Produkt ähnlich wie:

GOdrill™ • 5xD • Zylinderschaft • Metrisch

Vollhartmetall-Bohrer für verschiedene Werkstoffe

Material Nummer4150754

ISO Katalog NummerB042A11200CPGANSI Katalog NummerB042A11200CPG

- P Stahl

- M Rostfreier Stahl

- K Gusseisen

- N NE-Metalle

- S Hochwarmfeste Legierungen

- H Gehärtete Werkstoffe

Bohren

Bohren: Bohren von gestapelten Platten

DIN 6535

DIN 6537

Außenkühlung: Bohren

Zylinderschaft – ohne Spannfläche ≤h6

Zylinderschaft – Whistle Notch, 2°

Spiralwinkel: 30°

Sending to {{cadTool}} in progress...

Downloaded file will be available after import in the {{cadTool}} tool library.

| Material Nummer | 4150754 |

| ISO Katalog Nummer | B042A11200CPG |

| ANSI Katalog Nummer | B042A11200CPG |

| Sorte | KC7325 |

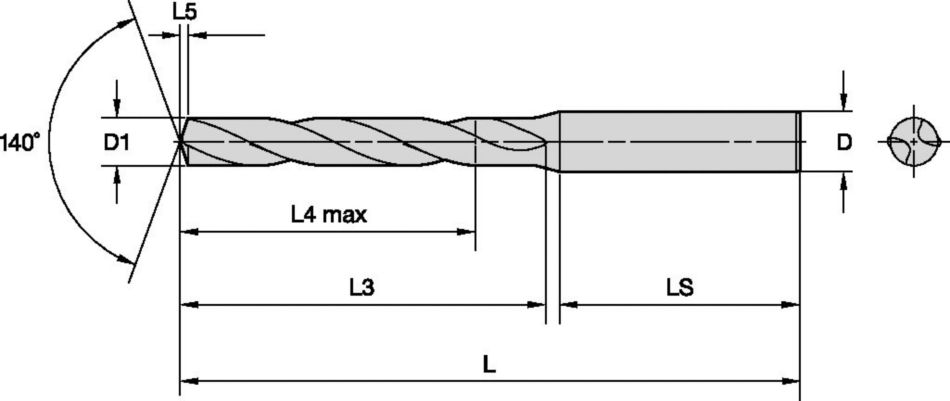

| [D1] Bohrerdurchmesser M | 11.2 mm |

| [D1] Bohrerdurchmesser M | 0.4409 in |

| [L] Gesamtlänge | 118 mm |

| [L] Gesamtlänge | 4.6457 in |

| [L3] Spannuten-Länge | 71 mm |

| [L3] Spannuten-Länge | 2.7953 in |

| [L4] Maximale Bohrtiefe | 56 mm |

| [L4] Maximale Bohrtiefe | 2.2047 in |

| [L5] Bohrerspitzenlänge | 1.92 mm |

| [L5] Bohrerspitzenlänge | 0.0756 in |

| [LS] Schaftlänge | 45 mm |

| [LS] Schaftlänge | 1.7717 in |

| [D] Adapter/Schaft/Bohrungsdurchmesser | 12 mm |

| [D] Adapter/Schaft/Bohrungsdurchmesser | 0.4724 in |

Werkstoffe

- Stahl

- Rostfreier Stahl

- Gusseisen

- NE-Metalle

- Hochwarmfeste Legierungen

- Gehärtete Werkstoffe

Uses and application

Bohren

Bohren: Bohren von gestapelten Platten

DIN 6535

DIN 6537

Außenkühlung: Bohren

Zylinderschaft – ohne Spannfläche ≤h6

Zylinderschaft – Whistle Notch, 2°

Spiralwinkel: 30°

Grades

KC7325

Zusammensetzung: Feinkörniges Hartmetallsubstrat mit PVD-TiN-TiAlN-Mehrlagenbeschichtung mit einer TiN-Oberschicht für eine bessere Erkennbarkeit von Verschleiß.

