 | 760 | 2510 | 2240 | 2090 | |

| 3 | – | – | – | 700 | 620 | 560 | 1100 | 980 | 900 | 600 | 500 | 420 | 770 | 690 | 640 | 2110 | 1870 | 1720 | |

| N | 1–2 | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – |

| 3 | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | |

| S | 1 | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – |

| 2 | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | |

| 3 | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | |

| 4 | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | |

| H | 1 | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – |

Recommended Starting Speeds [SFM]

| Gruppo materiali | K110M | KC520M | KCK15 | KTPK20 | KCPK30 | KY3500 | |||||||||||||

| P | 1 | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – |

| 2 | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | |

| 3 | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | |

| 4 | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | |

| 5 | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | |

| 6 | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | |

| M | 1 | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – |

| 2 | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | |

| 3 | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | |

| K | 1 | 510 | 480 | 450 | 1060 | 960 | 850 | 1660 | 1510 | 1340 | 910 | 770 | 640 | 1160 | 1050 | 940 | 3170 | 2880 | 2560 |

| 2 | 450 | 420 | 390 | 830 | 740 | 700 | 1310 | 1170 | 1090 | 720 | 590 | 520 | 920 | 830 | 760 | 2510 | 2240 | 2090 | |

| 3 | 400 | 350 | 310 | 700 | 620 | 560 | 1100 | 980 | 900 | 600 | 500 | 420 | 770 | 690 | 640 | 2110 | 1870 | 1720 | |

| N | 1–2 | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – |

| 3 | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | |

| S | 1 | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – |

| 2 | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | |

| 3 | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | |

| 4 | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | |

| H | 1 | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – |

Insert Selection

| Gruppo materiali | Lavorazione leggera | Uso generico | Lavorazione pesante | |||

| – | (Geometria leggera) | (Geometria robusta) | ||||

| – | resistenza all’usura |  | tenacità | |||

| – | Geometria | Qualità | Geometria | Qualità | Geometria | Qualità |

| P1–P2 | – | – | – | – | – | – |

| P3–P4 | – | – | – | – | – | – |

| P5–P6 | – | – | – | – | – | – |

| M1–M2 | – | – | – | – | – | – |

| M3 | – | – | – | – | – | – |

| K1–K2 | .E..GP | KC520M | .E..GP | KCK15 | .S..GP | KCK15 |

| K3 | .E..GP | KC520M | .E..GP | KCK15 | .S..GP | KCK15 |

| N1–N2 | – | – | – | – | – | – |

| N3 | – | – | – | – | – | – |

| S1–S2 | – | – | – | – | – | – |

| S3 | – | – | – | – | – | – |

| S4 | – | – | – | – | – | – |

| H1 | – | – | – | – | – | – |

| Gruppo materiali | Lavorazione leggera | Uso generico | Lavorazione pesante | |||

| – | (Geometria leggera) | (Geometria robusta) | ||||

| – | resistenza all’usura |  | tenacità | |||

| – | Geometria | Qualità | Geometria | Qualità | Geometria | Qualità |

| P1–P2 | – | – | – | – | – | – |

| P3–P4 | – | – | – | – | – | – |

| P5–P6 | – | – | – | – | – | – |

| M1–M2 | – | – | – | – | – | – |

| M3 | – | – | – | – | – | – |

| K1–K2 | .E..GP | KCK15 | .E..GP | KCK15 | .E..GP | KCK15 |

| K3 | .E..GP | KCK15 | .E..GP | KCK15 | .S..GP | KCPK30 |

| N1–N2 | – | – | – | – | – | – |

| N3 | – | – | – | – | – | – |

| S1–S2 | – | – | – | – | – | – |

| S3 | – | – | – | – | – | – |

| S4 | – | – | – | – | – | – |

| H1 | – | – | – | – | – | – |

I have read and accepted the Terms & Conditions of use