Producto similar a:

Round Inserts for KDM • RDPX-HN

Indexable Inserts • RD.X10...

Número de material1895254

Referencia ISORDPX1003M0SHNReferencia ANSIRDPX1003M0SHN

- P Acero

- K Fundición

- N Materiales no ferrosos

- H Materiales endurecidos

Sending to {{cadTool}} in progress...

Downloaded file will be available after import in the {{cadTool}} tool library.

- Información general

- Datos de aplicación

- Descargas

- Piezas compatibles Lado máquina

- Comentarios

- Preguntas y Respuestas

| Número de material | 1895254 |

| Referencia ISO | RDPX1003M0SHN |

| Referencia ANSI | RDPX1003M0SHN |

| Calidad | KC510M |

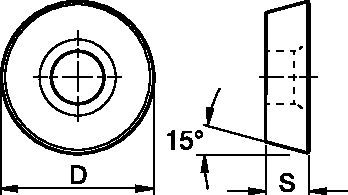

| Tamaño IC de plaquita [D] | 10 mm |

| Tamaño IC de plaquita [D] | 0.394 in |

| Grosor de plaquita [S] | 3.18 mm |

| Grosor de plaquita [S] | 0.125 in |

| Grosor medio de las virutas [HM] | 0.115 mm |

| Grosor medio de las virutas [HM] | 0.0045 in |

Materiales de la pieza de trabajo

- Acero

- Fundición

- Materiales no ferrosos

- Materiales endurecidos

Grades

KC510M

Calidad de metal duro recubierto con una capa de TiAiN (PVD). KC510M es una calidad de gran resistencia al desgaste, cuyo uso principal es el fresado de aluminio y aleaciones de alta temperatura en aplicaciones ligeras. También se puede utilizar para el mecanizado de acero y acero endurecido.

Features and benefits

- La geometría HN es la primera opción para mecanizado de acero de alta resistencia y duro hasta 55 HRC.

Crear una solución para calcular la velocidad y el avance

Después de crear una solución, sólo tiene que elegir el icono Avance y Velocidad y nuestro sistema le ofrecerá recomendaciones. Puede personalizar la información añadiendo su máquina y especificaciones o realizar ajustes utilizando los controles deslizantes.

Feeds

Con profundidad de corte axial de 5,00

| Geometría de plaquita | Avance inicial recomendado por diente (Fz) en relación con % de contacto radial (ae) | Geometría de plaquita | ||||||||||||||

| 10% | 20% | 30% | 40% | 50–100% | ||||||||||||

| .F..LP | 0,08 | 0,17 | 0,33 | 0,06 | 0,13 | 0,25 | 0,06 | 0,11 | 0,22 | 0,05 | 0,10 | 0,20 | 0,05 | 0,10 | 0,20 | .F..LP |

| .S..GN | 0,17 | 0,40 | 0,68 | 0,13 | 0,30 | 0,51 | 0,11 | 0,26 | 0,44 | 0,10 | 0,24 | 0,41 | 0,10 | 0,24 | 0,41 | .S..GN |

| .T..GN | 0,17 | 0,43 | 0,68 | 0,13 | 0,32 | 0,51 | 0,11 | 0,28 | 0,44 | 0,10 | 0,26 | 0,41 | 0,10 | 0,25 | 0,41 | .T..GN |

| .S..HP | 0,17 | 0,43 | 0,68 | 0,13 | 0,32 | 0,51 | 0,11 | 0,28 | 0,44 | 0,10 | 0,26 | 0,41 | 0,10 | 0,25 | 0,41 | .S..HP |

| .S..HN | 0,17 | 0,43 | 0,68 | 0,13 | 0,32 | 0,51 | 0,11 | 0,28 | 0,44 | 0,10 | 0,26 | 0,41 | 0,10 | 0,25 | 0,41 | .S..HN |

Con profundidad de corte axial de 2,00

| Mecanizado ligero | Aplicaciones generales | Mecanizado intensivo |

Con profundidad de corte axial de 1,00

| Geometría de plaquita | Avance inicial recomendado por diente (Fz) en relación con % de contacto radial (ae) | Geometría de plaquita | ||||||||||||||

| 10% | 20% | 30% | 40% | 50–100% | ||||||||||||

| .F..LP | 0,11 | 0,21 | 0,42 | 0,08 | 0,16 | 0,31 | 0,07 | 0,14 | 0,27 | 0,06 | 0,13 | 0,26 | 0,06 | 0,13 | 0,25 | .F..LP |

