Produkt podobny do:

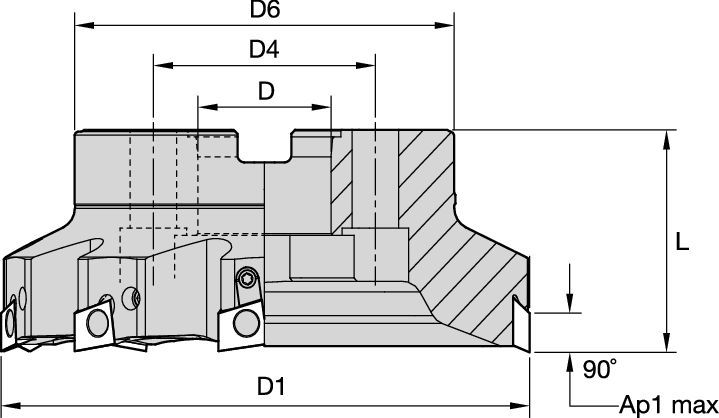

Fix-Perfect™ • Aluminum • Shell Mills • PM Line • Inch

Shell Mills • PM Line

Nr materiału1805715

Nr katalogowy ISO80A06RP90BG15C2WUPMNr katalogowy ANSI80A06RP90BG15C2WUPM

- P Steel

- K Cast Iron

- N Non-Ferrous

- H Hardened Materials

- .caption

Face Milling

Side Milling/Shoulder Milling: Square End

Milling - Through Coolant

Milling - Side and Face

Sending to {{cadTool}} in progress...

Downloaded file will be available after import in the {{cadTool}} tool library.

- Podsumowanie

- Parametry skrawania

- Do pobrania

- Pasujace produkty - strona maszyny

- Pasujace produkty - strona przedmiotu obrabianego

- Części zamienne

- Opinia

- Q&A

| Nr materiału | 1805715 |

| Nr katalogowy ISO | 80A06RP90BG15C2WUPM |

| Nr katalogowy ANSI | 80A06RP90BG15C2WUPM |

| [D1] Effective Cutting Diameter | 76.2 mm |

| [D1] Effective Cutting Diameter | 3 in |

| [D] Adapter / Shank / Bore Diameter | 25.4 mm |

| [D] Adapter / Shank / Bore Diameter | 1 in |

| [D6] Hub Diameter | 51.6 mm |

| [D6] Hub Diameter | 2.0315 in |

| [L] Overall Length | 44.45 mm |

| [L] Overall Length | 1.75 in |

| [AP1MAX] 1st Maximum Cutting Depth | 9.52 mm |

| [AP1MAX] 1st Maximum Cutting Depth | 0.375 in |

| Number of Inserts | 6 |

| Number of Adjustable Inserts | 2 |

| Weight Pounds | 1.85 |

| Max RPM | 16710 |

Materiały przedmiotu obrabianego

- Steel

- Cast Iron

- Non-Ferrous

- Hardened Materials

- .caption

Zastosowania

Face Milling

Side Milling/Shoulder Milling: Square End

Milling - Through Coolant

Milling - Side and Face

Właściwości i zalety

- High-speed Machining.

- Produces excellent surface finish and flatness.

- Fixed and adjustable pockets.

Złóż nowe rozwiązanie aby obliczyc parametry posuwu i prędkości

Po złóżeniu rozwiązania wybierz ikonę "Posuwy i prędkości" a system pokaże rekomendowane wartości. Możesz doprecyzować wyniki dodając maszynę i jej specyfikacje lub zmień wartości początkowe Używając suwaki.

Posuwy

Recommended Starting Feeds [IPT]

| Geometria płytki | Rekomendowane początkowe wartości posuwu na ząb (Fz) w relacji do % zaangażowania promieniowego (ae) | Geometria płytki | ||||||||||||||

| 5% | 10% | 20% | 30% | 40 | ||||||||||||

| BGHX… | .005 | .014 | .023 | .003 | .010 | .017 | .003 | .008 | .013 | .002 | .007 | .011 | .002 | .006 | .010 | BGHX… |

| Obróbka lekka | Obróbka średnia | Obróbka ciężka |

Prędkości

Recommended Starting Speeds [SFM]

| Grupa materiałowa | K110M | KC510M | KD1410 | KD1415 | |||||||||

| P | 1 | – | – | – | – | – | – | – | – | – | – | – | – |

| 2 | – | – | – | – | – | – | – | – | – | – | – | – | |

| 3 | – | – | – | – | – | – | – | – | – | – | – | – | |

| 4 | – | – | – | – | – | – | – | – | – | – | – | – | |

| 5 | – | – | – | – | – | – | – | – | – | – | – | – | |

| 6 | – | – | – | – | – | – | – | – | – | – | – | – | |

| M | 1 | – | – | – | – | – | – | – | – | – | – | – | – |

| 2 | – | – | – | – | – | – | – | – | – | – | – | – | |

| 3 | – | – | – | – | – | – | – | – | – | – | – | – | |

| K | 1 | – | – | – | – | – | – | – | – | – | – | – | – |

| 2 | – | – | – | – | – | – | – | – | – | – | – | – | |

| 3 | – | – | – | – | – | – | – | – | – | – | – | – | |

| N | 1–2 | 1650 | 1550 | 1475 | 2100 | 1870 | 1720 | 13150 | 11500 | 9800 | 13150 | 11500 | 9800 |

| 3 | 1350 | 1200 | 1050 | 1900 | 1750 | 1600 | 5250 | 4900 | 4600 | 5250 | 4900 | 4600 | |

| S | 1 | – | – | – | – | – | – | – | – | – | – | – | – |

| 2 | – | – | – | – | – | – | – | – | – | – | – | – | |

| 3 | – | – | – | – | – | – | – | – | – | – | – | – | |

| 4 | – | – | – | – | – | – | – | – | – | – | – | – | |

| H | 1 | – | – | – | – | – | – | – | – | – | – | – | – |

Dobór płytek

| Grupa materiałowa | Obróbka lekka | Obróbka średnia | Obróbka ciężka | |||

| – | (Lekka geometria) | (Zgrubna geometria) | ||||

| – | odporność na zużycie |  | ciągliwość | |||

| – | Geometria | Gatunek | Geometria | Gatunek | Geometria | Gatunek |

| P1–P2 | – | – | – | – | – | – |

| P3–P4 | – | – | – | – | – | – |

| P5–P6 | – | – | – | – | – | – |

| M1–M2 | – | – | – | – | – | – |

| M3 | – | – | – | – | – | – |

| K1–K2 | – | – | – | – | – | – |

| K3 | – | – | – | – | – | – |

| N1–N2 | BGHX… | K110M | BGHX… | KC510M | BGHX… | KD1415 |

| N3 | BGHX… | K110M | BGHX… | KD1410 | BGHX… | KD1410 |

| S1–S2 | – | – | – | – | – | – |

| S3 | – | – | – | – | – | – |

| S4 | – | – | – | – | – | – |

| H1 | – | – | – | – | – | – |

I have read and accepted the Terms & Conditions of use

CAD Drawings Models

Can’t find the file type you’re looking for?

Product data