Produto semelhante ao:

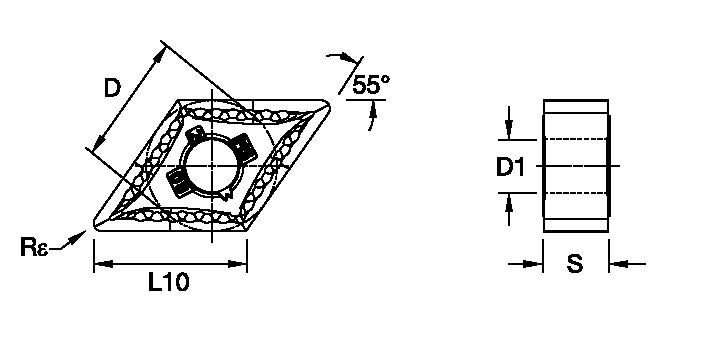

Insertos negativos • DNMG-MS

Insertos Kenloc™

Número de material2229694

ID do catálogo ISODNMG150408MSID do catálogo ASIDNMG432MS

- P Steel

- M Stainless Steel

- S High-Temp Alloys

Sending to {{cadTool}} in progress...

Downloaded file will be available after import in the {{cadTool}} tool library.

| Número de material | 2229694 |

| ID do catálogo ISO | DNMG150408MS |

| ID do catálogo ASI | DNMG432MS |

| Grade | KC5010 |

| [D] Insert IC Size | 12.7 mm |

| [D] Insert IC Size | 0.5 in |

| [L10] Insert Cutting Edge Length | 15.504 mm |

| [L10] Insert Cutting Edge Length | 0.6104 in |

| [S] Insert Thickness | 4.76 mm |

| [S] Insert Thickness | 0.1875 in |

| [Rε] Corner Radius | 0.8 mm |

| [Rε] Corner Radius | 0.031 in |

| [D1] Insert Hole Size | 5.16 mm |

| [D1] Insert Hole Size | 0.2031 in |

Materiais das peças

- Steel

- Stainless Steel

- High-Temp Alloys

Classes

KC5010

Composition: An advanced PVD AlTiN coating over a very deformation-resistant unalloyed carbide substrate. The new and improved coating enables speeds to be increased by 50–100%.

Application: The KC5010 grade is ideal for finishing to general machining of most workpiece materials at higher speeds. Excellent for machining most steels, stainless steels, cast irons, non-ferrous materials, and super alloys under stable conditions. It also performs well machining hardened and short chipping materials.

Características e benefícios

- Medium geometry utilized in high-temperature and stainless applications

Criar solução para calcular avanços e velocidade

Após criar uma solução basta escolher o ícone Avanços & Velocidades e o nosso sistema irá fornecer recomendações. Pode personalizar as informações adicionando a sua máquina e especificações ou fazer ajustes utilizando os controlos deslizantes.

I have read and accepted the Terms & Conditions of use

CAD Drawings Models

Can’t find the file type you’re looking for?

Product data