| .S..GN | 0,21 | 0,50 | 0,85 | 0,16 | 0,38 | 0,64 | 0,14 | 0,33 | 0,55 | 0,13 | 0,31 | 0,52 | 0,13 | 0,30 | 0,51 | .S..GN |

| .T..GN | 0,21 | 0,53 | 0,85 | 0,16 | 0,40 | 0,64 | 0,14 | 0,35 | 0,55 | 0,13 | 0,32 | 0,52 | 0,13 | 0,32 | 0,51 | .T..GN |

| .S..HP | 0,21 | 0,53 | 0,85 | 0,16 | 0,40 | 0,64 | 0,14 | 0,35 | 0,55 | 0,13 | 0,32 | 0,52 | 0,13 | 0,32 | 0,51 | .S..HP |

| .S..HN | 0,21 | 0,53 | 0,85 | 0,16 | 0,40 | 0,64 | 0,14 | 0,35 | 0,55 | 0,13 | 0,32 | 0,52 | 0,13 | 0,32 | 0,51 | .S..HN |

Con profundidad de corte axial de 0,50

| Geometría de plaquita | Avance inicial recomendado por diente (Fz) en relación con % de contacto radial (ae) | Geometría de plaquita | ||||||||||||||

| 10% | 20% | 30% | 40% | 50–100% | ||||||||||||

| .F..LP | 0,19 | 0,38 | 0,77 | 0,15 | 0,29 | 0,58 | 0,13 | 0,25 | 0,50 | 0,12 | 0,23 | 0,47 | 0,12 | 0,23 | 0,46 | .F..LP |

| .S..GN | 0,39 | 0,93 | 1,58 | 0,29 | 0,69 | 1,17 | 0,25 | 0,60 | 1,02 | 0,24 | 0,56 | 0,95 | 0,23 | 0,55 | 0,93 | .S..GN |

| .T..GN | 0,39 | 0,98 | 1,58 | 0,29 | 0,73 | 1,17 | 0,25 | 0,64 | 1,02 | 0,24 | 0,59 | 0,95 | 0,23 | 0,58 | 0,93 | .T..GN |

| .S..HP | 0,39 | 0,98 | 1,58 | 0,29 | 0,73 | 1,17 | 0,25 | 0,64 | 1,02 | 0,24 | 0,59 | 0,95 | 0,23 | 0,58 | 0,93 | .S..HP |

| .S..HN | 0,39 | 0,98 | 1,58 | 0,29 | 0,73 | 1,17 | 0,25 | 0,64 | 1,02 | 0,24 | 0,59 | 0,95 | 0,23 | 0,58 | 0,93 | .S..HN |

| Geometría de plaquita | Avance inicial recomendado por diente (Fz) en relación con % de contacto radial (ae) | Geometría de plaquita | ||||||||||||||

| 10% | 20% | 30% | 40% | 50–100% | ||||||||||||

| .F..LP | 0,14 | 0,28 | 0,56 | 0,11 | 0,21 | 0,42 | 0,09 | 0,18 | 0,36 | 0,09 | 0,17 | 0,34 | 0,08 | 0,17 | 0,33 | .F..LP |

| .S..GN | 0,28 | 0,67 | 1,14 | 0,21 | 0,50 | 0,85 | 0,18 | 0,44 | 0,74 | 0,17 | 0,41 | 0,69 | 0,17 | 0,40 | 0,68 | .S..GN |

| .T..GN | 0,28 | 0,71 | 1,14 | 0,21 | 0,53 | 0,85 | 0,18 | 0,46 | 0,74 | 0,17 | 0,43 | 0,69 | 0,17 | 0,42 | 0,68 | .T..GN |

| .S..HP | 0,28 | 0,71 | 1,14 | 0,21 | 0,53 | 0,85 | 0,18 | 0,46 | 0,74 | 0,17 | 0,43 | 0,69 | 0,17 | 0,42 | 0,68 | .S..HP |

| .S..HN | 0,28 | 0,71 | 1,14 | 0,21 | 0,53 | 0,85 | 0,18 | 0,46 | 0,74 | 0,17 | 0,43 | 0,69 | 0,17 | 0,42 | 0,68 | .S..HN |

