Produkt podobny do:

Chwyt 4xD SSF DFR

Korpusy wiertła Drill FIX DFR

Nr materiału3022344

Nr katalogowy ISODFR0688R4SSF100Nr katalogowy ANSIDFR0688R4SSF100

- P Steel

- M Stainless Steel

- K Cast Iron

- N Non-Ferrous

- S High-Temp Alloys

- .caption

Drilling

Drilling: Inclined Entry

Drilling: Inclined Exit

Drilling: X-Offset

Drilling: Convex

Shank - Cylindrical with Flat and Flange

Through Coolant: Radial: Indexable Drilling

Drilling: Blind

Chain Drilling

Drilling: Cross-Hole Drilling

Drilling: Half-Cylindrical Drilling

Drilling: Corner Drilling 45°

Sending to {{cadTool}} in progress...

Downloaded file will be available after import in the {{cadTool}} tool library.

- Podsumowanie

- Parametry skrawania

- Do pobrania

- Pasujace produkty - strona maszyny

- Pasujace produkty - strona przedmiotu obrabianego

- Części zamienne

- Opinia

- Q&A

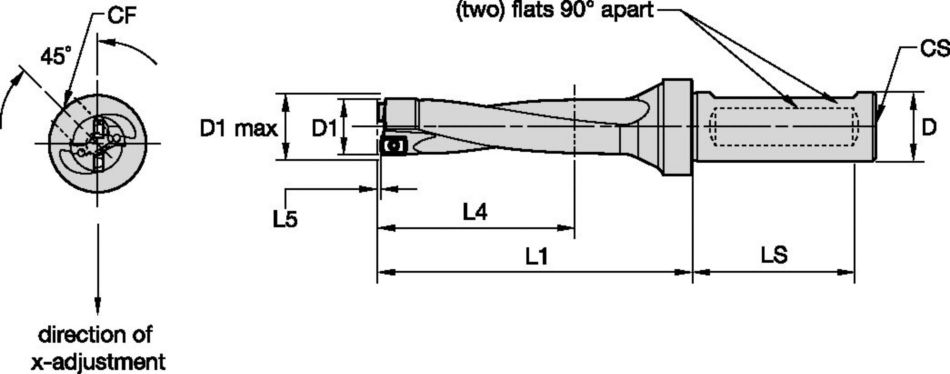

| Nr materiału | 3022344 |

| Nr katalogowy ISO | DFR0688R4SSF100 |

| Nr katalogowy ANSI | DFR0688R4SSF100 |

| [D] Adapter / Shank / Bore Diameter | 25.4 mm |

| [D] Adapter / Shank / Bore Diameter | 1 in |

| [D1] Drill Diameter M | 17.475 mm |

| [D1] Drill Diameter M | 0.688 in |

| [D1MAX] Drill Diameter Maximum | 18.476 mm |

| [D1MAX] Drill Diameter Maximum | 0.7274 in |

| [L1] Insert Gage Length | 94.16 mm |

| [L1] Insert Gage Length | 3.7071 in |

| [L4] Maximum Drilling Depth | 69.901 mm |

| [L4] Maximum Drilling Depth | 2.752 in |

| [L5] Drill Point Length | 0.618 mm |

| [L5] Drill Point Length | 0.0243 in |

| [LS] Shank Length | 76.2 mm |

| [LS] Shank Length | 3 in |

| Gage Insert | DFR0302. |

Materiały przedmiotu obrabianego

- Steel

- Stainless Steel

- Cast Iron

- Non-Ferrous

- High-Temp Alloys

- .caption

Zastosowania

Drilling

Drilling: Inclined Entry

Drilling: Inclined Exit

Drilling: X-Offset

Drilling: Convex

Shank - Cylindrical with Flat and Flange

Through Coolant: Radial: Indexable Drilling

Drilling: Blind

Chain Drilling

Drilling: Cross-Hole Drilling

Drilling: Half-Cylindrical Drilling

Drilling: Corner Drilling 45°

Właściwości i zalety

- Drill Fix DFR with rectangular-shaped inserts offer highest stability and feed rates at smaller sizes.

- X-offset design to adjust diameter size on turning machines and optimize tolerances on machining centers.

- Drill shipped with insert screws, side pipe plug, and Torx wrench.

Złóż nowe rozwiązanie aby obliczyc parametry posuwu i prędkości

Po złóżeniu rozwiązania wybierz ikonę "Posuwy i prędkości" a system pokaże rekomendowane wartości. Możesz doprecyzować wyniki dodając maszynę i jej specyfikacje lub zmień wartości początkowe Używając suwaki.

