Producto similar a:

KenTIP™ FS • Cuerpo de broca • 1,5 x D • Mango SS • Sistema métrico

Taladrado modular • Mango recto (SS)

Número de material6389477

Referencia ISOKTFS145R01SS16MReferencia ANSIKTFS145R01SS16M

- P Acero

- M Acero inoxidable

- K Fundición

- S Aleaciones de alta temperatura

- .caption

Drilling

Drilling: Stacked Plates

Taladrado — Con refrigeración interna

Mango — Liso cilíndrico ≤h6

Sending to {{cadTool}} in progress...

Downloaded file will be available after import in the {{cadTool}} tool library.

- Información general

- Datos de aplicación

- Descargas

- Piezas compatibles Lado máquina

- Piezas compatibles Lado de la pieza

- Piezas de recambio

- Comentarios

- Preguntas y Respuestas

| Número de material | 6389477 |

| Referencia ISO | KTFS145R01SS16M |

| Referencia ANSI | KTFS145R01SS16M |

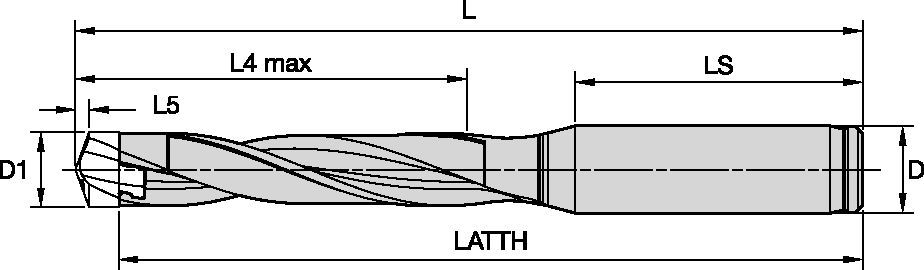

| Diámetro de broca M [D1] | 14.5 mm |

| Diámetro de broca M [D1] | 0.5709 in |

| Diámetro de broca máximo [D1MAX] | 14.999 mm |

| Diámetro de broca máximo [D1MAX] | 0.5905 in |

| Profundidad máxima de taladrado [L4] | 23 mm |

| Profundidad máxima de taladrado [L4] | 0.906 in |

| Longitud total [L] | 91 mm |

| Longitud total [L] | 3.5827 in |

| Soporte LG de conexión de plaquita [LATTH] | 82.6 mm |

| Soporte LG de conexión de plaquita [LATTH] | 3.252 in |

| Longitud de mango [LS] | 49 mm |

| Longitud de mango [LS] | 1.9291 in |

| Adaptador/Mango/Diá int [D] | 16 mm |

| Adaptador/Mango/Diá int [D] | 0.6299 in |

| Tamaño de asiento de la plaquita [SSC] | S |

Materiales de la pieza de trabajo

- Acero

- Acero inoxidable

- Fundición

- Aleaciones de alta temperatura

- .caption

Uses and application

Drilling

Drilling: Stacked Plates

Taladrado — Con refrigeración interna

Mango — Liso cilíndrico ≤h6

Features and benefits

- Los canales de virutas grandes y ultrapulidos garantizan una evacuación de virutas sin complicaciones, mejorando la vida y el rendimiento de la herramienta.

- Suministro de refrigerante a la punta de la broca y a la cara de desprendimiento para una entrega de refrigerante garantizada donde sea necesario.

- Cada cuerpo de broca viene con una llave inteligente KenTIP FS. El intercambio de plaquitas en la máquina es fácil y ahorra tiempo de inactividad y dinero.

Crear una solución para calcular la velocidad y el avance

Después de crear una solución, sólo tiene que elegir el icono Avance y Velocidad y nuestro sistema le ofrecerá recomendaciones. Puede personalizar la información añadiendo su máquina y especificaciones o realizar ajustes utilizando los controles deslizantes.

Datos de aplicación

| Grupo de materiales | Velocidad de corte | Pulgadas | ||||||||||||

| Rango | Avance recomendado por rev. | |||||||||||||

| Mín | Valor inicial | Máx. | .236 | .315 | .394 | .472 | .551 | .630 | .787 | .945 | 1.023 | |||

| P | 0 | 315 | 415 | 575 | IPR | .004 | .004 | .005 | .006 | .007 | .007 | .009 | .011 | .011 |

| 1 | 300 | 430 | 560 | IPR | .004 | .004 | .005 | .006 | .007 | .007 | .009 | .011 | .011 | |

| 2 | 330 | 460 | 590 | IPR | .004 | .004 | .005 | .006 | .007 | .007 | .009 | .011 | .011 | |

| 3 | 200 | 330 | 430 | IPR | .004 | .004 | .005 | .006 | .006 | .007 | .009 | .012 | .012 | |

| 4 | 200 | 330 | 430 | IPR | .004 | .004 | .005 | .006 | .006 | .007 | .009 | .010 | .010 | |

| 5 | 200 | 260 | 330 | IPR | .004 | .004 | .004 | .005 | .006 | .006 | .008 | .009 | .010 | |

| 6 | 200 | 230 | 260 | IPR | .004 | .004 | .004 | .005 | .006 | .006 | .008 | .009 | .010 | |

| K | 1 | 260 | 400 | 560 | IPR | .005 | .005 | .006 | .007 | .009 | .010 | .012 | .014 | .015 |

| 2 | 260 | 360 | 390 | IPR | .005 | .005 | .006 | .007 | .009 | .010 | .012 | .014 | .015 | |

| 3 | 160 | 260 | 330 | IPR | .004 | .005 | .005 | .006 | .007 | .008 | .011 | .013 | .013 | |

| Grupo de materiales | Velocidad de corte | Sistema métrico | ||||||||||||

| Rango | Avance recomendado por rev. | |||||||||||||

| Mín | Valor inicial | Máx. | 6,0 | 8,0 | 10,0 | 12,0 | 14,0 | 16,0 | 20,0 | 24,0 | 26,0 | |||

