Have you ever thought about how much production time your team could save by easily importing Kennametal tooling data into Autodesk Fusion CAM software? This simple integration can significantly streamline your workflow, reduce risk of errors and increase efficiency in your manufacturing processes.

The session features insights from industry experts like Katie Myers, global product manager at Kennametal. She discusses the 7792VX high-feed indexable mills, which are designed for face milling, pocketing, ramping, helical interpolation and plunging. The platform is perfect for removing material quickly and reducing cycle times. Autodesk experts include Graham Goodier, strategic partnerships manager, and Christopher Marion, senior solutions engineer.

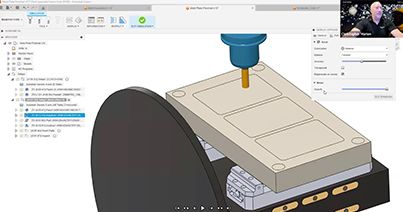

The Autodesk Fusion and Kennametal webinar offers step-by-step instructions on how to use the Kennametal Import Tool add-in.

You will learn how to:

- Access recommended tooling assemblies and cutting data based on your toolpaths and material

- Reduce programming time through automation in Fusion to increase manufacturing output

- Increase efficiency and extend tool life by combining Fusion toolpaths with machine simulation and Kennametal tooling

Take the first step towards a more efficient and productive workflow. Take your manufacturing to the next level!

Explore More Autodesk Fusion and Kennametal

Related Articles

- Kennametal Showcases Innovations Globally Kennametal has been taking the spotlight globally by showcasing the latest innovations at tradeshows including IMTS Chicago, AMB Stuttgart, & JIMTOF Tokyo.Kennametal has been taking the spotlight globally by showcasing the latest innovations at tradeshows including IMTS Chicago, AMB Stuttgart, & JIMTOF Tokyo.

- Webinar: Unlock Efficiency with Autodesk Fusion and Kennametal Tooling SolutionsDiscover how to import Kennametal tooling data into Autodesk Fusion and optimize your manufacturing processes with our in-depth webinar.Discover how to import Kennametal tooling data into Autodesk Fusion and optimize your manufacturing processes with our in-depth webinar.