Anwendung: Diese vielseitig einsetzbare Sorte wurde mit einer einzigartigen universellen Schnittgeometrie kombiniert und bietet hohe Vielseitigkeit und Zuverlässigkeit in allen Werkstoffgruppen bei mittleren Schnittbedingungen.

Features and benefits

- General purpose solid carbide drill for use across a wide range of materials

- Marginless design reduces friction and heat for longer tool life

- Gashing design for micro drilling ensures a free flow of chips in the center of the drill

- Uninterrupted straight cutting lip does not allow a starting point for wear

- Enables an even distribution of cutting forces and reduces chipping on the cutting-edge

- KC7325™ grade contains a double coating for broad applications and a TiN top layer serves for easier monitoring of wear on small drills

Lösung erstellen, um Vorschübe und Geschwindigkeiten zu berechnen

Nachdem Sie eine Lösung erstellt haben, wählen Sie einfach das Symbol für Vorschübe und Geschwindigkeiten und unser System gibt Ihnen Empfehlungen. Sie können die Informationen anpassen, indem Sie Ihre Maschine und Spezifikationen hinzufügen oder Anpassungen mithilfe der Schieberegler vornehmen.

Anwendungsdaten

GOdrill™ • B04_CPG • Sorte KC7325™ • Außenkühlung • Bohrerdurchmesser 1–20 mm • Metrisch

| Werkstoffgruppe |  |  | |||||||||||||

| Werkstoffgruppe | Schnittgeschwindigkeit | Zoll | |||||||||||||

| Bereich | Empfohlene Vorschubrate (f) pro Umdrehung | ||||||||||||||

| Min. | Startwert | Max. | 3/64 .047 | 5/64 .078 | 1/8 .125 | 3/16 .188 | 1/4 .250 | 5/16 .313 | 3/8 .375 | 1/2 .500 | 5/8 .625 | 3/4 .750 | |||

| P | 0 | 200 | 230 | 330 | IPR | .001–.003 | .002–.004 | .002–.004 | .003–.005 | .004–.007 | .004–.009 | .005–.010 | .006–.012 | .007–.014 | .009–.018 |

| 1 | 200 | 230 | 330 | IPR | .002–.004 | .002–.004 | .002–.005 | .004–.006 | .004–.009 | .005–.010 | .006–.012 | .007–.014 | .009–.017 | .011–.021 | |

| 2 | 260 | 300 | 330 | IPR | .002–.004 | .002–.004 | .002–.005 | .003–.006 | .005–.009 | .006–.010 | .007–.012 | .008–.014 | .009–.017 | .012–.021 | |

| 3 | 160 | 230 | 300 | IPR | .002–.004 | .002–.005 | .003–.006 | .004–.007 | .005–.009 | .006–.011 | .008–.013 | .009–.015 | .010–.019 | .013–.023 | |

| 4 | 160 | 230 | 330 | IPR | .002–.005 | .002–.005 | .002–.006 | .003–.007 | .005–.009 | .006–.011 | .007–.013 | .008–.015 | .009–.019 | .011–.023 | |

| 5 | 100 | 130 | 200 | IPR | .001–.002 | .002–.002 | .002–.003 | .002–.004 | .003–.006 | .004–.007 | .005–.009 | .006–.009 | .007–.013 | .009–.016 | |

| 6 | 100 | 130 | 200 | IPR | .001–.002 | .002–.002 | .002–.003 | .002–.004 | .003–.006 | .004–.007 | .005–.009 | .006–.009 | .007–.013 | .009–.016 | |

| M | 1 | 70 | 100 | 130 | IPR | .001–.002 | .001–.002 | .002–.003 | .002–.004 | .003–.004 | .004–.005 | .004–.006 | .005–.006 | .006–.007 | .006–.008 |

| 2 | 100 | 130 | 160 | IPR | .001–.002 | .001–.003 | .002–.003 | .002–.004 | .003–.005 | .004–.006 | .004–.006 | .005–.007 | .006–.008 | .006–.009 | |

| 3 | 70 | 100 | 130 | IPR | .001–.002 | .001–.002 | .002–.003 | .002–.004 | .003–.004 | .004–.005 | .004–.006 | .005–.006 | .006–.007 | .006–.008 | |

