Product Similar To :

Inserts for Fix-Perfect™ • Aluminium • BGHX15L5... • Finishing

Indexable Inserts • Fix-Perfect • BGHX15L5...

Material Number1794659

ISO Catalog IDBGHX15L5PCTRGG1WANSI Catalog IDBGHX15L5PCTRGG1W

- K Cast Iron

- N Non-Ferrous

Sending to {{cadTool}} in progress...

Downloaded file will be available after import in the {{cadTool}} tool library.

| Material Number | 1794659 |

| ISO Catalog ID | BGHX15L5PCTRGG1W |

| ANSI Catalog ID | BGHX15L5PCTRGG1W |

| Grade | K110M |

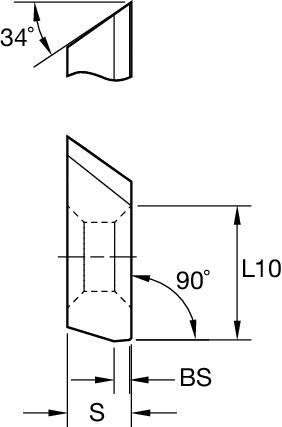

| [L10] Insert Cutting Edge Length | 9.96 mm |

| [L10] Insert Cutting Edge Length | 0.3921 in |

| [S] Insert Thickness | 5 mm |

| [S] Insert Thickness | 0.1969 in |

| [BS] Corner Facet Length | 4 mm |

| [BS] Corner Facet Length | 0.1574 in |

| Average Chip Thickness [HM] | 0.02 mm |

| Average Chip Thickness [HM] | 0.0008 in |

| Cutting Edges per Insert | 1 |

Workpiece Materials

- Cast Iron

- Non-Ferrous

Grades

K110M

Uncoated carbide grade K110M is a universal grade for machining non-ferrous material. For use in light and general machining. K110M can be used with or without coolant.

Features and benefits

- Roughing Fix-Perfect inserts for aluminium and non-ferrous materials.

- 9,5mm max depth of cut.

- Two cutting edges.

Create Solution to calculate Feeds and Speeds

After creating a solution just choose the Feeds & Speeds icon and our system will provide recommendations. You can customize the information by adding your machine and specifications or make adjustments using the sliders.

Feeds

Recommended Starting Feeds [mm]

| Insert Geometry | Recommended Starting Feed per Tooth (Fz) in Relation to % of Radial Engagement (ae) | Insert Geometry | ||||||||||||||

| 5% | 10% | 20% | 30% | 40 | ||||||||||||

| BGHX… | 0,12 | 0,35 | 0,58 | 0,08 | 0,25 | 0,42 | 0,06 | 0,19 | 0,31 | 0,06 | 0,16 | 0,27 | 0,05 | 0,15 | 0,25 | BGHX… |

| Light | General | Heavy |

Speeds

Recommended Starting Speeds [m/min]

| Material Group | K110M | KC510M | KD1410 | KD1415 | |||||||||

| P | 1 | – | – | – | – | – | – | – | – | – | – | – | – |

| 2 | – | – | – | – | – | – | – | – | – | – | – | – | |

| 3 | – | – | – | – | – | – | – | – | – | – | – | – | |

| 4 | – | – | – | – | – | – | – | – | – | – | – | – | |

| 5 | – | – | – | – | – | – | – | – | – | – | – | – | |

| 6 | – | – | – | – | – | – | – | – | – | – | – | – | |

| M | 1 | – | – | – | – | – | – | – | – | – | – | – | – |

| 2 | – | – | – | – | – | – | – | – | – | – | – | – | |

| 3 | – | – | – | – | – | – | – | – | – | – | – | – | |

| K | 1 | – | – | – | – | – | – | – | – | – | – | – | – |

| 2 | – | – | – | – | – | – | – | – | – | – | – | – | |

| 3 | – | – | – | – | – | – | – | – | – | – | – | – | |

| N | 1–2 | 505 | 475 | 450 | 640 | 570 | 525 | 4010 | 3505 | 2990 | 4010 | 3505 | 2990 |

| 3 | 410 | 365 | 320 | 580 | 535 | 490 | 1600 | 1495 | 1400 | 1600 | 1495 | 1400 | |

| S | 1 | – | – | – | – | – | – | – | – | – | – | – | – |

| 2 | – | – | – | – | – | – | – | – | – | – | – | – | |

| 3 | – | – | – | – | – | – | – | – | – | – | – | – | |

| 4 | – | – | – | – | – | – | – | – | – | – | – | – | |

| H | 1 | – | – | – | – | – | – | – | – | – | – | – | – |

Insert Selection

Insert Selection Guide

| Material Group | Light | General | Heavy | |||

| (Light geometry) | – | (Strong geometry) | ||||

| wear |  | toughness | ||||

| Geometry | Grade | Geometry | Grade | Geometry | Grade | |

| P1–P2 | – | – | – | – | – | – |

| P3–P4 | – | – | – | – | – | – |

| P5–P6 | – | – | – | – | – | – |

| M1–M2 | – | – | – | – | – | – |

| M3 | – | – | – | – | – | – |

| K1–K2 | – | – | – | – | – | – |

| K3 | – | – | – | – | – | – |

| N1–N2 | BGHX… | K110M | BGHX… | KC510M | BGHX… | KD1415 |

| N3 | BGHX… | K110M | BGHX… | KD1410 | BGHX… | KD1410 |

| S1–S2 | – | – | – | – | – | – |

| S3 | – | – | – | – | – | – |

| S4 | – | – | – | – | – | – |

| H1 | – | – | – | – | – | – |

I have read and accepted the Terms & Conditions of use