Prodotto simile a :

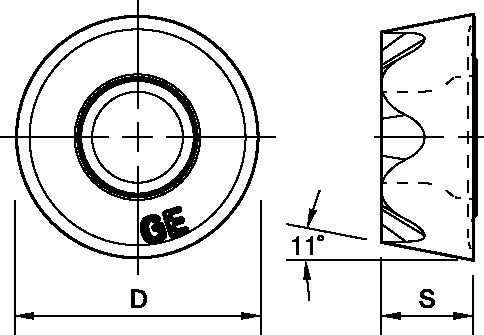

Round Inserts for KSRM • IC 1/2" • RPPT-SGE

Indexable Inserts

Material Number5172844

ISO Catalog IDRPPT43SGEANSI Catalog IDRPPT43SGE

- P Acciaio

- M Acciai inossidabili

- S Leghe resistenti al calore

Sending to {{cadTool}} in progress...

Downloaded file will be available after import in the {{cadTool}} tool library.

| Material Number | 5172844 |

| ISO Catalog ID | RPPT43SGE |

| ANSI Catalog ID | RPPT43SGE |

| Qualità | KC725M |

| [D] Dimensione IC inserto | 12.7 mm |

| [D] Dimensione IC inserto | 0.5 in |

| [S] Spessore inserto | 4.76 mm |

| [S] Spessore inserto | 0.188 in |

| Spessore medio del truciolo [HM] | 0.114 mm |

| Spessore medio del truciolo [HM] | 0.0045 in |

| Numero di posizioni inserto | 6 |

Materiale da lavorare

- Acciaio

- Acciai inossidabili

- Leghe resistenti al calore

Grades

KC725M

Coated carbide grade with an advanced PVD TiAlN coating. KC725M is a high-performance grade for milling steel, stainless steel, and high-temperature alloys. The good thermal shock resistance of the substrate makes this grade ideal for both wet and dry machining. Primarily for use in general and heavy machining.

Features and benefits

- -SGE geometry for general purpose in roughing operations in steel.

Crea una soluzione per calcolare avanzamenti e velocità

Dopo aver creato una soluzione, basta scegliere l'icona Avanzamento e Velocità e il nostro sistema fornirà dei suggerimenti. Puoi personalizzare le informazioni aggiungendo la tua macchina e le specifiche o apportare delle modifiche utilizzando i cursori.

Feeds

| Geometria dell'inserto | Avanzamento per dente programmato (fz) in base alla % della profondità di taglio radiale (ae) | Geometria dell'inserto | ||||||||||||||

| 10% | 20% | 30% | 40% | 50–100% | ||||||||||||

| .E..LEJ | .003 | .005 | .007 | .003 | .004 | .005 | .002 | .003 | .005 | .002 | .003 | .004 | .002 | .003 | .004 | .E..LEJ |

| .E..GE | .006 | .010 | .015 | .004 | .008 | .011 | .004 | .007 | .010 | .004 | .006 | .009 | .004 | .006 | .009 | .E..GE |

| .S..GEJ | .007 | .017 | .023 | .005 | .013 | .017 | .004 | .011 | .015 | .004 | .010 | .014 | .004 | .010 | .014 | .S..GEJ |

| .S..GE | .007 | .017 | .023 | .005 | .013 | .017 | .004 | .011 | .015 | .004 | .010 | .014 | .004 | .010 | .014 | .S..GE |

| Lavorazione leggera | Uso generico | Lavorazione pesante |

| Geometria dell'inserto | Avanzamento per dente programmato (fz) in base alla % della profondità di taglio radiale (ae) | Geometria dell'inserto | ||||||||||||||

| 10% | 20% | 30% | 40% | 50–100% | ||||||||||||

| .E..LEJ | .004 | .006 | .008 | .003 | .004 | .006 | .003 | .004 | .005 | .002 | .003 | .005 | .002 | .003 | .005 | .E..LEJ |

| .E..GE | .007 | .012 | .017 | .005 | .009 | .013 | .004 | .008 | .011 | .004 | .007 | .010 | .004 | .007 | .010 | .E..GE |

| .S..GEJ | .008 | .020 | .027 | .006 | .015 | .020 | .005 | .013 | .017 | .005 | .012 | .016 | .005 | .012 | .016 | .S..GEJ |

| .S..GE | .008 | .020 | .027 | .006 | .015 | .020 | .005 | .013 | .017 | .005 | .012 | .016 | .005 | .012 | .016 | .S..GE |

| Geometria dell'inserto | Avanzamento per dente programmato (fz) in base alla % della profondità di taglio radiale (ae) | Geometria dell'inserto | ||||||||||||||