| P | 0 | 95 | 125 | 175 | mm/r | 0,10 | 0,11 | 0,13 | 0,15 | 0,17 | 0,19 | 0,24 | 0,28 | 0,29 |

| 1 | 90 | 130 | 170 | mm/r | 0,10 | 0,11 | 0,13 | 0,15 | 0,17 | 0,19 | 0,24 | 0,28 | 0,29 | |

| 2 | 100 | 140 | 180 | mm/r | 0,10 | 0,11 | 0,13 | 0,15 | 0,17 | 0,19 | 0,24 | 0,28 | 0,29 | |

| 3 | 60 | 100 | 130 | mm/r | 0,10 | 0,11 | 0,12 | 0,14 | 0,16 | 0,18 | 0,23 | 0,30 | 0,31 | |

| 4 | 60 | 100 | 130 | mm/r | 0,10 | 0,11 | 0,12 | 0,14 | 0,16 | 0,18 | 0,23 | 0,25 | 0,26 | |

| 5 | 60 | 80 | 100 | mm/r | 0,09 | 0,10 | 0,11 | 0,12 | 0,14 | 0,16 | 0,20 | 0,24 | 0,25 | |

| 6 | 60 | 70 | 80 | mm/r | 0,09 | 0,10 | 0,11 | 0,12 | 0,14 | 0,16 | 0,20 | 0,24 | 0,25 | |

| K | 1 | 80 | 120 | 170 | mm/r | 0,12 | 0,14 | 0,16 | 0,19 | 0,23 | 0,26 | 0,30 | 0,36 | 0,37 |

| 2 | 80 | 110 | 120 | mm/r | 0,12 | 0,14 | 0,16 | 0,19 | 0,23 | 0,26 | 0,30 | 0,36 | 0,37 | |

| 3 | 50 | 80 | 100 | mm/r | 0,11 | 0,13 | 0,15 | 0,17 | 0,19 | 0,21 | 0,28 | 0,32 | 0,33 | |

| Grupo de materiales | Velocidad de corte | Sistema métrico | ||||||||||||

| Rango | Avance recomendado por rev. | |||||||||||||

| Mín | Valor inicial | Máx. | 6,0 | 8,0 | 10,0 | 12,0 | 14,0 | 16,0 | 20,0 | 24,0 | 26,0 | |||

| P | 0 | 95 | 125 | 175 | mm/r | 0,10 | 0,11 | 0,13 | 0,15 | 0,17 | 0,19 | 0,24 | 0,28 | 0,29 |

| 1 | 90 | 130 | 170 | mm/r | 0,10 | 0,11 | 0,13 | 0,15 | 0,17 | 0,19 | 0,24 | 0,28 | 0,29 | |

| 2 | 100 | 140 | 180 | mm/r | 0,10 | 0,11 | 0,13 | 0,15 | 0,17 | 0,19 | 0,24 | 0,28 | 0,29 | |

| 3 | 60 | 100 | 130 | mm/r | 0,10 | 0,11 | 0,12 | 0,14 | 0,16 | 0,18 | 0,23 | 0,30 | 0,31 | |

| 4 | 60 | 100 | 130 | mm/r | 0,10 | 0,11 | 0,12 | 0,14 | 0,16 | 0,18 | 0,23 | 0,25 | 0,26 | |

| 5 | 60 | 80 | 100 | mm/r | 0,09 | 0,10 | 0,11 | 0,12 | 0,14 | 0,16 | 0,20 | 0,24 | 0,25 | |

| 6 | 60 | 70 | 80 | mm/r | 0,09 | 0,10 | 0,11 | 0,12 | 0,14 | 0,16 | 0,20 | 0,24 | 0,25 | |

| K | 1 | 80 | 120 | 170 | mm/r | 0,12 | 0,14 | 0,16 | 0,19 | 0,23 | 0,26 | 0,30 | 0,36 | 0,37 |

| 2 | 80 | 110 | 120 | mm/r | 0,12 | 0,14 | 0,16 | 0,19 | 0,23 | 0,26 | 0,30 | 0,36 | 0,37 | |

| 3 | 50 | 80 | 100 | mm/r | 0,11 | 0,13 | 0,15 | 0,17 | 0,19 | 0,21 | 0,28 | 0,32 | 0,33 | |

| Grupo de materiales | Velocidad de corte | Sistema métrico | ||||||||||||

| Rango | Avance recomendado por rev. | |||||||||||||

| Mín | Valor inicial | Máx. | 6,0 | 8,0 | 10,0 | 12,0 | 14,0 | 16,0 | 20,0 | 24,0 | 26,0 | |||

| M | 1 | 50 | 60 | 90 | mm/r | 0,07 | 0,08 | 0,09 | 0,11 | 0,12 | 0,13 | 0,16 | 0,19 | 0,20 |

| 2 | 30 | 60 | 90 | mm/r | 0,07 | 0,08 | 0,09 | 0,11 | 0,12 | 0,13 | 0,16 | 0,19 | 0,20 | |

| 3 | 20 | 50 | 60 | mm/r | 0,07 | 0,08 | 0,09 | 0,11 | 0,12 | 0,13 | 0,16 | 0,19 | 0,20 | |

| Grupo de materiales | Velocidad de corte | Pulgadas | ||||||||||||

| Rango | Avance recomendado por rev. | |||||||||||||

| Mín | Valor inicial | Máx. | .236 | .315 | .394 | .472 | .551 | .630 | .787 | .945 | 1.023 | |||

| M | 1 | 160 | 200 | 300 | IPR | .003 | .003 | .004 | .004 | .005 | .005 | .006 | .007 | .008 |

| 2 | 100 | 200 | 300 | IPR | .003 | .003 | .004 | .004 | .005 | .005 | .006 | .007 | .008 | |

| 3 | 70 | 160 | 200 | IPR | .003 | .003 | .004 | .004 | .005 | .005 | .006 | .007 | .008 | |

| Grupo de materiales | Velocidad de corte | Sistema métrico | ||||||||||||

| Rango | Avance recomendado por rev. | |||||||||||||

| Mín | Valor inicial | Máx. | 6,0 | 8,0 | 10,0 | 12,0 | 14,0 | 16,0 | 20,0 | 24,0 | 26,0 | |||