Parametry skrawania

| Calowe | ||||||||||||

| Grupa materiałowa | Warunki obróbki | Gniazdo | Geometria | Gatunek | Prędkość skrawania | Zalecana wartość posuwu w zależności od średnicy (fz) | ||||||

| Zakres prędkości skrawania [SFM] | ||||||||||||

| Min. | Wartość początkowa | Maks. | 3,0 | 3,0 | 3,0 | |||||||

| P | 1 | 1 | – | 105 | 105 | 55 | – | 105 | mm/obrót | 0,05 | 0,05 | 0,05 |

| – | 105 | 105 | ||||||||||

| 2 | – | 105 | 105 | 55 | – | 105 | mm/obrót | 0,05 | 0,05 | 0,05 | ||

| – | 105 | 105 | ||||||||||

| 1 | – | 105 | 105 | 55 | – | 105 | mm/obrót | 0,05 | 0,05 | 0,05 | ||

| – | 105 | 105 | ||||||||||

| 1 | 1 | – | 105 | 105 | 55 | – | 105 | mm/obrót | 0,05 | 0,05 | 0,05 | |

| – | 105 | 105 | ||||||||||

| 1 | – | 105 | 105 | 55 | – | 105 | mm/obrót | 0,05 | 0,05 | 0,05 | ||

| – | 105 | 105 | ||||||||||

| 1 | – | 105 | 105 | 55 | – | 105 | mm/obrót | 0,05 | 0,05 | 0,05 | ||

| – | 105 | 105 | ||||||||||

| 2 | 2 | – | 105 | 105 | 55 | – | 105 | mm/obrót | 0,05 | 0,05 | 0,05 | |

| – | 105 | 105 | ||||||||||

| 1 | – | 105 | 105 | 55 | – | 105 | mm/obrót | 0,05 | 0,05 | 0,05 | ||

| – | 105 | 105 | ||||||||||

| 1 | – | 105 | 105 | 55 | – | 105 | mm/obrót | 0,05 | 0,05 | 0,05 | ||

| – | 105 | 105 | ||||||||||

| 1 | 1 | – | 105 | 105 | 55 | – | 105 | mm/obrót | 0,05 | 0,05 | 0,05 | |

| – | 105 | 105 | ||||||||||

| 1 | – | 105 | 105 | 55 | – | 105 | mm/obrót | 0,05 | 0,05 | 0,05 | ||

| – | 105 | 105 | ||||||||||

| 2 | – | 105 | 105 | 55 | – | 105 | mm/obrót | 0,05 | 0,05 | 0,05 | ||

| – | 105 | 105 | ||||||||||

| 1 | 1 | – | 105 | 105 | 55 | – | 105 | mm/obrót | 0,05 | 0,05 | 0,05 | |

| – | 105 | 105 | ||||||||||

| 1 | – | 105 | 105 | 55 | – | 105 | mm/obrót | 0,05 | 0,05 | 0,05 | ||

| – | 105 | 105 | ||||||||||

| 1 | – | 105 | 105 | 55 | – | 105 | mm/obrót | 0,05 | 0,05 | 0,05 | ||

| – | 105 | 105 | ||||||||||

| 1 | 1 | – | 105 | 105 | 55 | – | 105 | mm/obrót | 0,05 | 0,05 | 0,05 | |

| – | 105 | 105 | ||||||||||

| 2 | – | 105 | 105 | 55 | – | 105 | mm/obrót | 0,05 | 0,05 | 0,05 | ||

| – | 105 | 105 | ||||||||||

| 1 | – | 105 | 105 | 55 | – | 105 | mm/obrót | 0,05 | 0,05 | 0,05 | ||

| – | 105 | 105 | ||||||||||

| Calowe | ||||||||||||

| Prędkość skrawania | ||||||||||||

| Zakres prędkości skrawania [SFM] | Zalecana wartość posuwu w zależności od średnicy (fz) | |||||||||||

| Grupa materiałowa | Warunki obróbki | Gniazdo | Geometria | Gatunek | Min. | Wartość początkowa | Maks. | Ø | DFR02... .500"–.625" | DFR03... .688"–.750" | DFR04... .813"–1.00" | |

