Prodotto simile a :

KenCut™ FF • HPFSS • Square End • 5 Flutes • Weldon® Shank • Inch

Solid Carbide End Mill for Finishing of Steels, Stainless Steel, Cast Iron, and High-Temperature Alloys

Material Number4048646

ISO Catalog IDHPFSS500S5125ANSI Catalog IDHPFSS500S5125

- P Acciaio

- M Acciai inossidabili

- K Ghisa

- H Materiali temprati

Trochoidal Milling

Fresatura in rampa: Grezzo

Contornatura/fresatura a spallamento: Testa piana

Dimensioni utensile: Configurazione del vano: 5

Angolo elica: 45°

Stile angolo: Testa piana

Sending to {{cadTool}} in progress...

Downloaded file will be available after import in the {{cadTool}} tool library.

| Material Number | 4048646 |

| ISO Catalog ID | HPFSS500S5125 |

| ANSI Catalog ID | HPFSS500S5125 |

| Qualità | KCPM15 |

| Serie adattatore lato macchina | Weldon |

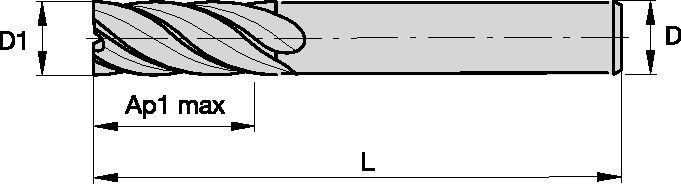

| [D1] Diametro di taglio effettivo | 12.7 mm |

| [D1] Diametro di taglio effettivo | 0.5 in |

| [D] Dia adattatore / stelo / foro | 12.7 mm |

| [D] Dia adattatore / stelo / foro | 0.5 in |

| [AP1MAX] 1° profondità di taglio massima | 31.75 mm |

| [AP1MAX] 1° profondità di taglio massima | 1.25 in |

| [L] Lunghezza complessiva | 76.2 mm |

| [L] Lunghezza complessiva | 3 in |

| [Z] Numero di vani | 5 |

Materiale da lavorare

- Acciaio

- Acciai inossidabili

- Ghisa

- Materiali temprati

Uses and application

Trochoidal Milling

Fresatura in rampa: Grezzo

Contornatura/fresatura a spallamento: Testa piana

Dimensioni utensile: Configurazione del vano: 5

Angolo elica: 45°

Stile angolo: Testa piana

Grades

KCPM15

Qualità di metallo duro rivestito con elevato spessore e processo di rivestimento PVD ottimizzato per la massima resistenza all'usura. Eccezionale protezione per la fresatura di acciaio inossidabile per ridurre la formazione di crateri, usura dei fianchi e intagli. Prestazioni eccellenti fino a 52 HRC.

Features and benefits

- Centre cutting for plunging and ramping operations.

Crea una soluzione per calcolare avanzamenti e velocità

Dopo aver creato una soluzione, basta scegliere l'icona Avanzamento e Velocità e il nostro sistema fornirà dei suggerimenti. Puoi personalizzare le informazioni aggiungendo la tua macchina e le specifiche o apportare delle modifiche utilizzando i cursori.

HPFSS 5 Flute • Steel, Stainless Steels, and Titanium

|  | |||||||||||||||

| Contornatura (A) | KCPM15 | Feed per Tooth — fz information is for side milling (A). | ||||||||||||||

| A | Velocità di taglio | D1 | ||||||||||||||

| inch | 1/8 | 3/16 | 1/4 | 5/16 | 3/8 | 7/16 | 1/2 | 5/8 | 3/4 | 1 | ||||||

| Gruppo materiali | ap | ae | min | max | .125 | .188 | .250 | .313 | .375 | .438 | .500 | .625 | .750 | 1.000 | ||

| P | 0 | 1.5 x D | 0.2 x D | 490 | 660 | IPT | .0009 | .0013 | .0018 | .0023 | .0027 | .0031 | .0034 | .0039 | .0044 | .0049 |

