Produto semelhante ao:

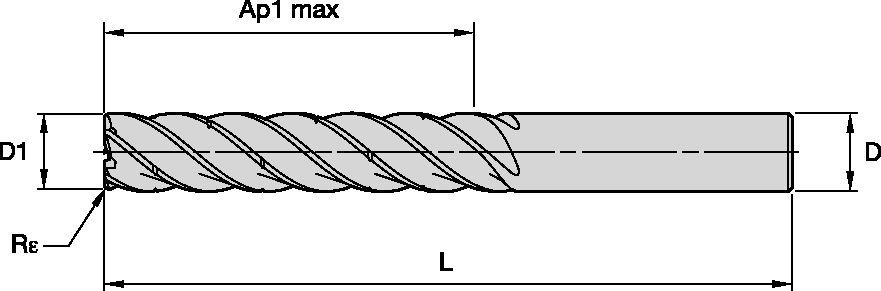

KOR5™ DS • Radiused • 5 Flutes • 5 x D • Plain Shank • Inch

KOR5™ DS Solid Carbide End Mill for Dynamic Milling of Steel and Stainless Steel

Número de material6764474

ID do catálogo ISOKOR5RA0750L375HAR060ID do catálogo ANSIKOR5RA0750L375HAR060

- P Steel

- M Stainless Steel

- K Cast Iron

- S High-Temp Alloys

- H Hardened Materials

Trochoidal Milling

Fresamento de rampa: 5°

Fresamento lateral/fresamento de canto: topo reto

Dimensões da ferramenta: Configuração de canal: 5

Haste — Cilíndrica lisa

Ângulo de hélice: 40°

Estilo de canto: Canto com raio«1

Sending to {{cadTool}} in progress...

Downloaded file will be available after import in the {{cadTool}} tool library.

| Número de material | 6764474 |

| ID do catálogo ISO | KOR5RA0750L375HAR060 |

| ID do catálogo ANSI | KOR5RA0750L375HAR060 |

| Grade | KC643M |

| Adapter Style Machine Side | Straight-Cylindrical |

| [D1] Effective Cutting Diameter | 19.05 mm |

| [D1] Effective Cutting Diameter | 0.75 in |

| [D] Adapter / Shank / Bore Diameter | 19.05 mm |

| [D] Adapter / Shank / Bore Diameter | 0.75 in |

| [AP1MAX] 1st Maximum Cutting Depth | 95.25 mm |

| [AP1MAX] 1st Maximum Cutting Depth | 3.75 in |

| [L] Overall Length | 177.8 mm |

| [L] Overall Length | 7 in |

| [Re] Corner Radius | 1.525 mm |

| [Re] Corner Radius | 0.06 in |

| [Z] Number of Flutes | 5 |

Materiais das peças

- Steel

- Stainless Steel

- Cast Iron

- High-Temp Alloys

- Hardened Materials

Usos e aplicações

Trochoidal Milling

Fresamento de rampa: 5°

Fresamento lateral/fresamento de canto: topo reto

Dimensões da ferramenta: Configuração de canal: 5

Haste — Cilíndrica lisa

Ângulo de hélice: 40°

Estilo de canto: Canto com raio«1

Classes

KC643M

Classe de granulação fina, com revestimento multicamada de PVD (AlTiN). A classe KC643M™ tem um revestimento duro PVD especialmente adequado para cortar aço, ferro fundido, aço inoxidável (com refrigeração) e titânio (com refrigeração). Essa classe pode ser usada para materiais com durezas até 52 HRC.

Características e benefícios

- Designed for trochoidal milling with low radial engagement and full length of cut.

- With chip deformers for ideal chip evacuation at high surface quality.

- Proprietary flute form reduces vibrations and improves tool life.

- Helix angle tailored to minimize vibration and optimize tool life.

- Front end geometry designed for maximum tool life in helical and ramping operations.

Criar solução para calcular avanços e velocidade

Após criar uma solução basta escolher o ícone Avanços & Velocidades e o nosso sistema irá fornecer recomendações. Pode personalizar as informações adicionando a sua máquina e especificações ou fazer ajustes utilizando os controlos deslizantes.