| K | 1 | 260 | 430 | 560 | IPR | .004–.007 | .004–.008 | .004–.009 | .005–.009 | .006–.012 | .008–.015 | .009–.017 | .010–.019 | .012–.024 | .015–.029 |

| 2 | 300 | 360 | 390 | IPR | .002–.005 | .003–.006 | .004–.007 | .005–.008 | .006–.010 | .008–.012 | .009–.014 | .010–.016 | .012–.019 | .015–.024 | |

| 3 | 260 | 360 | 430 | IPR | .002–.004 | .002–.005 | .003–.006 | .004–.008 | .005–.010 | .006–.012 | .007–.014 | .008–.016 | .010–.019 | .012–.024 | |

| N | 1 | 300 | 750 | 890 | IPR | .002–.005 | .002–.005 | .003–.006 | .004–.006 | .005–.008 | .006–.009 | .008–.011 | .009–.013 | .011–.016 | .013–.019 |

| 2 | 300 | 720 | 890 | IPR | .002–.003 | .002–.005 | .003–.006 | .004–.008 | .005–.009 | .006–.011 | .008–.013 | .009–.014 | .011–.017 | .013–.021 | |

| 3 | 300 | 590 | 740 | IPR | .004–.005 | .004–.006 | .005–.006 | .005–.006 | .006–.008 | .006–.009 | .008–.011 | .009–.013 | .011–.016 | .013–.017 | |

| 4 | 300 | 430 | 890 | IPR | .002–.003 | .002–.005 | .003–.006 | .004–.008 | .005–.009 | .006–.011 | .008–.013 | .009–.014 | .011–.016 | .013–.019 | |

| S | 1 | 70 | 80 | 100 | IPR | .000–.002 | .001–.002 | .001–.002 | .002–.003 | .002–.004 | .003–.005 | .004–.005 | .004–.006 | .005–.006 | .006–.007 |

| 2 | 30 | 70 | 100 | IPR | .000–.001 | .001–.001 | .001–.002 | .001–.002 | .002–.003 | .003–.004 | .003–.004 | .004–.005 | .004–.006 | .004–.006 | |

| 3 | 70 | 80 | 130 | IPR | .000–.001 | .001–.001 | .001–.002 | .001–.002 | .002–.003 | .002–.004 | .003–.004 | .003–.004 | .004–.005 | .004–.006 | |

| 4 | 70 | 80 | 160 | IPR | .000–.001 | .001–.001 | .001–.002 | .001–.002 | .002–.003 | .003–.004 | .003–.004 | .004–.005 | .004–.006 | .004–.006 | |

| H | 1 | 30 | 50 | 100 | IPR | .000–.001 | .001–.001 | .001–.002 | .001–.002 | .002–.003 | .003–.004 | .003–.004 | .004–.005 | .004–.006 | .004–.006 |

| 2 | 30 | 30 | 100 | IPR | .000–.001 | .001–.001 | .001–.002 | .001–.002 | .002–.003 | .002–.004 | .003–.004 | .003–.004 | .004–.005 | .004–.006 | |

| Werkstoffgruppe |  |  | |||||||||||||

| Schnittgeschwindigkeit | Metrisch | ||||||||||||||

| Bereich | Empfohlene Vorschubrate (f) pro Umdrehung | ||||||||||||||

| Min. | Startwert | Max. | 1,0 | 2,0 | 3,0 | 4,0 | 6,0 | 8,0 | 10,0 | 12,0 | 16,0 | 20,0 | |||

| P | 0 | 70 | 80 | 115 | mm/U | 0,03–0,08 | 0,04–0,09 | 0,05–0,11 | 0,08–0,14 | 0,09–0,19 | 0,11–0,22 | 0,13–0,26 | 0,15–0,30 | 0,19–0,36 | 0,24–0,46 |

| 1 | 60 | 70 | 100 | mm/U | 0,04–0,09 | 0,05–0,11 | 0,06–0,13 | 0,09–0,16 | 0,11–0,22 | 0,13–0,26 | 0,15–0,31 | 0,18–0,35 | 0,22–0,42 | 0,28–0,54 | |