| 10% | 20% | 30% | 40% | 50–100% | ||||||||||||

| .E..LEJ | .007 | .010 | .015 | .005 | .007 | .011 | .005 | .006 | .009 | .004 | .006 | .009 | .004 | .006 | .009 | .E..LEJ |

| .E..GE | .012 | .021 | .031 | .009 | .016 | .023 | .008 | .014 | .020 | .007 | .013 | .018 | .007 | .012 | .018 | .E..GE |

| .S..GEJ | .014 | .036 | .049 | .010 | .026 | .035 | .009 | .023 | .031 | .008 | .021 | .028 | .008 | .021 | .028 | .S..GEJ |

| .S..GE | .014 | .036 | .049 | .010 | .026 | .035 | .009 | .023 | .031 | .008 | .021 | .028 | .008 | .021 | .028 | .S..GE |

| Geometria dell'inserto | Avanzamento per dente programmato (fz) in base alla % della profondità di taglio radiale (ae) | Geometria dell'inserto | ||||||||||||||

| 10% | 20% | 30% | 40% | 50–100% | ||||||||||||

| .E..LEJ | .005 | .007 | .011 | .004 | .005 | .008 | .003 | .005 | .007 | .003 | .004 | .006 | .003 | .004 | .006 | .E..LEJ |

| .E..GE | .009 | .015 | .023 | .007 | .011 | .017 | .006 | .010 | .014 | .005 | .009 | .014 | .005 | .009 | .013 | .E..GE |

| .S..GEJ | .010 | .026 | .035 | .008 | .019 | .026 | .007 | .017 | .022 | .006 | .015 | .021 | .006 | .015 | .020 | .S..GEJ |

| .S..GE | .010 | .026 | .035 | .008 | .019 | .026 | .007 | .017 | .022 | .006 | .015 | .021 | .006 | .015 | .020 | .S..GE |

Speeds

Recommended Starting Speeds [SFM]

| Gruppo materiali | KC422M | KC522M | KC725M | KCPK30 | |||||||||

| P | 1 | – | – | – | 1300 | 1130 | 1060 | 1030 | 900 | 840 | 1780 | 1560 | 1450 |

| 2 | – | – | – | 1080 | 950 | 790 | 860 | 760 | 640 | 1100 | 1000 | 900 | |

| 3 | – | – | – | 1000 | 840 | 700 | 790 | 670 | 550 | 1000 | 900 | 820 | |

| 4 | – | – | – | 890 | 730 | 590 | 710 | 590 | 470 | 740 | 690 | 620 | |

| 5 | – | – | – | 730 | 660 | 590 | 590 | 530 | 470 | 1020 | 910 | 830 | |

| 6 | – | – | – | 650 | 490 | 400 | 520 | 400 | 310 | 620 | 540 | – | |

| M | 1 | – | – | – | 800 | 710 | 650 | 670 | 590 | 540 | 820 | 720 | 620 |

| 2 | – | – | – | 730 | 620 | 520 | 610 | 520 | 430 | 730 | 640 | 550 | |

| 3 | – | – | – | 550 | 480 | 370 | 460 | 400 | 310 | 570 | 520 | 460 | |

| K | 1 | – | – | – | 900 | 820 | 720 | – | – | – | 1160 | 1050 | 940 |

| 2 | – | – | – | 710 | 640 | 590 | – | – | – | 920 | 830 | 760 | |

| 3 | – | – | – | 590 | 530 | 480 | – | – | – | 770 | 690 | 640 | |

| N | 1–2 | 4220 | 3720 | 3440 | – | – | – | – | – | – | – | – | – |

| 3 | 3720 | 3440 | 3000 | – | – | – | – | – | – | – | – | – | |

| S | 1 | – | – | – | 160 | 140 | 110 | 140 | 120 | 100 | – | – | – |

| 2 | – | – | – | 160 | 140 | 110 | 140 | 120 | 100 | – | – | – | |

| 3 | – | – | – | 200 | 160 | 110 | 180 | 140 | 100 | – | – | – | |

| 4 | – | – | – | 280 | 200 | 140 | 240 | 180 | 120 | – | – | – | |

| H | 1 | – | – | – | 470 | 360 | 280 | – | – | – | – | – | – |

Maximum Linear Ramping and Helical Interpolation from Solid

| codice catalogo | Maximum Ramp Angle (ra) when hx = .01" and ae | Maximum Ramp Depth (ap) per pass when ae | Maximum Ramp Depth (ap) per pass when hx = .01" and ae ae1 | ae1 | Maximum Plunge Depth (ap) when hx = .01" and ae | ae2 | diametro minimo del foro (DH min) | diametro massimo del foro a fondo piatto (DH1 max) | Maximum Hole Diameter (No Flat Bottom) |

