Produto semelhante ao:

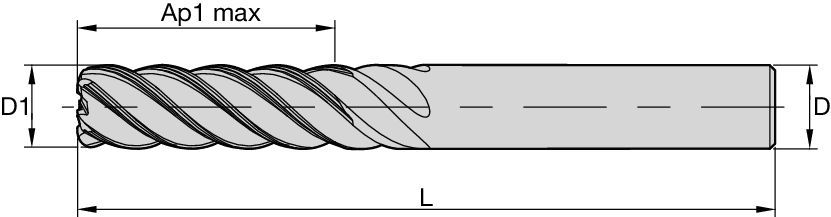

HARVI™ II Long • Square End • 5 Flutes • 3 x D • Plain Shank • Inch

HARVI™ II Long Solid Carbide End Mill for Finishing and Fine Finishing Applications

Número de material7077825

ID do catálogo ISOHA2L5SE0750L225HAID do catálogo ANSIHA2L5SE0750L225HA

- P Steel

- M Stainless Steel

- K Cast Iron

- S High-Temp Alloys

- H Hardened Materials

Trochoidal Milling

Fresamento lateral/fresamento de canto: topo reto

Dimensões da ferramenta: Configuração de canal: 5

Estilo de canto: Canto com raio«1

Estilo de canto: topo reto

Ângulo de hélice: 43°

Sending to {{cadTool}} in progress...

Downloaded file will be available after import in the {{cadTool}} tool library.

| Número de material | 7077825 |

| ID do catálogo ISO | HA2L5SE0750L225HA |

| ID do catálogo ANSI | HA2L5SE0750L225HA |

| Grade | KCSM15A |

| Adapter Style Machine Side | Straight-Cylindrical |

| [D1] Effective Cutting Diameter | 19.05 mm |

| [D1] Effective Cutting Diameter | 0.75 in |

| [D] Adapter / Shank / Bore Diameter | 19.05 mm |

| [D] Adapter / Shank / Bore Diameter | 0.75 in |

| [AP1MAX] 1st Maximum Cutting Depth | 57.15 mm |

| [AP1MAX] 1st Maximum Cutting Depth | 2.25 in |

| [L3] Usable Length | 69.533 mm |

| [L3] Usable Length | 2.7375 in |

| [L] Overall Length | 127 mm |

| [L] Overall Length | 5 in |

| [Z] Number of Flutes | 5 |

Materiais das peças

- Steel

- Stainless Steel

- Cast Iron

- High-Temp Alloys

- Hardened Materials

Usos e aplicações

Trochoidal Milling

Fresamento lateral/fresamento de canto: topo reto

Dimensões da ferramenta: Configuração de canal: 5

Estilo de canto: Canto com raio«1

Estilo de canto: topo reto

Ângulo de hélice: 43°

Características e benefícios

- Versatile solid carbide end mill for semi-finishing and finishing of thin walls and deep pockets in titanium, steels, and stainless steels with excellent surface finishes.

- HARVI™ II Long solid carbide end mills cover side milling operations and dynamic milling.

- HARVI™ II Long solid carbide end mills feature unequal flute spacing for chatter-free machining at highest feed rates.

- Back taper design for excellent wall straightness.

Criar solução para calcular avanços e velocidade

Após criar uma solução basta escolher o ícone Avanços & Velocidades e o nosso sistema irá fornecer recomendações. Pode personalizar as informações adicionando a sua máquina e especificações ou fazer ajustes utilizando os controlos deslizantes.

Dados de aplicação

HARVI II • UGDE • Unequal Flute Spacing • 3 x D Lengths of Cut

| Grupo de material |  | KCSM15A | Recommended feed per tooth (IPT = inch/th) for side milling. | ||||||||||

| Velocidade de corte | D1 | ||||||||||||

| frac. | 1/4 | 5/16 | 3/8 | 1/2 | 5/8 | 3/4 | 1 | ||||||

| ap | ae | min | max | dec. | .2500 | .3125 | .3750 | .5000 | .6250 | .7500 | 1.0000 | ||

| P | 0 | Apmax | 0.05 x D | 980 | 1310 | IPT | 0.0018 | 0.0023 | 0.0027 | 0.0034 | 0.0039 | 0.0044 | 0.0049 |