| P | 1 | S | O | MD | KCU25 | 1017 | 1066 | 1181 | SFM | .004–.006 | .004–.007 | .006–.010 |

| 1 | S | I | MD | KC7140 | 1017 | 1066 | 1181 | SFM | .004–.006 | .004–.007 | .006–.010 | |

| 1 | U | O | MD | KCU40 | 656 | 705 | 754 | SFM | .004–.006 | .004–.007 | .006–.010 | |

| 1 | U | I | MD | KC7140 | 656 | 705 | 754 | SFM | .004–.006 | .004–.007 | .006–.010 | |

| 1 | I | O | MD | KC7140 | 426 | 443 | 492 | SFM | .004–.006 | .004–.007 | .006–.010 | |

| 1 | I | I | MD | KC7140 | 426 | 443 | 492 | SFM | .004–.006 | .004–.007 | .006–.010 | |

| 2 | S | O | GD | KCPK10 | 1017 | 1066 | 1181 | SFM | .004–.006 | .004–.007 | .006–.010 | |

| 2 | S | I | LD | KC7140 | 1017 | 1066 | 1181 | SFM | .004–.006 | .004–.007 | .006–.010 | |

| 2 | U | O | GD | KCU40 | 656 | 705 | 754 | SFM | .004–.006 | .004–.007 | .006–.010 | |

| 2 | U | I | LD | KC7140 | 656 | 705 | 754 | SFM | .004–.006 | .004–.007 | .006–.010 | |

| 2 | I | O | MD | KC7140 | 426 | 443 | 492 | SFM | .004–.006 | .004–.007 | .006–.010 | |

| 2 | I | I | LD | KC7140 | 426 | 443 | 492 | SFM | .004–.006 | .004–.007 | .006–.010 | |

| 3 | S | O | GD | KCPK10 | 853 | 935 | 1050 | SFM | .004–.006 | .004–.007 | .006–.010 | |

| 3 | S | I | LD | KC7140 | 853 | 935 | 1050 | SFM | .004–.006 | .004–.007 | .006–.010 | |

| 3 | U | O | GD | KCU40 | 590 | 640 | 722 | SFM | .004–.006 | .004–.007 | .006–.010 | |

| 3 | U | I | LD | KC7140 | 590 | 640 | 722 | SFM | .004–.006 | .004–.007 | .006–.010 | |

| 3 | I | O | GD | KC7140 | 361 | 394 | 459 | SFM | .004–.006 | .004–.007 | .006–.010 | |

| 3 | I | I | LD | KC7140 | 361 | 394 | 459 | SFM | .004–.006 | .004–.007 | .006–.010 | |

| 4 | S | O | GD | KCU25 | 722 | 820 | 984 | SFM | .004–.006 | .004–.007 | .006–.010 | |

| 4 | S | I | LD | KC7140 | 722 | 820 | 984 | SFM | .004–.006 | .004–.007 | .006–.010 | |

| 4 | U | O | GD | KCU40 | 492 | 590 | 722 | SFM | .004–.006 | .004–.007 | .006–.010 | |

| 4 | U | I | LD | KC7140 | 492 | 590 | 722 | SFM | .004–.006 | .004–.007 | .006–.010 | |

| 4 | I | O | GD | KC7140 | 295 | 361 | 459 | SFM | .004–.006 | .004–.007 | .006–.010 | |

| 4 | I | I | LD | KC7140 | 295 | 361 | 459 | SFM | .004–.006 | .004–.007 | .006–.010 | |

| 5 | S | O | GD | KCU25 | 590 | 656 | 722 | SFM | .003–.005 | .004–.006 | .004–.007 | |

| 5 | S | I | LD | KC7140 | 590 | 656 | 722 | SFM | .003–.005 | .004–.006 | .004–.007 | |

| 5 | U | O | GD | KCU40 | 394 | 443 | 492 | SFM | .003–.005 | .004–.006 | .004–.007 | |

| 5 | U | I | LD | KC7140 | 394 | 443 | 492 | SFM | .003–.005 | .004–.006 | .004–.007 | |

| 5 | I | O | GD | KC7140 | 230 | 279 | 328 | SFM | .003–.005 | .004–.006 | .004–.007 | |

| 5 | I | I | LD | KC7140 | 230 | 279 | 328 | SFM | .003–.005 | .004–.006 | .004–.007 | |

| 6 | S | O | GD | KCU25 | 590 | 656 | 722 | SFM | .004–.006 | .004–.007 | .006–.010 | |

| 6 | S | I | LD | KC7140 | 590 | 656 | 722 | SFM | .004–.006 | .004–.007 | .006–.010 | |

| 6 | U | O | GD | KCU40 | 394 | 443 | 492 | SFM | .004–.006 | .004–.007 | .006–.010 | |

| 6 | U | I | LD | KC7140 | 394 | 443 | 492 | SFM | .004–.006 | .004–.007 | .006–.010 | |

| 6 | I | O | GD | KC7140 | 230 | 279 | 328 | SFM | .004–.006 | .004–.007 | .006–.010 | |

| 6 | I | I | LD | KC7140 | 230 | 279 | 328 | SFM | .004–.006 | .004–.007 | .006–.010 | |

| Calowe | ||||||||||||

| Grupa materiałowa | Warunki obróbki | Gniazdo | Geometria | Gatunek | Prędkość skrawania | Zalecana wartość posuwu w zależności od średnicy (fz) | ||||||

