Produkt podobny do:

D4FIX-MN

Nr materiału4054651

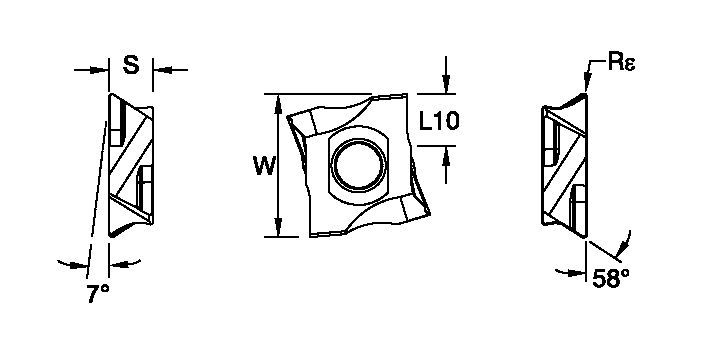

Nr katalogowy ISOD4FIX140604RMNNr katalogowy ASID4FIX140604RMN

- P Steel

Sending to {{cadTool}} in progress...

Downloaded file will be available after import in the {{cadTool}} tool library.

| Nr materiału | 4054651 |

| Nr katalogowy ISO | D4FIX140604RMN |

| Nr katalogowy ASI | D4FIX140604RMN |

| Grade | KCP40 |

| [L10] Insert Cutting Edge Length | 7.1 mm |

| [L10] Insert Cutting Edge Length | 0.28 in |

| [S] Insert Thickness | 5.9 mm |

| [S] Insert Thickness | 0.233 in |

| [Rε] Corner Radius | 0.4 mm |

| [Rε] Corner Radius | 0.016 in |

Materiały przedmiotu obrabianego

- Steel

Gatunki

KCP40

Composition: A tough carbide grade with a moderately thick TiN-MT-TiCN-Al2O3 coating.

Application: For heavy roughing of carbon, alloy, and stainless steels. The substrate-coating combination provides unbelievable toughness and operational security allowing high metal removal rates even in most demanding interrupted cuts.

Złóż nowe rozwiązanie aby obliczyc parametry posuwu i prędkości

Po złóżeniu rozwiązania wybierz ikonę "Posuwy i prędkości" a system pokaże rekomendowane wartości. Możesz doprecyzować wyniki dodając maszynę i jej specyfikacje lub zmień wartości początkowe Używając suwaki.

I have read and accepted the Terms & Conditions of use

CAD Drawings Models

Can’t find the file type you’re looking for?

Product data