| M | 1 | 50 | 60 | 90 | mm/r | 0,07 | 0,08 | 0,09 | 0,11 | 0,12 | 0,13 | 0,16 | 0,19 | 0,20 |

| 2 | 30 | 60 | 90 | mm/r | 0,07 | 0,08 | 0,09 | 0,11 | 0,12 | 0,13 | 0,16 | 0,19 | 0,20 | |

| 3 | 20 | 50 | 60 | mm/r | 0,07 | 0,08 | 0,09 | 0,11 | 0,12 | 0,13 | 0,16 | 0,19 | 0,20 | |

| Grupo de materiales | Velocidad de corte | Sistema métrico | ||||||||||||

| Rango | Avance recomendado por rev. | |||||||||||||

| Mín | Valor inicial | Máx. | 6,0 | 8,0 | 10,0 | 12,0 | 14,0 | 16,0 | 20,0 | 24,0 | 26,0 | |||

| K | 1 | 100 | 175 | 200 | mm/r | 0,12 | 0,14 | 0,16 | 0,19 | 0,23 | 0,26 | 0,30 | 0,36 | 0,37 |

| 2 | 100 | 160 | 180 | mm/r | 0,12 | 0,14 | 0,16 | 0,19 | 0,23 | 0,26 | 0,30 | 0,36 | 0,37 | |

| 3 | 70 | 85 | 120 | mm/r | 0,11 | 0,13 | 0,15 | 0,17 | 0,19 | 0,21 | 0,28 | 0,32 | 0,33 | |

| Grupo de materiales | Velocidad de corte | Pulgadas | ||||||||||||

| Rango | Avance recomendado por rev. | |||||||||||||

| Mín | Valor inicial | Máx. | .236 | .315 | .394 | .472 | .551 | .630 | .787 | .945 | 1.023 | |||

| K | 1 | 330 | 570 | 660 | IPR | .005 | .005 | .006 | .007 | .009 | .010 | .012 | .014 | .015 |

| 2 | 330 | 520 | 590 | IPR | .005 | .005 | .006 | .007 | .009 | .010 | .012 | .014 | .015 | |

| 3 | 230 | 280 | 390 | IPR | .004 | .005 | .005 | .006 | .007 | .008 | .011 | .013 | .013 | |

| Grupo de materiales | Velocidad de corte | Sistema métrico | ||||||||||||

| Rango | Avance recomendado por rev. | |||||||||||||

| Mín | Valor inicial | Máx. | 6,0 | 8,0 | 10,0 | 12,0 | 14,0 | 16,0 | 20,0 | 24,0 | 26,0 | |||

| K | 1 | 100 | 175 | 200 | mm/r | 0,12 | 0,14 | 0,16 | 0,19 | 0,23 | 0,26 | 0,30 | 0,36 | 0,37 |

| 2 | 100 | 160 | 180 | mm/r | 0,12 | 0,14 | 0,16 | 0,19 | 0,23 | 0,26 | 0,30 | 0,36 | 0,37 | |

| 3 | 70 | 85 | 120 | mm/r | 0,11 | 0,13 | 0,15 | 0,17 | 0,19 – 0,42 | 0,21 | 0,28 | 0,32 | 0,33 | |

| Grupo de materiales | Velocidad de corte | Sistema métrico | |||||||||

| Rango | Avance recomendado por rev. | ||||||||||

| Mín | Valor inicial | Máx. | 6,0 | 8,0 | 10,0 | 12,0 | 16,0 | 20,0 | |||

| S | 4 | 10 | 13 | 20 | mm/r | 0,02–0,08 | 0,03–0,10 | 0,04–0,12 | 0,05–0,16 | 0,05–0,18 | 0,06–0,20 |

| N | 1 | 100 | 230 | 270 | mm/r | 0,13–0,22 | 0,16–0,24 | 0,20–0,28 | 0,24–0,32 | 0,28–0,40 | 0,32–0,48 |

| 2 | 100 | 220 | 270 | mm/r | 0,14–0,23 | 0,16–0,28 | 0,20–0,32 | 0,24–0,36 | 0,28–0,40 | 0,32–0,52 | |

| 3 | 90 | 180 | 230 | mm/r | 0,13–0,22 | 0,16–0,24 | 0,20–0,28 | 0,24–0,32 | 0,28–0,40 | 0,32–0,48 | |

| 4 | 90 | 130 | 200 | mm/r | 0,10–0,18 | 0,16–0,28 | 0,20–0,32 | 0,24–0,36 | 0,28–0,40 | 0,32–0,52 | |

| C | 2 | 70 | 110 | 140 | mm/r | 0,03-0,10 | 0,04-0,12 | 0,05-0,15 | 0,05-0,18 | 0,06-0,21 | 0,07-0,23 |

| 3 | 10 | 13 | 20 | mm/r | 0,02-0,08 | 0,03-0,10 | 0,04-0,12 | 0,05-0,16 | 0,05-0,18 | 0,06-0,20 | |

| 4 | 10 | 20 | 40 | mm/r | 0,02-0,08 | 0,03-0,10 | 0,04-0,12 | 0,05-0,16 | 0,05-0,18 | 0,06-0,20 | |

| Grupo de materiales | Velocidad de corte | Pulgadas | |||||||||

| Rango | Avance recomendado por rev. | ||||||||||

| Mín | Valor inicial | Máx. | 1/4 0,250 | 5/16 0,313 | 3/8 0,375 | 1/2 0,500 | 5/8 0,625 | 3/4 0,750 | |||