| 2 | 80 | 90 | 100 | mm/U | 0,04–0,09 | 0,05–0,11 | 0,06–0,13 | 0,08–0,16 | 0,12–0,22 | 0,14–0,26 | 0,17–0,31 | 0,20–0,35 | 0,24–0,42 | 0,31–0,53 | |

| 3 | 50 | 70 | 90 | mm/U | 0,05–0,11 | 0,06–0,13 | 0,07–0,15 | 0,09–0,17 | 0,13–0,23 | 0,15–0,28 | 0,19–0,33 | 0,22–0,38 | 0,26–0,47 | 0,34–0,59 | |

| 4 | 50 | 70 | 100 | mm/U | 0,04–0,12 | 0,05–0,13 | 0,06–0,15 | 0,08–0,17 | 0,12–0,23 | 0,14–0,28 | 0,17–0,33 | 0,19–0,38 | 0,23–0,47 | 0,29–0,59 | |

| 5 | 30 | 40 | 60 | mm/U | 0,03–0,05 | 0,04–0,06 | 0,05–0,07 | 0,06–0,10 | 0,08–0,14 | 0,10–0,18 | 0,12–0,22 | 0,14–0,24 | 0,18–0,32 | 0,23–0,41 | |

| 6 | 30 | 40 | 60 | mm/U | 0,03–0,05 | 0,04–0,06 | 0,05–0,07 | 0,06–0,10 | 0,08–0,14 | 0,10–0,18 | 0,12–0,22 | 0,14–0,24 | 0,18–0,32 | 0,23–0,41 | |

| M | 1 | 20 | 30 | 40 | mm/U | 0,02–0,05 | 0,03–0,06 | 0,04–0,07 | 0,05–0,09 | 0,08–0,11 | 0,09–0,12 | 0,10–0,14 | 0,12–0,16 | 0,14–0,18 | 0,16–0,20 |

| 2 | 30 | 40 | 50 | mm/U | 0,02–0,06 | 0,03–0,07 | 0,04–0,08 | 0,06–0,10 | 0,08–0,12 | 0,09–0,14 | 0,10–0,16 | 0,12–0,18 | 0,14–0,20 | 0,16–0,22 | |

| 3 | 20 | 30 | 40 | mm/U | 0,02–0,05 | 0,03–0,06 | 0,04–0,07 | 0,06–0,09 | 0,08–0,11 | 0,09–0,12 | 0,10–0,14 | 0,12–0,16 | 0,14–0,18 | 0,16–0,20 | |

| K | 1 | 80 | 130 | 170 | mm/U | 0,09–0,18 | 0,10–0,20 | 0,11–0,22 | 0,12–0,24 | 0,16–0,31 | 0,20–0,38 | 0,23–0,44 | 0,25–0,49 | 0,31–0,60 | 0,38–0,74 |

| 2 | 90 | 110 | 120 | mm/U | 0,06–0,13 | 0,08–0,15 | 0,10–0,17 | 0,12–0,19 | 0,16–0,25 | 0,20–0,31 | 0,23–0,36 | 0,25–0,40 | 0,31–0,48 | 0,38–0,60 | |

| 3 | 80 | 110 | 130 | mm/U | 0,05–0,11 | 0,06–0,13 | 0,07–0,15 | 0,09–0,19 | 0,12–0,25 | 0,14–0,30 | 0,17–0,35 | 0,19–0,40 | 0,25–0,48 | 0,30–0,60 | |

| N | 1 | 90 | 230 | 270 | mm/U | 0,05–0,12 | 0,06–0,13 | 0,08–0,14 | 0,10–0,16 | 0,12–0,20 | 0,16–0,24 | 0,20–0,28 | 0,24–0,32 | 0,28–0,40 | 0,32–0,48 |

| 2 | 90 | 220 | 270 | mm/U | 0,04–0,08 | 0,06–0,12 | 0,08–0,16 | 0,10–0,20 | 0,12–0,24 | 0,16–0,28 | 0,20–0,32 | 0,24–0,36 | 0,28–0,44 | 0,32–0,52 | |