| 1 | Apmax | 0.05 x D | 980 | 1310 | IPT | 0.0018 | 0.0023 | 0.0027 | 0.0034 | 0.0039 | 0.0044 | 0.0049 | |

| 2 | Apmax | 0.05 x D | 920 | 1250 | IPT | 0.0018 | 0.0023 | 0.0027 | 0.0034 | 0.0039 | 0.0044 | 0.0049 | |

| 3 | Apmax | 0.05 x D | 790 | 1050 | IPT | 0.0015 | 0.0020 | 0.0023 | 0.0029 | 0.0034 | 0.0039 | 0.0045 | |

| 4 | Apmax | 0.05 x D | 590 | 980 | IPT | 0.0014 | 0.0017 | 0.0020 | 0.0026 | 0.0030 | 0.0034 | 0.0039 | |

| 5 | Apmax | 0.05 x D | 390 | 660 | IPT | 0.0012 | 0.0016 | 0.0018 | 0.0023 | 0.0027 | 0.0031 | 0.0036 | |

| 6 | Apmax | 0.05 x D | 330 | 490 | IPT | 0.0010 | 0.0013 | 0.0015 | 0.0019 | 0.0022 | 0.0025 | 0.0028 | |

| M | 1 | Apmax | 0.05 x D | 590 | 750 | IPT | 0.0015 | 0.0020 | 0.0023 | 0.0029 | 0.0034 | 0.0039 | 0.0045 |

| 2 | Apmax | 0.05 x D | 390 | 520 | IPT | 0.0012 | 0.0016 | 0.0018 | 0.0023 | 0.0027 | 0.0031 | 0.0036 | |

| 3 | Apmax | 0.05 x D | 390 | 460 | IPT | 0.0010 | 0.0013 | 0.0015 | 0.0019 | 0.0022 | 0.0025 | 0.0028 | |

| K | 1 | Apmax | 0.05 x D | 790 | 980 | IPT | 0.0018 | 0.0023 | 0.0027 | 0.0034 | 0.0039 | 0.0044 | 0.0049 |

| 2 | Apmax | 0.05 x D | 720 | 920 | IPT | 0.0015 | 0.0020 | 0.0023 | 0.0029 | 0.0034 | 0.0039 | 0.0045 | |

| 3 | Apmax | 0.05 x D | 720 | 850 | IPT | 0.0012 | 0.0016 | 0.0018 | 0.0023 | 0.0027 | 0.0031 | 0.0036 | |

| S | 1 | Apmax | 0.05 x D | 330 | 590 | IPT | 0.0015 | 0.0020 | 0.0023 | 0.0029 | 0.0034 | 0.0039 | 0.0045 |

| 2 | Apmax | 0.05 x D | 160 | 330 | IPT | 0.0008 | 0.0010 | 0.0012 | 0.0015 | 0.0018 | 0.0021 | 0.0024 | |

| 3 | Apmax | 0.05 x D | 160 | 260 | IPT | 0.0008 | 0.0010 | 0.0012 | 0.0015 | 0.0018 | 0.0021 | 0.0024 | |

| 4 | Apmax | 0.05 x D | 330 | 390 | IPT | 0.0011 | 0.0014 | 0.0017 | 0.0021 | 0.0025 | 0.0028 | 0.0033 | |

| H | 1 | Apmax | 0.05 x D | 520 | 920 | IPT | 0.0014 | 0.0017 | 0.0020 | 0.0026 | 0.0030 | 0.0034 | 0.0039 |

| 2 | Apmax | 0.05 x D | 460 | 790 | IPT | 0.0010 | 0.0013 | 0.0015 | 0.0019 | 0.0022 | 0.0025 | 0.0028 | |

Tolerância

| Tolerâncias das fresas de topo | |||

| D1 | Tolerância | D | Tolerância h6 + / - |

| All | +.000/- .002" | ≤1/8" | +0/-.00024" |

| +0/-.00031" | |||

| +0/-.00035" | |||

| +0/-.00043" | |||

| 0/.00051" | |||

I have read and accepted the Terms & Conditions of use

CAD Drawings Models

Can’t find the file type you’re looking for?

Product data