| S | 4 | 30 | 40 | 70 | IPR | 0.001–0.003 | 0.001–0.004 | 0.002–0.005 | 0.002–0.006 | 0.002–0.007 | 0.002–0.008 |

| N | 1 | 330 | 750 | 890 | IPR | 0.005–0.009 | 0.006–0.009 | 0.008–0.011 | 0.009–0.013 | 0.011–0.016 | 0.013–0.019 |

| 2 | 330 | 720 | 890 | IPR | 0.006–0.009 | 0.006–0.011 | 0.008–0.013 | 0.009–0.014 | 0.011–0.017 | 0.013–0.021 | |

| 3 | 300 | 590 | 750 | IPR | 0.005–0.009 | 0.006–0.009 | 0.008–0.011 | 0.009–0.013 | 0.011–0.016 | 0.013–0.019 | |

| 4 | 300 | 430 | 660 | IPR | 0.004–0.007 | 0.006–0.011 | 0.008–0.013 | 0.009–0.014 | 0.011–0.016 | 0.013–0.019 | |

| C | 4 | 230 | 360 | 460 | IPR | 0.001-0.004 | 0.002-0.005 | 0.002-0.006 | 0.002-0.007 | 0.002-0.008 | 0.003-0.009 |

| 4 | 30 | 40 | 70 | IPR | 0.001-0.003 | 0.001-0.004 | 0.002-0.005 | 0.002-0.006 | 0.002-0.007 | 0.002-0.008 | |

| 4 | 30 | 70 | 130 | IPR | 0.001-0.003 | 0.001-0.004 | 0.002-0.005 | 0.002-0.006 | 0.002-0.007 | 0.002-0.008 | |

| Grupo de materiales | Velocidad de corte | Sistema métrico | |||||||||

| Rango | Avance recomendado por rev. | ||||||||||

| Mín | Valor inicial | Máx. | 6.0 | 8.0 | 10.0 | 12.0 | 16.0 | 20.0 | |||

| S | 4 | 10 | 13 | 20 | mm/r | 0.02~0.08 | 0.03~0.10 | 0.04~0.12 | 0.05~0.16 | 0.05~0.18 | 0.06~0.20 |

| N | 1 | 100 | 230 | 270 | mm/r | 0.13~0.22 | 0.16~0.24 | 0.20~0.28 | 0.24~0.32 | 0.28~0.40 | 0.32~0.48 |

| 2 | 100 | 220 | 270 | mm/r | 0.14~0.23 | 0.16~0.28 | 0.20~0.32 | 0.24~0.36 | 0.28~0.40 | 0.32~0.52 | |

| 3 | 90 | 180 | 230 | mm/r | 0.13~0.22 | 0.16~0.24 | 0.20~0.28 | 0.24~0.32 | 0.28~0.40 | 0.32~0.48 | |

| 4 | 90 | 130 | 200 | mm/r | 0.10~0.18 | 0.16~0.28 | 0.20~0.32 | 0.24~0.36 | 0.28~0.40 | 0.32~0.52 | |

| C | 2 | 70 | 110 | 140 | mm/r | 0.03~0.10 | 0.04~0.12 | 0.05~0.15 | 0.05~0.18 | 0.06~0.21 | 0.07~0.23 |

| 3 | 10 | 13 | 20 | mm/r | 0.02~0.08 | 0.03~0.10 | 0.04~0.12 | 0.05~0.16 | 0.05~0.18 | 0.06~0.20 | |

| 4 | 10 | 20 | 40 | mm/r | 0.02~0.08 | 0.03~0.10 | 0.04~0.12 | 0.05~0.16 | 0.05~0.18 | 0.06~0.20 | |

| Grupo de materiales | Velocidad de corte | Pulgadas | |||||||||

| Rango | Avance recomendado por rev. | ||||||||||

| Mín | Valor inicial | Máx. | 1/4 0,250 | 5/16 0,313 | 3/8 0,375 | 1/2 0,500 | 5/8 0,625 | 3/4 0,750 | |||

| C | 1 | 260 | 330 | 490 | IPR | 0,002 | 0,002 | 0,002 | 0,002 | 0,002 | 0,002 |

| Grupo de materiales | Velocidad de corte | Sistema métrico | |||||||||

| Rango | Avance recomendado por rev. | ||||||||||

| Mín | Valor inicial | Máx. | 6,0 | 8,0 | 10,0 | 12,0 | 16,0 | 20,0 | |||

| C | 1 | 80 | 100 | 150 | mm/r | 0,05 | 0,05 | 0,05 | 0,05 | 0,05 | 0,05 |

| Grupo de materiales | Velocidad de corte | Sistema métrico | |||||||||

| Rango | Avance recomendado por rev. | ||||||||||

| Mín | Valor inicial | Máx. | 6,0 | 8.0 | 10.0 | 12.0 | 16.0 | 20.0 | |||

| C | 1 | 80 | 100 | 150 | mm/r | 0.05~0.20 | 0.05~0.20 | 0.05~0.20 | 0.05~0.20 | 0.05~0.20 | 0.05~0.20 |

| Grupo de materiales | Velocidad de corte | Sistema métrico | ||||||||||||

| Rango | Avance recomendado por rev. | |||||||||||||

| Mín | Valor inicial | Máx. | 6,0 | 8,0 | 10,0 | 12,0 | 14,0 | 16,0 | 20,0 | 24,0 | 26,0 | |||

| P | 0 | 110 | 140 | 170 | mm/r | 0,10–0,19 | 0,11–0,22 | 0,13–0,24 | 0,15–0,26 | 0,17–0,29 | 0,19–0,31 | 0,21–0,34 | 0,23–0,38 | 0,24–0,40 |

| 1 | 110 | 140 | 170 | mm/r | 0,10–0,19 | 0,11–0,22 | 0,13–0,24 | 0,15–0,26 | 0,17–0,29 | 0,19–0,31 | 0,21–0,34 | 0,23–0,38 | 0,24–0,40 | |

| 2 | 100 | 120 | 140 | mm/r | 0,10–0,19 | 0,11–0,22 | 0,13–0,24 | 0,15–0,26 | 0,17–0,29 | 0,19–0,31 | 0,21–0,34 | 0,23–0,38 | 0,24–0,40 | |