| Zakres prędkości skrawania [SFM] | ||||||||||||

| Min. | Wartość początkowa | Maks. | Numer | |||||||||

| Min | Maks. | 3,0 | 3,0 | 3,0 | P | 1 | ||||||

| 105 | 55 | – | ||||||||||

| 105 | 105 | 55 | – | 105 | mm/obrót | 0,05 | 0,05 | 0,05 | 2 | |||

| 105 | 55 | – | ||||||||||

| 105 | 105 | 55 | – | 105 | mm/obrót | 0,05 | 0,05 | 0,05 | 1 | |||

| 105 | 55 | – | ||||||||||

| – | 105 | 105 | 55 | – | 105 | mm/obrót | 0,05 | 0,05 | 0,05 | 1 | ||

| 105 | 55 | – | ||||||||||

| 105 | 105 | 55 | – | 105 | mm/obrót | 0,05 | 0,05 | 0,05 | 1 | |||

| 105 | 55 | – | ||||||||||

| 105 | 105 | 55 | – | 105 | mm/obrót | 0,05 | 0,05 | 0,05 | 1 | |||

| 105 | 55 | – | ||||||||||

| – | 105 | 105 | 55 | – | 105 | mm/obrót | 0,05 | 0,05 | 0,05 | 2 | ||

| 105 | 55 | – | ||||||||||

| 105 | 105 | 55 | – | 105 | mm/obrót | 0,05 | 0,05 | 0,05 | 1 | |||

| 105 | 55 | – | ||||||||||

| 105 | 105 | 55 | – | 105 | mm/obrót | 0,05 | 0,05 | 0,05 | 1 | |||

| 105 | 55 | – | ||||||||||

| Calowe | ||||||||||||

| Prędkość skrawania | ||||||||||||

| Zakres prędkości skrawania [SFM] | Zalecana wartość posuwu w zależności od średnicy (fz) | |||||||||||

| Grupa materiałowa | Warunki obróbki | Gniazdo | Geometria | Gatunek | Min. | Wartość początkowa | Maks. | Ø | DFR02... .500"–.625" | DFR03... .688"–.750" | DFR04... .813"–1.00" | |

| M | 1 | S | O | MD | KC7140 | 492 | 623 | 754 | SFM | .003–.005 | .003–.006 | .004–.007 |

| 1 | S | I | MD | KC7140 | 492 | 623 | 754 | SFM | .003–.005 | .003–.006 | .004–.007 | |

| 1 | U | O | MD | KC7140 | 328 | 426 | 525 | SFM | .003–.005 | .003–.006 | .004–.007 | |

| 1 | U | I | MD | KC7140 | 328 | 426 | 525 | SFM | .003–.005 | .003–.006 | .004–.007 | |

| 1 | I | O | MD | KC7140 | 197 | 262 | 328 | SFM | .003–.005 | .003–.006 | .004–.007 | |

| 1 | I | I | MD | KC7140 | 197 | 262 | 328 | SFM | .003–.005 | .003–.006 | .004–.007 | |

| 2 | S | O | MD | KC7140 | 492 | 590 | 689 | SFM | .003–.005 | .003–.006 | .004–.007 | |

| 2 | S | I | MD | KC7140 | 492 | 590 | 689 | SFM | .003–.005 | .003–.006 | .004–.007 | |

| 2 | U | O | MD | KC7140 | 328 | 426 | 525 | SFM | .003–.005 | .003–.006 | .004–.007 | |

| 2 | U | I | MD | KC7140 | 328 | 426 | 525 | SFM | .003–.005 | .003–.006 | .004–.007 | |

| 2 | I | O | MD | KC7140 | 197 | 262 | 328 | SFM | .003–.005 | .003–.006 | .004–.007 | |

| 2 | I | I | MD | KC7140 | 197 | 262 | 328 | SFM | .003–.005 | .003–.006 | .004–.007 | |

| 3 | S | O | MD | KC7140 | 328 | 426 | 525 | SFM | .003–.005 | .003–.006 | .004–.007 | |

| 3 | S | I | MD | KC7140 | 328 | 426 | 525 | SFM | .003–.005 | .003–.006 | .004–.007 | |

| 3 | U | O | MD | KC7140 | 262 | 361 | 459 | SFM | .003–.005 | .003–.006 | .004–.007 | |

| 3 | U | I | MD | KC7140 | 262 | 361 | 459 | SFM | .003–.005 | .003–.006 | .004–.007 | |

| 3 | I | O | MD | KC7140 | 164 | 230 | 295 | SFM | .003–.005 | .003–.006 | .004–.007 | |

| 3 | I | I | MD | KC7140 | 164 | 230 | 295 | SFM | .003–.005 | .003–.006 | .004–.007 | |

| Calowe | ||||||||||||

| Grupa materiałowa | Gniazdo | Gniazdo | Geometria | Gatunek | Prędkość skrawania | Zalecana wartość posuwu w zależności od średnicy (fz) | ||||||

