Benzer Ürün:

Mill 4-11™ • Carbide Insert • LNPU11-SGE • Medium Machining

Shoulder milling insert with four cutting edges per insert

Ürün Numarası6131502

ISO Katalog NoLNPU110408SRGEANSI Catalog NoLNPU432SRGE

- P Steel

- M Stainless Steel

- K Cast Iron

- S High-Temp Alloys

- H Hardened Materials

Sending to {{cadTool}} in progress...

Downloaded file will be available after import in the {{cadTool}} tool library.

| Ürün Numarası | 6131502 |

| ISO Katalog No | LNPU110408SRGE |

| ANSI Catalog No | LNPU432SRGE |

| Grade | KC522M |

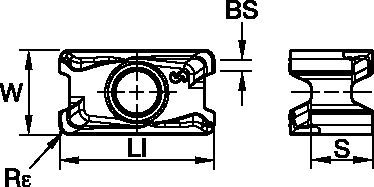

| [LI] Insert Length | 12.1 mm |

| [LI] Insert Length | 0.476 in |

| [S] Insert Thickness | 4.83 mm |

| [S] Insert Thickness | 0.19 in |

| [W] Insert Width | 6.6 mm |

| [W] Insert Width | 0.2598 in |

| [BS] Corner Facet Length | 0.9 mm |

| [BS] Corner Facet Length | 0.036 in |

| [Rε] Corner Radius | 0.8 mm |

| [Rε] Corner Radius | 0.031 in |

| Average Chip Thickness [HM] | 0.1 mm |

| Average Chip Thickness [HM] | 0.0039 in |

| Cutting Edges per Insert | 4 |

İş Parçası Malzemeleri

- Steel

- Stainless Steel

- Cast Iron

- High-Temp Alloys

- Hardened Materials

Kaliteler

KC522M

Coated carbide grade with a AlTiN (PVD) coating. KC522M is engineered to provide better performance in general machining of steel, stainless steel, cast iron, and high-temperature alloys. KC522M resists breakage and offers improved wear resistance and increased strength.

Özellikler ve avantajlar

- Pressed-to-size, for lowest cost per cutting edge

İlerleme ve Devir hesaplamak için Çözüm Oluşturun

Bir çözüm oluşturduktan sonra, sadece İlerleme ve Devir simgesini seçin ve sistemimiz öneriler sunacaktır. Makinenizi ve teknik özelliklerinizi ekleyerek bilgileri özelleştirebilir veya kaydırıcıları kullanarak ayarlamalar yapabilirsiniz.

Uç Seçimi

Kesici uç seçme rehberi

| Mill 4-11™ • Insert Selection Guide | ||||||

| Malzeme grubu | Hafif işleme | Genel amaçlı kullanım | Ağır işleme | |||

| – | (Hafif geometri) | – | (Sert geometri) | |||

| – | Aşınma direnci |  | Tokluk | |||

| – | Geometri | Kalite | Geometri | Kalite | Geometri | Kalite |

| P1–P2 | .E..GD | KCPM40 | .S..GD | KCPM40 | .E..HD | KCPM40 |

| P3–P4 | .E..GD | KCPK30 | .S..GD | KCPK30 | .E..HD | KCPK30 |

| P5–P6 | .E..GD | KC725M | .S..GD | KC725M | .E..HD | KC725M |

| M1–M2 | .E..GD | KCSM40 | .S..GD | KCSM40 | .E..HD | KCSM40 |

| M3 | .E..GD | KCPM40 | .S..GD | KCPM40 | .E..HD | KCPM40 |

| K1–K2 | .E..GD | KCK20B | .E..GD | KCK20B | .S..GD | KCK15 |

| K3 | .E..GD | KCK20B | .S..GD | KCK15 | .E..HD | KCPK30 |

| N1–N2 | .F..LDJ | KC410M | .E..LDJ | KC422M | .E..LDJ | KC422M |

| N3 | .F..LDJ | KC410M | .F..LDJ | KC410M | .F..LDJ | KC410M |

| S1–S2 | .E..GD | KC725M | .S..GD | KC725M | .E..HD | KC725M |

| S3 | .E..GD | KCSM40 | .S..GD | KCSM40 | .E..HD | KCSM40 |

| S4 | .E..GD | KCSM40 | .S..GD | KCSM40 | .E..HD | KCSM40 |

| H1 | – | – | – | – | – | – |

I have read and accepted the Terms & Conditions of use

CAD Drawings Models

Can’t find the file type you’re looking for?

Product data