| 3 | 80 | 100 | 120 | mm/r | 0,10–0,17 | 0,11–0,20 | 0,12–0,22 | 0,14–0,24 | 0,16–0,26 | 0,18–0,28 | 0,20–0,31 | 0,21–0,35 | 0,22–0,36 | |

| 4 | 70 | 90 | 110 | mm/r | 0,10–0,17 | 0,11–0,20 | 0,12–0,22 | 0,14–0,24 | 0,16–0,26 | 0,18–0,28 | 0,20–0,31 | 0,21–0,35 | 0,22–0,36 | |

| 5 | 60 | 80 | 100 | mm/r | 0,09–0,16 | 0,10–0,18 | 0,11–0,20 | 0,13–0,22 | 0,15–0,24 | 0,16–0,26 | 0,18–0,29 | 0,19–0,33 | 0,20–0,34 | |

| 6 | 60 | 80 | 100 | mm/r | 0,09–0,16 | 0,10–0,18 | 0,11–0,20 | 0,13–0,22 | 0,15–0,24 | 0,16–0,26 | 0,18–0,29 | 0,19–0,33 | 0,20–0,34 | |

| M | 1 | 40 | 60 | 80 | mm/r | 0,07–0,12 | 0,08–0,14 | 0,09–0,16 | 0,11–0,18 | 0,12–0,20 | 0,13–0,22 | 0,14–0,24 | 0,15–0,26 | 0,16–0,27 |

| 2 | 35 | 55 | 70 | mm/r | 0,07–0,12 | 0,08–0,14 | 0,09–0,16 | 0,11–0,18 | 0,12–0,20 | 0,13–0,22 | 0,14–0,24 | 0,15–0,26 | 0,16–0,27 | |

| K | 1 | 90 | 120 | 175 | mm/r | 0,12-0,21 | 0,14-0,24 | 0,16-0,28 | 0,18-0,32 | 0,20-0,36 | 0,22-0,40 | 0,25-0,44 | 0,28-0,48 | 0,29-0,50 |

| 2 | 80 | 110 | 140 | mm/r | 0,12–0,21 | 0,14–0,24 | 0,16–0,28 | 0,18–0,32 | 0,20–0,36 | 0,22–0,40 | 0,25–0,44 | 0,28–0,48 | 0,29–0,50 | |

| 3 | 70 | 80 | 100 | mm/r | 0,11-0,19 | 0,13-0,22 | 0,14-0,25 | 0,16-0,28 | 0,18-0,32 | 0,21-0,36 | 0,23-0,40 | 0,26-0,44 | 0,27-0,46 | |

| Grupo de materiales | Velocidad de corte | Pulgadas | ||||||||||||

| Rango | Avance recomendado por rev. | |||||||||||||

| Mín | Valor inicial | Máx. | .236 | .315 | .394 | .472 | .551 | .630 | .787 | .945 | 1.023 | |||

| P | 0 | 360 | 460 | 560 | IPR | 0.004–0.007 | 0.004–0.009 | 0.005–0.009 | 0.006–0.010 | 0.007–0.011 | 0.007–0.012 | 0.008–0.013 | 0.009–0.015 | 0.009–0.016 |

| 1 | 360 | 460 | 560 | IPR | 0.004–0.007 | 0.004–0.009 | 0.005–0.009 | 0.006–0.010 | 0.007–0.011 | 0.007–0.012 | 0.008–0.013 | 0.009–0.015 | 0.009–0.016 | |

| 2 | 330 | 400 | 460 | IPR | 0.004–0.007 | 0.004–0.009 | 0.005–0.009 | 0.006–0.010 | 0.007–0.011 | 0.007–0.012 | 0.008–0.013 | 0.009–0.015 | 0.009–0.016 | |

| 3 | 260 | 330 | 400 | IPR | 0.004–0.007 | 0.004–0.008 | 0.005–0.009 | 0.006–0.009 | 0.006–0.010 | 0.007–0.011 | 0.008–0.012 | 0.008–0.014 | 0.009–0.014 | |

| 4 | 230 | 330 | 360 | IPR | 0.004–0.007 | 0.004–0.008 | 0.005–0.009 | 0.006–0.009 | 0.006–0.010 | 0.007–0.011 | 0.008–0.012 | 0.008–0.014 | 0.009–0.014 | |

| 5 | 200 | 260 | 330 | IPR | 0.004–0.006 | 0.004–0.007 | 0.004–0.008 | 0.005–0.009 | 0.006–0.009 | 0.006–0.010 | 0.007–0.011 | 0.007–0.013 | 0.008–0.013 | |

| 6 | 200 | 260 | 330 | IPR | 0.004–0.006 | 0.004–0.007 | 0.004–0.008 | 0.005–0.009 | 0.006–0.009 | 0.006–0.010 | 0.007–0.011 | 0.007–0.013 | 0.008–0.013 | |

| M | 1 | 130 | 200 | 260 | IPR | 0.003–0.005 | 0.003–0.006 | 0.004–0.006 | 0.004–0.007 | 0.005–0.008 | 0.005–0.009 | 0.006–0.009 | 0.006–0.010 | 0.006–0.011 |

| 2 | 120 | 180 | 230 | IPR | 0.003–0.005 | 0.003–0.006 | 0.004–0.006 | 0.004–0.007 | 0.005–0.008 | 0.005–0.009 | 0.006–0.009 | 0.006–0.010 | 0.006–0.011 | |

| K | 1 | 300 | 400 | 580 | IPR | 0.005-0.008 | 0.006-0.009 | 0.006-0.011 | 0.007-0.013 | 0.008-0.014 | 0.009-0.016 | 0.010-0.017 | 0.011-0.019 | 0.011-0.020 |

| 2 | 260 | 360 | 460 | IPR | 0.005–0.008 | 0.006–0.009 | 0.006–0.011 | 0.007–0.013 | 0.008–0.014 | 0.009–0.016 | 0.010–0.017 | 0.011–0.019 | 0.011–0.020 | |