Dados de aplicação

KOR5™ DS • 5 Flutes • 5 x D • Application Data • Inch

| Grupo de material |  |  | |||||||||||

| Fresamento lateral (A) | Recommended feed per tooth (IPT = inch/th) for side milling (A). | ||||||||||||

| A | KC643M | D1 | |||||||||||

| Velocidade de corte | frac. | 1/4 | 3/8 | 1/2 | 5/8 | 3/4 | 1 | ||||||

| ap | ae | Mín. | Máx. | dec. | .2500 | .3750 | .5000 | .6250 | .7500 | 1.0000 | |||

| P | 0 | 5 x D | 0.05 x D | 500 | – | 1770 | IPT | .0029 | .0044 | .0054 | .0063 | .0070 | .0078 |

| 1 | 5 x D | 0.05 x D | 500 | – | 1770 | IPT | .0029 | .0044 | .0054 | .0063 | .0070 | .0078 | |

| 2 | 5 x D | 0.05 x D | 460 | – | 1680 | IPT | .0029 | .0044 | .0054 | .0063 | .0070 | .0078 | |

| 3 | 5 x D | 0.05 x D | 400 | – | 1420 | IPT | .0024 | .0037 | .0046 | .0055 | .0062 | .0072 | |

| 4 | 5 x D | 0.05 x D | 300 | – | 1330 | IPT | .0022 | .0033 | .0041 | .0048 | .0054 | .0062 | |

| 5 | 5 x D | 0.05 x D | 200 | – | 890 | IPT | .0020 | .0029 | .0037 | .0044 | .0049 | .0058 | |

| 6 | 5 x D | 0.05 x D | 170 | – | 660 | IPT | .0017 | .0024 | .0031 | .0036 | .0040 | .0045 | |

| M | 1 | 5 x D | 0.05 x D | 300 | – | 1020 | IPT | .0024 | .0037 | .0046 | .0055 | .0062 | .0072 |

| 2 | 5 x D | 0.05 x D | 200 | – | 710 | IPT | .0020 | .0029 | .0037 | .0044 | .0049 | .0058 | |

| 3 | 5 x D | 0.05 x D | 200 | – | 620 | IPT | .0017 | .0024 | .0031 | .0036 | .0040 | .0045 | |

| K | 1 | 5 x D | 0.05 x D | 400 | – | 1330 | IPT | .0029 | .0044 | .0054 | .0063 | .0070 | .0078 |

| 2 | 5 x D | 0.05 x D | 370 | – | 1240 | IPT | .0024 | .0037 | .0046 | .0055 | .0062 | .0072 | |

| 3 | 5 x D | 0.05 x D | 370 | – | 1150 | IPT | .0020 | .0029 | .0037 | .0044 | .0049 | .0058 | |

| S | 1 | 5 x D | 0.05 x D | 170 | – | 800 | IPT | .0024 | .0037 | .0046 | .0055 | .0062 | .0072 |

| 2 | 5 x D | 0.05 x D | 80 | – | 710 | IPT | .0020 | .0029 | .0037 | .0044 | .0049 | .0058 | |

| 3 | 5 x D | 0.05 x D | 80 | – | 350 | IPT | .0013 | .0019 | .0025 | .0029 | .0033 | .0039 | |

| 4 | 5 x D | 0.05 x D | 170 | – | 530 | IPT | .0017 | .0027 | .0034 | .0040 | .0045 | .0053 | |

| H | 1 | 5 x D | 0.05 x D | 270 | – | 1240 | IPT | .0022 | .0033 | .0041 | .0048 | .0054 | .0062 |

| 2 | 5 x D | 0.05 x D | 230 | – | 1060 | IPT | .0017 | .0024 | .0031 | .0036 | .0040 | .0045 | |

TechnicalInfo

KOR5™ DS • 5 Flutes • 5 x D • Adjustment factor table for feed calculation • Inch

| Ae/D1 | 0.50% | 1.00% | 1.50% | 2.00% | 4.00% | 5.00% | |

| Speed factor | Kv | 2.00 | 1.97 | 1.93 | 1.38 | 1.03 | 1.00 |

| Feed factor | KFz | 1.27 | 1.18 | 1.14 | 1.09 | 1.05 | 1.00 |

I have read and accepted the Terms & Conditions of use

CAD Drawings Models

Can’t find the file type you’re looking for?

Product data