| Zakres prędkości skrawania [SFM] | ||||||||||||

| Min. | Wartość początkowa | Maks. | 1 | 1 | – | 105 | ||||||

| 105 | 55 | – | 105 | mm/obrót | 0,05 | 0,05 | 0,05 | 1 | 1 | – | 105 | |

| 105 | mm/obrót | 0,05 | ||||||||||

| – | 105 | mm/obrót | 0,05 | 0,05 | 0,05 | 2 | 2 | – | 105 | |||

| 105 | mm/obrót | 0,05 | ||||||||||

| – | 105 | mm/obrót | 0,05 | 0,05 | 0,05 | 1 | 1 | – | 105 | |||

| 105 | mm/obrót | 0,05 | ||||||||||

| 55 | – | 105 | mm/obrót | 0,05 | 0,05 | 0,05 | 1 | 1 | – | 105 | ||

| 105 | mm/obrót | 0,05 | ||||||||||

| – | 105 | mm/obrót | 0,05 | 0,05 | 0,05 | 1 | 1 | – | 105 | |||

| 105 | mm/obrót | 0,05 | ||||||||||

| – | 105 | mm/obrót | 0,05 | 0,05 | 0,05 | 1 | 1 | – | 105 | |||

| 105 | mm/obrót | 0,05 | ||||||||||

| 55 | – | 105 | mm/obrót | 0,05 | 0,05 | 0,05 | 2 | 2 | – | 105 | ||

| 105 | mm/obrót | 0,05 | ||||||||||

| – | 105 | mm/obrót | 0,05 | 0,05 | 0,05 | 1 | 1 | – | 105 | |||

| 105 | mm/obrót | 0,05 | ||||||||||

| – | 105 | mm/obrót | 0,05 | 0,05 | 0,05 | 1 | 1 | – | 105 | |||

| 105 | mm/obrót | 0,05 | ||||||||||

| Calowe | ||||||||||||

| Prędkość skrawania | ||||||||||||

| Zakres prędkości skrawania [SFM] | Zalecana wartość posuwu w zależności od średnicy (fz) | |||||||||||

| Grupa materiałowa | Warunki obróbki | Gniazdo | Geometria | Gatunek | Min. | Wartość początkowa | Maks. | Ø | DFR02... .500"–.625" | DFR03... .688"–.750" | DFR04... .813"–1.00" | |

| K | 1 | S | O | GD | KCPK10 | 656 | 787 | 984 | SFM | .004–.007 | .005–.008 | .006–.009 |

| 1 | S | I | LD | KCU40 | 656 | 787 | 984 | SFM | .004–.007 | .005–.008 | .006–.009 | |

| 1 | U | O | GD | KCU25 | 394 | 508 | 656 | SFM | .004–.007 | .005–.008 | .006–.009 | |

| 1 | U | I | LD | KC7140 | 394 | 508 | 656 | SFM | .004–.007 | .005–.008 | .006–.009 | |

| 1 | I | O | GD | KCU40 | 262 | 328 | 410 | SFM | .004–.007 | .005–.008 | .005–.009 | |

| 1 | I | I | LD | KC7140 | 262 | 328 | 410 | SFM | .004–.007 | .005–.008 | .005–.009 | |

| 2 | S | O | GD | KCPK10 | 590 | 722 | 853 | SFM | .004–.007 | .005–.008 | .006–.009 | |

| 2 | S | I | LD | KCU40 | 590 | 722 | 853 | SFM | .004–.007 | .005–.008 | .006–.009 | |

| 2 | U | O | GD | KCU25 | 361 | 459 | 558 | SFM | .004–.007 | .005–.008 | .005–.009 | |

| 2 | U | I | LD | KC7140 | 361 | 459 | 558 | SFM | .004–.007 | .005–.008 | .005–.009 | |

| 2 | I | O | GD | KCU40 | 262 | 328 | 394 | SFM | .004–.007 | .005–.008 | .006–.009 | |

| 2 | I | I | LD | KC7140 | 262 | 328 | 394 | SFM | .004–.007 | .005–.008 | .006–.009 | |

| 3 | S | O | GD | KCPK10 | 590 | 722 | 853 | SFM | .004–.007 | .005–.008 | .005–.009 | |

| 3 | S | I | LD | KCU40 | 590 | 722 | 853 | SFM | .004–.007 | .005–.008 | .005–.009 | |

| 3 | U | O | GD | KCU25 | 361 | 459 | 558 | SFM | .004–.007 | .005–.008 | .006–.009 | |

| 3 | U | I | LD | KC7140 | 361 | 459 | 558 | SFM | .004–.007 | .005–.008 | .006–.009 | |

| 3 | I | O | GD | KCU40 | 262 | 328 | 394 | SFM | .004–.007 | .005–.008 | .005–.009 | |

| 3 | I | I | LD | KC7140 | 262 | 328 | 394 | SFM | .004–.007 | .005–.008 | .005–.009 | |

| Calowe | ||||||||||||

| Grupa materiałowa | Warunki obróbki | Gniazdo | Geometria | Gatunek | Prędkość skrawania | Zalecana wartość posuwu w zależności od średnicy (fz) | ||||||

| Zakres prędkości skrawania [SFM] | ||||||||||||

| Min. | Wartość początkowa | Maks. | – | 105 | mm/obrót | 0,05 | ||||||

| 0,05 | 0,05 | 2 | 2 | – | 105 | 105 | 55 | – | 105 | mm/obrót | 0,05 | |

| 1 | 1 | – | ||||||||||

| 1 | 1 | – | 105 | 105 | 55 | – | 105 | mm/obrót | 0,05 | |||

| 1 | 1 | – | ||||||||||

| Calowe | ||||||||||||

| Prędkość skrawania | ||||||||||||

| Zakres prędkości skrawania [SFM] | Zalecana wartość posuwu w zależności od średnicy (fz) | |||||||||||