| 1 | 1.5 x D | 0.2 x D | 490 | 660 | IPT | .0009 | .0013 | .0018 | .0023 | .0027 | .0031 | .0034 | .0039 | .0044 | .0049 | |

| 2 | 1.5 x D | 0.2 x D | 460 | 620 | IPT | .0009 | .0013 | .0018 | .0023 | .0027 | .0031 | .0034 | .0039 | .0044 | .0049 | |

| 3 | 1.5 x D | 0.2 x D | 390 | 520 | IPT | .0007 | .0011 | .0015 | .0020 | .0023 | .0026 | .0029 | .0034 | .0039 | .0045 | |

| 4 | 1.5 x D | 0.2 x D | 300 | 490 | IPT | .0007 | .0010 | .0014 | .0017 | .0020 | .0023 | .0026 | .0030 | .0034 | .0039 | |

| 5 | 1.5 x D | 0.2 x D | 200 | 330 | IPT | .0006 | .0009 | .0012 | .0016 | .0018 | .0021 | .0023 | .0027 | .0031 | .0036 | |

| 6 | 1.5 x D | 0.2 x D | 300 | 490 | IPT | .0007 | .0010 | .0014 | .0017 | .0020 | .0023 | .0026 | .0030 | .0034 | .0039 | |

| M | 1 | 1.5 x D | 0.2 x D | 200 | 260 | IPT | .0006 | .0009 | .0012 | .0016 | .0018 | .0021 | .0023 | .0027 | .0031 | .0036 |

| 2 | 1.5 x D | 0.2 x D | 300 | 380 | IPT | .0007 | .0011 | .0015 | .0020 | .0023 | .0026 | .0029 | .0034 | .0039 | .0045 | |

| 3 | 1.5 x D | 0.2 x D | 200 | 260 | IPT | .0006 | .0009 | .0012 | .0016 | .0018 | .0021 | .0023 | .0027 | .0031 | .0036 | |

| K | 1 | 1.5 x D | 0.2 x D | 200 | 230 | IPT | .0005 | .0008 | .0010 | .0013 | .0015 | .0017 | .0019 | .0022 | .0025 | .0028 |

| 2 | 1.5 x D | 0.2 x D | 390 | 490 | IPT | .0009 | .0013 | .0018 | .0023 | .0027 | .0031 | .0034 | .0039 | .0044 | .0049 | |

| 3 | 1.5 x D | 0.2 x D | 360 | 460 | IPT | .0007 | .0011 | .0015 | .0020 | .0023 | .0026 | .0029 | .0034 | .0039 | .0045 | |

| S | 1 | 1.5 x D | 0.2 x D | – | – | IPT | .0004 | .0006 | .0008 | .0010 | .0012 | .0014 | .0015 | .0018 | .0021 | .0024 |

| 2 | 1.5 x D | 0.2 x D | – | – | IPT | .0007 | .0011 | .0015 | .0020 | .0023 | .0026 | .0029 | .0034 | .0039 | .0045 | |

| 3 | 1.5 x D | 0.2 x D | – | – | IPT | .0004 | .0006 | .0008 | .0010 | .0012 | .0014 | .0015 | .0018 | .0021 | .0024 | |

| 4 | 1.5 x D | 0.2 x D | – | – | IPT | .0004 | .0006 | .0008 | .0010 | .0012 | .0014 | .0015 | .0018 | .0021 | .0024 | |

| H | 1 | 1.5 x D | 0.2 x D | 260 | 460 | IPT | .0007 | .0010 | .0014 | .0017 | .0020 | .0023 | .0026 | .0030 | .0034 | .0039 |

Tolleranza

| Tolleranze delle frese in metallo duro | |||

| D1 | Tolleranza | D | Tolleranza h6 + / - |

| All | +.000/- .002" | ≤1/8" | +0/-.00024" |

| +0/-.00031" | |||

| +0/-.00035" | |||

| +0/-.00043" | |||

| +0/-.00051" | |||

I have read and accepted the Terms & Conditions of use