| 3 | 230 | 260 | 330 | IPR | 0.004-0.007 | 0.005-0.009 | 0.006-0.010 | 0.006-0.011 | 0.007-0.013 | 0.008-0.014 | 0.009-0.016 | 0.010-0.017 | 0.011-0.018 | |

| Grupo de materiales | Velocidad de corte | Sistema métrico | ||||||||||||

| Rango | Avance recomendado por rev. | |||||||||||||

| Mín | Valor inicial | Máx. | 6,0 | 8,0 | 10,0 | 12,0 | 14,0 | 16,0 | 20,0 | 24,0 | 26,0 | |||

| P | 0 | 110 | 140 | 170 | mm/r | 0,10–0,19 | 0,11–0,22 | 0,13–0,24 | 0,15–0,26 | 0,17–0,29 | 0,19–0,31 | 0,21–0,34 | 0,23–0,38 | 0,24–0,40 |

| 1 | 110 | 140 | 170 | mm/r | 0,10–0,19 | 0,11–0,22 | 0,13–0,24 | 0,15–0,26 | 0,17–0,29 | 0,19–0,31 | 0,21–0,34 | 0,23–0,38 | 0,24–0,40 | |

| 2 | 100 | 120 | 140 | mm/r | 0,10–0,19 | 0,11–0,22 | 0,13–0,24 | 0,15–0,26 | 0,17–0,29 | 0,19–0,31 | 0,21–0,34 | 0,23–0,38 | 0,24–0,40 | |

| 3 | 80 | 100 | 120 | mm/r | 0,10–0,17 | 0,11–0,20 | 0,12–0,22 | 0,14–0,24 | 0,16–0,26 | 0,18–0,28 | 0,20–0,31 | 0,21–0,35 | 0,22–0,36 | |

| 4 | 70 | 90 | 110 | mm/r | 0,10–0,17 | 0,11–0,20 | 0,12–0,22 | 0,14–0,24 | 0,16–0,26 | 0,18–0,28 | 0,20–0,31 | 0,21–0,35 | 0,22–0,36 | |

| 5 | 60 | 80 | 100 | mm/r | 0,09–0,16 | 0,10–0,18 | 0,11–0,20 | 0,13–0,22 | 0,15–0,24 | 0,16–0,26 | 0,18–0,29 | 0,19–0,33 | 0,20–0,34 | |

| 6 | 60 | 80 | 100 | mm/r | 0,09–0,16 | 0,10–0,18 | 0,11–0,20 | 0,13–0,22 | 0,15–0,24 | 0,16–0,26 | 0,18–0,29 | 0,19–0,33 | 0,20–0,34 | |

| M | 1 | 40 | 60 | 80 | mm/r | 0,07–0,12 | 0,08–0,14 | 0,09–0,16 | 0,11–0,18 | 0,12–0,20 | 0,13–0,22 | 0,14–0,24 | 0,15–0,26 | 0,16–0,27 |

| 2 | 35 | 55 | 70 | mm/r | 0,07–0,12 | 0,08–0,14 | 0,09–0,16 | 0,11–0,18 | 0,12–0,20 | 0,13–0,22 | 0,14–0,24 | 0,15–0,26 | 0,16–0,27 | |

| K | 1 | 90 | 120 | 175 | mm/r | 0,12-0,21 | 0,14-0,24 | 0,16-0,28 | 0,18-0,32 | 0,20-0,36 | 0,22-0,40 | 0,25-0,44 | 0,28-0,48 | 0,29-0,50 |

| 2 | 80 | 110 | 140 | mm/r | 0,12–0,21 | 0,14–0,24 | 0,16–0,28 | 0,18–0,32 | 0,20–0,36 | 0,22–0,40 | 0,25–0,44 | 0,28–0,48 | 0,29–0,50 | |

| 3 | 70 | 80 | 100 | mm/r | 0,11-0,19 | 0,13-0,22 | 0,14-0,25 | 0,16-0,28 | 0,18-0,32 | 0,21-0,36 | 0,23-0,40 | 0,26-0,44 | 0,27-0,46 | |

| Grupo de materiales | Velocidad de corte | Sistema métrico | |||||||||||

| Rango | Avance recomendado por rev. | ||||||||||||

| Mín | Valor inicial | Máx. | 6,0 | 8,0 | 10,0 | 12,0 | 16,0 | 20,0 | 24,0 | 26,0 | |||

| P | 0 | 70 | 125 | 175 | mm/r | 0,09–0,18 | 0,10–0,21 | 0,12–0,24 | 0,14–0,30 | 0,18–0,36 | 0,23–0,42 | 0,27–0,48 | 0,28–0,50 |

| 1 | 70 | 120 | 170 | mm/r | 0,09–0,18 | 0,10–0,22 | 0,12–0,24 | 0,14–0,30 | 0,18–0,36 | 0,23–0,42 | 0,27–0,48 | 0,28–0,50 | |

| 2 | 90 | 135 | 180 | mm/r | 0,09–0,18 | 0,10–0,25 | 0,12–0,27 | 0,14–0,33 | 0,18–0,39 | 0,23–0,45 | 0,27–0,51 | 0,28–0,50 | |

| 3 | 60 | 95 | 130 | mm/r | 0,09–0,16 | 0,10–0,28 | 0,11–0,29 | 0,13–0,33 | 0,17–0,37 | 0,22–0,41 | 0,28–0,45 | 0,30–0,46 | |

| 4 | 50 | 90 | 130 | mm/r | 0,09–0,16 | 0,10–0,28 | 0,11–0,29 | 0,13–0,33 | 0,17–0,37 | 0,22–0,41 | 0,24–0,45 | 0,25–0,46 | |

| 5 | 30 | 65 | 100 | mm/r | 0,09–0,15 | 0,10–0,18 | 0,10–0,22 | 0,11–0,27 | 0,15–0,32 | 0,19–0,37 | 0,23–0,42 | 0,24–0,43 | |

| 6 | 40 | 60 | 80 | mm/r | 0,09–0,15 | 0,09–0,18 | 0,10–0,22 | 0,10–0,27 | 0,15–0,32 | 0,19–0,37 | 0,23–0,42 | 0,24–0,43 | |