| 3 | 90 | 180 | 225 | mm/U | 0,10–0,13 | 0,11–0,14 | 0,12–0,14 | 0,13–0,16 | 0,14–0,20 | 0,16–0,24 | 0,20–0,28 | 0,24–0,32 | 0,28–0,40 | 0,32–0,44 | |

| 4 | 90 | 130 | 270 | mm/U | 0,04–0,08 | 0,06–0,12 | 0,08–0,16 | 0,10–0,20 | 0,12–0,24 | 0,16–0,28 | 0,20–0,32 | 0,24–0,36 | 0,28–0,40 | 0,32–0,48 | |

| S | 1 | 20 | 25 | 30 | mm/U | 0,01–0,04 | 0,02–0,05 | 0,03–0,06 | 0,04–0,08 | 0,06–0,10 | 0,08–0,12 | 0,09–0,13 | 0,10–0,14 | 0,12–0,16 | 0,14–0,18 |

| 2 | 10 | 20 | 30 | mm/U | 0,01–0,03 | 0,02–0,03 | 0,02–0,04 | 0,03–0,06 | 0,05–0,08 | 0,07–0,10 | 0,08–0,11 | 0,09–0,12 | 0,10–0,14 | 0,11–0,16 | |

| 3 | 20 | 25 | 40 | mm/U | 0,01–0,03 | 0,02–0,03 | 0,02–0,04 | 0,02–0,05 | 0,04–0,07 | 0,06–0,09 | 0,07–0,10 | 0,08–0,11 | 0,09–0,13 | 0,10–0,15 | |

| 4 | 20 | 25 | 50 | mm/U | 0,01–0,03 | 0,02–0,03 | 0,02–0,04 | 0,03–0,06 | 0,05–0,08 | 0,07–0,10 | 0,08–0,11 | 0,09–0,12 | 0,10–0,14 | 0,11–0,16 | |

| H | 1 | 10 | 15 | 30 | mm/U | 0,01–0,03 | 0,02–0,03 | 0,02–0,04 | 0,03–0,06 | 0,05–0,08 | 0,07–0,10 | 0,08–0,11 | 0,09–0,12 | 0,10–0,14 | 0,11–0,16 |

| 2 | 10 | 10 | 30 | mm/U | 0,01–0,03 | 0,02–0,03 | 0,02–0,04 | 0,02–0,05 | 0,04–0,07 | 0,06–0,09 | 0,07–0,10 | 0,08–0,11 | 0,09–0,13 | 0,10–0,15 | |

|  | ||||||||||||||

| Schnittgeschwindigkeit | Metrisch | ||||||||||||||

| Bereich | Empfohlene Vorschubrate (f) pro Umdrehung | ||||||||||||||

| Werkstoffgruppe | Min. | Startwert | Max. | 1,0 | 2,0 | 3,0 | 4,0 | 6,0 | 8,0 | 10,0 | 12,0 | 16,0 | 20,0 | ||

| P | 0 | 70 | 80 | 115 | mm/dev | 0,03 | 0,04 | 0,05 | 0,08 | 0,09 | 0,11 | 0,13 | 0,15 | 0,19 | 0,24 |

| 1 | 60 | 70 | 100 | mm/dev | 0,04 | 0,05 | 0,06 | 0,09 | 0,11 | 0,13 | 0,15 | 0,18 | 0,22 | 0,28 | |

| 2 | 80 | 90 | 100 | mm/dev | 0,04 | 0,05 | 0,06 | 0,08 | 0,12 | 0,14 | 0,17 | 0,20 | 0,24 | 0,31 | |

| 3 | 50 | 70 | 90 | mm/dev | 0,05 | 0,06 | 0,07 | 0,09 | 0,13 | 0,15 | 0,19 | 0,22 | 0,26 | 0,34 | |

| 4 | 50 | 70 | 100 | mm/dev | 0,04 | 0,05 | 0,06 | 0,08 | 0,12 | 0,14 | 0,17 | 0,19 | 0,23 | 0,29 | |