| Grupa materiałowa | Warunki obróbki | Gniazdo | Geometria | Gatunek | Min. | Wartość początkowa | Maks. | Ø | DFR02... .500"–.625" | DFR03... .688"–.750" | DFR04... .813"–1.00" | |

| N | 1 | S | O | ST | KD1425 | 1312 | 1968 | 2624 | SFM | .003–.004 | .004–.006 | .005–.006 |

| 1 | S | I | ST | KD1425 | 1312 | 1968 | 2624 | SFM | .003–.004 | .004–.006 | .005–.006 | |

| 1 | U | O | LD | KCU40 | 984 | 1312 | 1640 | SFM | .003–.004 | .004–.006 | .005–.006 | |

| 1 | U | I | LD | KCU40 | 984 | 1312 | 1640 | SFM | .003–.004 | .004–.006 | .005–.006 | |

| 1 | I | O | LD | KCU40 | 656 | 984 | 1312 | SFM | .003–.004 | .004–.006 | .005–.006 | |

| 1 | I | I | LD | KCU40 | 656 | 984 | 1312 | SFM | .003–.004 | .004–.006 | .005–.006 | |

| 2 | S | O | ST | KD1425 | 1230 | 1804 | 2542 | SFM | .003–.004 | .004–.006 | .005–.006 | |

| 2 | S | I | ST | KD1425 | 1230 | 1804 | 2542 | SFM | .003–.004 | .004–.006 | .005–.006 | |

| 2 | U | O | LD | KCU40 | 820 | 1148 | 1476 | SFM | .003–.004 | .004–.006 | .005–.006 | |

| 2 | U | I | LD | KCU40 | 820 | 1148 | 1476 | SFM | .003–.004 | .004–.006 | .005–.006 | |

| 2 | I | O | LD | KCU40 | 574 | 820 | 1066 | SFM | .003–.004 | .004–.006 | .005–.006 | |

| 2 | I | I | LD | KCU40 | 574 | 820 | 1066 | SFM | .003–.004 | .004–.006 | .005–.006 | |

| 3 | S | O | ST | KD1425 | 1148 | 1640 | 2132 | SFM | .003–.004 | .004–.006 | .005–.006 | |

| 3 | S | I | ST | KD1425 | 1148 | 1640 | 2132 | SFM | .003–.004 | .004–.006 | .005–.006 | |

| 3 | U | O | LD | KCU40 | 820 | 1148 | 1476 | SFM | .003–.004 | .004–.006 | .005–.006 | |

| 3 | U | I | LD | KCU40 | 820 | 1148 | 1476 | SFM | .003–.004 | .004–.006 | .005–.006 | |

| 3 | I | O | LD | KCU40 | 492 | 820 | 1148 | SFM | .003–.004 | .004–.006 | .005–.006 | |

| 3 | I | I | LD | KCU40 | 492 | 820 | 1148 | SFM | .003–.004 | .004–.006 | .005–.006 | |

| 4 | S | O | ST | KD1425 | 1312 | 1968 | 2624 | SFM | .003–.004 | .004–.006 | .005–.006 | |

| 4 | S | I | ST | KD1425 | 1312 | 1968 | 2624 | SFM | .003–.004 | .004–.006 | .005–.006 | |

| 4 | U | O | LD | KCU40 | 820 | 1148 | 1486 | SFM | .003–.004 | .004–.006 | .005–.006 | |

| 4 | U | I | LD | KCU40 | 820 | 1148 | 1486 | SFM | .003–.004 | .004–.006 | .005–.006 | |

| 4 | I | O | LD | KCU40 | 656 | 984 | 1312 | SFM | .003–.004 | .004–.006 | .005–.006 | |

| 4 | I | I | LD | KCU40 | 656 | 984 | 1312 | SFM | .003–.004 | .004–.006 | .005–.006 | |

| 5 | S | O | HP | KD1425 | 1312 | 1968 | 2624 | SFM | .003–.004 | .004–.006 | .005–.006 | |

| 5 | S | I | HP | KD1425 | 1312 | 1968 | 2624 | SFM | .003–.004 | .004–.006 | .005–.006 | |

| 5 | U | O | HP | KCU40 | 820 | 1148 | 1476 | SFM | .003–.004 | .004–.006 | .005–.006 | |

| 5 | U | I | HP | KCU40 | 820 | 1148 | 1476 | SFM | .003–.004 | .004–.006 | .005–.006 | |

| 5 | I | O | HP | KCU40 | 656 | 984 | 1312 | SFM | .003–.004 | .004–.006 | .005–.006 | |

| 5 | I | I | HP | KCU40 | 656 | 984 | 1312 | SFM | .003–.004 | .004–.006 | .005–.006 | |

| 6 | S | O | ST | KD1425 | 1312 | 1968 | 2624 | SFM | .003–.004 | .004–.006 | .005–.006 | |

| 6 | S | I | ST | KD1425 | 1312 | 1968 | 2624 | SFM | .003–.004 | .004–.006 | .005–.006 | |

| 6 | U | O | LD | KCU40 | 820 | 1148 | 1476 | SFM | .003–.004 | .004–.006 | .005–.006 | |