At .197 Axial Depth of Cut (ap)

| Geometría de plaquita | Avance inicial recomendado por diente (Fz) en relación con % de contacto radial (ae) | Geometría de plaquita | ||||||||||||||

| 10% | 20% | 30% | 40% | 50–100% | ||||||||||||

| .F..LP | .007 | .014 | .028 | .005 | .010 | .021 | .005 | .009 | .018 | .004 | .008 | .017 | .004 | .008 | .017 | .F..LP |

| .S..GN | .014 | .033 | .059 | .010 | .024 | .042 | .009 | .021 | .036 | .008 | .020 | .034 | .008 | .019 | .033 | .S..GN |

| .T..GN | .014 | .036 | .059 | .010 | .026 | .042 | .009 | .023 | .036 | .008 | .021 | .034 | .008 | .021 | .033 | .T..GN |

| .S..HP | .014 | .036 | .059 | .010 | .026 | .042 | .009 | .023 | .036 | .008 | .021 | .034 | .008 | .021 | .033 | .S..HP |

| .S..HN | .014 | .036 | .059 | .010 | .026 | .042 | .009 | .023 | .036 | .008 | .021 | .034 | .008 | .021 | .033 | .S..HN |

At .098 Axial Depth of Cut (ap)

| Mecanizado ligero | Aplicaciones generales | Mecanizado intensivo |

At .049 Axial Depth of Cut (ap)

| Geometría de plaquita | Avance inicial recomendado por diente (Fz) en relación con % de contacto radial (ae) | Geometría de plaquita | ||||||||||||||

| 10% | 20% | 30% | 40% | 50–100% | ||||||||||||

| .F..LP | .003 | .007 | .014 | .003 | .005 | .010 | .002 | .004 | .009 | .002 | .004 | .008 | .002 | .004 | .008 | .F..LP |

| .S..GN | .007 | .016 | .028 | .005 | .012 | .020 | .004 | .010 | .018 | .004 | .009 | .016 | .004 | .009 | .016 | .S..GN |

| .T..GN | .007 | .017 | .028 | .005 | .013 | .020 | .004 | .011 | .018 | .004 | .010 | .016 | .004 | .010 | .016 | .T..GN |

| .S..HP | .007 | .017 | .028 | .005 | .013 | .020 | .004 | .011 | .018 | .004 | .010 | .016 | .004 | .010 | .016 | .S..HP |

| .S..HN | .007 | .017 | .028 | .005 | .013 | .020 | .004 | .011 | .018 | .004 | .010 | .016 | .004 | .010 | .016 | .S..HN |

At .025 Axial Depth of Cut (ap)

| Geometría de plaquita | Avance inicial recomendado por diente (Fz) en relación con % de contacto radial (ae) | Geometría de plaquita | ||||||||||||||

| 10% | 20% | 30% | 40% | 50–100% | ||||||||||||

| .F..LP | .005 | .010 | .021 | .004 | .008 | .015 | .003 | .007 | .013 | .003 | .006 | .012 | .003 | .006 | .012 | .F..LP |

| .S..GN | .010 | .024 | .042 | .008 | .018 | .031 | .007 | .015 | .027 | .006 | .014 | .025 | .006 | .014 | .024 | .S..GN |

| .T..GN | .010 | .026 | .042 | .008 | .019 | .031 | .007 | .017 | .027 | .006 | .015 | .025 | .006 | .015 | .024 | .T..GN |

| .S..HP | .010 | .026 | .042 | .008 | .019 | .031 | .007 | .017 | .027 | .006 | .015 | .025 | .006 | .015 | .024 | .S..HP |

| .S..HN | .010 | .026 | .042 | .008 | .019 | .031 | .007 | .017 | .027 | .006 | .015 | .025 | .006 | .015 | .024 | .S..HN |

| Geometría de plaquita | Avance inicial recomendado por diente (Fz) en relación con % de contacto radial (ae) | Geometría de plaquita | ||||||||||||||

| 10% | 20% | 30% | 40% | 50–100% | ||||||||||||

| .F..LP | .004 | .008 | .016 | .003 | .006 | .012 | .003 | .005 | .010 | .002 | .005 | .009 | .002 | .005 | .009 | .F..LP |

| .F..GN | .004 | .008 | .016 | .003 | .006 | .012 | .003 | .005 | .010 | .002 | .005 | .009 | .002 | .005 | .009 | .F..GN |

| .T..GN | .008 | .020 | .032 | .006 | .015 | .023 | .005 | .013 | .020 | .005 | .012 | .019 | .005 | .012 | .018 | .T..GN |

| .S..GN | .008 | .020 | .032 | .006 | .015 | .023 | .005 | .013 | .020 | .005 | .012 | .019 | .005 | .012 | .018 | .S..GN |

| .S..HP | .008 | .020 | .032 | .006 | .015 | .023 | .005 | .013 | .020 | .005 | .012 | .019 | .005 | .012 | .018 | .S..HP |

