What is Reaming?

But what is reaming, anyway? Simply put, a reamer is a multi-tooth, rotary cutting tool that removes relatively small amounts of material along its leading edges as it passes. It is considered a finishing tool, and requires a pre-drilled hole of a specific diameter to function properly. Straight-flute and helical designs are available, as are so-called left-hand and right-hand versions of the latter (more on this shortly).

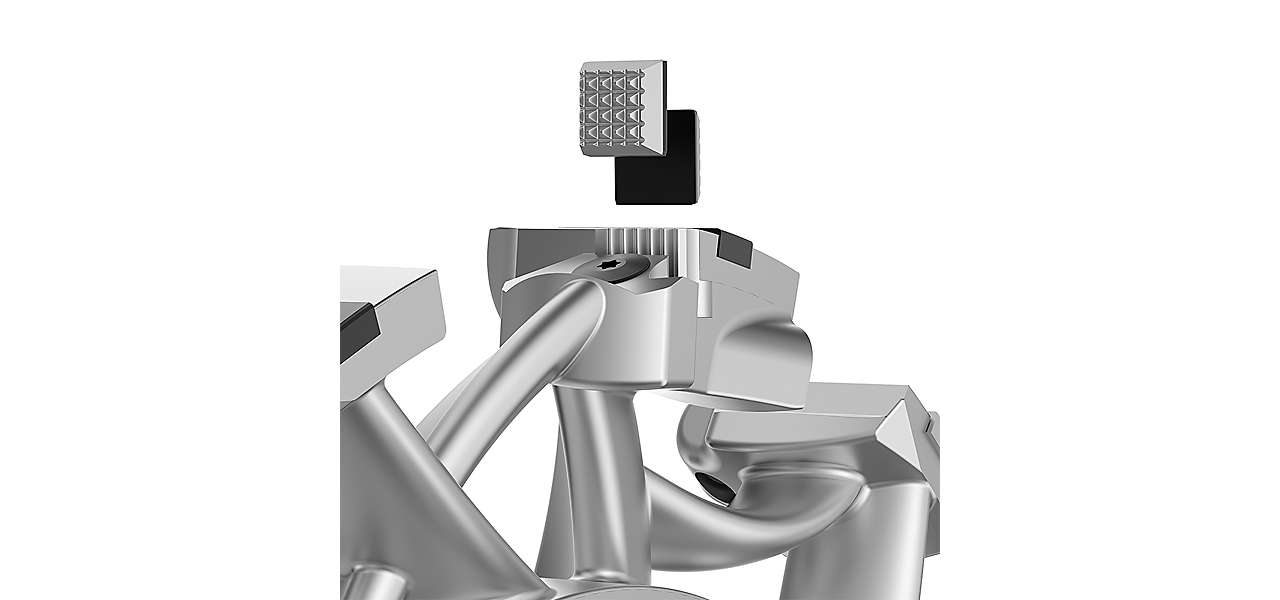

Machinists face a bewildering number of choices when selecting a reamer. Shell, Rose, Hand, Taper, Structural…it's an extensive list. For most applications, however, CNC and manual machinists will use either a Machine reamer or a Chucking reamer, in that order. Expandable reamers are another option, especially for larger holes (say anything above 3/4" or so) or where it’s difficult to achieve the proper hole size. And as you’ll see, modular reaming systems with replaceable heads have become an attractive option over recent years.

Machinists must also decide whether to use carbide or high-speed steel (HSS) reamers. The latter is perfectly fine for softer materials such as aluminum and plastic, and in limited production runs where tool life is less of a concern. For all else, carbide-tipped, modular, or solid carbide tools are preferred. Some cutting tool providers (Kennametal is one) also offer reamers with brazed polycrystalline diamond (PCD) tips; though more expensive than the alternatives, these high-performance tools are ideal for higher volume work in abrasive materials like high silicon aluminum, carbon fiber composites, and certain glass-filled polymers.