| 6 | U | I | LD | KCU40 | 820 | 1148 | 1476 | SFM | .003–.004 | .004–.006 | .005–.006 | |

| 6 | I | O | LD | KMF | 656 | 984 | 1312 | SFM | .003–.004 | .004–.006 | .005–.006 | |

| 6 | I | I | LD | KMF | 656 | 984 | 1312 | SFM | .003–.004 | .004–.006 | .005–.006 | |

| Calowe | ||||||||||||

| Grupa materiałowa | Warunki obróbki | Gniazdo | Geometria | Gatunek | Prędkość skrawania | Zalecana wartość posuwu w zależności od średnicy (fz) | ||||||

| Zakres prędkości skrawania [SFM] | ||||||||||||

| Min. | Wartość początkowa | Maks. | ||||||||||

| Calowe | ||||||||||||

| Prędkość skrawania | ||||||||||||

| Zakres prędkości skrawania [SFM] | Zalecana wartość posuwu w zależności od średnicy (fz) | |||||||||||

| Grupa materiałowa | Warunki obróbki | Gniazdo | Geometria | Gatunek | Min. | Wartość początkowa | Maks. | Ø | DFR02... .500"-.625" | DFR03... .688"-.750" | DFR04... .813"-1.00" | |

| S | 1 | S | O | GD | KCU40 | 197 | 230 | 246 | SFM | .002–.002 | .002–.003 | .002–.004 |

| 1 | S | I | LD | KCU40 | 197 | 230 | 246 | SFM | .002–.002 | .002–.003 | .002–.004 | |

| 1 | U | O | GD | KCU40 | 131 | 164 | 197 | SFM | .002–.002 | .002–.003 | .002–.004 | |

| 1 | U | I | LD | KC7140 | 131 | 164 | 197 | SFM | .002–.002 | .002–.003 | .002–.004 | |

| 1 | I | O | MD | KC7140 | 82 | 98 | 131 | SFM | .002–.002 | .002–.003 | .002–.004 | |

| 1 | I | I | MD | KC7140 | 82 | 98 | 131 | SFM | .002–.002 | .002–.003 | .002–.004 | |

| 2 | S | O | GD | KCU40 | 164 | 197 | 230 | SFM | .002–.002 | .002–.003 | .002–.004 | |

| 2 | S | I | LD | KCU40 | 164 | 197 | 230 | SFM | .002–.002 | .002–.003 | .002–.004 | |

| 2 | U | O | GD | KCU40 | 98 | 131 | 164 | SFM | .002–.002 | .002–.003 | .002–.004 | |

| 2 | U | I | LD | KC7140 | 98 | 131 | 164 | SFM | .002–.002 | .002–.003 | .002–.004 | |

| 2 | I | O | MD | KC7140 | 82 | 98 | 131 | SFM | .002–.002 | .002–.003 | .002–.004 | |

| 2 | I | I | MD | KC7140 | 82 | 98 | 131 | SFM | .002–.002 | .002–.003 | .002–.004 | |

| 3 | S | O | GD | KCU40 | 230 | 262 | 295 | SFM | .002–.004 | .002–.003 | .002–.004 | |

| 3 | S | I | LD | KCU40 | 230 | 262 | 295 | SFM | .002–.004 | .002–.003 | .002–.004 | |

| 3 | U | O | GD | KCU40 | 164 | 197 | 230 | SFM | .002–.003 | .002–.004 | .002–.004 | |

| 3 | U | I | LD | KC7140 | 164 | 197 | 230 | SFM | .002–.003 | .002–.004 | .002–.004 | |

| 3 | I | O | MD | KC7140 | 98 | 131 | 164 | SFM | .002–.003 | .002–.004 | .002–.004 | |

| 3 | I | I | MD | KC7140 | 98 | 131 | 164 | SFM | .002–.003 | .002–.004 | .002–.004 | |

| 4 | S | O | GD | KCU40 | 230 | 262 | 295 | SFM | .002–.003 | .002–.004 | .002–.004 | |

| 4 | S | I | LD | KCU40 | 230 | 262 | 295 | SFM | .002–.003 | .002–.004 | .002–.004 | |

| 4 | U | O | GD | KCU40 | 164 | 197 | 230 | SFM | .002–.003 | .002–.004 | .002–.004 | |

| 4 | U | I | LD | KC7140 | 164 | 197 | 230 | SFM | .002–.003 | .002–.004 | .002–.004 | |

| 4 | I | O | MD | KC7140 | 98 | 131 | 164 | SFM | .002–.003 | .002–.004 | .002–.004 | |

| 4 | I | I | MD | KC7140 | 98 | 131 | 164 | SFM | .002–.003 | .002–.004 | .002–.004 | |

DFR™ • PCD • Calowe

| Metryczne | ||||||||||

| Grupa materiałowa | Warunki obróbki | Gniazdo | Geometria | Gatunek | Prędkość skrawania | Zalecana wartość posuwu w zależności od średnicy (fz) | ||||