| M | 1 | 20 | 55 | 90 | mm/r | 0,07–0,12 | 0,08–0,13 | 0,08–0,14 | 0,10–0,18 | 0,12–0,22 | 0,15–0,26 | 0,18–0,27 | 0,19–0,28 |

| 2 | 30 | 60 | 90 | mm/r | 0,07–0,12 | 0,08–0,13 | 0,08–0,16 | 0,10–0,18 | 0,12–0,22 | 0,15–0,26 | 0,18–0,27 | 0,19–0,28 | |

| 3 | 20 | 40 | 60 | mm/r | 0,07–0,12 | 0,08–0,12 | 0,08–0,14 | 0,10–0,16 | 0,12–0,22 | 0,15–0,26 | 0,18–0,27 | 0,19–0,28 | |

| K | 1 | 80 | 140 | 200 | mm/r | 0,11–0,26 | 0,13–0,32 | 0,15–0,44 | 0,18–0,49 | 0,25–0,58 | 0,29–0,64 | 0,35–0,70 | 0,36–0,75 |

| 2 | 80 | 130 | 180 | mm/r | 0,11–0,26 | 0,13–0,31 | 0,15–0,36 | 0,18–0,40 | 0,25–0,48 | 0,29–0,60 | 0,35–0,70 | 0,36–0,75 | |

| 3 | 70 | 95 | 120 | mm/r | 0,10-0,22 | 0,12-0,25 | 0,15-0,35 | 0,16-0,40 | 0,20-0,48 | 0,26-0,60 | 0,30-0,63 | 0,32-0,65 | |

| S | 1 | 10 | 20 | 30 | mm/r | 0,05–0,09 | 0,06–0,10 | 0,07–0,12 | 0,08–0,13 | 0,10–0,15 | 0,11–0,17 | 0,12–0,19 | 0,13–0,21 |

| 2 | 10 | 20 | 30 | mm/r | 0,05–0,09 | 0,06–0,10 | 0,07–0,12 | 0,08–0,13 | 0,10–0,15 | 0,11–0,17 | 0,12–0,19 | 0,13–0,21 | |

| 3 | 15 | 25 | 35 | mm/r | 0,05–0,09 | 0,06–0,10 | 0,07–0,12 | 0,08–0,13 | 0,10–0,15 | 0,11–0,17 | 0,12–0,19 | 0,13–0,21 | |

| 4 | 20 | 30 | 40 | mm/r | 0,04–0,07 | 0,05–0,09 | 0,05–0,10 | 0,07–0,12 | 0,08–0,13 | 0,08–0,13 | 0,09–0,15 | 0,10–0,17 | |

| Grupo de materiales | Velocidad de corte | Pulgadas | |||||||||||

| Rango | Avance recomendado por rev. | ||||||||||||

| Mín | Valor inicial | Máx. | .236 | .315 | .394 | .472 | .630 | .787 | .945 | 1.023 | |||

| P | 0 | 230 | 410 | 570 | IPR | .004–.007 | .004–.008 | .005–.009 | .006–.012 | .007–.014 | .009–.016 | .011–.019 | .011–.020 |

| 1 | 230 | 390 | 560 | IPR | .004–.007 | .004–.009 | .005–.009 | .006–.012 | .007–.014 | .009–.016 | .011–.019 | .011–.020 | |

| 2 | 300 | 440 | 590 | IPR | .004–.007 | .004–.010 | .005–.011 | .006–.013 | .007–.015 | .009–.018 | .011–.020 | .011–.020 | |

| 3 | 200 | 310 | 430 | IPR | .004–.006 | .004–.011 | .004–.011 | .005–.013 | .007–.015 | .009–.016 | .011–.018 | .012–.018 | |

| 4 | 160 | 300 | 430 | IPR | .004–.006 | .004–.011 | .004–.011 | .005–.013 | .007–.015 | .009–.016 | .009–.018 | .010–.018 | |

| 5 | 100 | 210 | 330 | IPR | .004–.006 | .004–.007 | .004–.009 | .004–.011 | .006–.013 | .008–.015 | .009–.016 | .009–.017 | |

| 6 | 130 | 200 | 260 | IPR | .004–.006 | .004–.007 | .004–.009 | .004–.011 | .006–.013 | .008–.015 | .009–.016 | .009–.017 | |

| M | 1 | 70 | 180 | 300 | IPR | .003–.005 | .003–.005 | .003–.006 | .004–.007 | .005–.009 | .006–.010 | .007–.011 | .008–.011 |

| 2 | 100 | 200 | 300 | IPR | .003–.005 | .003–.005 | .003–.006 | .004–.007 | .005–.009 | .006–.010 | .007–.011 | .008–.011 | |

| 3 | 70 | 130 | 200 | IPR | .003–.005 | .003–.005 | .003–.006 | .004–.006 | .005–.009 | .006–.010 | .007–.011 | .008–.011 | |

| K | 1 | 260 | 460 | 660 | IPR | .004–.010 | .005–.013 | .006–.017 | .007–.019 | .010–.023 | .011–.025 | .014–.028 | .014–.030 |

| 2 | 260 | 430 | 590 | IPR | .004–.010 | .005–.012 | .006–.014 | .007–.016 | .010–.019 | .011–.024 | .014–.028 | .014–.030 | |

| 3 | 230 | 310 | 390 | IPR | .004–.009 | .005–.010 | .006–.014 | .006–.016 | .008–.019 | .010–.024 | .012–.025 | .013–.026 | |

| S | 1 | 30 | 70 | 100 | IPR | .002–.004 | .002–.004 | .003–.005 | .003–.005 | .004–.006 | .004–.007 | .005–.008 | .005–.008 |

| 2 | 30 | 70 | 100 | IPR | .002–.004 | .002–.004 | .003–.005 | .003–.005 | .004–.006 | .004–.007 | .005–.008 | .005–.008 | |