| 5 | 30 | 40 | 60 | mm/dev | 0,03 | 0,04 | 0,05 | 0,06 | 0,08 | 0,10 | 0,12 | 0,14 | 0,18 | 0,23 | |

| 6 | 30 | 40 | 60 | mm/dev | 0,03 | 0,04 | 0,05 | 0,06 | 0,08 | 0,10 | 0,12 | 0,14 | 0,18 | 0,23 | |

| M | 1 | 20 | 30 | 40 | mm/dev | 0,02 | 0,03 | 0,04 | 0,05 | 0,08 | 0,09 | 0,10 | 0,12 | 0,14 | 0,16 |

| 2 | 30 | 40 | 50 | mm/dev | 0,02 | 0,03 | 0,04 | 0,06 | 0,08 | 0,09 | 0,10 | 0,12 | 0,14 | 0,16 | |

| 3 | 20 | 30 | 40 | mm/dev | 0,02 | 0,03 | 0,04 | 0,06 | 0,08 | 0,09 | 0,10 | 0,12 | 0,14 | 0,16 | |

| K | 1 | 80 | 130 | 170 | mm/dev | 0,09 | 0,10 | 0,11 | 0,12 | 0,16 | 0,20 | 0,23 | 0,25 | 0,31 | 0,38 |

| 2 | 90 | 110 | 120 | mm/dev | 0,06 | 0,08 | 0,10 | 0,12 | 0,16 | 0,20 | 0,23 | 0,25 | 0,31 | 0,38 | |

| 3 | 80 | 110 | 130 | mm/dev | 0,05 | 0,06 | 0,07 | 0,09 | 0,12 | 0,14 | 0,17 | 0,19 | 0,25 | 0,30 | |

| N | 1 | 90 | 230 | 270 | mm/dev | 0,05 | 0,06 | 0,08 | 0,10 | 0,12 | 0,16 | 0,20 | 0,24 | 0,28 | 0,32 |

| 2 | 90 | 220 | 270 | mm/dev | 0,04 | 0,06 | 0,08 | 0,10 | 0,12 | 0,16 | 0,20 | 0,24 | 0,28 | 0,32 | |

| 3 | 90 | 180 | 225 | mm/dev | 0,10 | 0,11 | 0,12 | 0,13 | 0,14 | 0,16 | 0,20 | 0,24 | 0,28 | 0,32 | |

| 5 | 90 | 130 | 270 | mm/dev | 0,04 | 0,06 | 0,08 | 0,10 | 0,12 | 0,16 | 0,20 | 0,24 | 0,28 | 0,32 | |

| S | 1 | 20 | 25 | 30 | mm/dev | 0,01 | 0,02 | 0,03 | 0,04 | 0,06 | 0,08 | 0,09 | 0,10 | 0,12 | 0,14 |

| 2 | 10 | 20 | 30 | mm/dev | 0,01 | 0,02 | 0,02 | 0,03 | 0,05 | 0,07 | 0,08 | 0,09 | 0,10 | 0,11 | |

| 3 | 20 | 25 | 40 | mm/dev | 0,01 | 0,02 | 0,02 | 0,02 | 0,04 | 0,06 | 0,07 | 0,08 | 0,09 | 0,10 | |

| 4 | 20 | 25 | 50 | mm/dev | 0,01 | 0,02 | 0,02 | 0,03 | 0,05 | 0,07 | 0,08 | 0,09 | 0,10 | 0,11 | |

| H | 1 | 10 | 15 | 30 | mm/dev | 0,01 | 0,02 | 0,02 | 0,03 | 0,05 | 0,07 | 0,08 | 0,09 | 0,10 | 0,11 |

| 2 | 10 | 10 | 30 | mm/dev | 0,01 | 0,02 | 0,02 | 0,02 | 0,04 | 0,06 | 0,07 | 0,08 | 0,09 | 0,10 | |