| Zakres prędkości skrawania | ||||||||||

| Min. | Wartość początkowa | Maks. | Ø | DFR04 20,50–24,00 mm | ||||||

| N | 1 | S | O | ST | KD1425 | 396 | 720 | 841 | mm/obr. | 0,06–0,08 |

| I | ST | KD1425 | ||||||||

| 2 | S | O | ST | KD1425 | 369 | 670 | 782 | mm/obr. | 0,12–0,18 | |

| I | ST | KD1425 | ||||||||

| 3 | S | O | ST | KD1425 | 341 | 619 | 723 | mm/obr. | 0,12–0,18 | |

| I | ST | KD1425 | ||||||||

| 4 | S | O | ST | KD1425 | 475 | 720 | 841 | mm/obr. | 0,12–0,18 | |

| I | ST | KD1425 | ||||||||

| 5 | S | O | ST | KD1425 | 480 | 720 | 864 | mm/obr. | 0,06–0,08 | |

| I | ST | KD1425 | ||||||||

| Calowe | ||||||||||

| Grupa materiałowa | Warunki obróbki | Gniazdo | Geometria | Gatunek | Prędkość skrawania | Zalecana wartość posuwu w zależności od średnicy (fz) | ||||

| Zakres prędkości skrawania [SFM] | ||||||||||

| Min. | Wartość początkowa | Maks. | Ø | DFR04 0,813"–1,00" | ||||||

| N | 1 | S | O | ST | KD1425 | 1300 | 2362 | 2760 | cal/obr. | 0.002–0.003 |

| I | ST | KD1425 | ||||||||

| 2 | S | O | ST | KD1425 | 1209 | 2197 | 2567 | cal/obr. | 0,005–0,007 | |

| I | ST | KD1425 | ||||||||

| 3 | S | O | ST | KD1425 | 1118 | 2032 | 2374 | cal/obr. | 0,005–0,007 | |

| I | ST | KD1425 | ||||||||

| 4 | S | O | ST | KD1425 | 1560 | 2362 | 2760 | cal/obr. | 0,005–0,007 | |

| I | ST | KD1425 | ||||||||

| 5 | S | O | ST | KD1425 | 1575 | 2362 | 2834 | cal/obr. | 0,002–0,003 | |

| I | ST | KD1425 | ||||||||

| Metryczne | ||||||||||

| Prędkość skrawania | ||||||||||

| Zakres prędkości skrawania | Zalecana wartość posuwu w zależności od średnicy (fz) | |||||||||

| Grupa materiałowa | Warunki obróbki | Gniazdo | Geometria | Gatunek | Min. | Wartość początkowa | Maks. | Ø | DFR04 20,50–24,00 mm | |

| N | 1 | S | O | ST | KD1425 | 396 | 720 | 841 | mm/r | 0,06–0,08 |

| 1 | S | I | ST | KD1425 | 396 | 720 | 841 | mm/r | 0,06–0,08 | |

| 2 | S | O | ST | KD1425 | 369 | 670 | 782 | mm/r | 0,12–0,18 | |

| 2 | S | I | ST | KD1425 | 369 | 670 | 782 | mm/r | 0,12–0,18 | |

| 3 | S | O | ST | KD1425 | 341 | 619 | 723 | mm/r | 0,12–0,18 | |

| 3 | S | I | ST | KD1425 | 341 | 619 | 723 | mm/r | 0,12–0,18 | |

| 4 | S | O | ST | KD1425 | 475 | 720 | 841 | mm/r | 0,12–0,18 | |

| 4 | S | I | ST | KD1425 | 475 | 720 | 841 | mm/r | 0,12–0,18 | |

| 5 | S | O | ST | KD1425 | 480 | 720 | 864 | mm/r | 0,06–0,08 | |

| 5 | S | I | ST | KD1425 | 480 | 720 | 864 | mm/r | 0,06–0,08 | |

Warning

OSTRZEŻENIE • Drill Fix DFR

| OSTRZEŻENIE Podczas operacji obróbki otworów przelotowych w trakcie przechodzenia narzędzia przez przedmiot obrabiany powstaje wiór materiału w postaci kawałka metalu lub krążka. Gdy wiertło jest nieruchome, a przedmiot obrabiany obraca się, ten kawałek metalu może zostać wyrzucony z uchwytu w wyniku działania siły odśrodkowej. Należy zapewnić odpowiednie osłony w celu ochrony osób postronnych. |

Dimension

Dimensions • Chwyt stożkowy DFR

| D | LS |

| 20 | 50 |

I have read and accepted the Terms & Conditions of use

CAD Drawings Models

Can’t find the file type you’re looking for?

Product data