Speeds

Velocidades iniciales recomendadas (m/min)

| Grupo de materiales | K110M | KC510M | KC522M | KC725M | KCPM20 | KCPK30 | KTPK20 | |||||||||||||||

| P | 1 | – | – | – | – | – | – | 395 | 345 | 325 | 315 | 275 | 255 | 660 | 580 | 535 | 545 | 475 | 440 | 440 | 360 | 310 |

| 2 | – | – | – | – | – | – | 330 | 290 | 240 | 260 | 230 | 195 | 410 | 370 | 330 | 335 | 305 | 275 | 270 | 225 | 190 | |

| 3 | – | – | – | – | – | – | 305 | 255 | 215 | 240 | 205 | 170 | 370 | 330 | 305 | 305 | 275 | 250 | 245 | 205 | 170 | |

| 4 | – | – | – | 295 | 240 | 200 | 270 | 225 | 180 | 215 | 180 | 145 | 275 | 255 | 230 | 225 | 210 | 190 | 185 | 160 | 130 | |

| 5 | – | – | – | – | – | – | 225 | 200 | 180 | 180 | 160 | 145 | 330 | 300 | 275 | 310 | 275 | 255 | 255 | 205 | 175 | |

| 6 | – | – | – | – | – | – | 200 | 150 | 120 | 160 | 120 | 95 | 230 | 200 | 175 | 190 | 165 | – | 150 | 125 | – | |

| M | 1 | – | – | – | – | – | – | 245 | 215 | 200 | 205 | 180 | 165 | 270 | 240 | 205 | 250 | 220 | 190 | 285 | 235 | 200 |

| 2 | – | – | – | – | – | – | 225 | 190 | 160 | 185 | 160 | 130 | 245 | 215 | 190 | 225 | 195 | 170 | 260 | 220 | 185 | |

| 3 | – | – | – | – | – | – | 170 | 145 | 115 | 140 | 120 | 95 | 195 | 175 | 150 | 175 | 160 | 140 | 195 | 160 | – | |

| K | 1 | 155 | 145 | 135 | 350 | 315 | 285 | 275 | 250 | 220 | – | – | – | 435 | 390 | 350 | 355 | 320 | 285 | 275 | 235 | 195 |

| 2 | 135 | 130 | 120 | 275 | 250 | 230 | 215 | 195 | 180 | – | – | – | 345 | 310 | 280 | 280 | 255 | 230 | 220 | 180 | 160 | |

| 3 | 120 | 105 | 95 | 235 | 205 | 190 | 180 | 160 | 145 | – | – | – | 290 | 255 | 240 | 235 | 210 | 195 | 185 | 150 | 130 | |

| N | 1–2 | 605 | 565 | 540 | 770 | 685 | 630 | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – |

| 3 | 495 | 440 | 385 | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | |

| S | 1 | – | – | – | – | – | – | 50 | 45 | 35 | 45 | 35 | 30 | – | – | – | – | – | – | – | – | – |

| 2 | – | – | – | – | – | – | 50 | 45 | 35 | 45 | 35 | 30 | – | – | – | – | – | – | – | – | – | |

| 3 | – | – | – | – | – | – | 60 | 50 | 35 | 55 | 45 | 30 | – | – | – | – | – | – | – | – | – | |

| 4 | – | – | – | – | – | – | 85 | 60 | 45 | 75 | 55 | 35 | – | – | – | – | – | – | – | – | – | |

| H | 1 | – | – | – | 190 | 155 | 110 | 145 | 110 | 85 | – | – | – | 170 | 140 | 115 | – | – | – | – | – | – |

Recommended Starting Speeds [SFM]

| Grupo de materiales | KC110M | KC510M | KC522M | KC725M | KCPM20 | KCPK30 | KTPK20 | |||||||||||||||

| P | 1 | – | – | – | – | – | – | 1300 | 1130 | 1060 | 1030 | 900 | 840 | 2170 | 1910 | 1760 | 1780 | 1560 | 1450 | 1440 | 1180 | 1010 |

| 2 | – | – | – | – | – | – | 1080 | 950 | 790 | 860 | 760 | 640 | 1340 | 1210 | 1090 | 1100 | 1000 | 900 | 890 | 740 | 620 | |

| 3 | – | – | – | – | – | – | 1000 | 840 | 700 | 790 | 670 | 550 | 1210 | 1090 | 1000 | 1000 | 900 | 820 | 800 | 670 | 560 | |