Toleranz

| Toleranz • Zoll | ||

| Nenndurchmesserbereich | D1 Toleranz | D Toleranz h6 |

| .0394–.1181 | .0000/-.0006 (h8) | .0000/-.0002 |

| .0000/-.0005 (h7) | .0000/-.0003 | |

| .0000/-.0006 (h7) | .0000/-.0004 | |

| .0000/-.0007 (h7) | .0000/-.0004 | |

| .0000/-.0008 (h7) | .0000/-.0005 | |

| Toleranz • Metrisch | ||

| Nenndurchmesserbereich | D1 Toleranz | D Toleranz h6 |

| 1–3 | 0,000/-0,014 (h8) | 0,000/-0,006 |

| 0,000/-0,012 (h7) | 0,000/-0,008 | |

| 0,000/-0,015 (h7) | 0,000/-0,009 | |

| 0,000/-0,018 (h7) | 0,000/-0,011 | |

| 0,000/-0,021 (h7) | 0,000/-0,013 | |

Dimension

Abmessungen von Kennametal Vollhartmetall-Bohrer (Baureihe B*)

| mm | KURZ* | LANG* | EXTRA LANG** | |||||||||

| Ø | DIN 6535 | ~3 x D | ~5 x D | ~8 x D | ||||||||

| D1 min | D1 max | D | LS min | L | L3 | L4 | L | L3 | L4 | L | L3 | L4 |

| 1,000 | 1,400 | 4 | 28 | 58 | 7 | 5 | 58 | 9 | 6 | 58 | 12 | 10 |

| 1,401 | 1,900 | 4 | 28 | 58 | 9 | 6 | 58 | 12 | 9 | 58 | 18 | 15 |

| 1,901 | 2,300 | 4 | 28 | 58 | 13 | 9 | 58 | 18 | 14 | 66 | 26 | 22 |

| 2,301 | 2,990 | 4 | 28 | 58 | 17 | 12 | 58 | 22 | 17 | 66 | 30 | 25 |

| 3,000 | 3,750 | 6 | 36 | 62 | 20 | 14 | 66 | 28 | 23 | 78 | 40 | 33 |

| 3,751 | 4,750 | 6 | 36 | 66 | 24 | 17 | 74 | 36 | 29 | 87 | 49 | 41 |

| 4,751 | 6,000 | 6 | 36 | 66 | 28 | 20 | 82 | 44 | 35 | 94 | 56 | 48 |

| 6,001 | 7,000 | 8 | 36 | 79 | 34 | 24 | 91 | 53 | 43 | 105 | 67 | 57 |

| 7,001 | 8,000 | 8 | 36 | 79 | 41 | 29 | 91 | 53 | 43 | 110 | 72 | 61 |

| 8,001 | 10,000 | 10 | 40 | 89 | 47 | 35 | 103 | 61 | 49 | 122 | 80 | 68 |

| 10,001 | 12,000 | 12 | 45 | 102 | 55 | 40 | 118 | 71 | 56 | 141 | 94 | 79 |

| 12,001 | 14,000 | 14 | 45 | 107 | 60 | 43 | 124 | 77 | 60 | 155 | 108 | 91 |

| 14,001 | 16,000 | 16 | 48 | 115 | 65 | 45 | 133 | 83 | 63 | 171 | 121 | 101 |

| 16,001 | 18,000 | 18 | 48 | 123 | 73 | 51 | 143 | 93 | 71 | 185 | 135 | 113 |

| 18,001 | 20,000 | 20 | 50 | 131 | 79 | 55 | 153 | 101 | 77 | 200 | 148 | 124 |

| 20,001 | 22,000 | 20 | 50 | 141 | 86 | 60 | 167 | 112 | 85 | 217 | 162 | 136 |

| 22,001 | 25,000 | 25 | 56 | 153 | 95 | 65 | 184 | 126 | 98 | 238 | 180 | 150 |

| * D1 20 mm gemäß DIN 6537K | ||||||||||||

| * D1 | ||||||||||||

| ** gemäß Werksnorm | ||||||||||||

I have read and accepted the Terms & Conditions of use

CAD Drawings Models

Can’t find the file type you’re looking for?

Product data