| KSRM125R4303C125L600 | 5.30° | 0.055 | 0.250 | 0.406 | 0.250 | 0.500 | 1.688 | 2.001 | 2.500 |

| KSRM125R4302C125L600 | 5.95° | 0.061 | 0.250 | 0.413 | 0.250 | 0.500 | 1.674 | 2.001 | 2.500 |

| KSRM125R4303C125L1000 | 5.30° | 0.055 | 0.250 | 0.406 | 0.250 | 0.500 | 1.688 | 2.001 | 2.500 |

| KSRM125R4302C125L1000 | 5.95° | 0.061 | 0.250 | 0.413 | 0.250 | 0.500 | 1.674 | 2.001 | 2.500 |

| KSRM150R4304C125L600 | 4.74° | 0.069 | 0.250 | 0.421 | 0.250 | 0.500 | 2.157 | 2.502 | 3.000 |

| KSRM150R4303C125L600 | 5.31° | 0.077 | 0.250 | 0.429 | 0.250 | 0.500 | 2.142 | 2.502 | 3.000 |

| KSRM150R4304C125L1000 | 4.74° | 0.069 | 0.250 | 0.421 | 0.250 | 0.500 | 2.157 | 2.502 | 3.000 |

| KSRM150R4303C125L1000 | 5.31° | 0.077 | 0.250 | 0.429 | 0.250 | 0.500 | 2.142 | 2.502 | 3.000 |

| KSRM125R4303M16L150 | 5.30° | 0.055 | 0.250 | 0.406 | 0.250 | 0.500 | 1.688 | 2.001 | 2.500 |

| KSRM125R4302M16L150 | 6.43° | 0.065 | 0.250 | 0.418 | 0.250 | 0.500 | 1.665 | 2.001 | 2.500 |

| KSRM150R4304M16L150 | 4.74° | 0.069 | 0.250 | 0.421 | 0.250 | 0.500 | 2.157 | 2.502 | 3.000 |

| KSRM150R4303M16L150 | 5.31° | 0.077 | 0.250 | 0.429 | 0.250 | 0.500 | 2.142 | 2.502 | 3.000 |

| KSRM200R4305S075L197 | 11.43° | 0.250 | 0.250 | 0.499 | 0.250 | 0.500 | 3.001 | 3.501 | 4.000 |

| KSRM200R4303S075L197 | 11.45° | 0.250 | 0.250 | 0.499 | 0.250 | 0.500 | 3.001 | 3.501 | 4.000 |

| KSRM250R4306S075L197 | 8.16° | 0.250 | 0.250 | 0.500 | 0.250 | 0.500 | 4.001 | 4.500 | 5.000 |

| KSRM250R4304S075L197 | 8.16° | 0.250 | 0.250 | 0.500 | 0.250 | 0.500 | 4.001 | 4.500 | 5.000 |

| KSRM300R4307S100L197 | 6.35° | 0.250 | 0.250 | 0.500 | 0.250 | 0.500 | 5.001 | 5.500 | 6.000 |

| KSRM300R4305S100L197 | 6.35° | 0.250 | 0.250 | 0.500 | 0.250 | 0.500 | 5.001 | 5.500 | 6.000 |

Insert Selection

| Gruppo materiali | Lavorazione leggera | Uso generico | Lavorazione pesante | |||

| – | (Geometria leggera) | – | (Geometria robusta) | |||

| – | resistenza all’usura |  | tenacità | |||

| – | Geometria | Qualità | Geometria | Qualità | Geometria | Qualità |

| P1–P2 | .E..LEJ | KC725M | .E..GE | KC725M | .S..GE | KCPK30 |

| P3–P4 | .E..LEJ | KC725M | .S..GE | KCPK30 | – | – |

| P5–P6 | .E..GE | KCPK30 | .S..GE | KCPK30 | – | – |

| M1–M2 | .E..LEJ | KC725M | .E..LEJ | KC725M | .S..GE | KC725M |

| M3 | .S..GEJ | KC725M | .E..GE | KC725M | .S..GE | KCPK30 |

| K1–K2 | – | – | .S..GE | KCPK30 | – | – |

| K3 | – | – | .S..GE | KCPK30 | – | – |

| N1–N2 | .E..LEJ | KC422M | .E..LEJ | KC422M | .E..LEJ | KC422M |

| N3 | .E..LEJ | KC422M | .E..LEJ | KC422M | .E..LEJ | KC422M |

| S1–S2 | .E..LEJ | KC725M | .S..GEJ | KC725M | .S..GE | KC725M |

| S3 | .E..LEJ | KC725M | .S..GEJ | KC725M | .S..GE | KC725M |

| S4 | .E..LEJ | KC725M | .E..GE | KC725M | .S..GE | KC725M |

| H1 | – | – | .S..GE | KC522M | – | – |

I have read and accepted the Terms & Conditions of use