| 4 | – | – | – | 960 | 780 | 660 | 890 | 730 | 590 | 710 | 590 | 470 | 910 | 840 | 760 | 740 | 690 | 620 | 600 | 520 | 430 | |

| 5 | – | – | – | – | – | – | 730 | 660 | 590 | 590 | 530 | 470 | 1090 | 980 | 900 | 1020 | 910 | 830 | 830 | 680 | 580 | |

| 6 | – | – | – | – | – | – | 650 | 490 | 400 | 520 | 400 | 310 | 760 | 660 | 570 | 620 | 540 | – | 500 | 410 | – | |

| M | 1 | – | – | – | – | – | – | 800 | 710 | 650 | 670 | 590 | 540 | 880 | 790 | 680 | 820 | 720 | 620 | 940 | 770 | 650 |

| 2 | – | – | – | – | – | – | 730 | 620 | 520 | 610 | 520 | 430 | 800 | 700 | 620 | 730 | 640 | 550 | 850 | 720 | 600 | |

| 3 | – | – | – | – | – | – | 550 | 480 | 370 | 460 | 400 | 310 | 640 | 570 | 490 | 570 | 520 | 460 | 640 | 530 | – | |

| K | 1 | 510 | 480 | 450 | 1150 | 1040 | 940 | 900 | 820 | 720 | – | – | – | 1420 | 1280 | 1150 | 1160 | 1050 | 940 | 910 | 770 | 640 |

| 2 | 450 | 420 | 390 | 910 | 820 | 760 | 710 | 640 | 590 | – | – | – | 1130 | 1010 | 920 | 920 | 830 | 760 | 720 | 590 | 520 | |

| 3 | 400 | 350 | 310 | 770 | 680 | 620 | 590 | 530 | 480 | – | – | – | 950 | 840 | 780 | 770 | 690 | 640 | 600 | 500 | 420 | |

| N | 1–2 | 1980 | 1860 | 1770 | 2520 | 2240 | 2060 | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – |

| 3 | 1620 | 1440 | 1260 | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | |

| S | 1 | – | – | – | – | – | – | 160 | 140 | 110 | 140 | 120 | 100 | – | – | – | – | – | – | – | – | – |

| 2 | – | – | – | – | – | – | 160 | 140 | 110 | 140 | 120 | 100 | – | – | – | – | – | – | – | – | – | |

| 3 | – | – | – | – | – | – | 200 | 160 | 110 | 180 | 140 | 100 | – | – | – | – | – | – | – | – | – | |

| 4 | – | – | – | – | – | – | 280 | 200 | 140 | 240 | 180 | 120 | – | – | – | – | – | – | – | – | – | |

| H | 1 | – | – | – | 630 | 510 | 360 | 470 | 360 | 280 | – | – | – | 550 | 460 | 370 | – | – | – | – | – | – |

Insert Selection

| Grupo de materiales | Mecanizado ligero | Aplicaciones generales | Mecanizado intensivo | |||

| – | (Geometría ligera) | – | (Geometría fuerte) | |||

| – | resistencia |  | tenacidad | |||

| – | Geometría | Calidad | Geometría | Calidad | Geometría | Calidad |

| P1–P2 | .F..LP | KC725M | .S..HP | KC725M | .S..HP | KC725M |

| P3–P4 | .S..HP | KC522M | .S..HP | KCPK30 | .S..HP | KCPK30 |

| P5–P6 | .S..HP | KC522M | .S..HP | KCPM20 | .S..HN | KCPM20 |

| M1–M2 | .F..LP | KC725M | .S..HP | KC725M | – | – |

| M3 | .S..HP | KC522M | .S..HP | KC725M | – | – |

| K1–K2 | .S..GN | KC510M | .S..HP | KCPK30 | .S..HP | KCPK30 |

| K3 | .S..GN | KC510M | .S..HP | KCPK30 | .S..HP | KCPK30 |

| N1–N2 | .F..LP | K110M | .F..LP | K110M | .F..LP | KC510M |

| N3 | .F..LP | K110M | .F..LP | KC510M | .F..LP | KC510M |

| S1–S2 | – | – | .S..HP | KC725M | – | – |

| S3 | – | – | .S..HP | KC725M | – | – |

| S4 | – | – | .S..HP | KC725M | – | – |

| H1 | .S..HN | KC510M | .S..HN | KC510M | .S..HN | KCPM20 |

I have read and accepted the Terms & Conditions of use

CAD Drawings Models

Can’t find the file type you’re looking for?

Product data