| 3 | 50 | 80 | 110 | IPR | .002–.004 | .002–.004 | .003–.005 | .003–.005 | .004–.006 | .004–.007 | .005–.008 | .005–.008 | |

| 4 | 70 | 100 | 130 | IPR | .002–.003 | .002–.004 | .002–.004 | .003–.005 | .003–.005 | .003–.005 | .004–.006 | .004–.007 | |

| Grupo de materiales | Velocidad de corte | Sistema métrico | |||||||||||

| Rango | Avance recomendado por rev. | ||||||||||||

| Mín | Valor inicial | Máx. | 6,0 | 8,0 | 10,0 | 12,0 | 16,0 | 20,0 | 24,0 | 26,0 | |||

| P | 0 | 70 | 125 | 175 | mm/r | 0,09–0,18 | 0,10–0,21 | 0,12–0,24 | 0,14–0,30 | 0,18–0,36 | 0,23–0,42 | 0,27–0,48 | 0,28–0,50 |

| 1 | 70 | 120 | 170 | mm/r | 0,09–0,18 | 0,10–0,22 | 0,12–0,24 | 0,14–0,30 | 0,18–0,36 | 0,23–0,42 | 0,27–0,48 | 0,28–0,50 | |

| 2 | 90 | 135 | 180 | mm/r | 0,09–0,18 | 0,10–0,25 | 0,12–0,27 | 0,14–0,33 | 0,18–0,39 | 0,23–0,45 | 0,27–0,51 | 0,28–0,50 | |

| 3 | 60 | 95 | 130 | mm/r | 0,09–0,16 | 0,10–0,28 | 0,11–0,29 | 0,13–0,33 | 0,17–0,37 | 0,22–0,41 | 0,28–0,45 | 0,30–0,46 | |

| 4 | 50 | 90 | 130 | mm/r | 0,09–0,16 | 0,10–0,28 | 0,11–0,29 | 0,13–0,33 | 0,17–0,37 | 0,22–0,41 | 0,24–0,45 | 0,25–0,46 | |

| 5 | 30 | 65 | 100 | mm/r | 0,09–0,15 | 0,10–0,18 | 0,10–0,22 | 0,11–0,27 | 0,15–0,32 | 0,19–0,37 | 0,23–0,42 | 0,24–0,43 | |

| 6 | 40 | 60 | 80 | mm/r | 0,09–0,15 | 0,09–0,18 | 0,10–0,22 | 0,10–0,27 | 0,15–0,32 | 0,19–0,37 | 0,23–0,42 | 0,24–0,43 | |

| M | 1 | 20 | 55 | 90 | mm/r | 0,07–0,12 | 0,08–0,13 | 0,08–0,14 | 0,10–0,18 | 0,12–0,22 | 0,15–0,26 | 0,18–0,27 | 0,19–0,28 |

| 2 | 30 | 60 | 90 | mm/r | 0,07–0,12 | 0,08–0,13 | 0,08–0,16 | 0,10–0,18 | 0,12–0,22 | 0,15–0,26 | 0,18–0,27 | 0,19–0,28 | |

| 3 | 20 | 40 | 60 | mm/r | 0,07–0,12 | 0,08–0,12 | 0,08–0,14 | 0,10–0,16 | 0,12–0,22 | 0,15–0,26 | 0,18–0,27 | 0,19–0,28 | |

| K | 1 | 80 | 140 | 200 | mm/r | 0,11–0,26 | 0,13–0,32 | 0,15–0,44 | 0,18–0,49 | 0,25–0,58 | 0,29–0,64 | 0,35–0,70 | 0,36–0,75 |

| 2 | 80 | 130 | 180 | mm/r | 0,11–0,26 | 0,13–0,31 | 0,15–0,36 | 0,18–0,40 | 0,25–0,48 | 0,29–0,60 | 0,35–0,70 | 0,36–0,75 | |

| 3 | 70 | 95 | 120 | mm/r | 0,10-0,22 | 0,12-0,25 | 0,15-0,35 | 0,16-0,40 | 0,20-0,48 | 0,26-0,60 | 0,30-0,63 | 0,32-0,65 | |

| S | 1 | 10 | 20 | 30 | mm/r | 0,05–0,09 | 0,06–0,10 | 0,07–0,12 | 0,08–0,13 | 0,10–0,15 | 0,11–0,17 | 0,12–0,19 | 0,13–0,21 |

| 2 | 10 | 20 | 30 | mm/r | 0,05–0,09 | 0,06–0,10 | 0,07–0,12 | 0,08–0,13 | 0,10–0,15 | 0,11–0,17 | 0,12–0,19 | 0,13–0,21 | |

| 3 | 15 | 25 | 35 | mm/r | 0,05–0,09 | 0,06–0,10 | 0,07–0,12 | 0,08–0,13 | 0,10–0,15 | 0,11–0,17 | 0,12–0,19 | 0,13–0,21 | |

| 4 | 20 | 30 | 40 | mm/r | 0,04–0,07 | 0,05–0,09 | 0,05–0,10 | 0,07–0,12 | 0,08–0,13 | 0,08–0,13 | 0,09–0,15 | 0,10–0,17 | |

Tolerancia

| Tolerancia • Sistema métrico | |

| D1 sistema métrico | Tolerancia k8 |

| 6 | 0,000/+0,018 |

| 0,000/+0,022 | |

| 0,000/+0,027 | |

| 0,000/+0,033 | |

| Tolerancia • Pulgadas | |

| D1 pulgadas | Tolerancia k8 |

| 0.2362 | 0.0000/+0.0007 |

| 0.0000/+0.0009 | |

| 0.0000/+0.0011 | |

| 0.0000/+0.0013 | |

I have read and accepted the Terms & Conditions of use

CAD Drawings Models

Can’t find the file type you’re looking for?

Product data

![KTIP CLAVE D=14.00[0.552]-16.99[0.669] KTIP CLAVE D=14.00[0.552]-16.99[0.669]](https://images.kennametal.com/is/image/Kennametal/43601?$PRODUCT-REFERENCE-THUMBNAIL-IMAGE$)